Modified asphalt for warm-mixed thin overlay and preparation method and application thereof

A thin-layer coating, modified asphalt technology, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of poor anti-scattering performance, poor anti-aging performance, and many difficult preparation steps, and achieve good anti-scattering performance. Effects of scattering properties and excellent anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

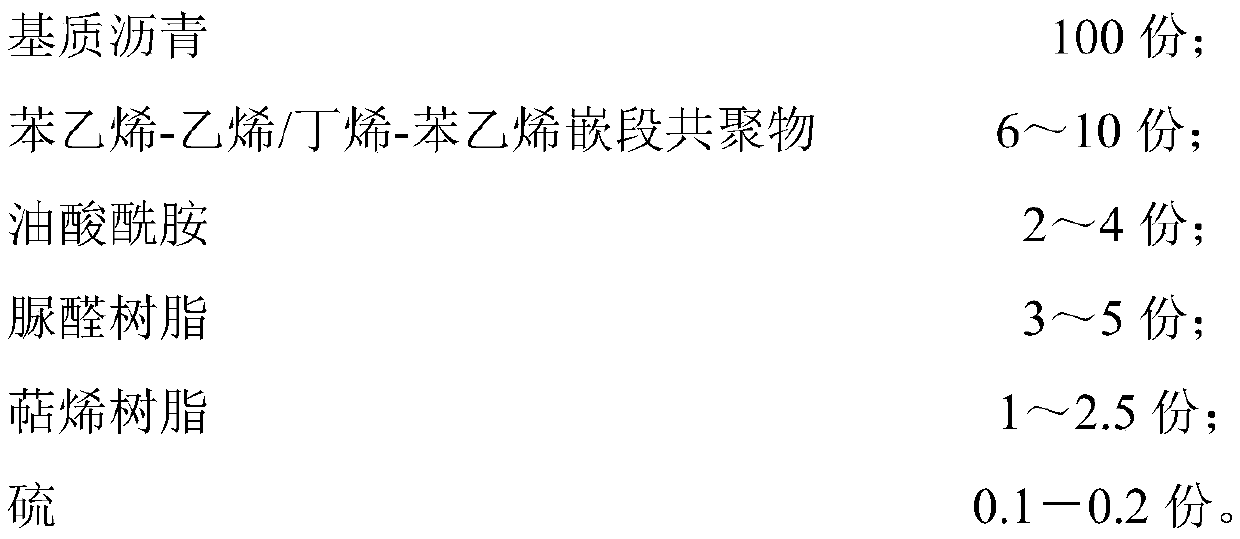

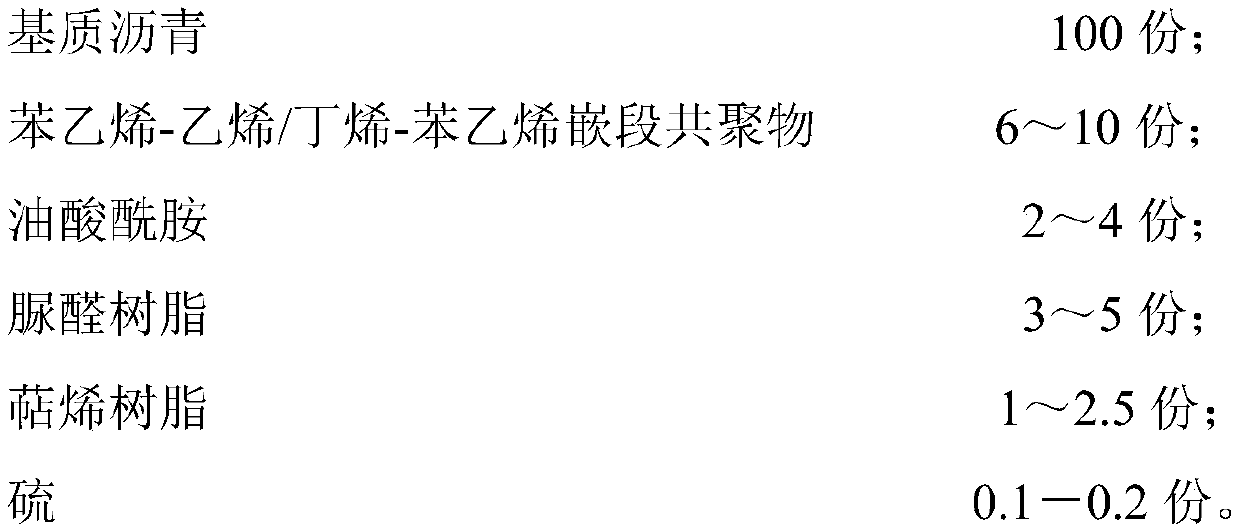

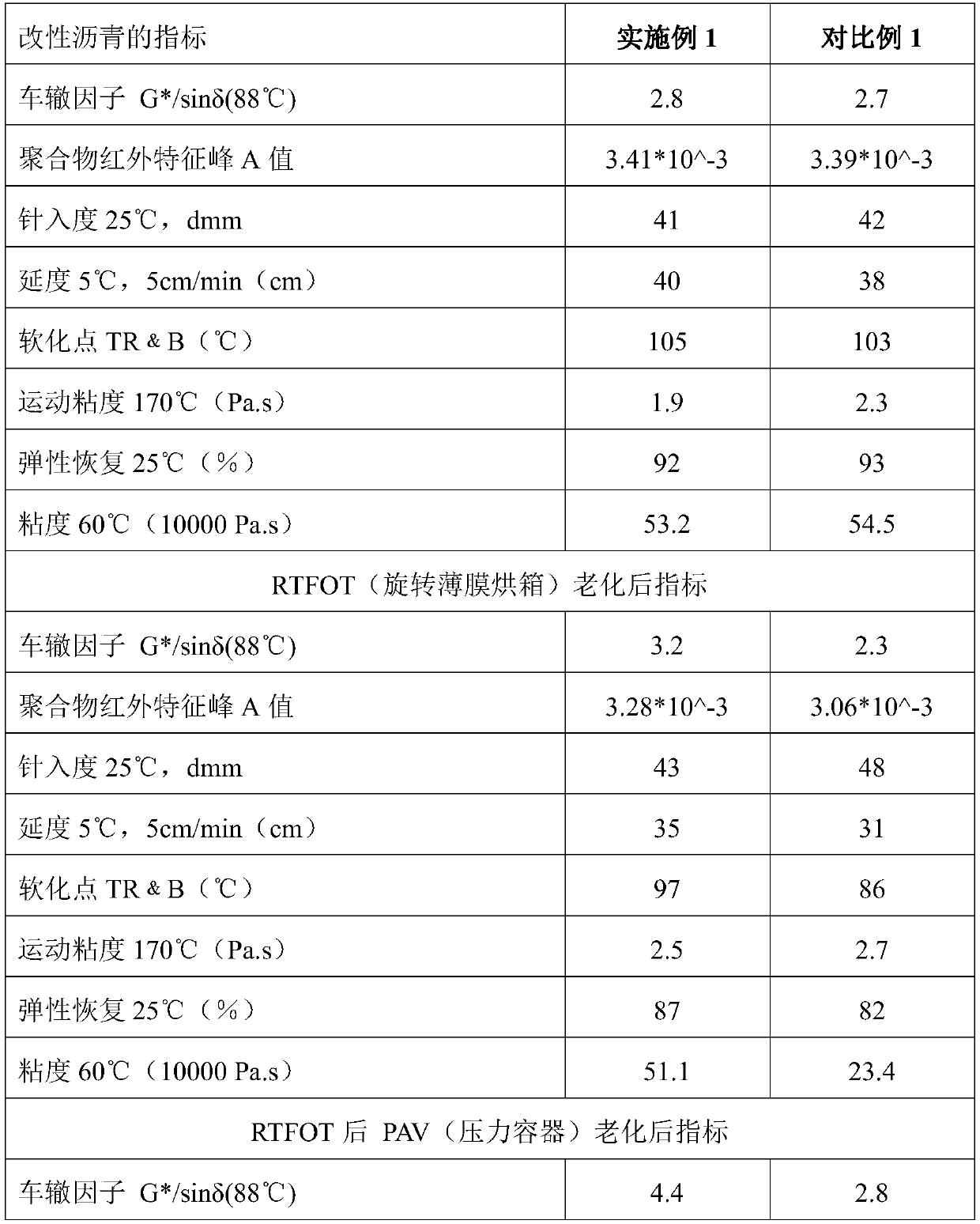

Embodiment 1

[0035] Take 10 kg of Esso No. 70 asphalt with a penetration of 70, heat it to 180 ° C, and add styrene-ethylene / butylene-styrene block copolymer (Sinopec SEBS, model YH-601) (the number average molecular weight is 160,000) 0.8 kg, 0.4 kg of urea-formaldehyde resin, and 0.2 kg of terpene resin, the mixture was passed through a colloid mill, and a strong mixer was used to stir for 4 hours at a stirring speed of 200 rpm. After adding 0.015 kg of sulfur and stirring for 2 hours, add 0.3 One kilogram of oleic acid amide was stirred for 1.5 hours to prepare modified asphalt, and the performance test results are shown in Table 1 and Table 2.

Embodiment 2

