Method for firing Taoxun

A technology of pottery Xun and Nixing pottery clay, which is applied to clay products, instruments, and other household utensils. It can solve the problems of easy cracking and small specific gravity, and achieve the effect of not being easily broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

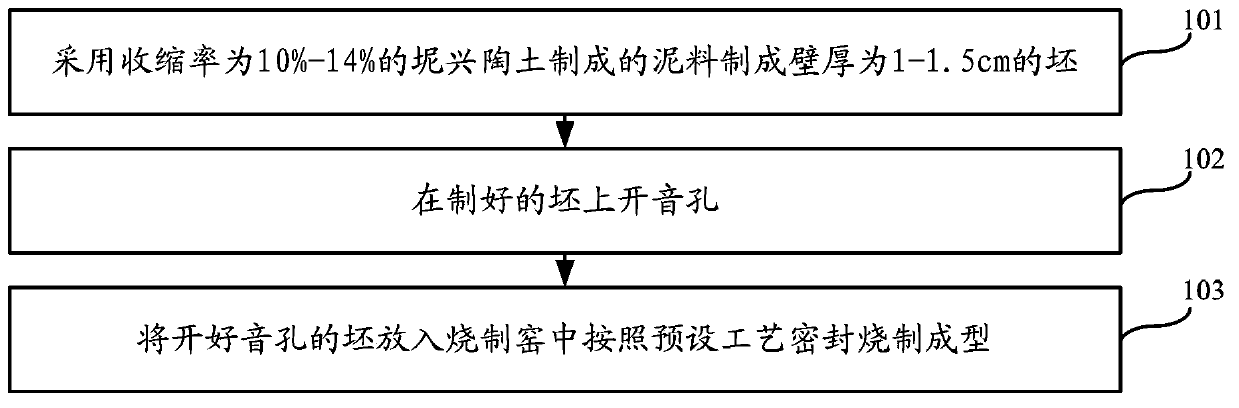

[0015] Such as figure 1 The shown method flow chart of firing pottery Xun, this method specifically comprises the following steps:

[0016] 101. Using mud made of Nixing pottery clay with a shrinkage rate of 10%-14% to make a blank with a wall thickness of 1-1.5cm;

[0017] 102. Open a sound hole on the finished blank;

[0018] 103. Put the billet with the sound hole into the firing kiln and seal and fire it according to the preset process.

[0019] In the method for firing pottery Xun provided by the present invention, Nixing pottery clay is used as a raw material, and its molding temperature is 1100°C, which belongs to high-temperature molding pottery clay. Pottery Xun is hard and not easy to break.

[0020] The mud made of Nixing pottery clay can be purchased directly, but when making pottery xuns that can be played, it is necessary to use mud with a shrinkage rate of 10%-14% and make the wall thickness 1-1.5cm The finished product fired from the thick billet can meet t...

Embodiment 2

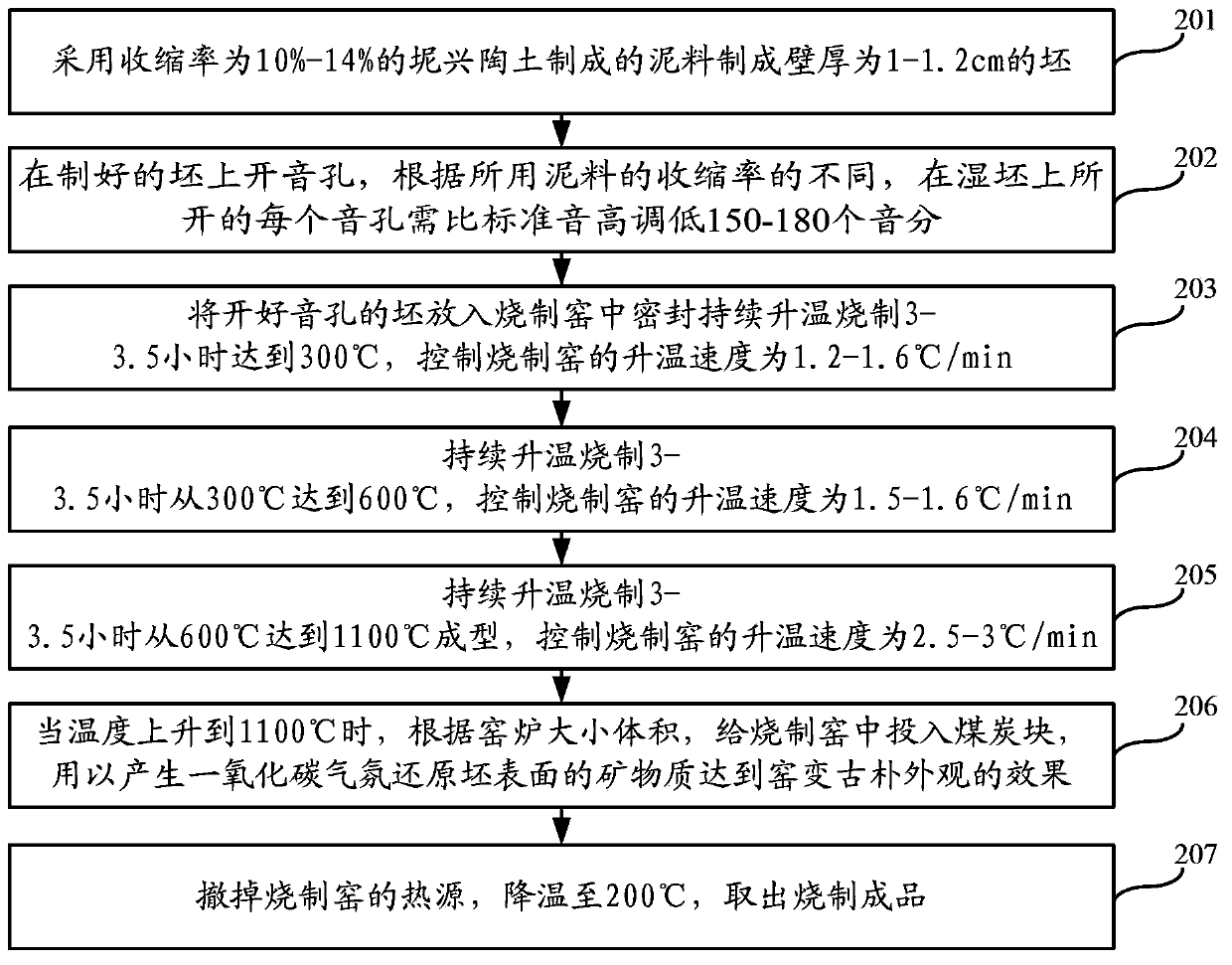

[0022] Such as figure 2 The shown method flow chart of firing pottery Xun, this method specifically comprises the following steps:

[0023] 201. The mud made of Nixing pottery clay with a shrinkage rate of 10%-14% is used to make a blank with a wall thickness of 1-1.2cm;

[0024] 202. Open the sound hole on the finished billet. According to the shrinkage rate of the mud used, each sound hole opened on the wet billet needs to be lowered by 150-180 cents than the standard pitch;

[0025] 203. Put the billet with the sound holes into the firing kiln, seal and continue heating and firing for 3-3.5 hours to reach 300°C, and control the heating rate of the firing kiln to 1.2-1.6°C / min;

[0026] 204. Continue heating and firing for 3-3.5 hours to reach 600°C, and control the heating rate of the firing kiln to 1.5-1.6°C / min;

[0027] 205. Continue heating and firing for 3-3.5 hours to reach 1100°C for molding, and control the heating rate of the firing kiln to 2.5-3°C / min;

[0028...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com