High-heat flame-retardant PPO (polyphenylene oxide) alloy material and preparation method thereof

An alloy material and scorching technology, which is applied in the field of high scorching flame retardant PPO alloy material and its preparation, can solve the problems of affecting the injection molding processability, affecting the performance of modified materials, affecting the dyeing performance, etc., so as to improve the mechanical properties and easy dyeing properties. , The effect of improving heat resistance and flame retardant performance, and good market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

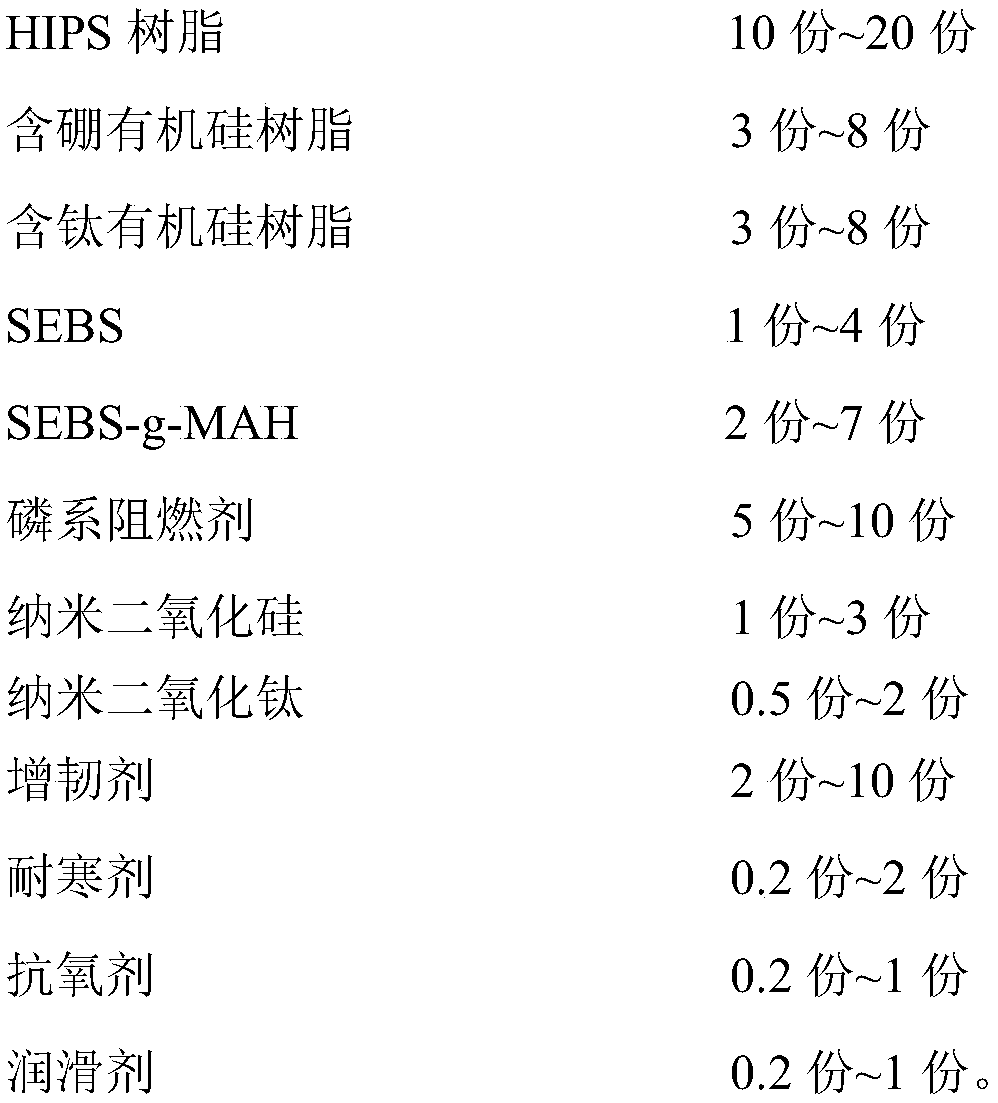

[0037] A high burning heat flame retardant PPO alloy material is made of the following components in parts by weight:

[0038]

[0039] Wherein, the titanium-containing silicone resin contains Si-O-Si chain segments and Si-O-Ti chain segments.

[0040] Among them, the PPO resin is the PPO resin with the product model LXR045 produced by China National Bluestar Group Co., Ltd.; the HIPS resin is the HIPS resin with the product model 825N produced by Taiwan Chemicals of Taiwan, China.

[0041] In this example, the grafting rate of SEBS-g-MAH was 0.9%.

[0042] Among them, the phosphorus-based flame retardant is an ultra-high phosphorus content flame retardant produced by Guangdong Shenghua Plastic Technology Co., Ltd.; the toughening agent is an ethylene terpolymer with a product model of PTW produced by DuPont; It is butyl rubber; the antioxidant is a mixture of antioxidant 1098 and antioxidant 168; the lubricant is PETS lubricant produced by Lonza Group.

[0043] The prepa...

