Preparation method of aramid fiber filter bag and aramid fiber filter bag

An aramid fiber and filter bag technology, applied in the field of aramid fiber, can solve the problems of weak bonding and inert surface of aramid fiber, and achieve the effects of stable quality, improved heat sealing effect and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Preparation of filter material: use aramid fibers with a fineness of 14 μm and a length of 55 mm to prepare filter materials. 500g / m 2 , the thickness is 1.8mm;

[0019] (2) Preparation of silane coupling agent solution: silane coupling agent A-15 14.2ml / L, emulsifier 0.6ml / L, catalyst 0.10g / L, after mixing the raw materials in the formula evenly, add water to 1 liter, Make the finishing solution uniform by mechanical stirring;

[0020] Wherein the emulsifier is Tween 80, and the catalyst is lead acetate;

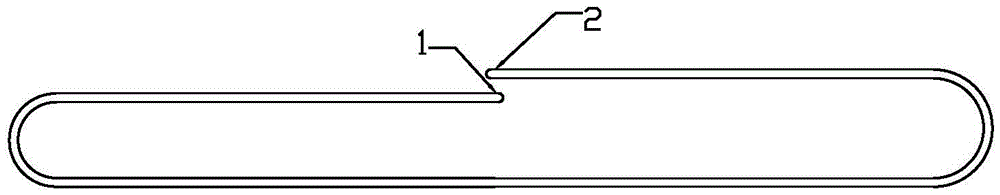

[0021] (3) Surface coating: place the prepared silane coupling agent solution in the rubber material machine, control the dosage and osmotic pressure of the rubber material under the action of the gear pump, so that the treatment agent penetrates into the seam port 1 under the filter material, and Evenly coated on the surface of aramid fiber raw material at the lower seam, where the speed of gluing is 5.5m / min, and then dried by drying equipment;

[0022] (4)...

Embodiment 2

[0026] (1) Preparation of filter material: use aramid fibers with a fineness of 14 μm and a length of 55 mm to prepare filter materials. 500g / m 2 , the thickness is 1.8mm;

[0027] (2) Preparation of silane coupling agent solution: the mass concentration of silane coupling agent A-151 is 2%, the concentration of industrial alcohol is 99%, and the silane coupling agent A-151 and alcohol are mechanically stirred to make the solution evenly mixed;

[0028] (3) Surface coating: place the prepared silane coupling agent solution in the rubber material machine, control the dosage and osmotic pressure of the rubber material under the action of the gear pump, so that the treatment agent penetrates into the seam port 1 under the filter material, and Evenly coated on the surface of aramid fiber raw material at the lower seam, where the speed of gluing is 5.5m / min, and then dried by drying equipment;

[0029] (4) Heat sealing process: Heat the treated aramid fiber felt through a heat se...

Embodiment 3

[0032] (1) Preparation of filter material: use aramid fibers with a fineness of 14 μm and a length of 55 mm to prepare filter materials. 500g / m 2 , the thickness is 1.8mm;

[0033] (2) Preparation of silane coupling agent solution: silane coupling agent A-151 10ml / L, emulsifier 2ml / L, catalyst 1.55g / L, mix each raw material in the formula evenly, add water to 1 liter, and mechanically Stir to make the finishing liquid uniform;

[0034] Wherein the emulsifier is polyoxyethylene polyoxypropylene benzyl biphenol ether, and the catalyst is fatty acid salt;

[0035] (3) Surface coating: place the prepared silane coupling agent solution in the rubber material machine, control the dosage and osmotic pressure of the rubber material under the action of the gear pump, so that the treatment agent penetrates into the seam port 1 under the filter material, and Evenly coated on the surface of aramid fiber raw material at the lower seam, where the speed of gluing is 5.5m / min, and then dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com