Method for recovering zinc from high iron and high lead leaching residue through microwave-ultrasonic wave combination

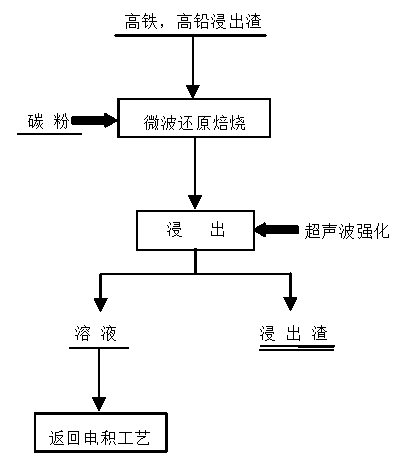

An ultrasonic and leaching slag technology, applied in microwave and ultrasonic applications, to achieve efficient recovery, shorten leaching time, and avoid local sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Take 250g of boiler dust high-iron and high-lead leaching slag from a metallurgical plant in Yunnan, containing 12.34% zinc, 20.85% iron, 12.20% lead, 6.12% silicon dioxide, and 1091.9g / t indium, of which the main metal substances are ZnFe 2 o 4 , PbSO 4 ,Such as figure 2 shown. Then add 1% carbon powder by mass, mix well, heat to 600°C by microwave, keep the temperature for 2 hours, then stop heating, and pass N 2 Protect the atmosphere to prevent the oxidation of ferric oxide until the temperature drops below 100°C to obtain leached slag after reduction;

[0021] (2) Add the leached slag after reduction obtained in step (1), and add a sulfuric acid solution with a concentration of 150g / L at a liquid-solid ratio (L / Kg) of 8:1, and then irradiate the mixed solution with ultrasonic waves at 75°C Intensive leaching for 3 hours, the conditions of ultrasonic radiation are: the ultrasonic frequency is 20KHz, the ultrasonic power distributed per liter of mixed liqui...

Embodiment 2

[0023] (1) Take 250g of high-iron and high-lead leaching slag, add carbon powder with 5% of its mass, mix well, heat to 800°C by microwave, keep the temperature for 1 hour, then stop heating, and pass in N 2 Protect the atmosphere to prevent the oxidation of ferric oxide until the temperature drops below 100°C to obtain leached slag after reduction;

[0024] (2) Add the leached slag after reduction obtained in step (1), and add a sulfuric acid solution with a concentration of 70g / L at a liquid-solid ratio of 5:1. The conditions of irradiation are: the ultrasonic frequency is 22KHz, the ultrasonic power distributed per liter of mixed liquid is 100W, the leaching liquid is obtained through solid-liquid separation, and then the leaching liquid is subsequently purified, and metal zinc is recovered through electrowinning. The recovery rate of zinc reaches 95%, and the leaching rate of iron is 39%.

Embodiment 3

[0026] (1) Take 250g of high-iron and high-lead leaching slag, add 7% of its mass carbon powder, mix well, heat to 550°C by microwave, keep the temperature for 3 hours, then stop heating, and pass in N 2 Protect the atmosphere to prevent the oxidation of ferric oxide until the temperature drops below 100°C to obtain leached slag after reduction;

[0027] (2) Add the leached slag after reduction obtained in step (1), and add a sulfuric acid solution with a concentration of 170g / L at a liquid-solid ratio of 3:1. The conditions of irradiation are: ultrasonic frequency is 25KHz, the ultrasonic power distributed per liter of mixed liquid is 160W, leachate is obtained through solid-liquid separation, and the leachate is subsequently purified, and metal zinc is recovered through electrowinning. The recovery rate of zinc reaches 97%, and the leaching rate of iron is 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com