A kind of making and firing method of Jun porcelain xun

A technology of porcelain xun and sound hole, which is applied in the field of ceramics, can solve the problems that the pitch and timbre of ceramic xun are difficult to control, and the pitch and timbre of ceramic xun are greatly affected, so as to achieve good surface decoration effect, improve artistic appreciation, and not easy to break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

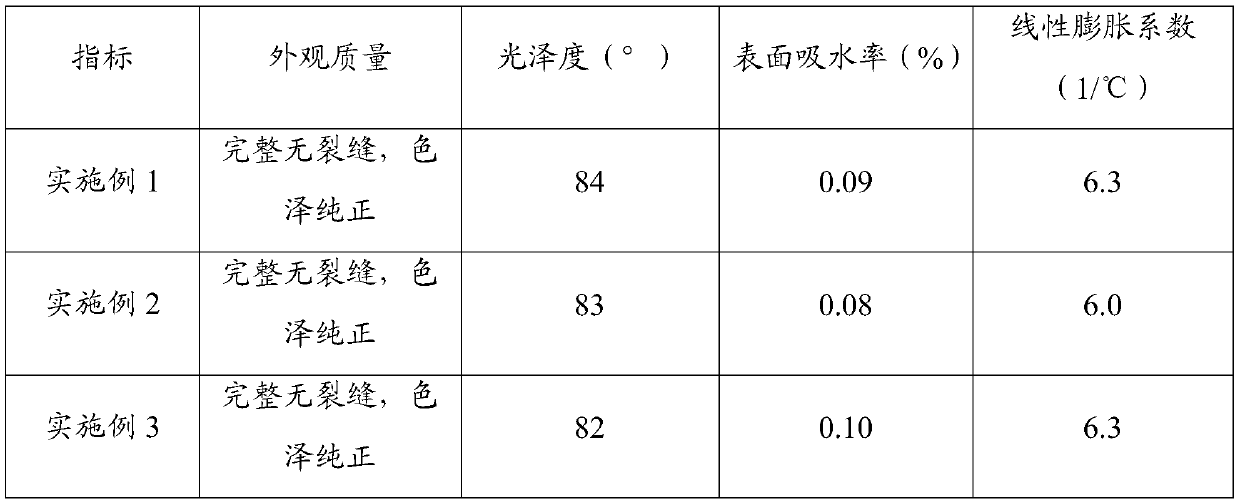

Embodiment 1

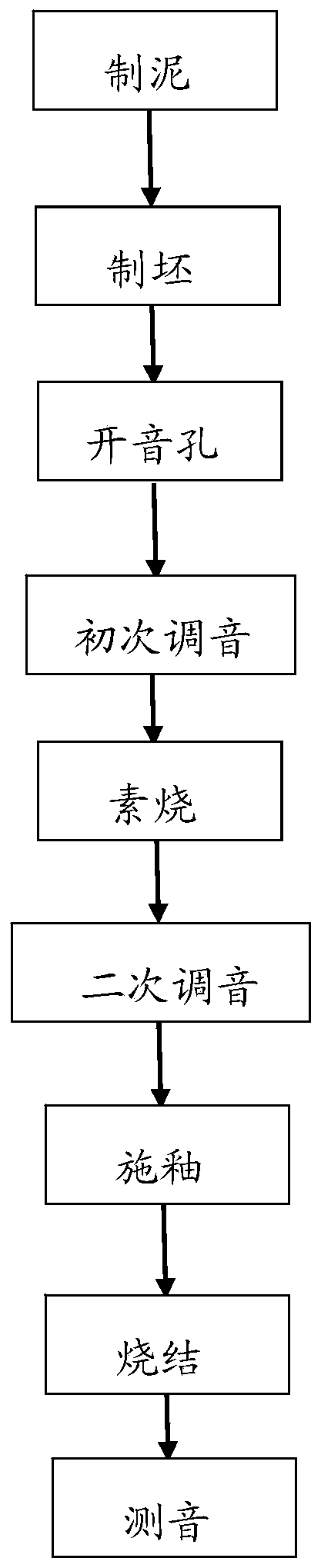

[0036] A kind of making and firing method of Jun porcelain Xun, its technological process see figure 1 , specifically follow the steps below:

[0037] Step 1, mud making

[0038] Step 1.1, weighing 40 parts of kaolin, 10 parts of soda stone, 15 parts of Mujie clay, 5 parts of quartz sand, 0.5 parts of vermiculite, 1 part of plant ash, 2 parts of sodium alginate, and 0.5 parts of phenolic resin powder according to parts by weight;

[0039] In step 1.2, the raw materials weighed in step 1.1 are pulverized and mixed to obtain a mixture, and the mixture is put into a ball mill, then water of the same quality as the mixture is added to the ball mill, and ground until the fineness of the mixture is 250 mesh, and The sieve residue is 0.1%, and the ground mud is obtained, and the ground mud is left to stand for 24 hours for later use;

[0040] Step 2, blank making

[0041] Put the mud prepared in step 1.2 in a vacuum machine, pump out the air in the mud, and then inject the mud tha...

Embodiment 2

[0057] A kind of making and firing method of Jun porcelain Xun, its technological process see figure 1 , specifically follow the steps below:

[0058] Step 1, mud making

[0059] Step 1.1, weighing 45 parts of kaolin, 8 parts of soda stone, 12 parts of wood knot clay, 10 parts of quartz sand, 1 part of vermiculite, 1 part of plant ash, 1.5 parts of sodium alginate, and 1 part of phenolic resin powder according to parts by weight;

[0060] In step 1.2, the raw materials weighed in step 1.1 are pulverized and mixed to obtain a mixture, and the mixture is put into a ball mill, then water of the same quality as the mixture is added to the ball mill, and ground until the fineness of the mixture is 250 mesh, and The sieve residue is 0.15%, and the ground mud is obtained, and the ground mud is left to stand for 24 hours for subsequent use;

[0061] Step 2, blank making

[0062] Put the mud prepared in step 1.2 in a vacuum machine, pump out the air in the mud, and then inject the m...

Embodiment 3

[0076] A kind of making and firing method of Jun porcelain Xun, its technological process see figure 1 , specifically follow the steps below:

[0077] Step 1, mud making

[0078] Step 1.1, weighing 50 parts of kaolin, 5 parts of soda stone, 10 parts of Mujie clay, 12 parts of quartz sand, 0.5 parts of vermiculite, 2 parts of plant ash, 2 parts of sodium alginate, and 1 part of phenolic resin powder according to parts by weight;

[0079] In step 1.2, the raw materials weighed in step 1.1 are pulverized and mixed to obtain a mixture, and the mixture is put into a ball mill, then water of the same quality as the mixture is added to the ball mill, and ground until the fineness of the mixture is 250 mesh, and The sieve residue is 0.2%, and the ground mud is obtained, and the ground mud is left to stand for 24 hours for subsequent use;

[0080] Step 2, blank making

[0081] Put the mud prepared in step 1.2 in a vacuum machine, pump out the air in the mud, and then inject the mud ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com