Patents

Literature

66results about How to "Avoid stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric power cabinet used for outdoor building engineering

ActiveCN107257096AAvoid damageAchieve moisture resistanceSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsTransverse planeControl engineering

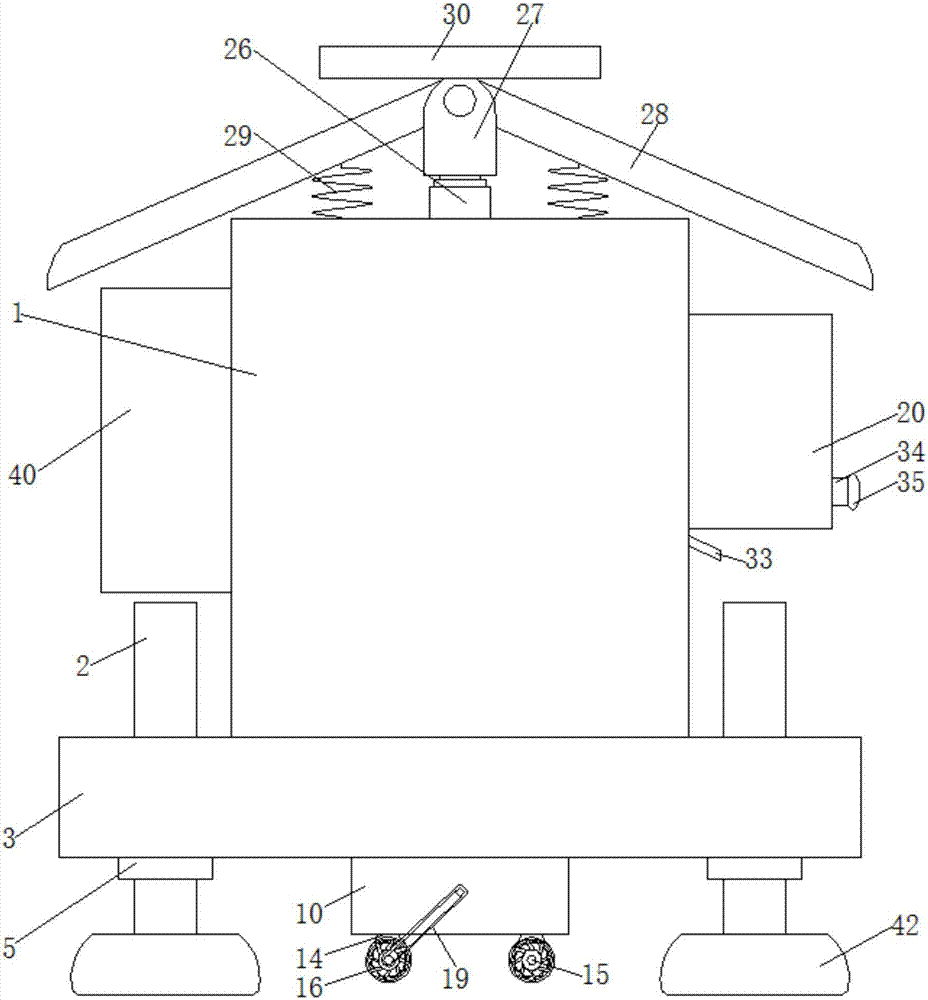

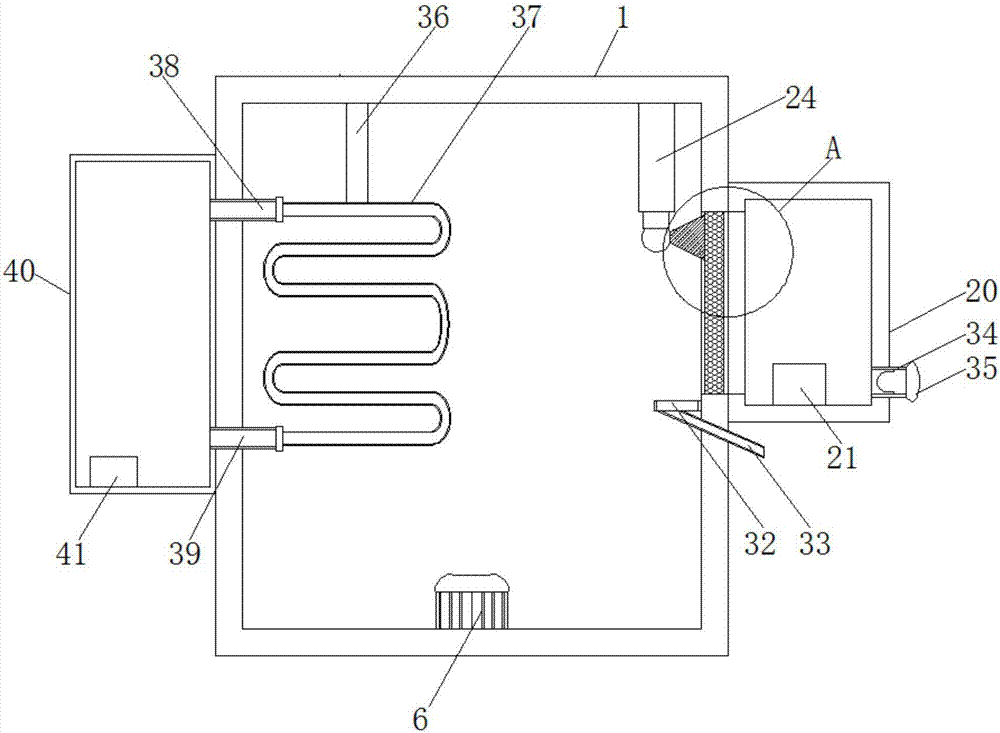

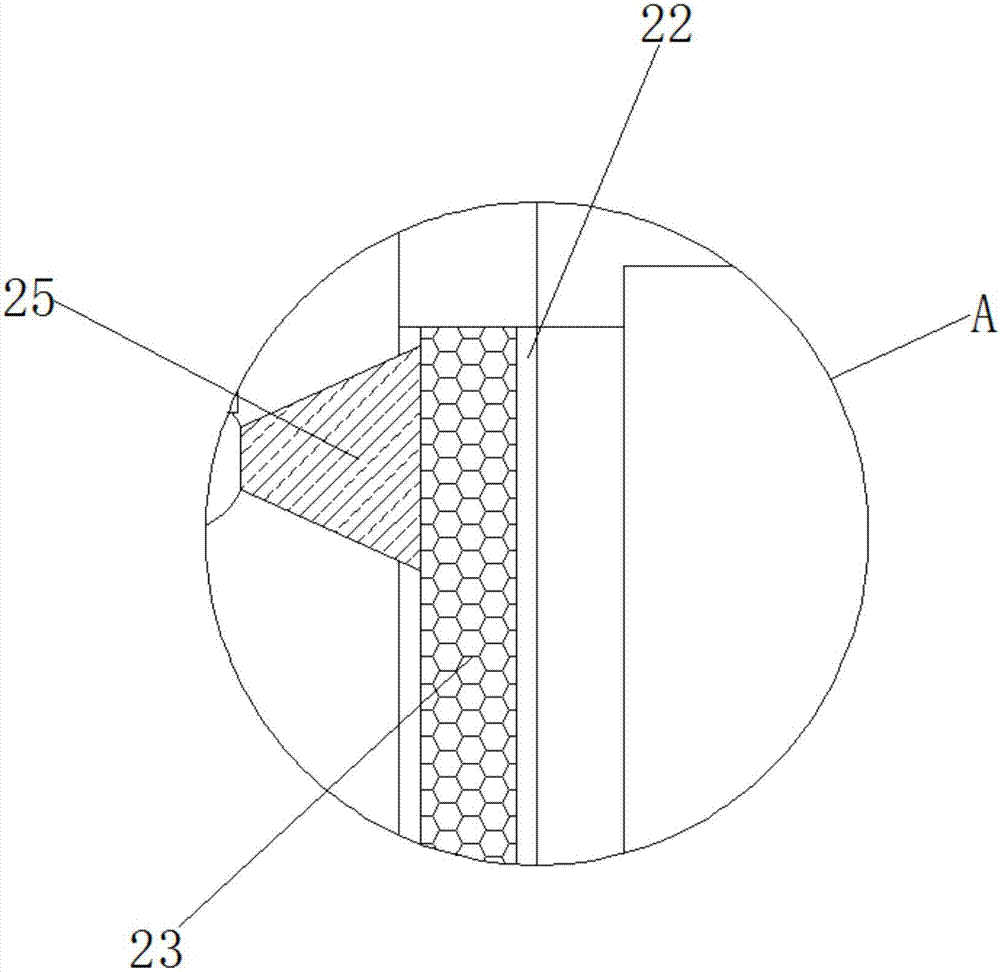

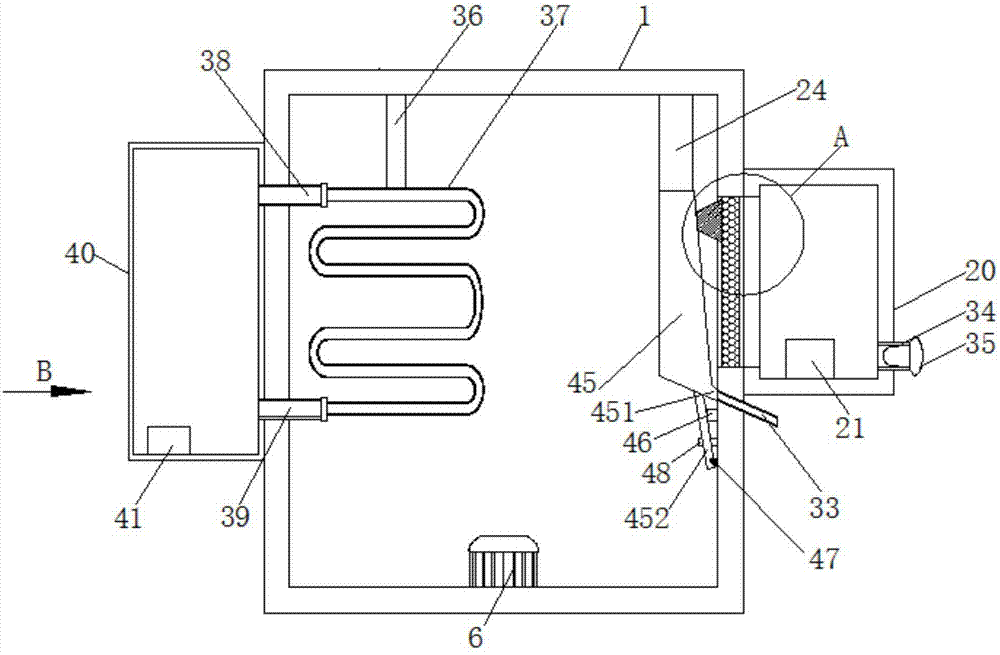

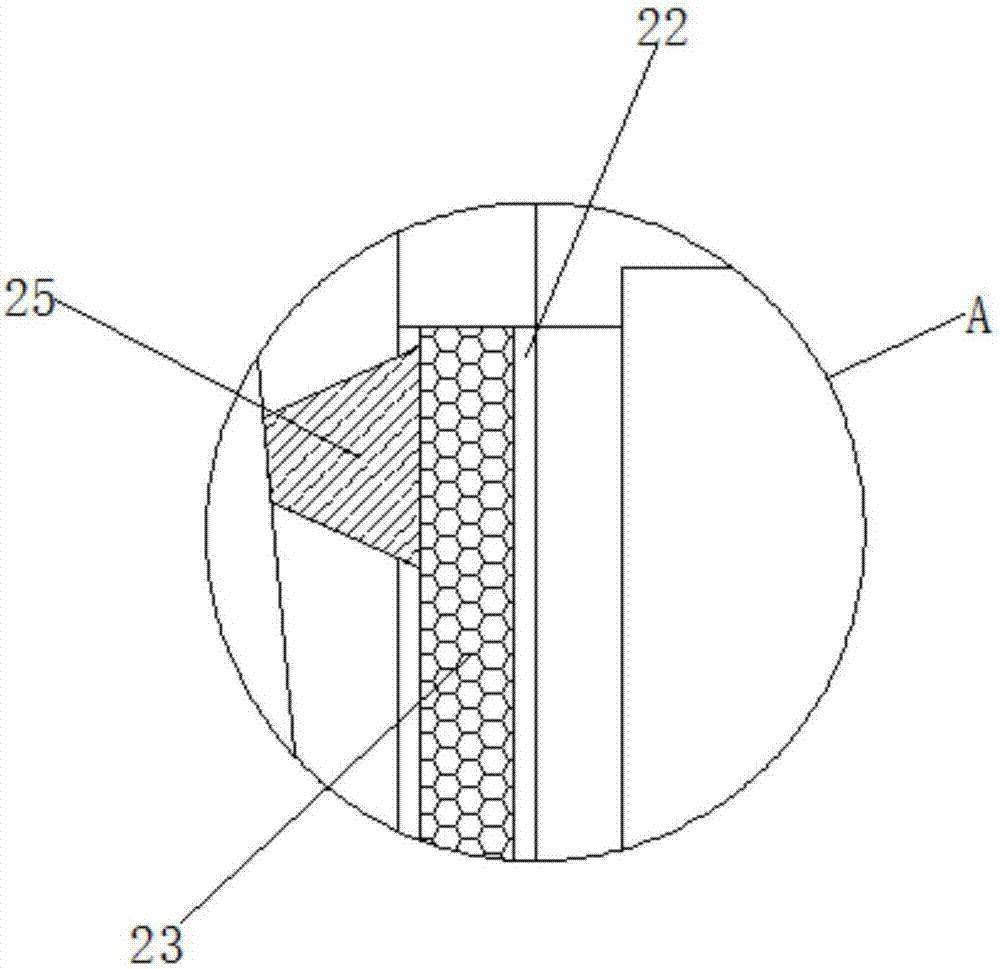

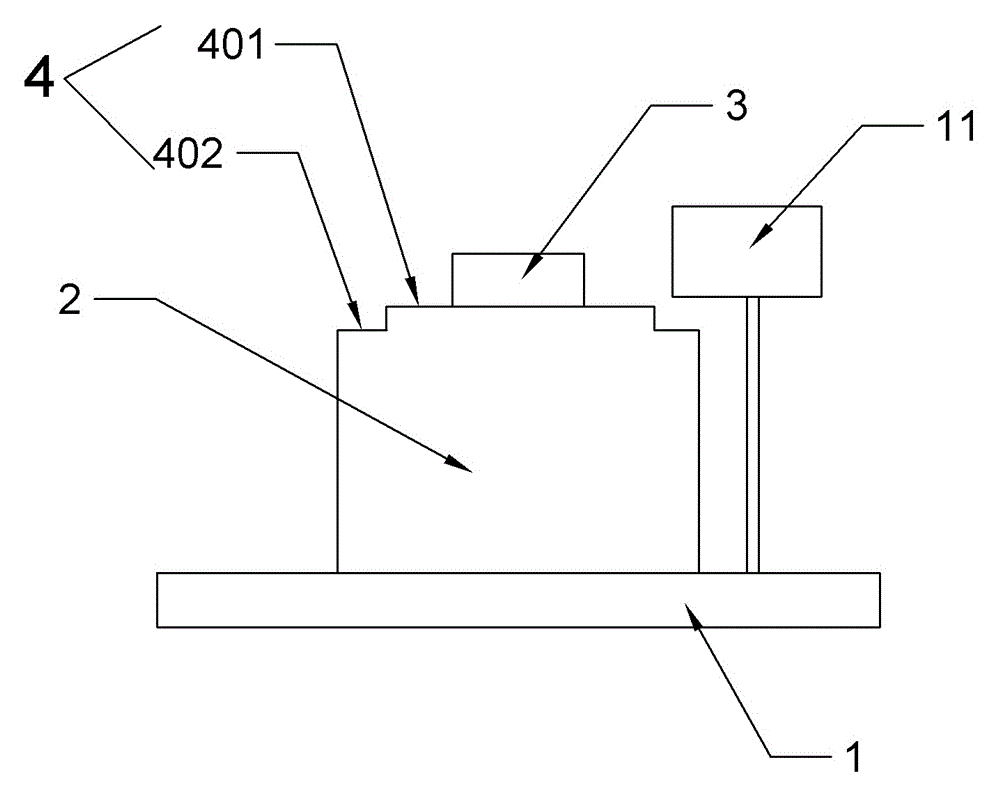

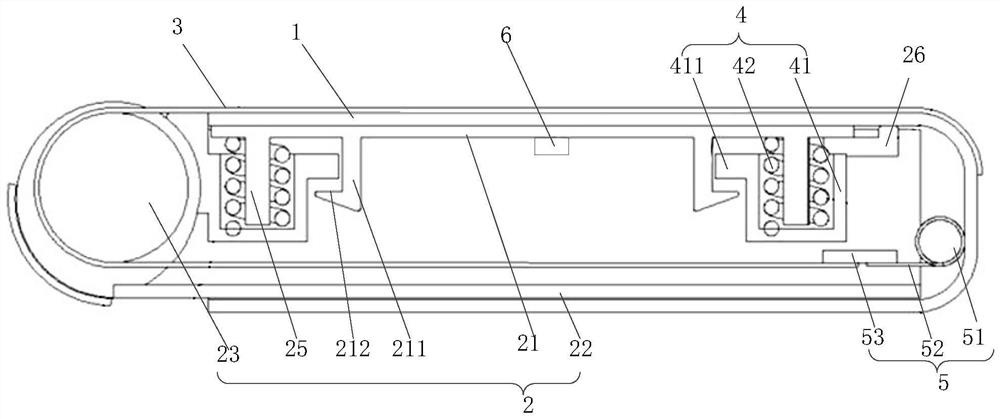

The invention provides an electric power cabinet used for outdoor building engineering. The electric power cabinet comprises an electric power cabinet body, supporting legs and a transverse plate. There are two supporting legs. The two supporting legs are fixedly connected through the transverse plate. A bottom portion of the electric power cabinet body is fixedly installed on a top portion of the transverse plate. The electric power cabinet body is located between the two supporting legs. An internal portion of the transverse plate is provided with a cavity. Surfaces of the supporting legs are provided with threads. The electric power cabinet used for outdoor building engineering is provided with a condenser pipe, a water inlet pipe, a water outlet pipe, a water tank and a hydraulic pump. Condensate water in the condenser pipe carries out heat dissipation processing on an inner cavity of the electric power cabinet body. When the condensate water in the condenser pipe is used up, the hydraulic pump is started so that the condensate water in the water tank enters into the condenser pipe through the water inlet pipe and enters into the inner cavity of the water tank through the water outlet pipe; the condensate water in the condenser pipe is recycled; and heat dissipation is accelerated and heat dissipation efficiency is increased.

