Gas density relay for self-test junction contact resistance

A technology of gas density and contact resistance, applied in the field of electric power, can solve problems such as hidden safety hazards, reduced insulation strength on the surface of insulating parts, and hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

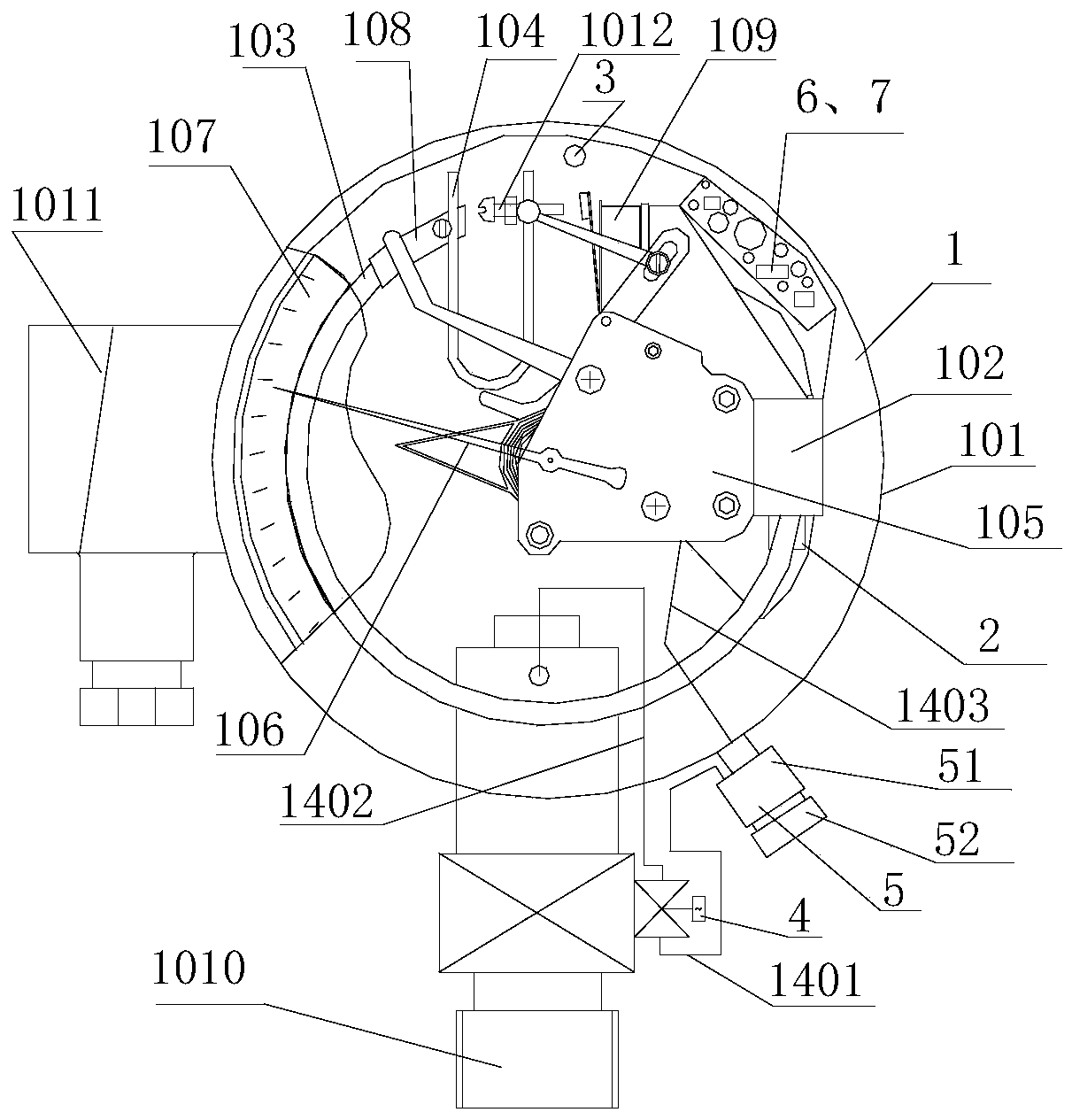

[0077] figure 1 It is a schematic structural diagram of a gas density relay for self-testing contact resistance of a contact point used for high and medium voltage electrical equipment in Example 1 of the present application. Such as figure 1 As shown, the gas density relay 1 includes: a housing 101, and a base 102, an end seat 108, a pressure detector 103, a temperature compensating element 104, several signal generators 109, and a core 105 arranged in the housing 101 , Pointer 106, Dial 107 and Equipment Connection Joint 1010. One end of the pressure detector 103 is fixed on the base 102 and communicated with it, and the other end of the pressure detector 103 is connected to one end of the temperature compensation element 104 through the end seat 108, the The other end of the temperature compensating element 104 is provided with a crossbeam, and the crossbeam is provided with an adjusting member that pushes the signal generator 109 to make the contacts of the signal genera...

