Special strippable protection glue for hard chromium plating

A strippable, protective adhesive technology, applied in the direction of coating, etc., can solve the problems of decreased adhesive film adhesion in the boundary area, part processing failure, leakage corrosion damage to the substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

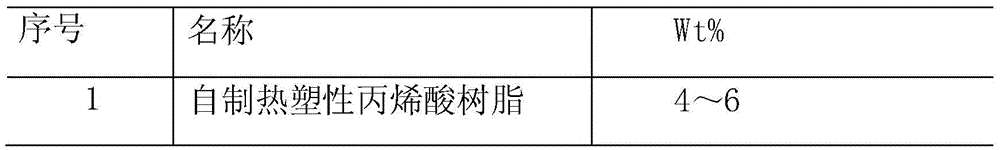

[0027] 1. Synthetic thermoplastic acrylic resin

[0028] Add 120g of xylene into a three-necked flask with stirring, a thermometer and a dropping funnel, heat to reflux at 130-140°C, and keep the temperature constant.

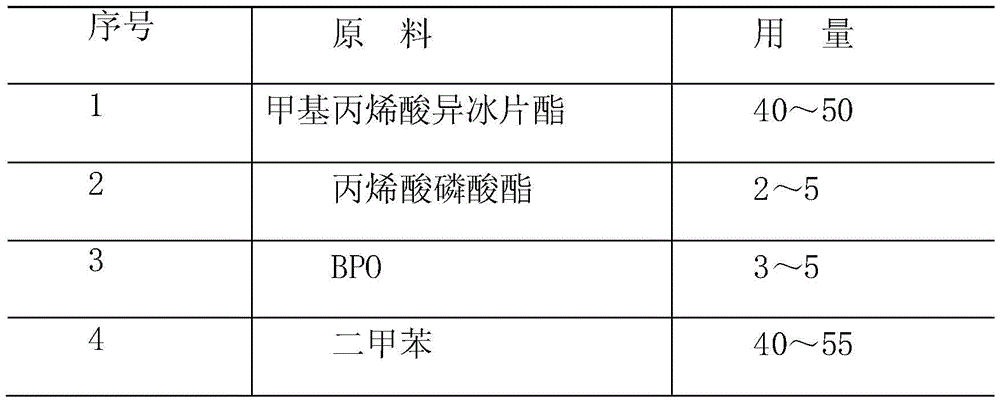

[0029] Dissolve 9g of BPO completely with 60g of xylene, then add 190g of isobornyl methacrylate and 10g of phosphate acrylate, and stir evenly. Pour the above mixture into the dropping funnel, drop it into the three-necked flask at a constant speed, and control the dropping within three hours. Keep warm for one hour.

[0030] Dissolve 0.5g of BPO with 20g of xylene completely. Pour the above mixture into the dropping funnel, drop it into the three-necked flask at a constant speed, and control the dropping in half an hour. Keep warm for one hour.

[0031] Dissolve 0.5g of BPO with 20g of xylene completely. Pour the above mixture into the dropping funnel, drop it into the three-necked flask at a constant speed, and control the dropping in half an hour. Kee...

Embodiment 2

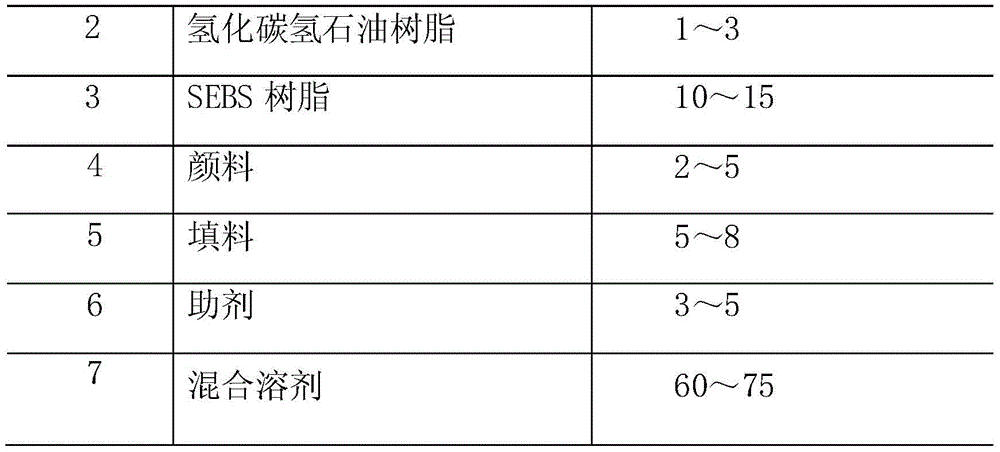

[0040] Take by weighing 13g SEBS resin and 1.2g hydrogenated C5 petroleum resin resin, add 29.5g toluene and 29.5g xylene, make it dissolve completely, then add prepared acrylic resin 8.2g, 4.0g white carbon black, 2.8g talc powder, 3.0g chromium oxide green, 0.6g BYK-066N, 0.5g YCK-2160, 3.8g toluene and 3.9g xylene, after mixing evenly, go to the grinding and dispersing machine to grind and disperse, add 0.4g BYK-410 during the grinding and dispersing process, grind The fineness is less than 35 microns, and it is made into a special peelable protective glue for hard chrome plating.

[0041] Coat the peelable protective glue specially made for hard chrome plating on the parts that need to be chrome-plated, and conduct a chrome-plating test after drying for 20 hours.

[0042] The test performance results are as follows:

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com