Flame retardant resin composition and insulated electrical wire

A technology of insulated wires and compositions, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the problems of not meeting the proper performance of insulated wires, high polypropylene content, and inability to provide scratch and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

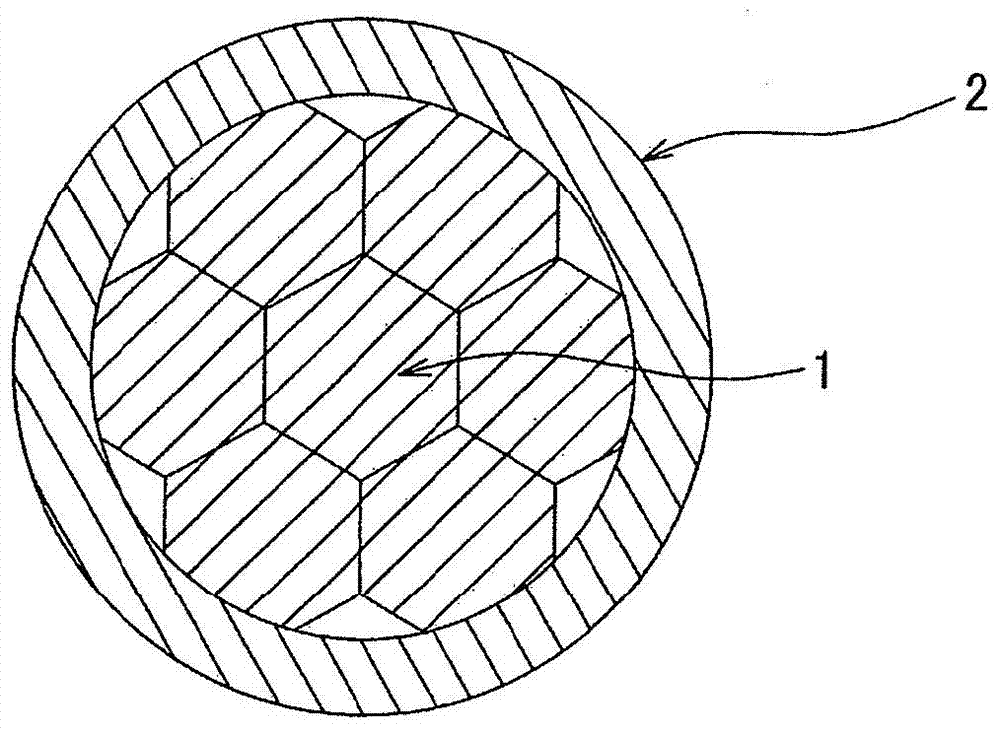

Image

Examples

Embodiment Construction

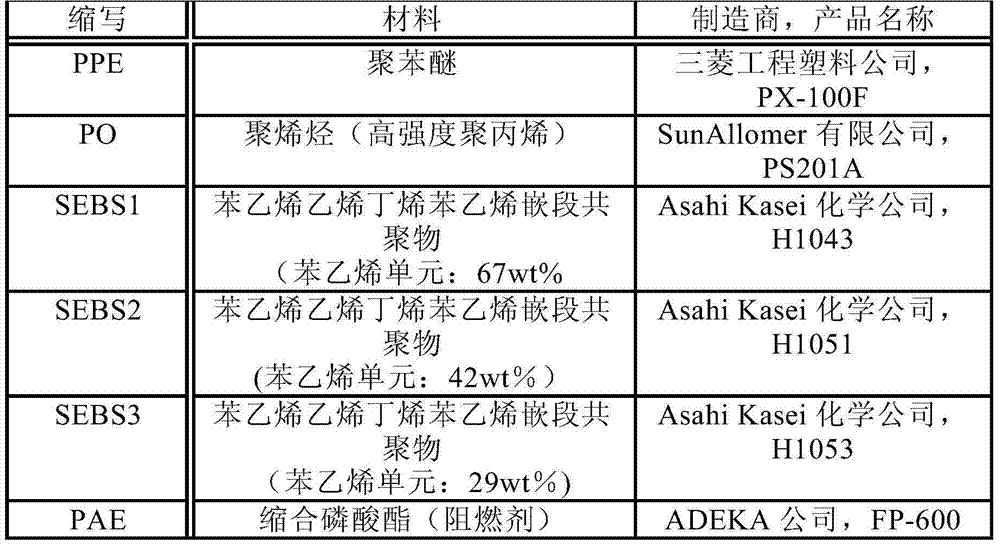

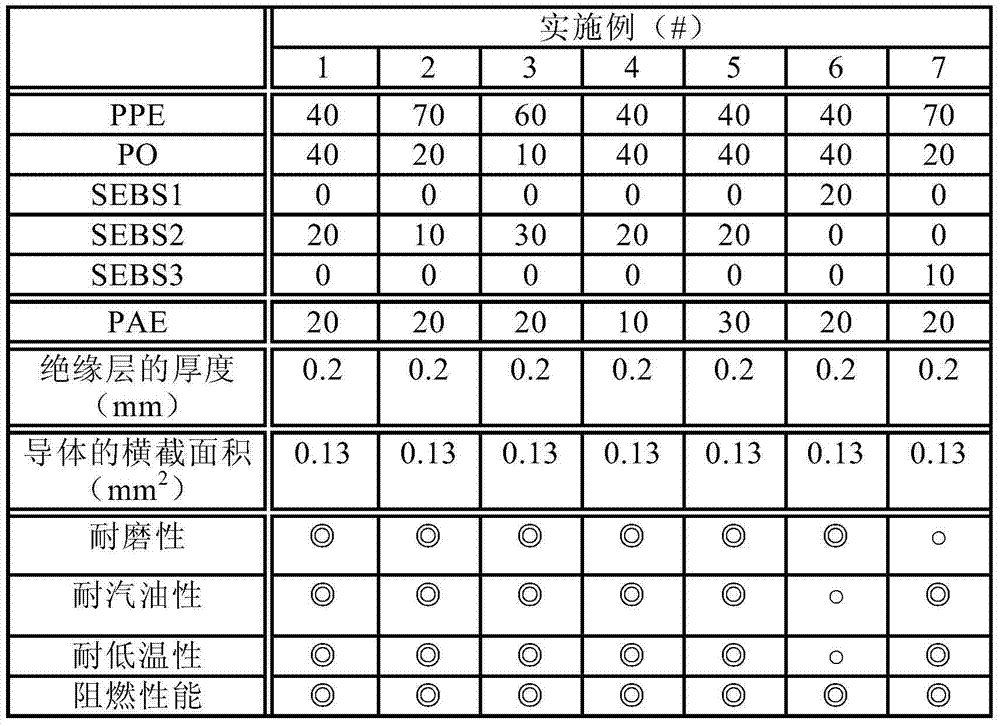

[0023] As described above, the flame retardant resin composition according to the present invention contains: (A) 100 parts by weight of the base resin and (B) 10 to 30 parts by weight of the condensed phosphoric acid ester. The base resin (100 parts by weight) contains: (A1) 40 to 70 parts by weight of polyphenylene ether, (A2) 10 to 40 parts by weight of polyolefin, and (A3) 10 to 30 parts by weight of styrene ethylene butene styrene Block copolymer (styrene ethylene butylene styrene block copolymer).

[0024] The polyphenylene ether (PPE) that can be used in the present invention is available from companies such as Mitsubishi Engineering Plastics. The polyphenylene ether may be present in an amount of 40 parts by weight to 70 parts by weight in 100 parts by weight of the base resin. In the case where the polyphenylene ether is present in an amount of less than 40 parts by weight in 100 parts by weight of the base resin, it will be difficult to achieve desired abrasion resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com