Owner:温州鼎高电器成套有限公司

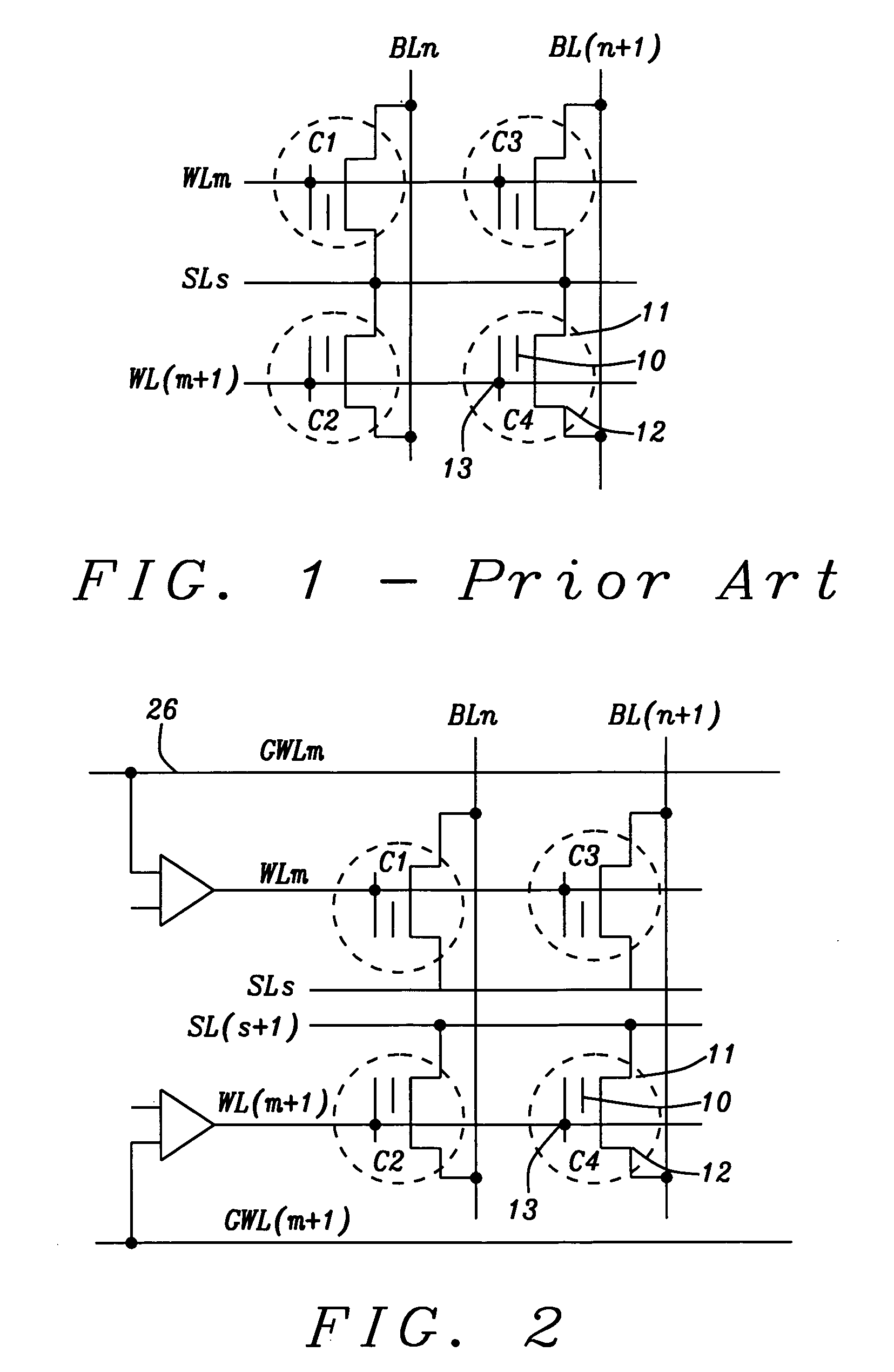

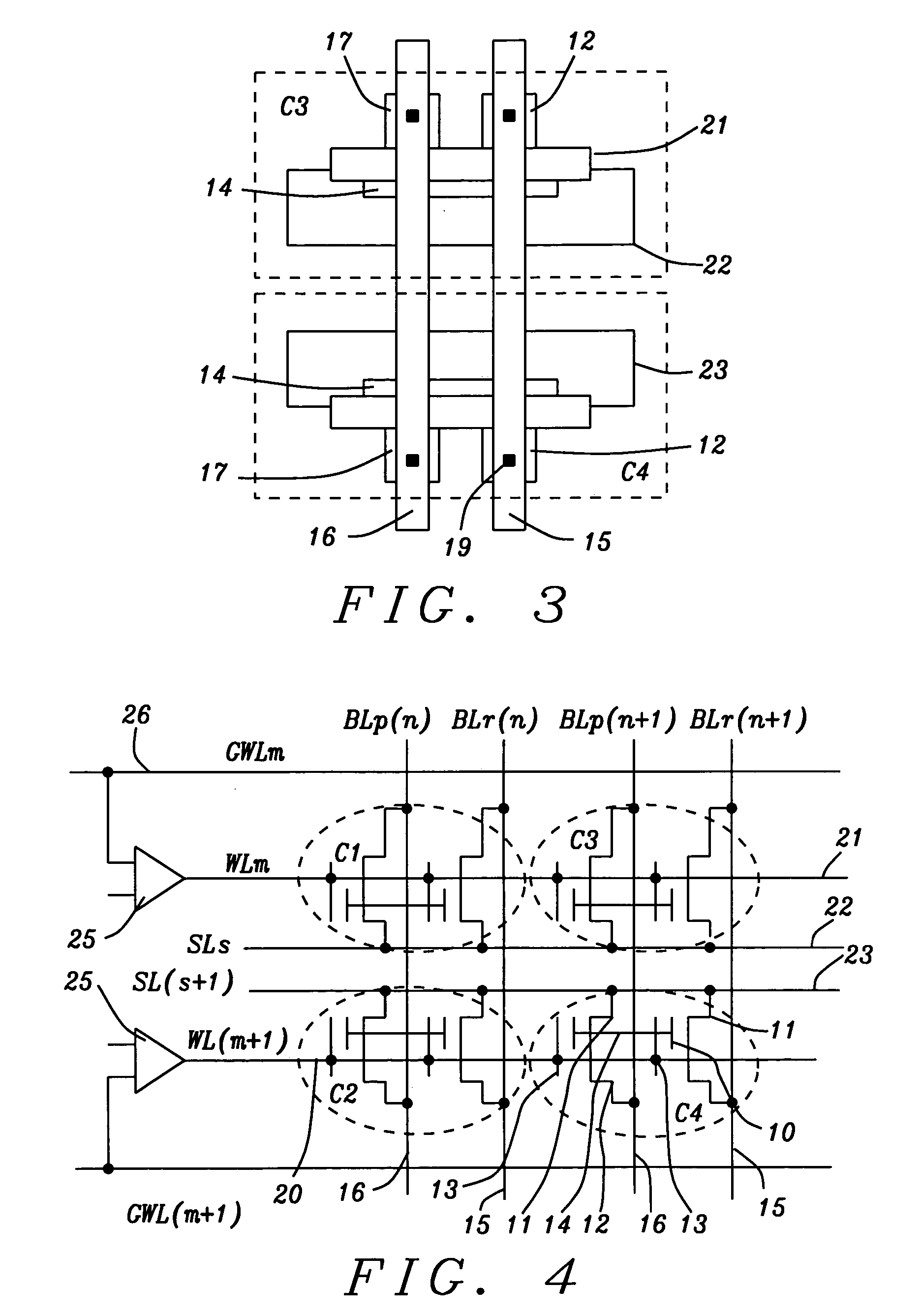

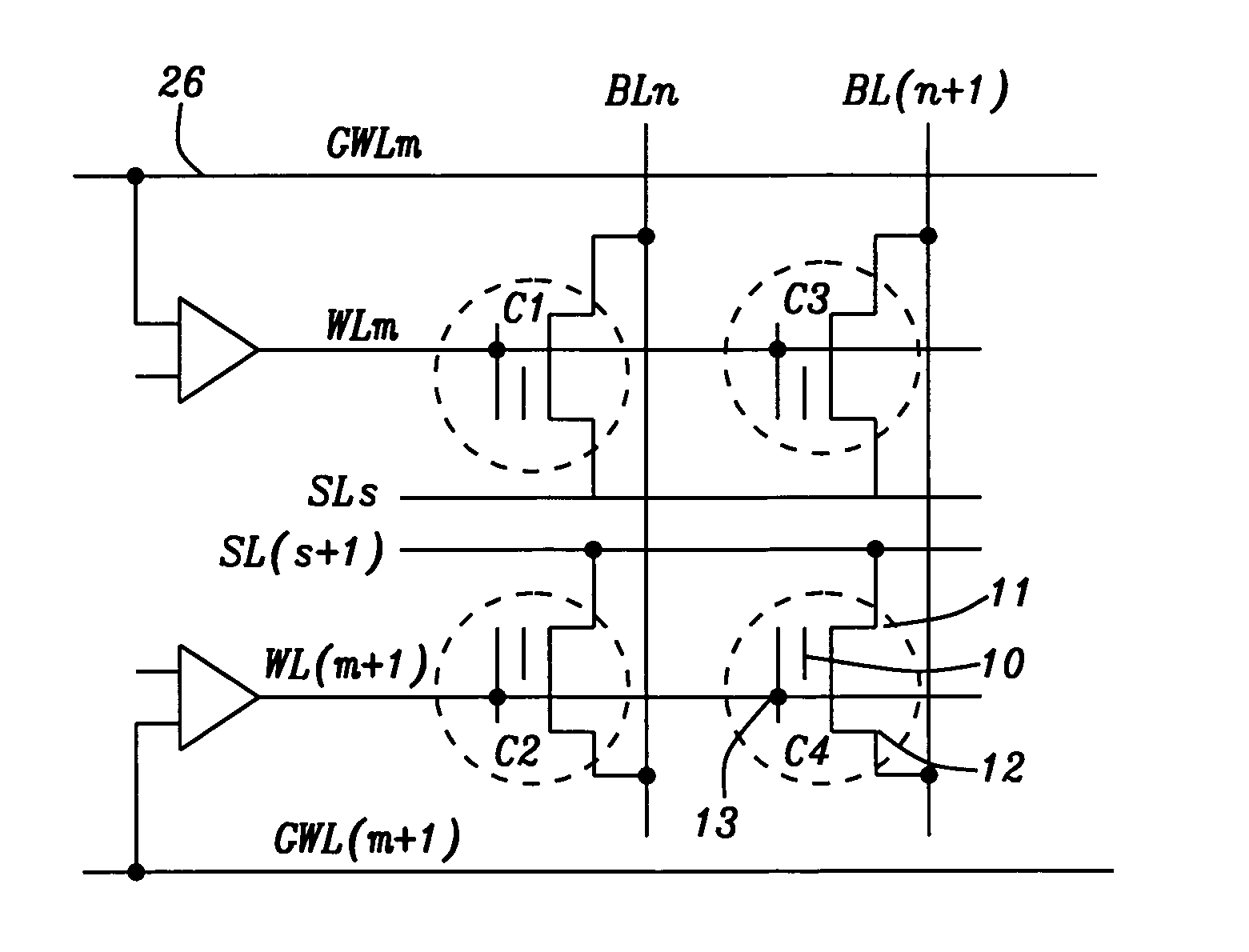

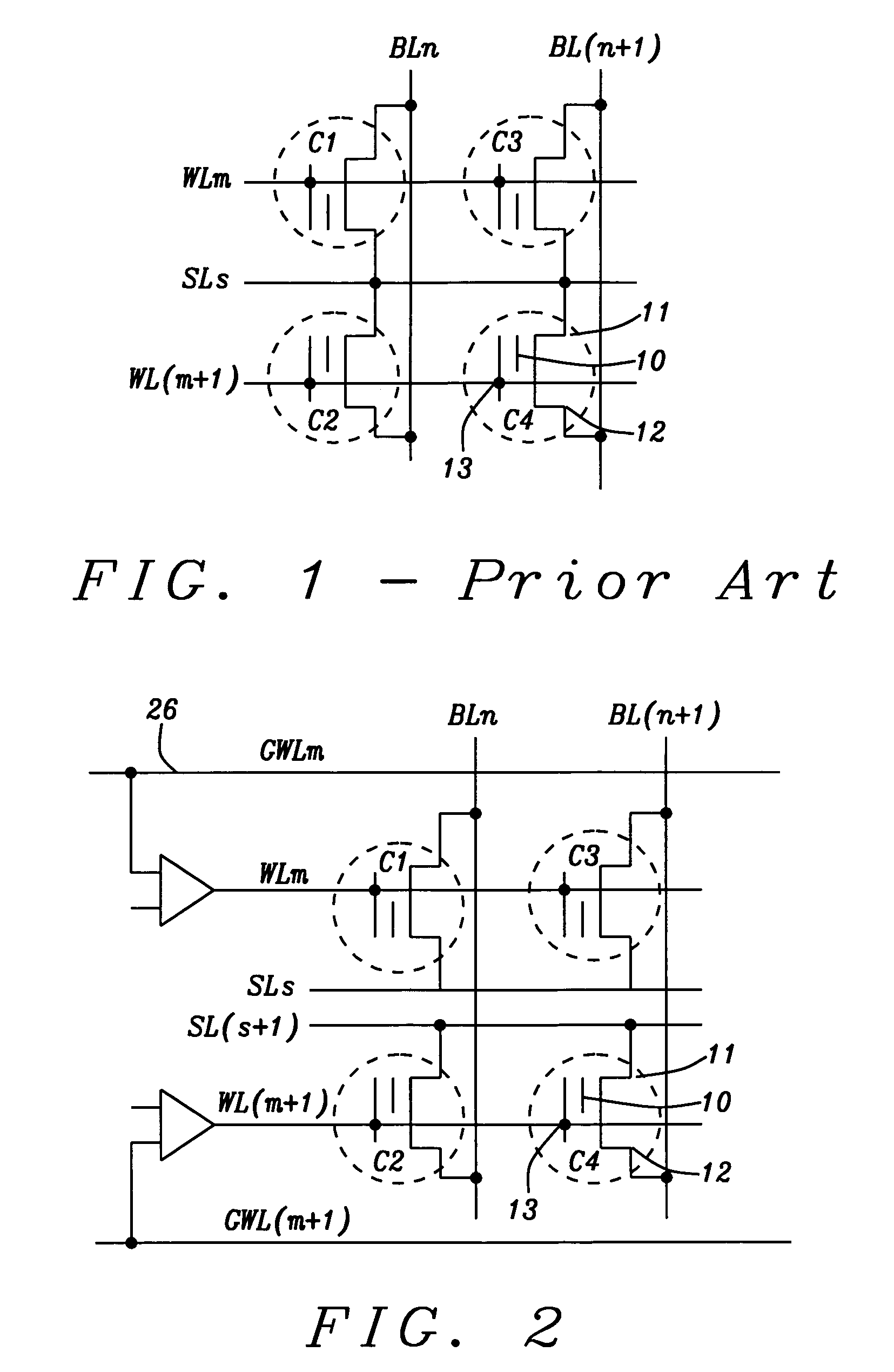

