Biodegradable thermoplastic starch resin for thin-film material, preparation method thereof and products thereof

A thermoplastic starch and biodegradation technology, which is applied in the field of biodegradable thermoplastic starch resin and its preparation, can solve the problems that the material strength cannot meet the use requirements, white pollution, and affect the ecological balance, etc., and achieve low product price and high biodegradation rate , the effect of good market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

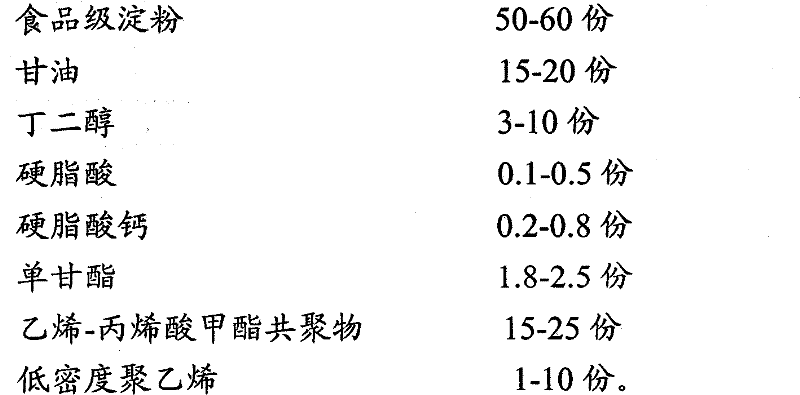

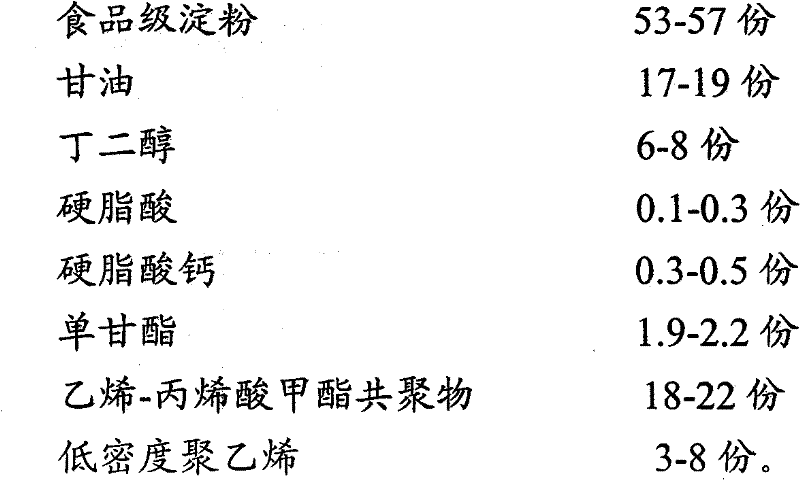

Method used

Image

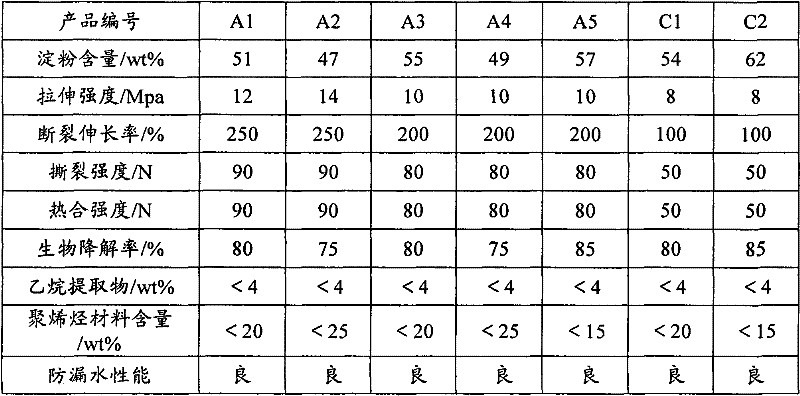

Examples

Embodiment 1

[0023] This example is used to illustrate the biodegradable starch resin provided by the present invention and its preparation method.

[0024] The composition of raw materials is: 55 kg of food grade corn starch, 18 kg of glycerin, 7 kg of butanediol, 0.2 kg of stearic acid, 0.4 kg of calcium stearate, 2 kg of monoglyceride, 20 kg of ethylene-methyl acrylate copolymer, Low-density polyethylene 5 kg.

[0025] Among them, the water content of cornstarch is 13wt%; the density of monoglyceride is 0.916g / cm 3 , the ester content is 30%; the number average molecular weight of ethylene-methyl acrylate copolymer is 150,000, the molecular weight distribution is 1.2, the melt index is 25 g / 10 minutes, and the density is 0.94 g / cm 3 , the content of acrylic acid is 9%; the number average molecular weight of low-density polyethylene is 250,000, the molecular weight distribution is 1.2, and the density is 0.918g / cm 3 .

[0026] The preparation process is as follows:

[0027] (1) Carry...

Embodiment 2

[0032] This example is used to illustrate the biodegradable starch resin provided by the present invention and its preparation method.

[0033] The raw materials are as follows: 53 kg of food grade potato starch, 19 kg of glycerin, 8 kg of butanediol, 0.3 kg of stearic acid, 0.6 kg of calcium stearate, 1.8 kg of monoglyceride, 22 kg of ethylene-methyl acrylate copolymer, Low density polyethylene 8 kg. Among them, the water content of cornstarch is 12wt%; the density of monoglyceride is 0.92g / cm 3 , the ester content is 32%; the number-average molecular weight of the ethylene-methyl acrylate copolymer is 180,000, the molecular weight distribution is 1.2, the melt index is 20 g / 10 minutes (190°C, 2.16 kg), and the density is 0.93 g / cm 3 , the content of acrylic acid is 10%; the number-average molecular weight of low-density polyethylene is 100,000, the molecular weight distribution is 1.2, and the density is 0.918g / cm 3 , a melt index of 6 g / 10 minutes (190° C., 2.16 kg).

[...

Embodiment 3

[0040]This example is used to illustrate the biodegradable starch resin provided by the present invention and its preparation method.

[0041] The raw materials are: 57 kg of food grade sweet potato starch, 16 kg of glycerin, 6 kg of butanediol, 0.4 kg of stearic acid, 0.6 kg of calcium stearate, 2.2 kg of monoglyceride, 19 kg of ethylene-ethyl acrylate copolymer, Low-density polyethylene 3 kg.

[0042] Wherein, the water content of sweet potato starch is 14wt%; The density of monoglyceride is 0.916g / cm 3 , the ester content is 30%; the number average molecular weight of ethylene-ethyl acrylate copolymer is 200,000, the molecular weight distribution is 1.2, the melt index is 15 g / 10 minutes, and the density is 0.94 g / cm 3 , the content of acrylic acid is 8%; the number average molecular weight of low-density polyethylene is 300,000, the molecular weight distribution is 1.2, and the density is 0.918g / cm 3 , a melt index of 5 g / 10 minutes (190° C., 2.16 kg).

[0043] The prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com