Method and equipment for curing phenolic aldehyde foam material

A phenolic foam material and equipment technology, applied in the field of phenolic resin, can solve problems such as cracking, inconsistent shrinkage, deformation, etc., and achieve the effects of accelerating chemical reactions, ensuring product quality, and uniform heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

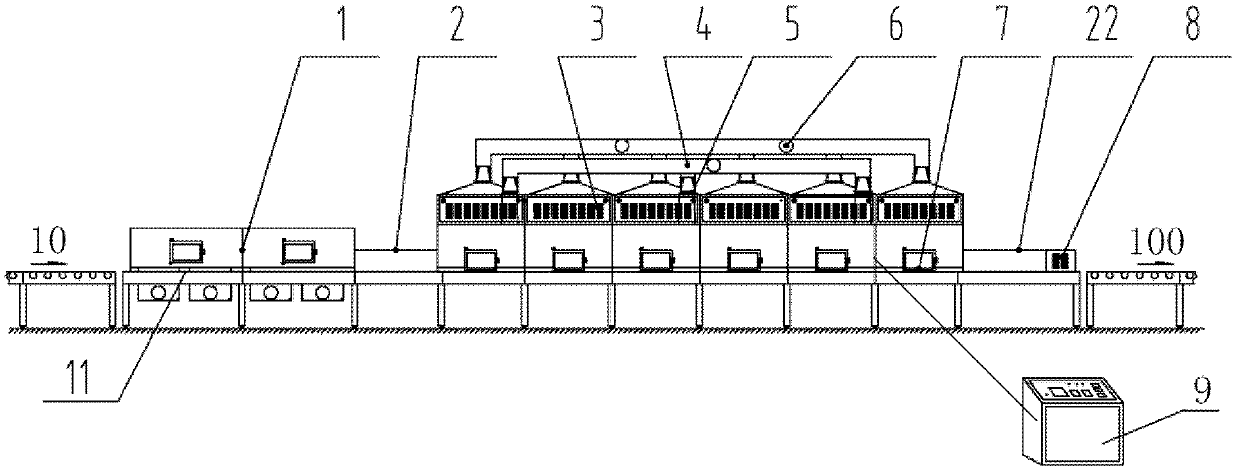

[0050] (1) Ripening equipment

[0051] Such as figure 1 As shown, the curing equipment includes a conveyor 11, here is a conveyor belt, the input end 10 of the conveyor is used to input the phenolic foam material to be cured, and the output end 100 of the conveyor is used to output the cured phenolic foam material, a first microwave suppressor 2, a microwave radiation device 3, a second microwave suppressor 22 and a cooling device 8 are sequentially arranged between the input end 10 of the transmission device and the output end 100 of the transmission device, and the microwave radiation The device 3 is connected with the microwave control device 9, and the moisture discharge pipeline 4 is arranged above the microwave cabinet, and the moisture discharge pipeline 4 communicates with the interior of the microwave cabinet through the moisture discharge pipeline regulating valve 5, so that The opening degree of the regulating valve 5 of the dehumidification pipeline is 1 / 4, an exh...

Embodiment 2

[0057] (1) Ripening equipment

[0058] Adopt the same curing equipment as (1) in Embodiment 1, the difference is: the microwave radiation device 3 is a microwave box, there is no infrared hot air device between the input end 10 of the transmission device and the first microwave suppressor 2 .

[0059] (2) Aging process of phenolic foam material

[0060] Use the curing equipment in this embodiment (1) to ripen the phenolic foam insulation board, and the specific steps are: the phenolic foam insulation board enters the first microwave suppressor 2 from the input end 10 of the transmission device, and then enters the microwave box , microwave curing is carried out in the microwave box, after the microwave radiation is completed, the product enters the cooling device 8 for cooling treatment after passing through the second microwave suppressor 22, and the cooled product has been matured, output through the output terminal 100 of the transmission device, and enter The packaging s...

Embodiment 3

[0062] (1) Ripening equipment

[0063] The same curing equipment as (1) in Example 1 is used, the difference is that the microwave radiation device 3 is two microwave cabinets.

[0064] (2) Aging process of phenolic foam material

[0065] Use the curing equipment in this embodiment (1) to cure the phenolic foam insulation board, and the specific steps are the same as the method in embodiment 1 (2), the difference is: wherein, the temperature in the infrared hot air box is 80 ° C; Along the direction from the input end 10 to the output end 100, set the preset temperature of each microwave box to 60°C and 70°C in turn; the time to pass through the infrared hot air box is 30 minutes, and the phenolic foam insulation board needs to pass through each microwave box. The total time required to complete the entire curing process is 93 minutes.

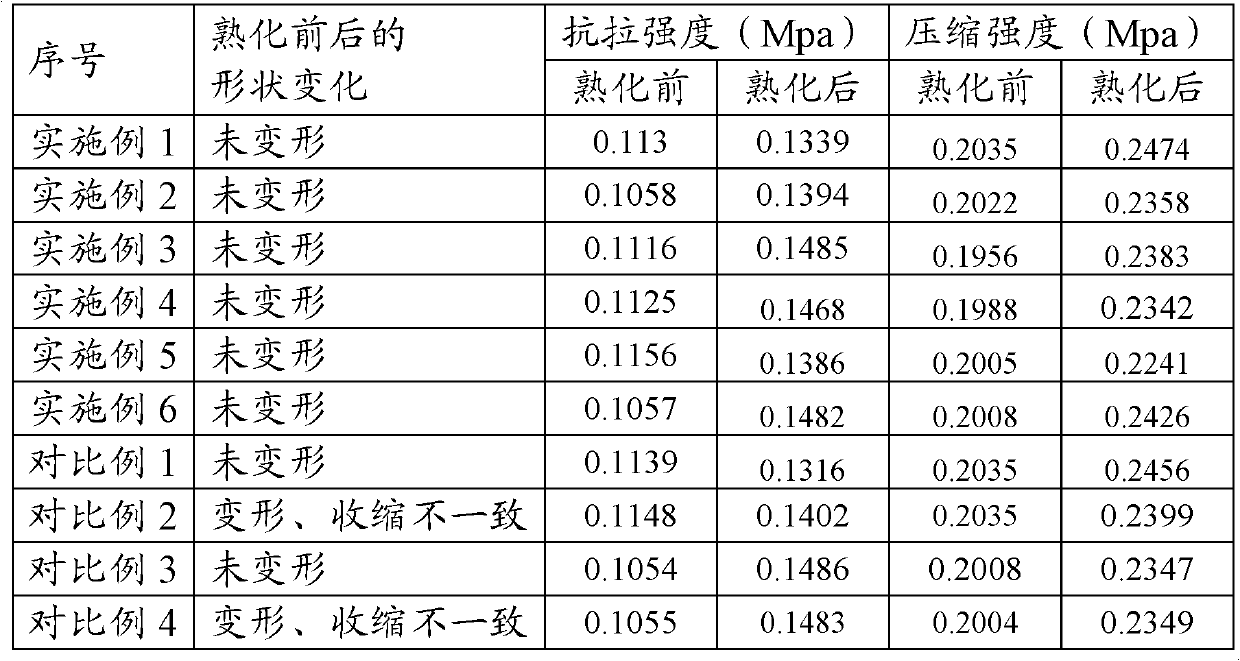

[0066] Detect various indexes of the phenolic foam insulation board after curing in this embodiment, and the specific indexes are shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com