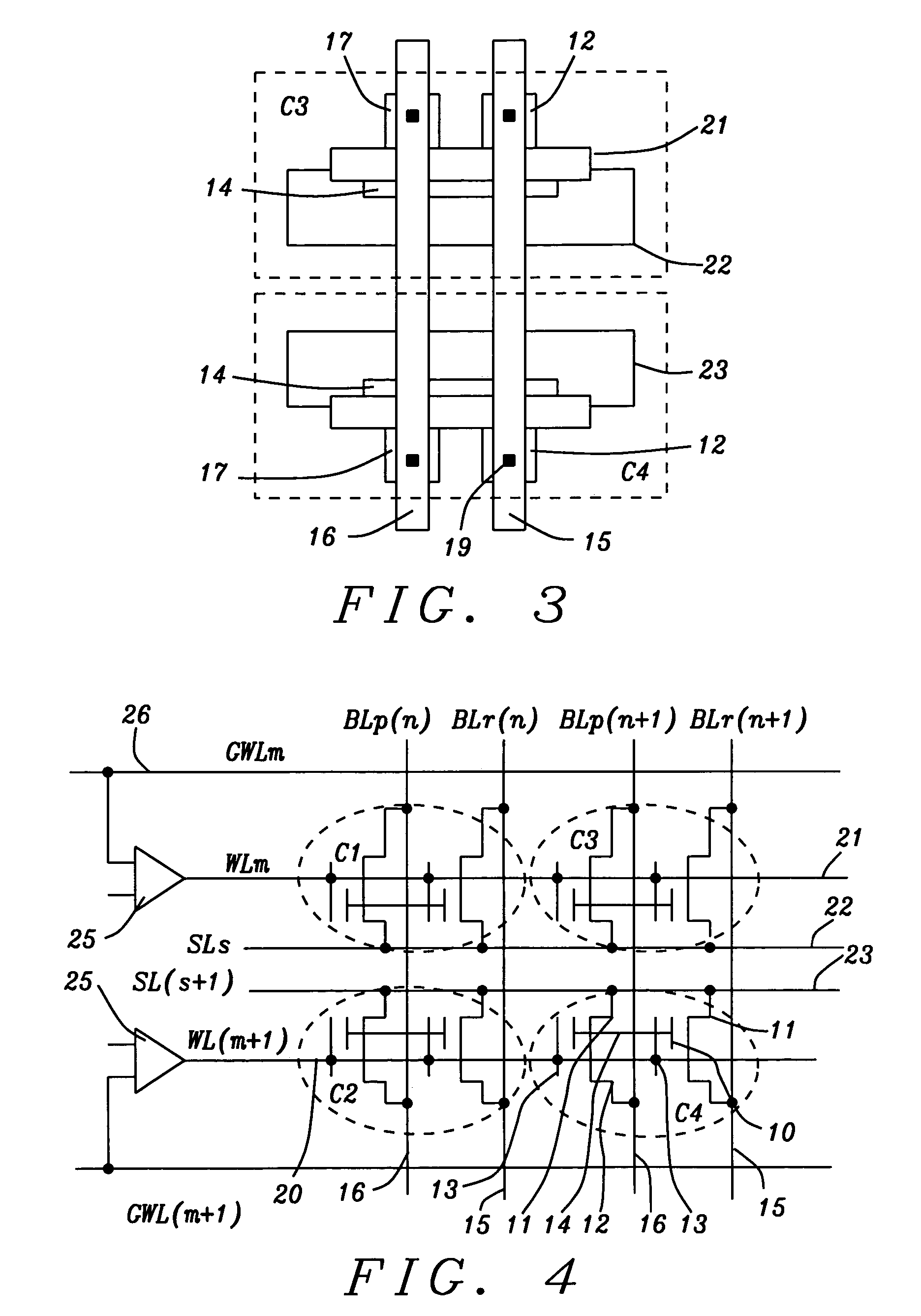

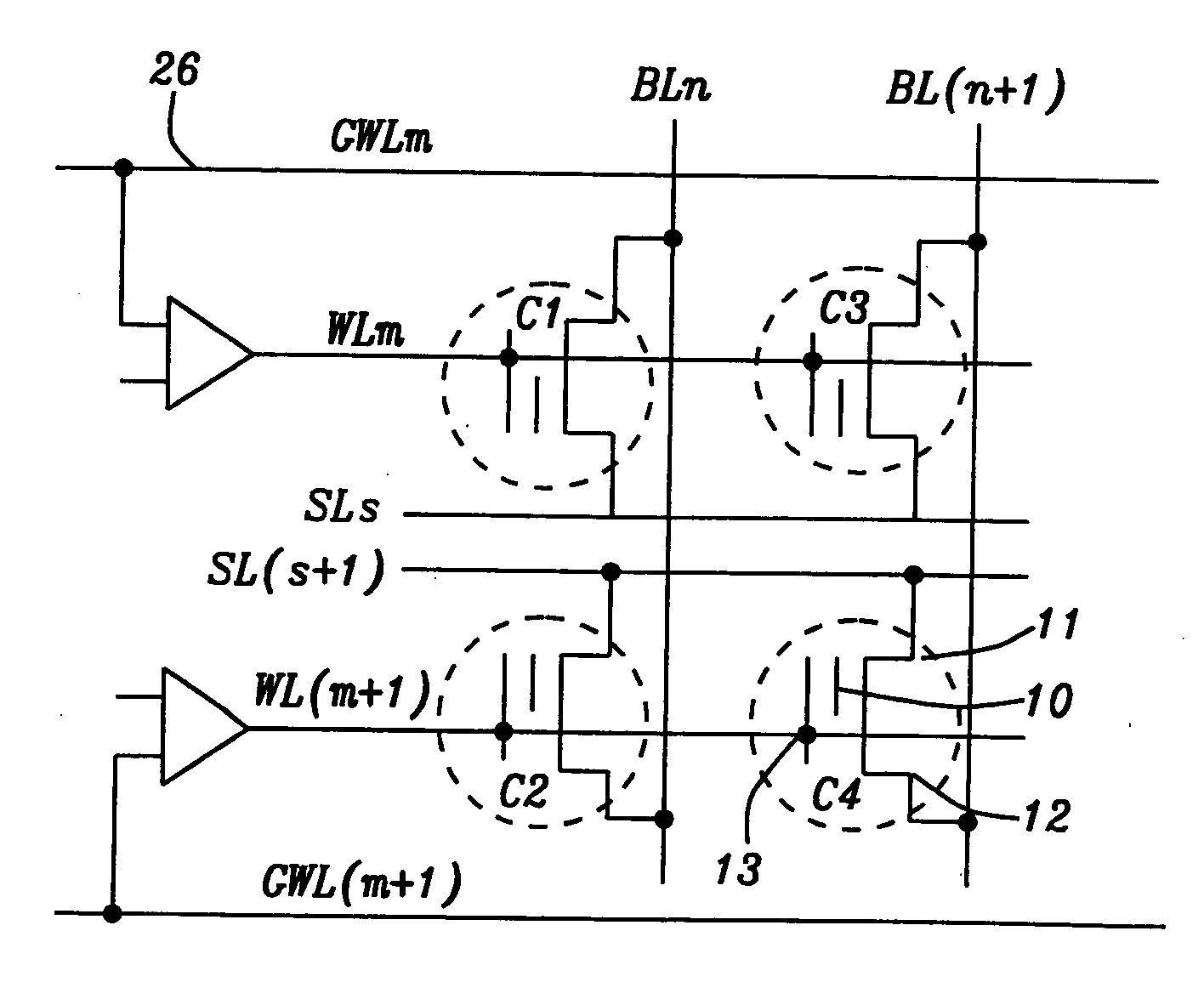

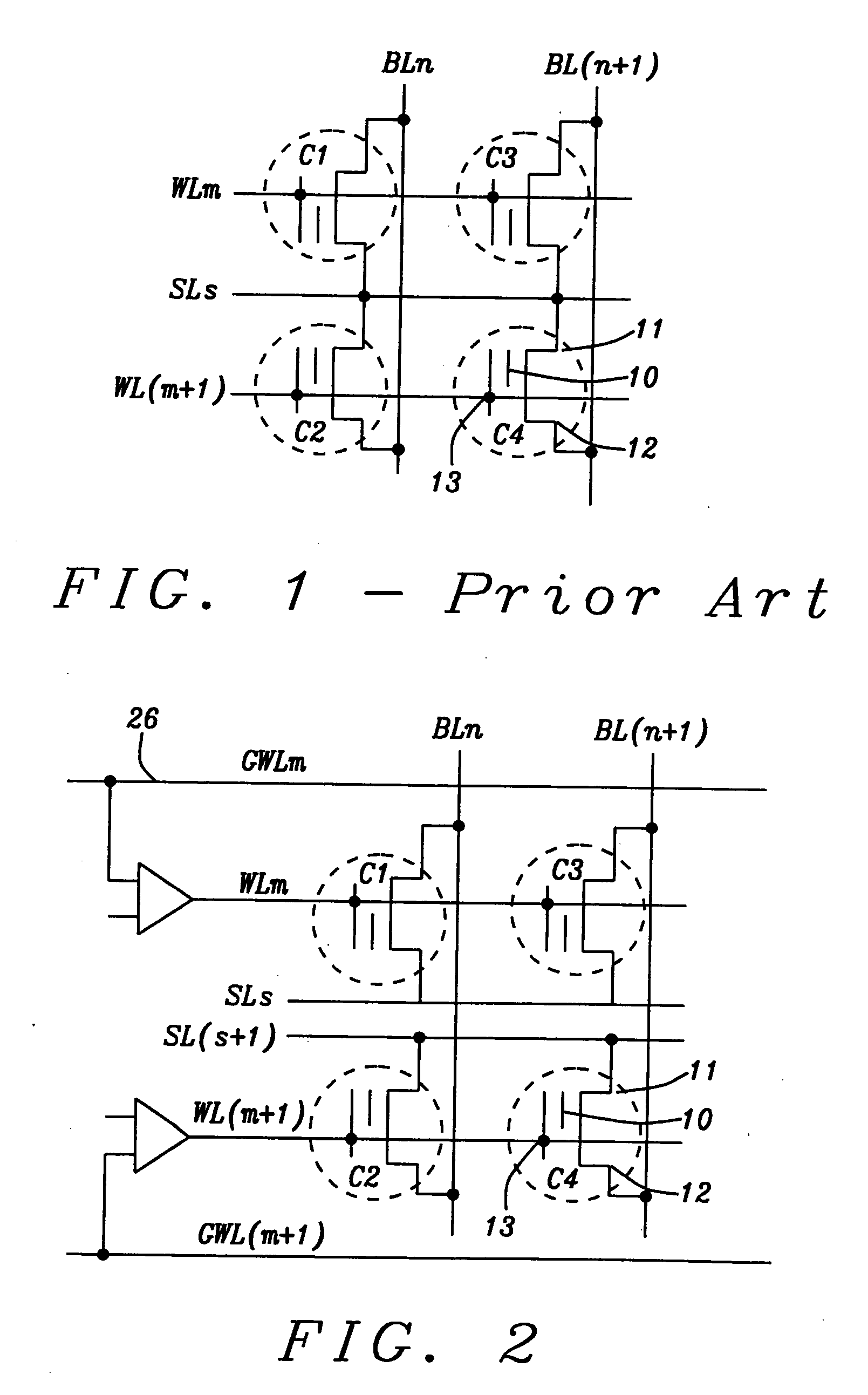

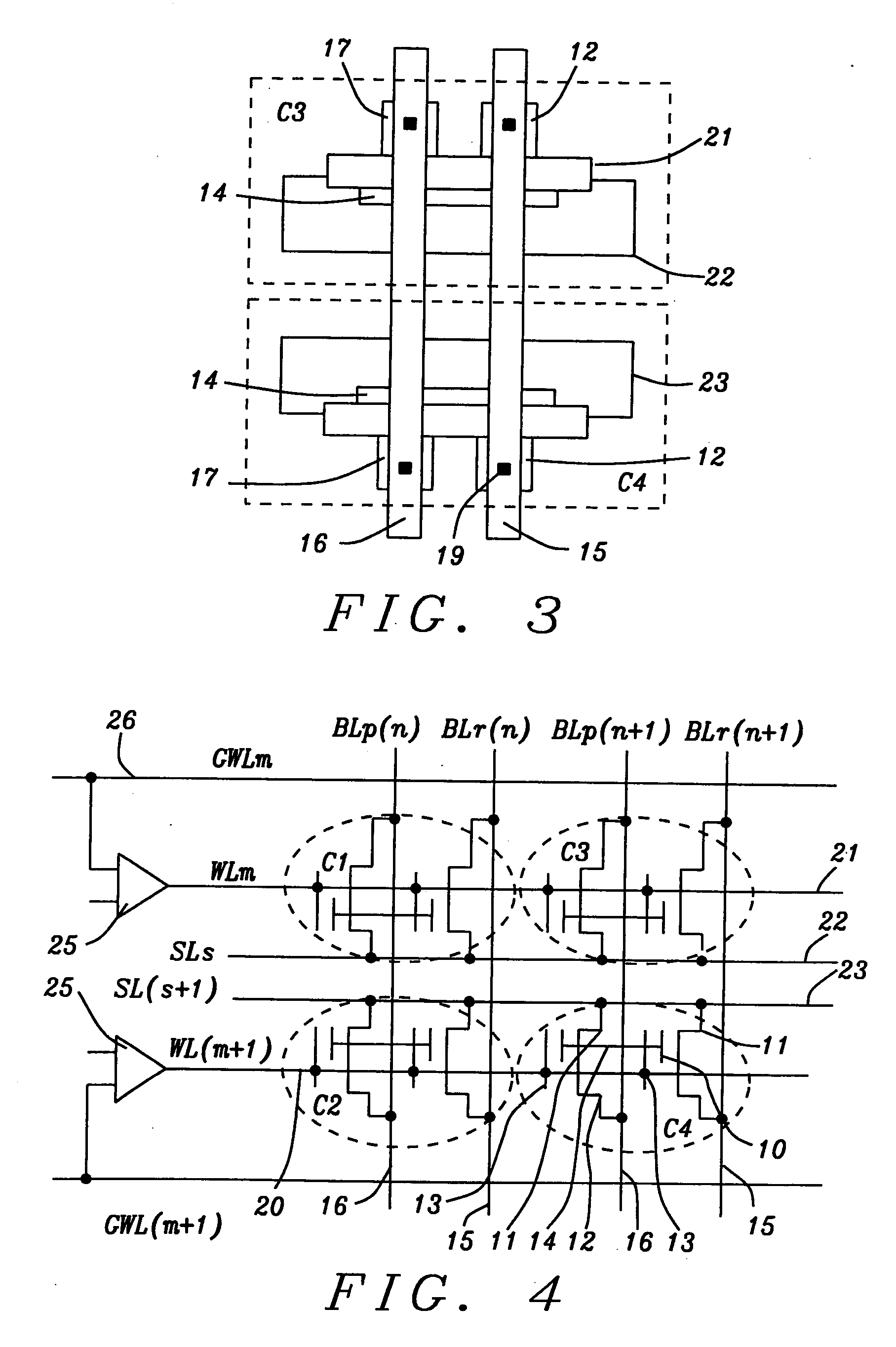