Embodiment 2

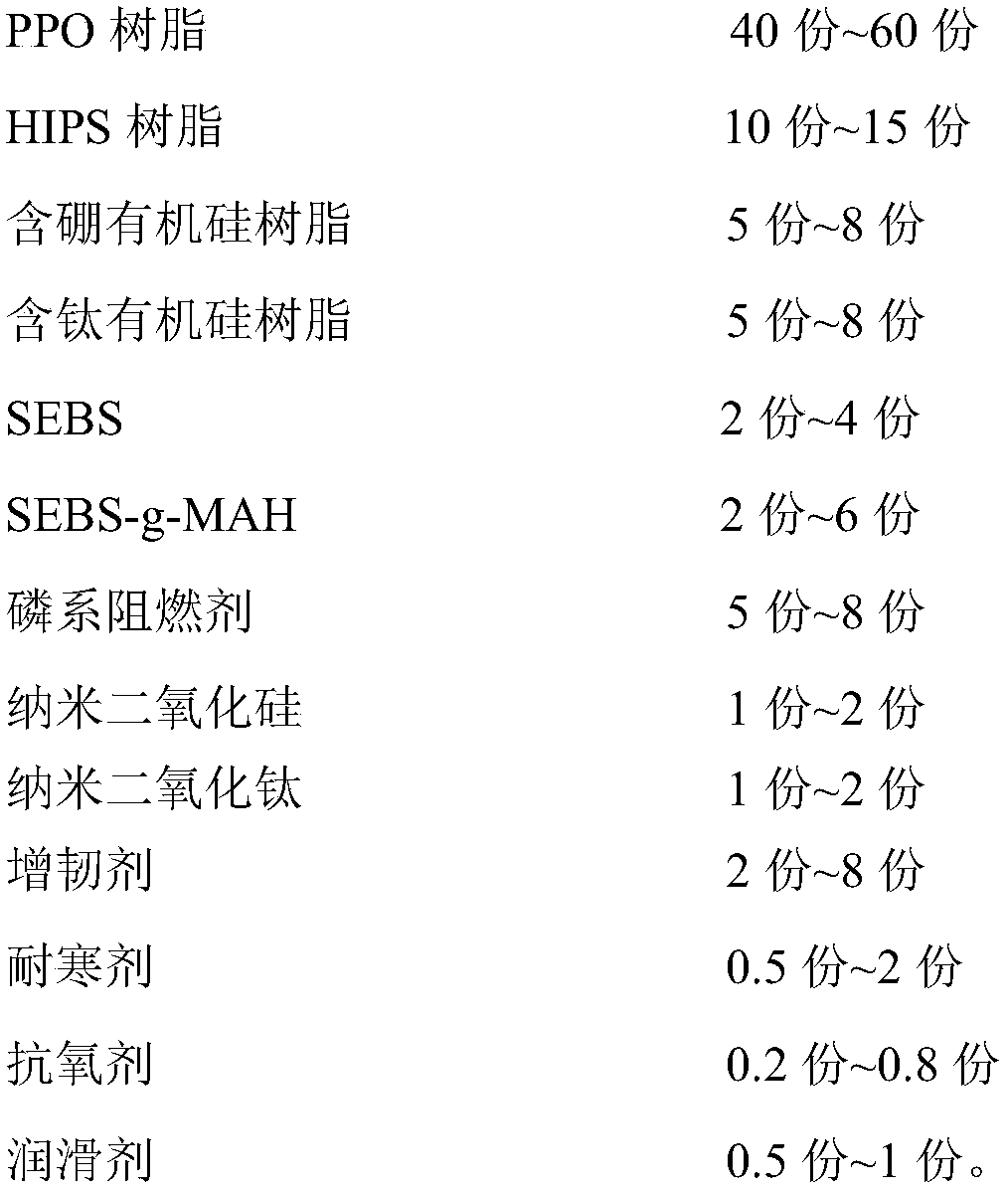

[0048] A high burning heat flame retardant PPO alloy material is made of the following components in parts by weight:

[0049]

[0050] Wherein, the titanium-containing silicone resin contains Si-O-Si chain segments and Si-O-Ti chain segments.

[0051] Among them, the PPO resin is the PPO resin with the product model LXR045 produced by China National Bluestar Group Co., Ltd.; the HIPS resin is the HIPS resin with the product model 825N produced by Taiwan Chemicals of Taiwan, China.

[0052] In this example, the grafting ratio of SEBS-g-MAH was 0.8%.

[0053] Among them, the phosphorus-based flame retardant is an ultra-high phosphorus content flame retardant produced by Guangdong Shenghua Plastic Technology Co., Ltd.; the toughening agent is an ethylene terpolymer with a product model of PTW produced by DuPont; It is butyl rubber; the antioxidant is a mixture of antioxidant 1098 and antioxidant 168; the lubricant is PETS lubricant produced by Lonza Group.

[0054] The prepar...

Embodiment 3

[0059] A high burning heat flame retardant PPO alloy material is made of the following components in parts by weight:

[0060]

[0061] Wherein, the titanium-containing silicone resin contains Si-O-Si chain segments and Si-O-Ti chain segments.

[0062] Among them, the PPO resin is the PPO resin with the product model LXR045 produced by China National Bluestar Group Co., Ltd.; the HIPS resin is the HIPS resin with the product model 825N produced by Taiwan Chemicals of Taiwan, China.

[0063] In this example, the grafting ratio of SEBS-g-MAH was 1%.

[0064] Among them, the phosphorus-based flame retardant is an ultra-high phosphorus content flame retardant produced by Guangdong Shenghua Plastic Technology Co., Ltd.; the toughening agent is an ethylene terpolymer with a product model of PTW produced by DuPont; It is butyl rubber; the antioxidant is a mixture of antioxidant 1098 and antioxidant 168; the lubricant is PETS lubricant produced by Lonza Group.

[0065] The prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com