High-filling high-transparency biodegradable air bubble film and preparation method thereof

A technology of light transmission and bubble film, applied in the field of bubble film, can solve the problems of air leakage at the bubble point, reduce the light transmittance of the bubble bag, and reduce the adhesion between the melt and the metal roller, so as to reduce thermal degradation, Excellent penetrability and the effect of improving fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

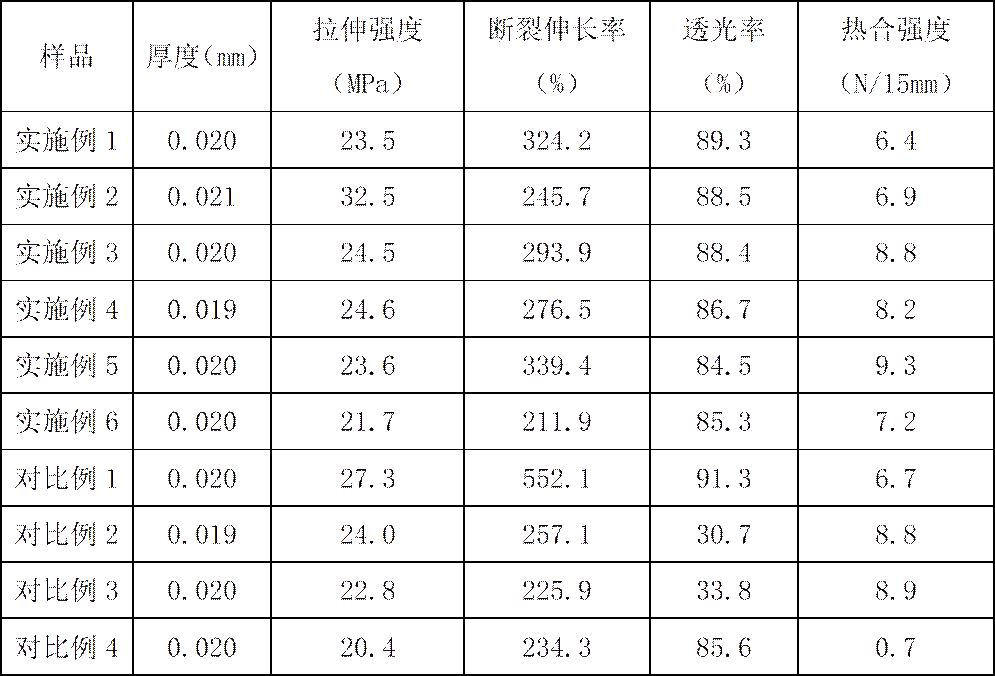

Examples

Embodiment 1

[0031] S1: Vacuum dry 70g of PBAT, 4g of L-polylactic acid (PLLA) for 2 hours at a drying temperature of 100°C, dry 4g of polycaprolactone for 2 hours at a drying temperature of 80°C, and dry 20g of inorganic filler silicon micropowder. Number ≥ 3000 Vacuum drying 4h, drying temperature 100 ℃;

[0032] S2: Weigh the dried PBAT, L-polylactic acid (PLLA), polycaprolactone, and inorganic filler silicon micropowder, then weigh 0.7g of plasticizer trioctyl citrate, 1g of antioxidant tea polyphenol, 0.3 The chain extender ADR-4468 of g is placed in a high-speed mixer for high-speed mixing, the high-speed mixing time is 10 minutes, and the rotation speed is kept at 300rpm;

[0033] S3: Put the mixed material in a twin-screw extruder to melt and blend, extrude and granulate, the extrusion temperature is 160°C, the die head temperature is 130°C, and the screw speed is 300rpm to obtain blended pellets;

[0034] S4: Put the obtained blended pellets into the air bubble film casting machi...

Embodiment 2

[0036] S1: 63g of PBAT, 12g of D-polylactic acid (PDLA) were vacuum-dried for 5 hours at a drying temperature of 80°C, 3g of polycaprolactone was vacuum-dried for 5 hours at a drying temperature of 45°C, and 20g of inorganic fillers were precipitated with barium sulfate. And the number of mesh ≥ 3000 vacuum drying 8h, drying temperature 150 ℃;

[0037] S2: Weigh the dried PBAT, dextrorotatory polylactic acid (PDLA), polycaprolactone, and inorganic filler precipitated barium sulfate, then weigh 1g of plasticizer tributyl citrate, 0.7g of phytic acid, 0.3g of The chain extender ADR-4370 is placed in a high-speed mixer for high-speed mixing, the high-speed mixing time is 5 minutes, and the speed is kept at 600rpm;

[0038] S3: Put the mixed material in a twin-screw extruder to melt and blend, extrude and granulate, the extrusion temperature is 175°C, the die head temperature is 150°C, and the screw speed is 180rpm to obtain blended pellets;

[0039] S4: Put the obtained blended ...

Embodiment 3

[0041] S1: Vacuum dry 62.5g of PBAT, 6g of racemic polylactic acid (PDLLA) for 6 hours at a drying temperature of 60°C, dry 6g of polycaprolactone for 6 hours at a drying temperature of 60°C, and dry 23g of inorganic filler sodium sulfate , and the number of mesh ≥ 3000 is vacuum dried for 6 hours, and the drying temperature is 60°C;

[0042] S2: Weigh the dried PBAT, racemic polylactic acid (PDLLA), polycaprolactone, and inorganic filler sodium sulfate, then weigh 1g of plasticizer glycerin, 0.5g of antioxidant 1010, and 1.0g of chain extender The agent ADR-4368 is placed in a high-speed mixer for high-speed mixing, the high-speed mixing time is 8 minutes, and the speed is kept at 600rpm;

[0043]S3: Put the mixed materials in a twin-screw extruder to melt and blend, extrude and granulate, the extrusion temperature is 185°C, the die head temperature is 180°C, and the screw speed is 200rpm to obtain blended pellets;

[0044] S4: Put the obtained blended pellets into a bubble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com