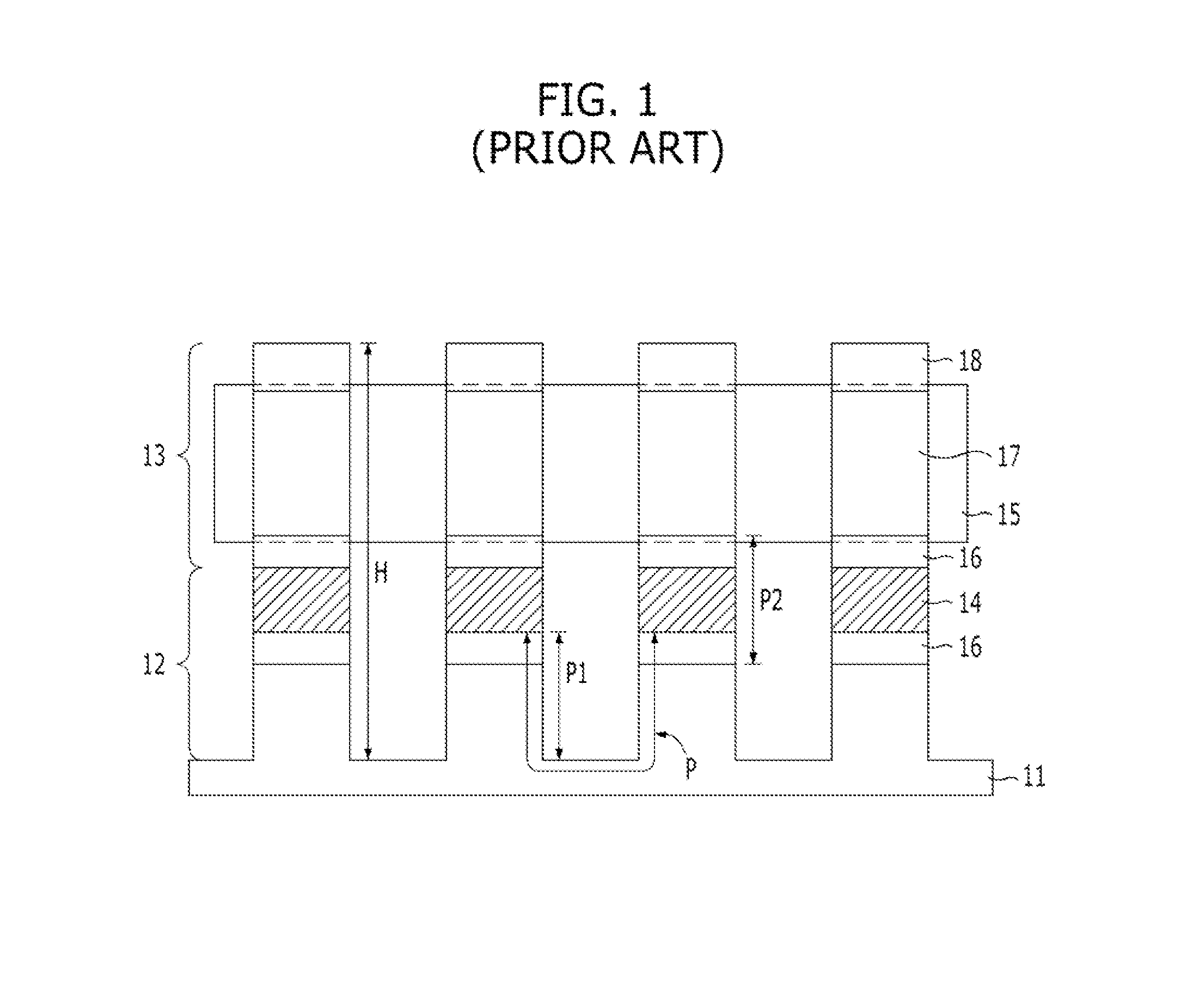

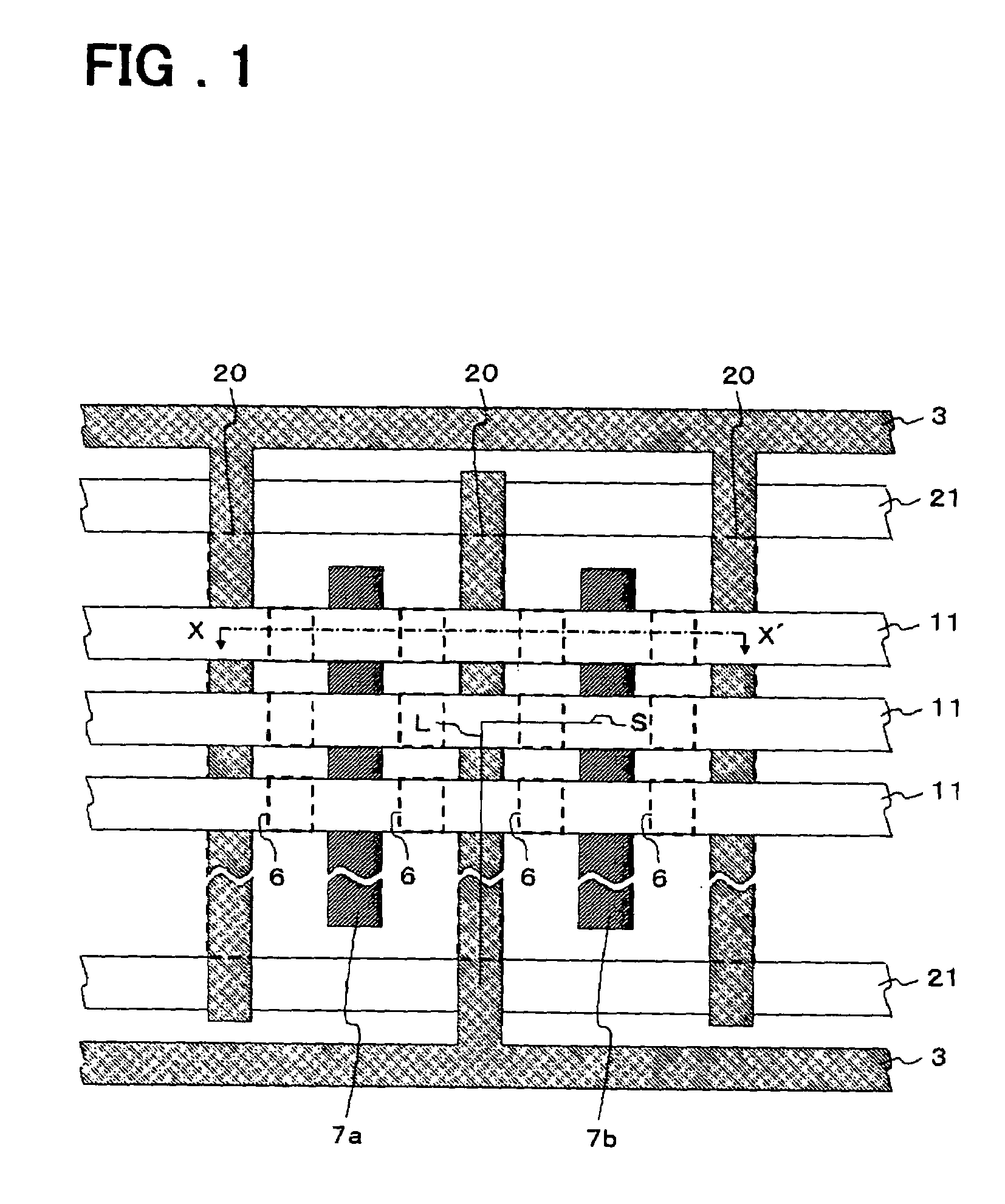

Array structure of two-transistor cells with merged floating gates for byte erase and re-write if disturbed algorithm