[0037]Take 10 kg of matrix asphalt with a penetration of 60, heat it to 160 ° C, add 0.6 kg of styrene-ethylene / butylene-styrene block copolymer (the copolymer is a star structure, and the styrene content is 37% , elongation at break ≥ 400%), 0.3 kg of urea-formaldehyde resin (urea-formaldehyde resin viscosity is 0.25Pa s), 0.1 kg of terpene resin (softening point 80 ° C), the mixture is passed through a colloid mill, and a strong mixer is used at 200 rpm Stir at a stirring speed of 1 / min for 2 hours, add 0.01 kg of sulfur and stir for 0.5 hour, then add 0.2 kg of oleic acid amide and stir for 0.5 hour to prepare modified asphalt.

Embodiment 3

[0039] Take 10 kg of matrix asphalt with a penetration of 60, heat it to 160°C, add 1 kg of styrene-ethylene / butylene-styrene block copolymer (the copolymer is a star structure, and the styrene content is 34% , elongation at break ≥ 400%), 0.5 kg of urea-formaldehyde resin (the viscosity of urea-formaldehyde resin is 0.4 Pa s), 0.25 kg of terpene resin (softening point 140 ° C), the mixture is passed through a colloid mill, and a strong mixer is used at 200 rpm Stir at a stirring speed of 1 / min for 6 hours, add 0.02 kg of sulfur and stir for 3 hours, then add 0.4 kg of oleic acid amide and stir for 3 hours to prepare modified asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com