Wire stitching device

A suturing device and wire technology, which is applied to insulation/armoured cable repair equipment and other directions, can solve the problems of poor tape repair and suturing effect, waste of manpower and financial resources for wires, and poor suturing effect, etc., to achieve good heating sealing effect, improve Efficiency and quality, the effect of improving sewing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

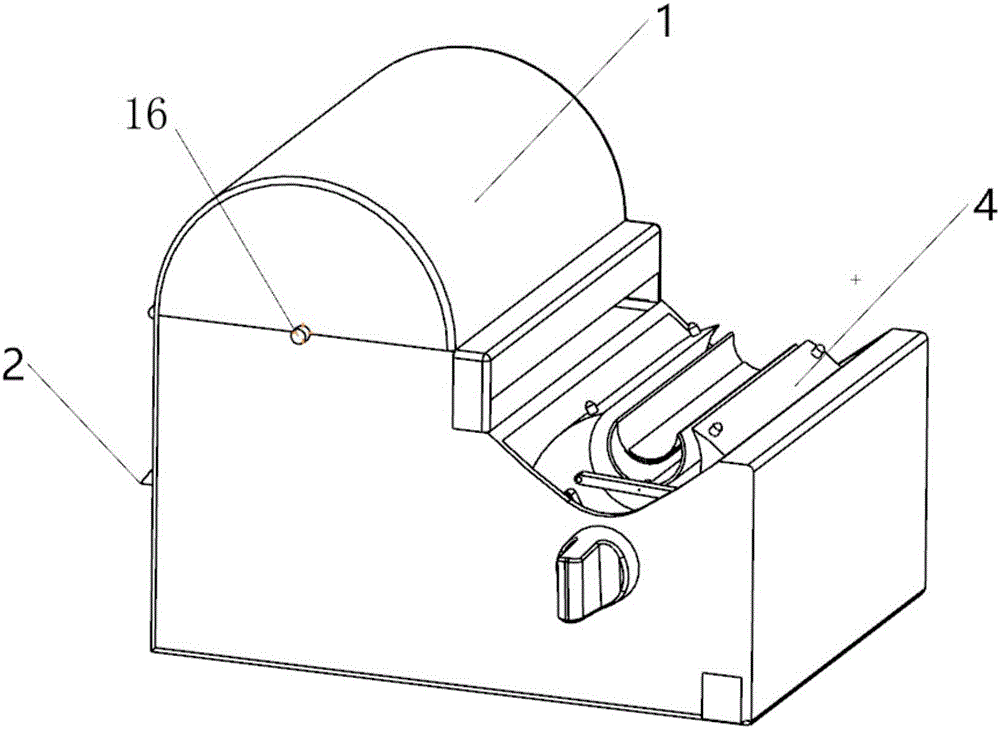

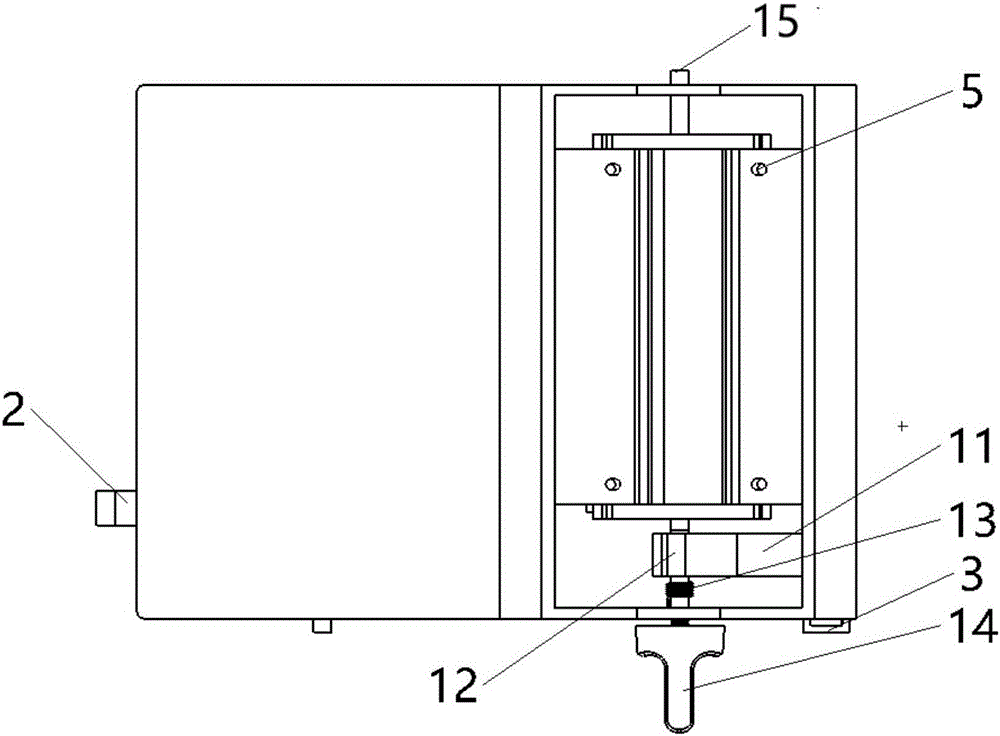

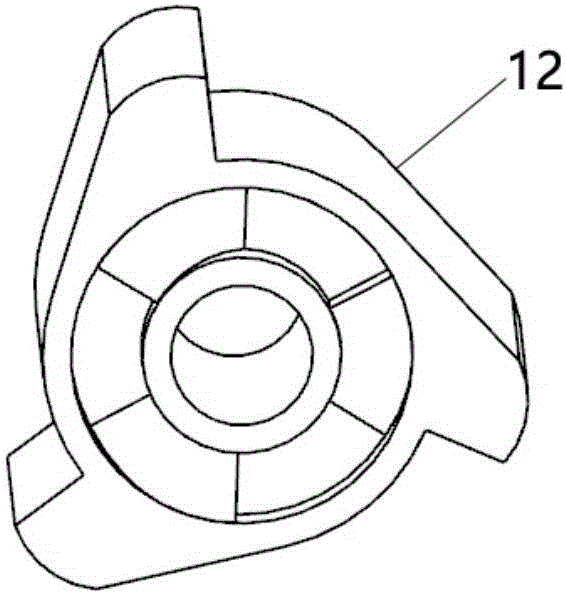

[0021] A wire suture device as shown in the accompanying drawings, including a box body 1, a power switch 2, a storage box 3, a sheave 4, a shaft pin 5, a manipulator 6, a connecting bracket 7, a switch column 8, a spring leaf 9, and a fixing rod 10. Blocking piece 11, lock wheel 12, spring 13, knob 14, sheave shaft 15, support shaft 16, fixed shaft 17. A sheave shaft 15 and a support shaft 16 are installed in the casing 1, and an insulating material is housed on the support shaft 16. The sheave 4 is fixedly connected on the sheave shaft 15, the two ends of the sheave 4 are equipped with a fixed rod 10, the middle part of the fixed rod 10 is equipped with a fixed shaft 17, the manipulator 6 and the connecting bracket 7 are divided into left and right pieces, and the manipulator 6 passes through the fixed shaft 17 Connect with fixed bar 10, make manipulator 6 be fixed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com