Embodiment 2

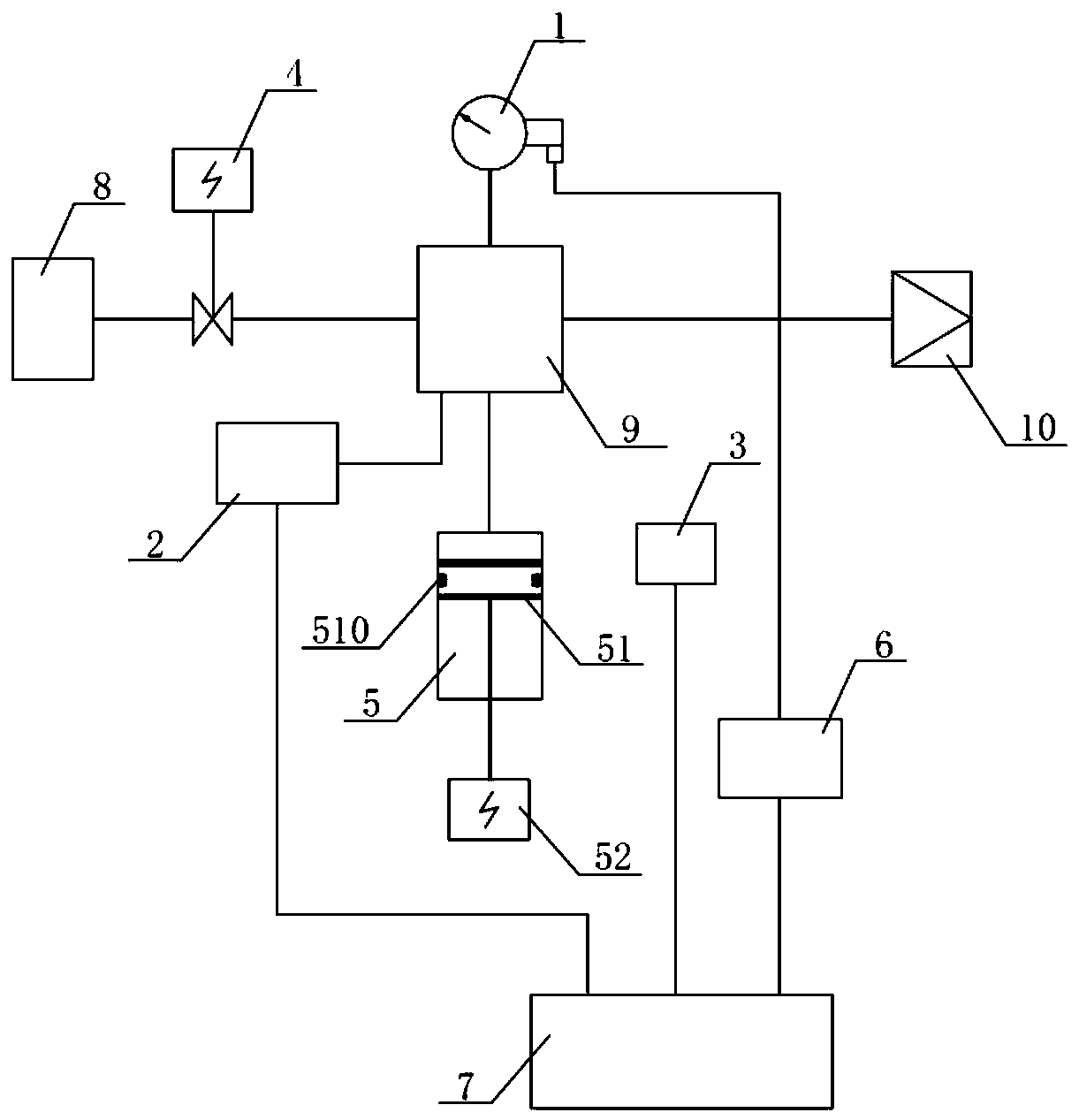

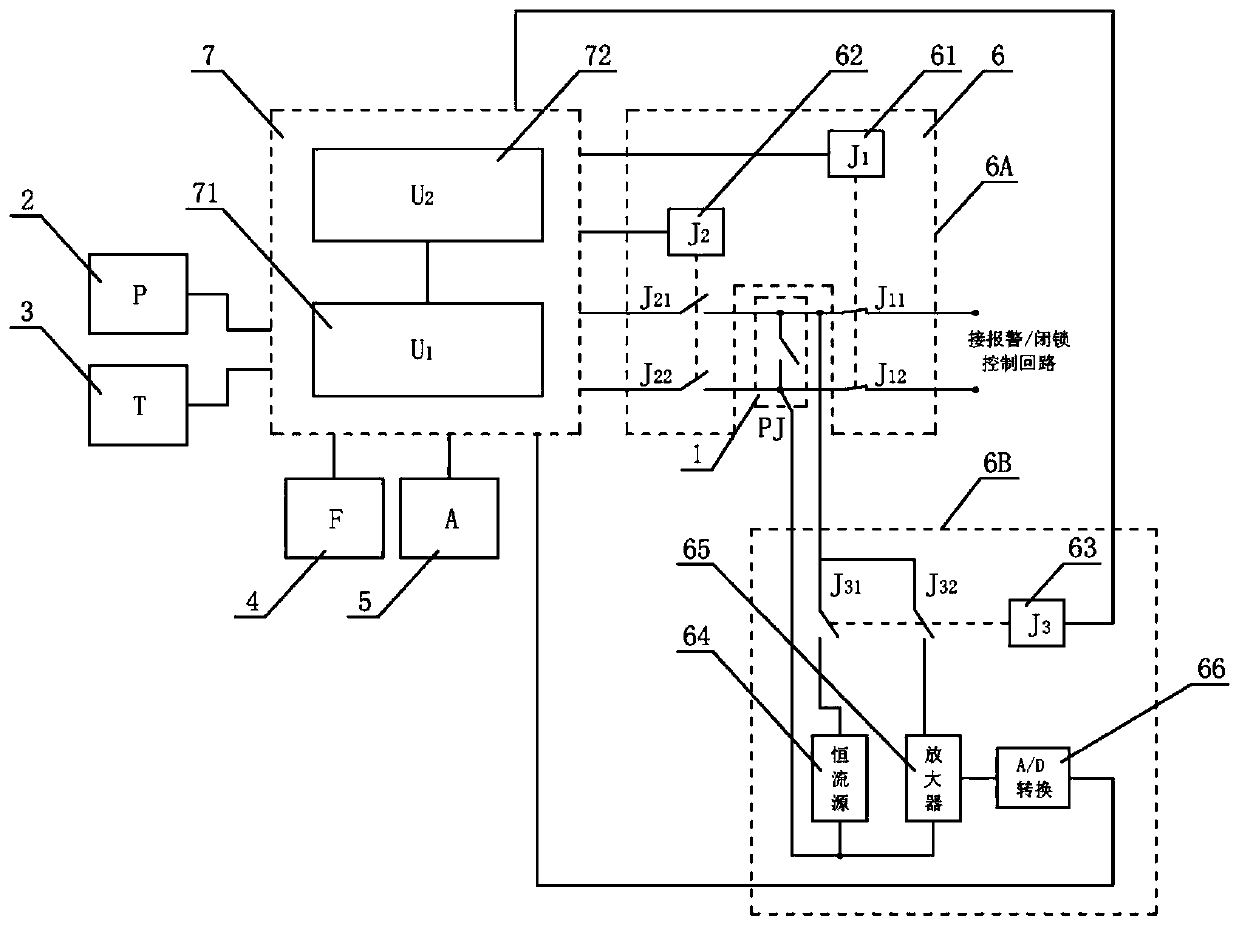

[0109] Such as Figure 4 As shown, the gas density monitoring device for self-test contact contact resistance provided by Embodiment 2 of the present invention includes: a gas density relay 1 (the gas density relay 1 mainly also includes: a housing, and a base, a pressure Detector, temperature compensation element, movement, pointer, dial, end seat, several signal generators and electrical equipment connection joints), pressure sensor 2, temperature sensor 3, valve 4, pressure adjustment mechanism 5, online calibration contact signal Sampling unit 6 and intelligent processor 7.

[0110] The air inlet of the valve 4 is sealed and connected to the electrical equipment through the electrical equipment connecting joint 1010 , and the air outlet of the valve 4 communicates with the base of the gas density relay 1 and the pressure detector. The pressure sensor 2, the temperature sensor 3, the online verification contact signal sampling unit 6, and the intelligent processor 7 are ar...

Embodiment 3

[0118] Such as Figure 5 As shown, the gas density monitoring device for self-test contact contact resistance provided by Embodiment 3 of the present invention includes: gas density relay 1, pressure sensor 2, temperature sensor 3, valve 4, pressure adjustment mechanism 5, online calibration contact signal sampling Unit 6, intelligent processor 7. The air inlet of the valve 4 is sealed and connected to the electrical equipment through the electrical equipment connection joint, and the air outlet of the valve 4 communicates with the base of the gas density relay 1 , the pressure sensor 2 and the pressure regulating mechanism 5 . The pressure sensor 2 , temperature sensor 3 , valve 4 and pressure regulating mechanism 5 are arranged on the rear side of the housing of the gas density relay 1 . The online verification contact signal sampling unit 6 and the intelligent processor 7 are arranged on the electrical equipment connection joint. The pressure sensor 2 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com