Mold release film

A release film and release layer technology, which is used in film/sheet adhesives, synthetic resin layered products, chemical instruments and methods, etc. The problem of large quantity and high cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

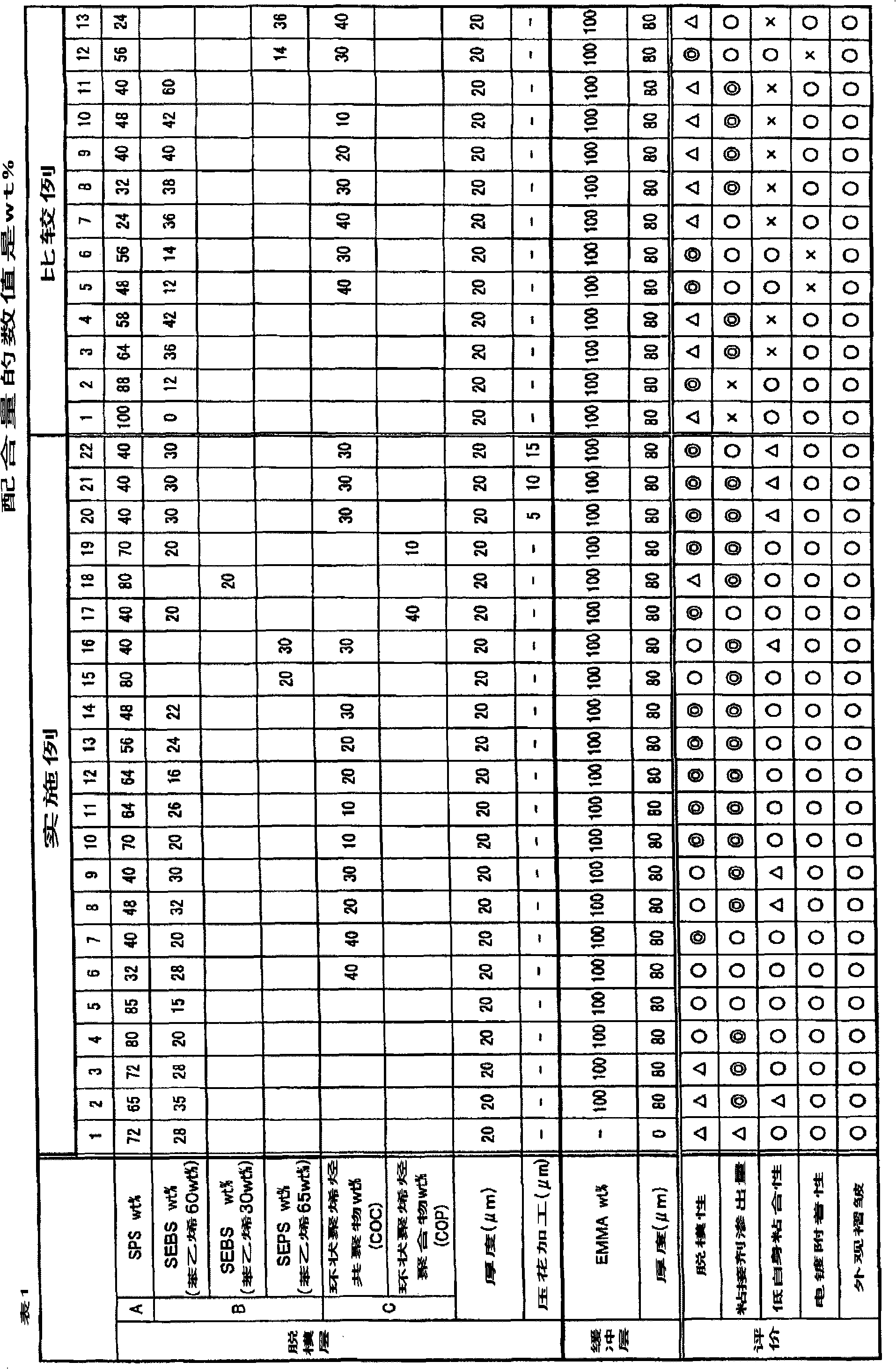

Embodiment 1~22 and comparative example 1~13

[0061] (preparation of samples)

[0062] In Example 1, the release layer resin having the composition shown in Table 1 was supplied to one extruder, and extruded from a single-layer die (300° C.) to form a release single-layer film of a predetermined thickness. In addition, in Example 2, the polymers of the respective compositions shown in Table 1 were supplied to two extruders as the release layer resin and the buffer layer resin, and they were co-extruded from a double-layer die (300° C.) to obtain Release multilayer film of specified thickness.

[0063] In Examples 3 to 22 and Comparative Examples 1 to 13, the polymers of the compositions shown in Table 1 as the release layer resin, buffer layer resin, and release layer resin were supplied to three extruders, and the three-layer die head (300°C) co-extrusion to make a release multilayer film of specified thickness. In addition, in Examples 20 to 22, surface processing was performed by off-line embossing (Ofline Emboss) us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com