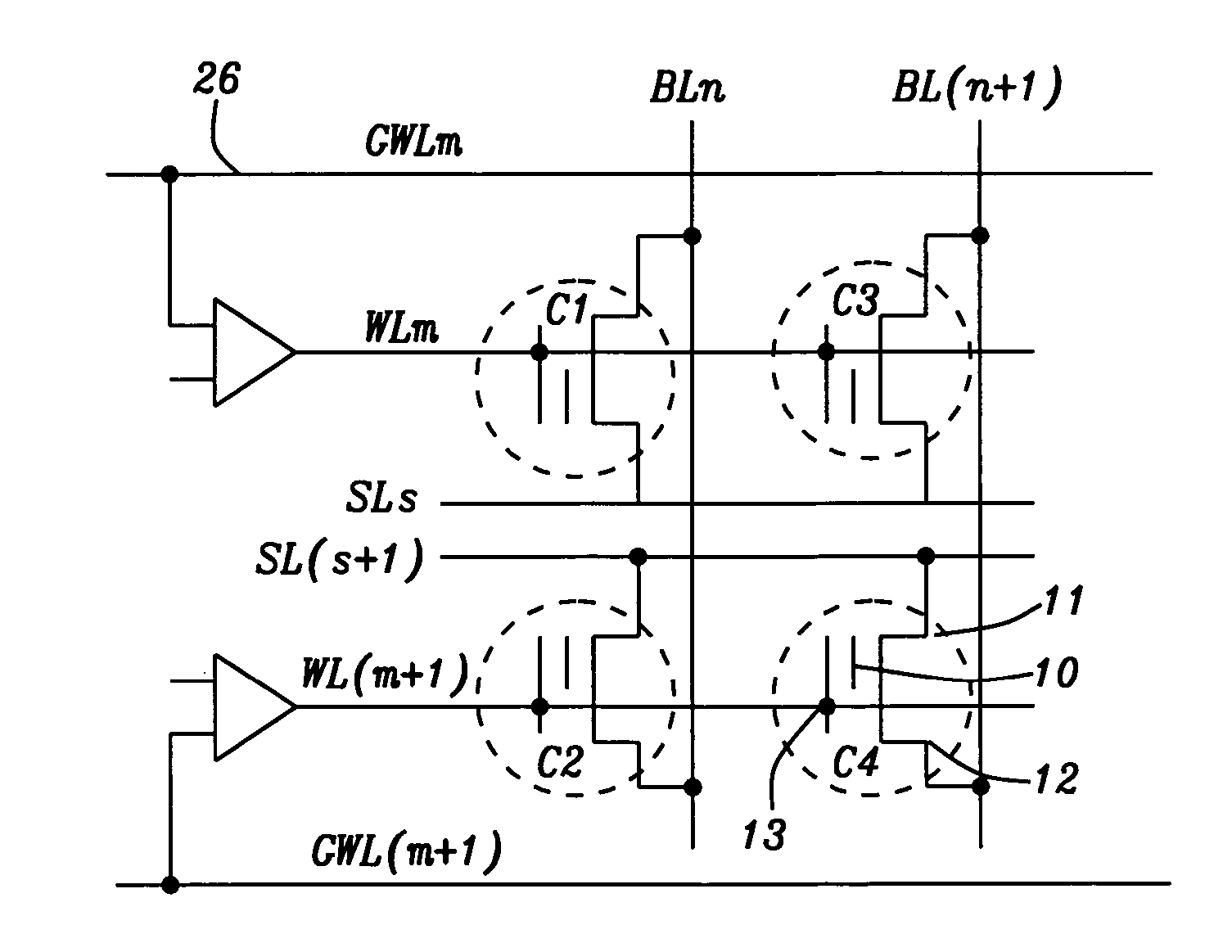

Variations in memory array and cell configuration are shown, which eliminate punch-through disturb, reverse-tunnel. Several configurations are shown which range from combined and separate source lines for each row of cells, a two transistor cell containing a read transistor and a program transistor connected by a merged floating gate, and a two transistor cell where the program transistor has an extra implant to raise the Vt of the transistor to protect against punch-through disturb. A method is also described to rewrite disturbed cells, which were not selected to be programmed.

Owner:TAIWAN SEMICON MFG CO LTD

Array structure of two-transistor cells with merged floating gates for byte erase and re-write if disturbed algorithm

InactiveUS7072215B2Disturb conditionEliminates reverse tunnelingRead-only memoriesDigital storageArray data structureEngineering

Variations in memory array and cell configuration are shown, which eliminate punch-through disturb, reverse-tunnel. Several configurations are shown which range from combined and separate source lines for each row of cells, a two transistor cell containing a read transistor and a program transistor connected by a merged floating gate, and a two transistor cell where the program transistor has an extra implant to raise the Vt of the transistor to protect against punch-through disturb. A method is also described to rewrite disturbed cells, which were not selected to be programmed.

Owner:TAIWAN SEMICON MFG CO LTD

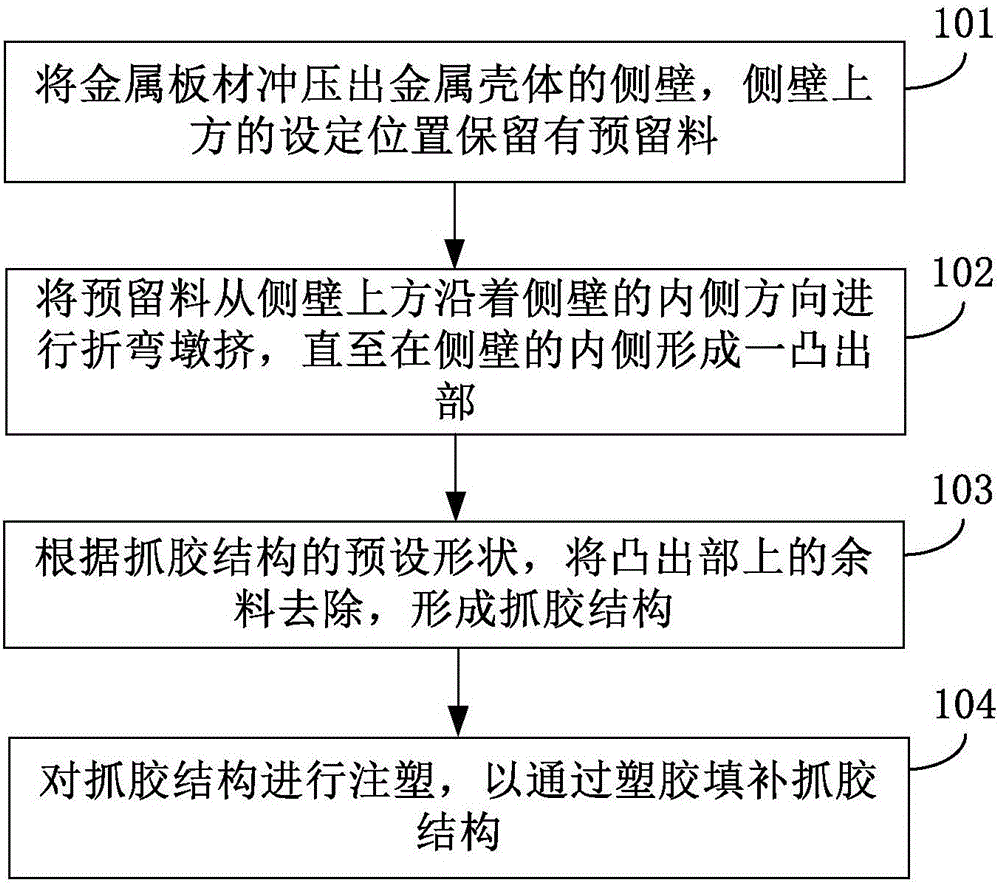

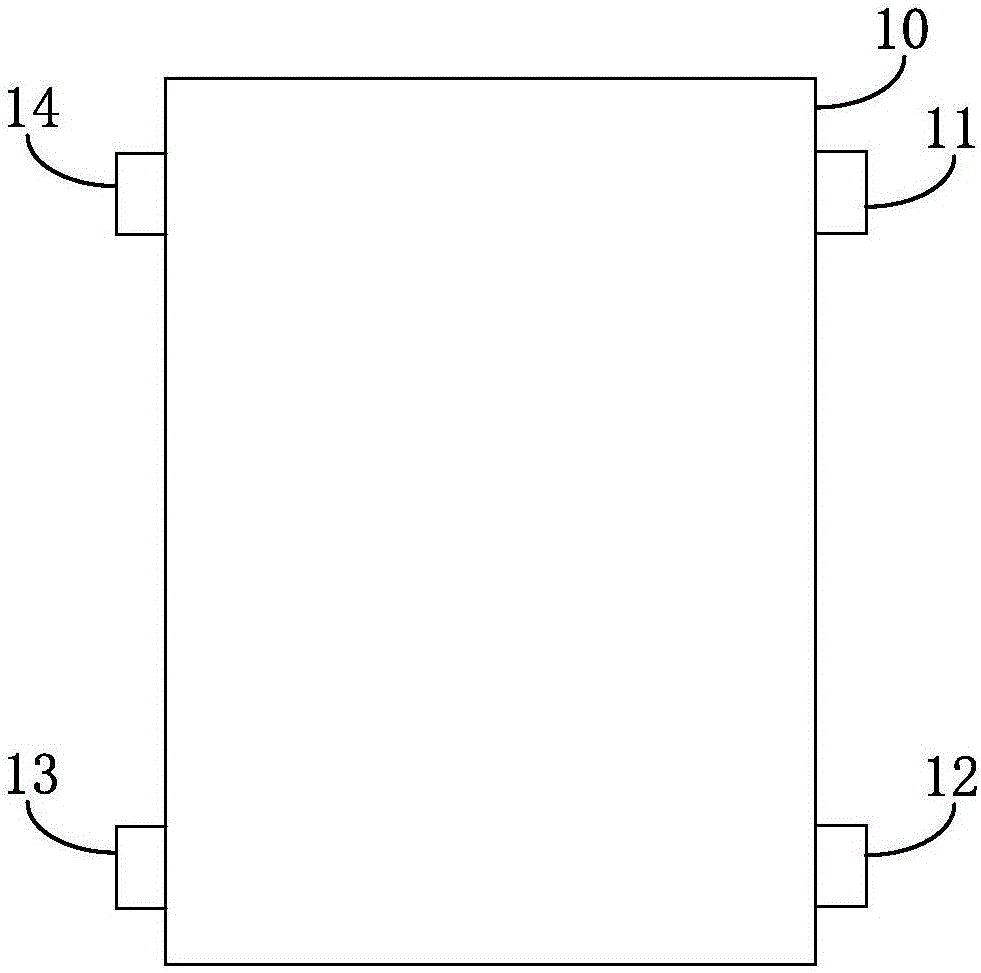

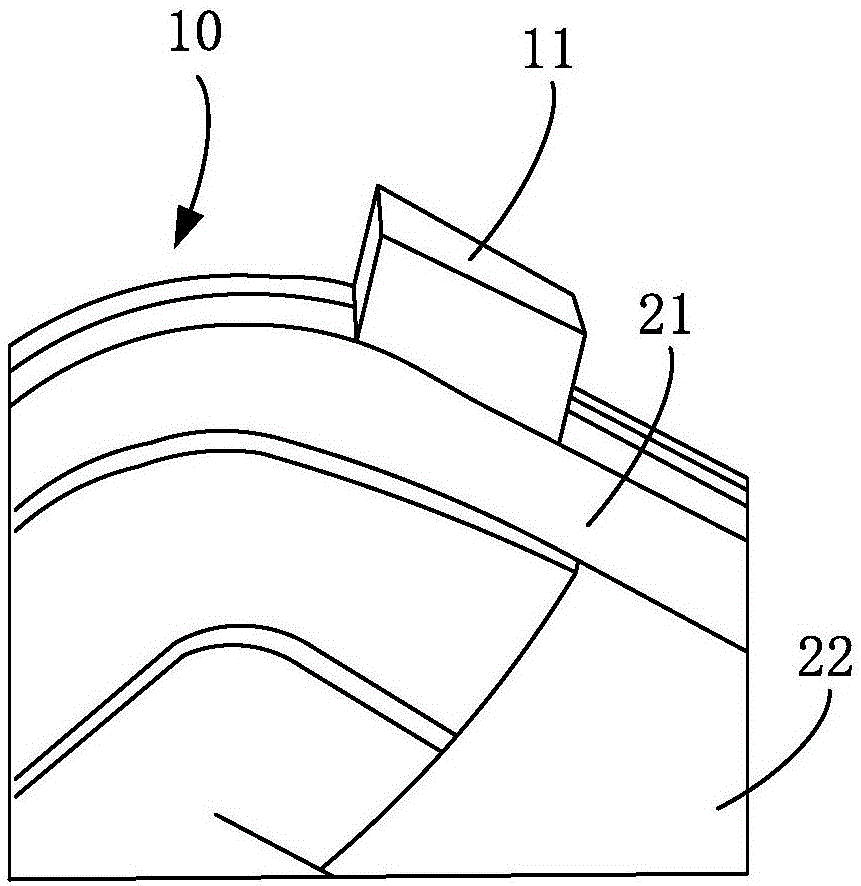

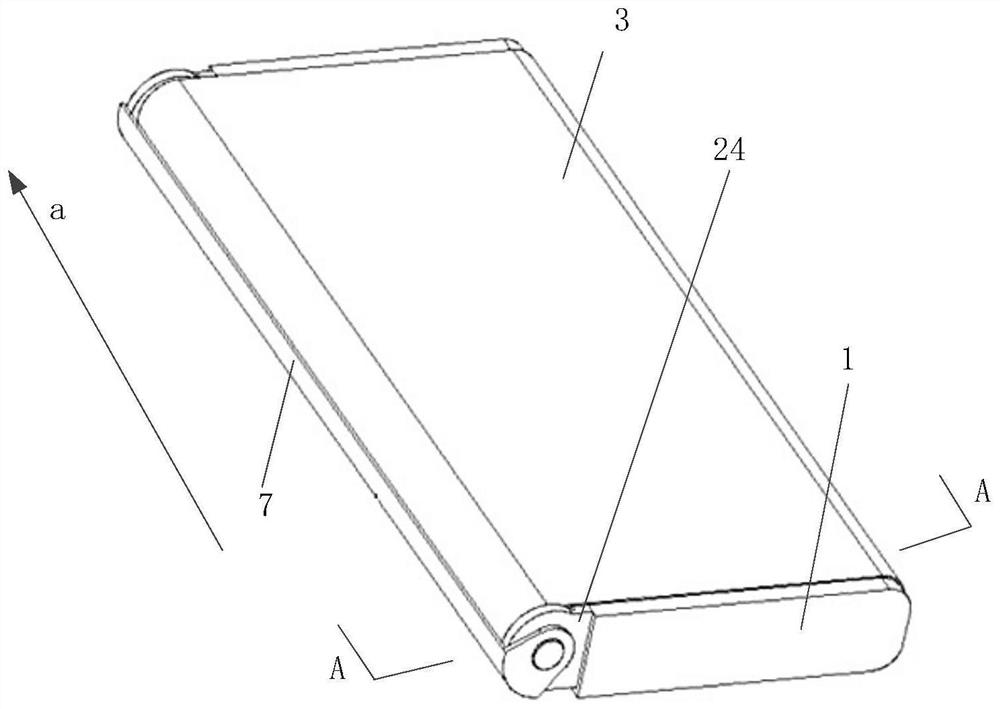

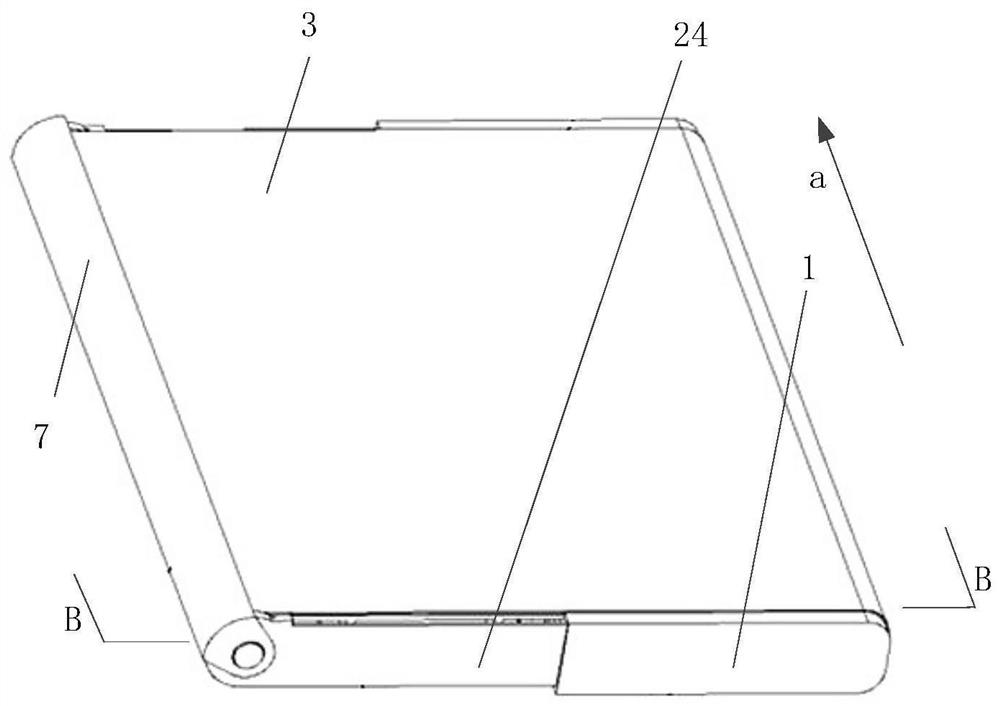

Metal shell manufacturing method and metal shell, electronic equipment

InactiveCN106462199AAvoid stampingReduce the difficulty of stamping and formingMetal casingsSubstation equipmentMetallic materialsMetal sheet

The present disclosure relates to a method of manufacturing a metal shell and a metal case and an electronic device. Said method comprising: punching a sheet metal sheet into a side wall of a metal shell, said reservation position being retained above said side wall; placing said reservation material from said side wall above said side wall And a plurality of protrusions are formed on the inner side of the side wall; and the remaining material on the protruding portion is removed in accordance with a predetermined shape of the gripping structure to form the gripping structure And injecting the gripping structure to fill the gripping structure with plastic. The technical solution of the present invention can avoid the press molding of the metal sheet by CNC, reduce the difficulty of forming the metal material, save the time of processing the metal shell, and improve the production efficiency of the metal shell.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

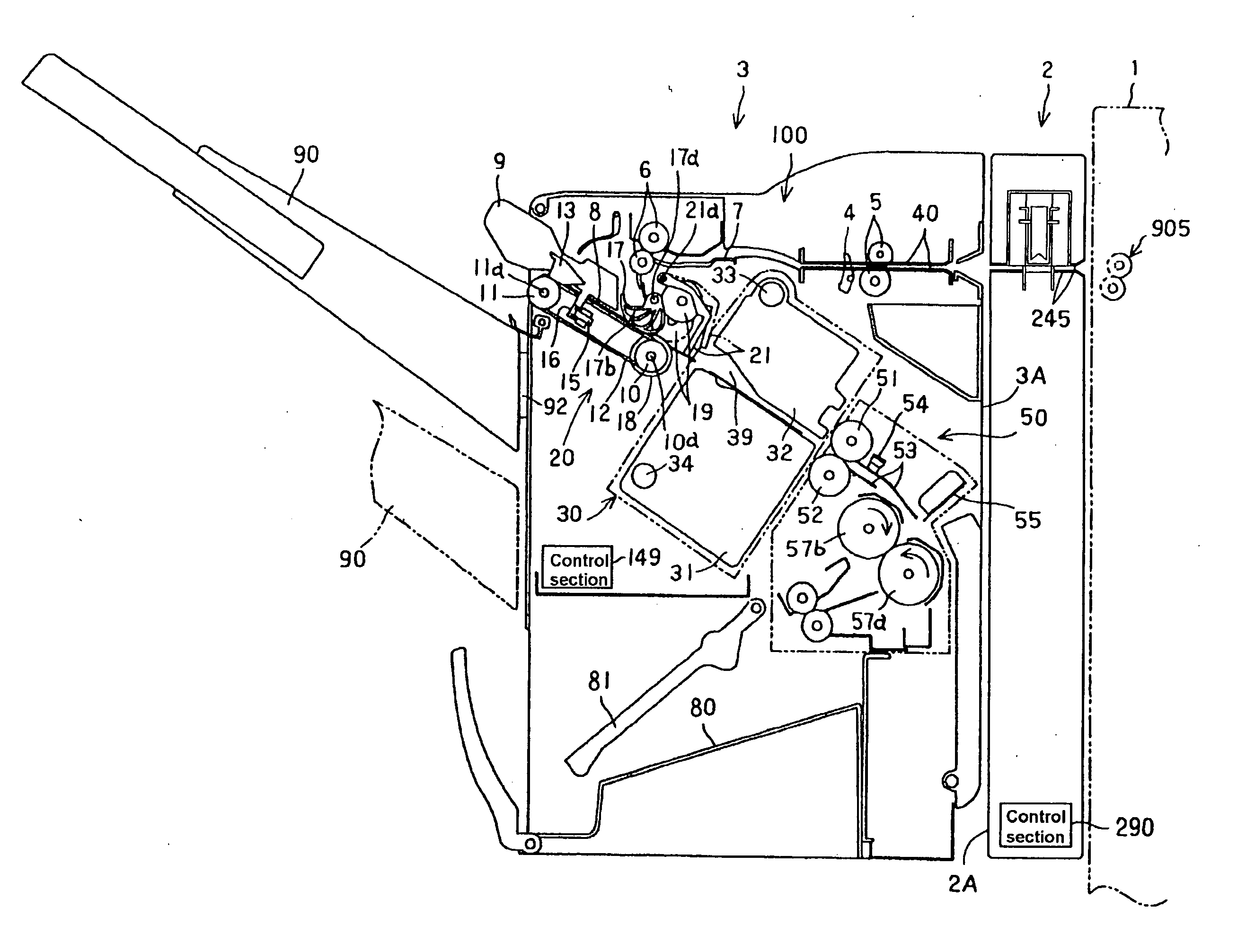

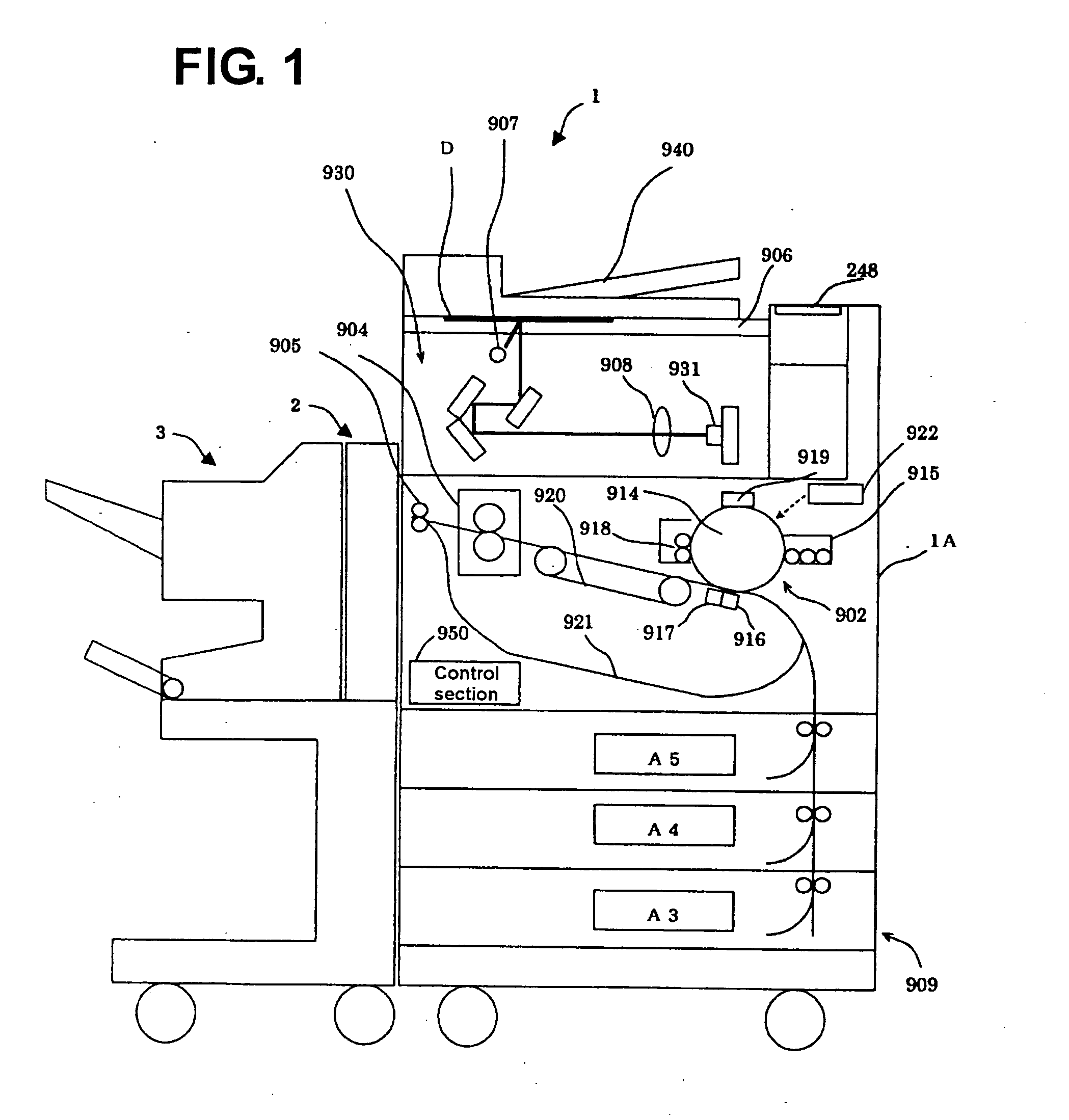

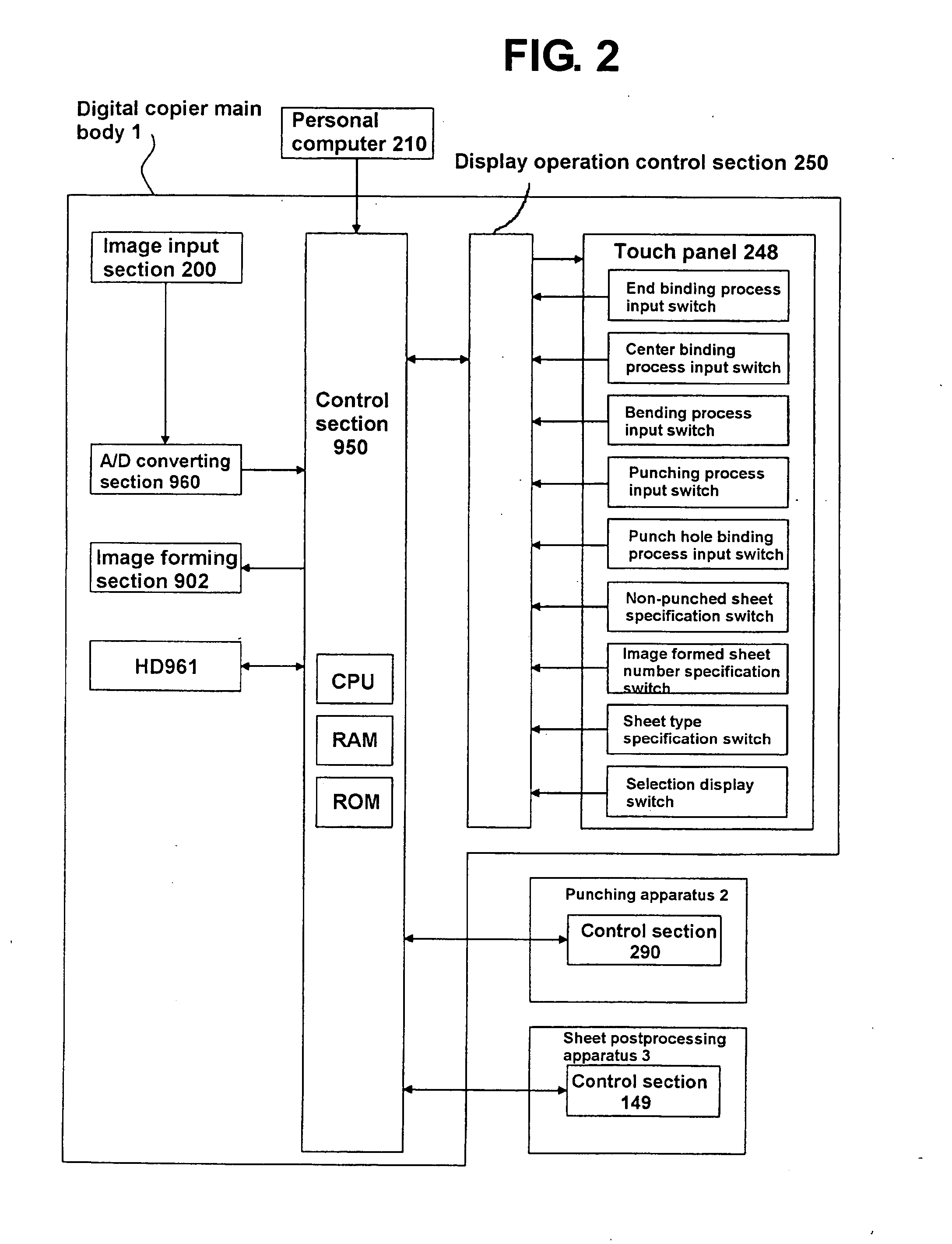

Sheet post-processing apparatus and image forming apparatus

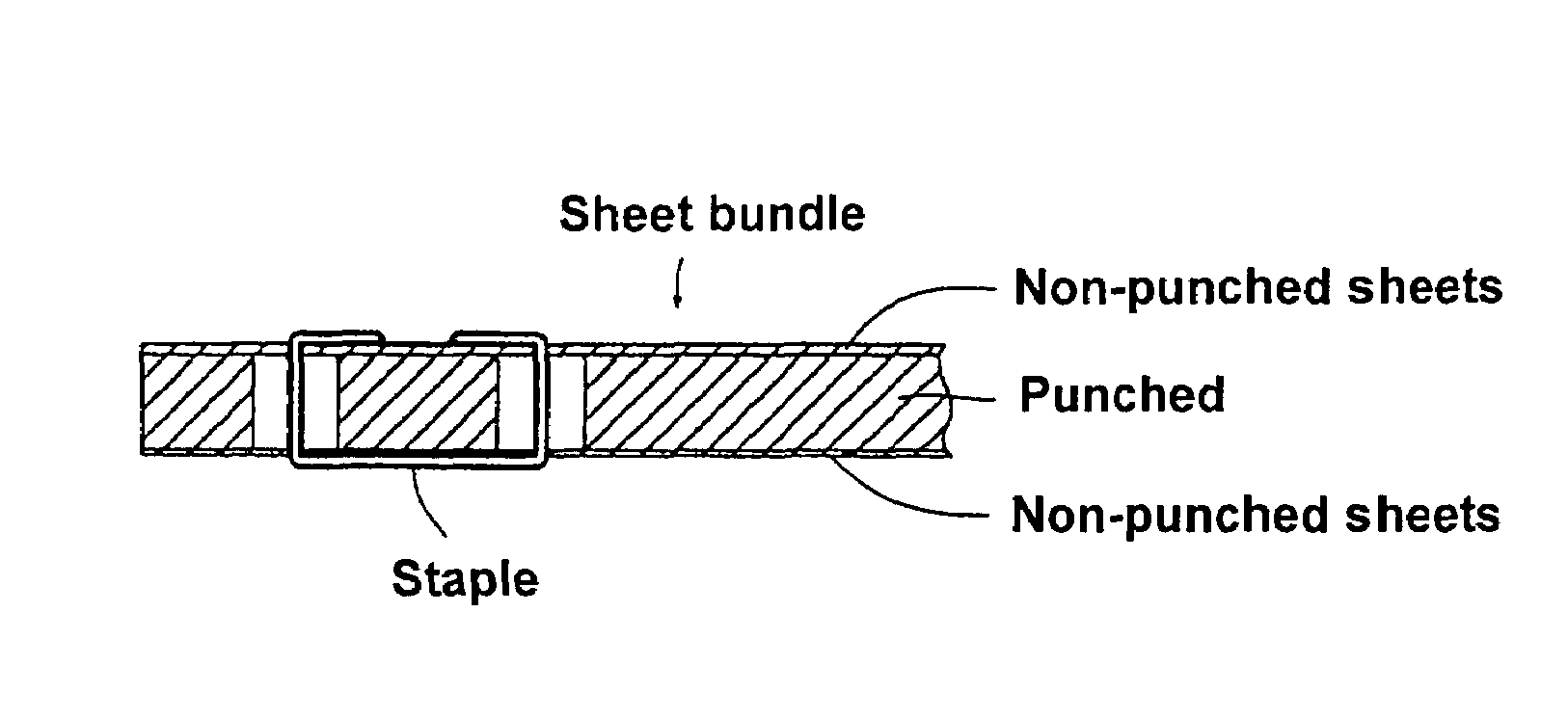

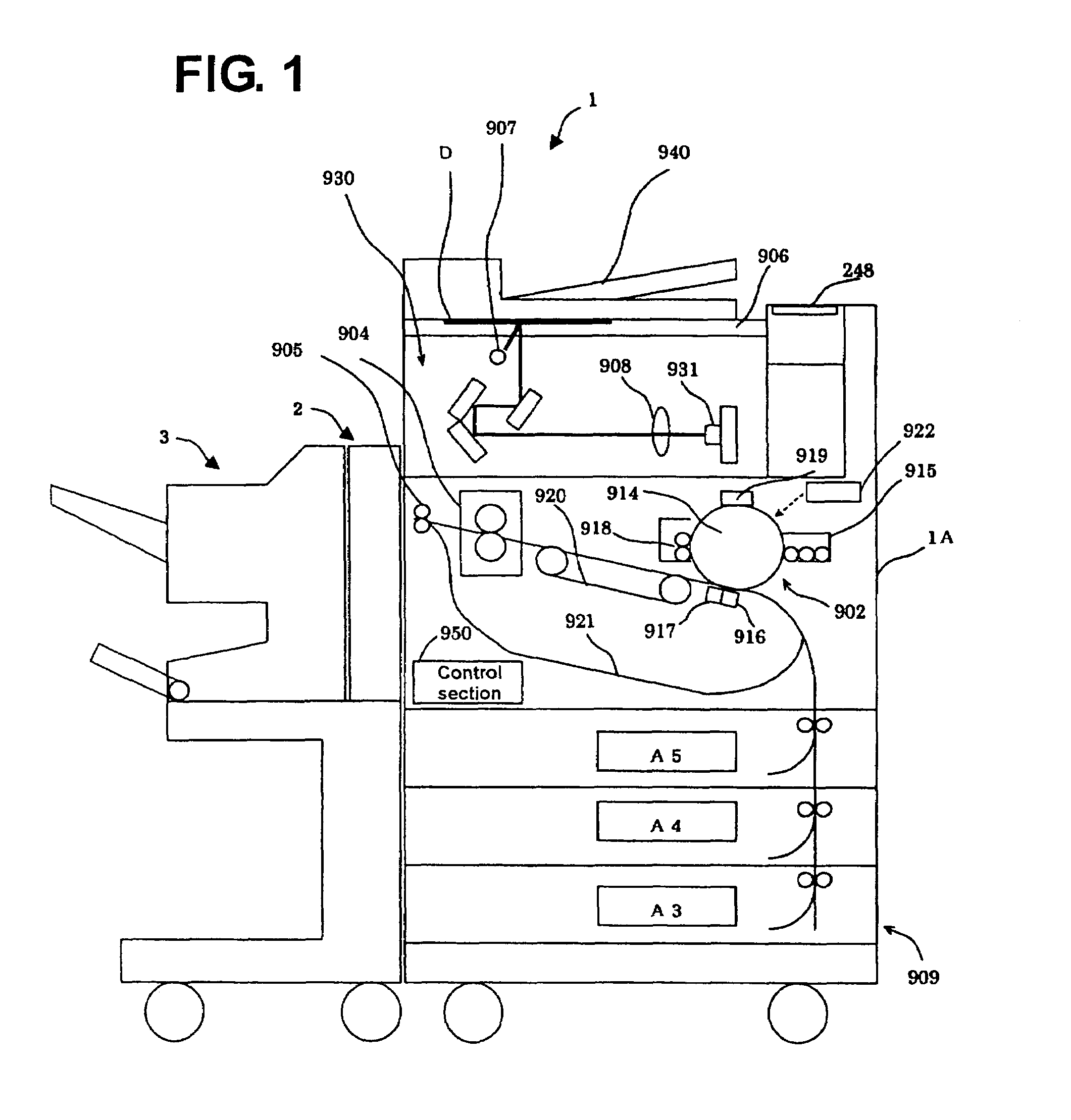

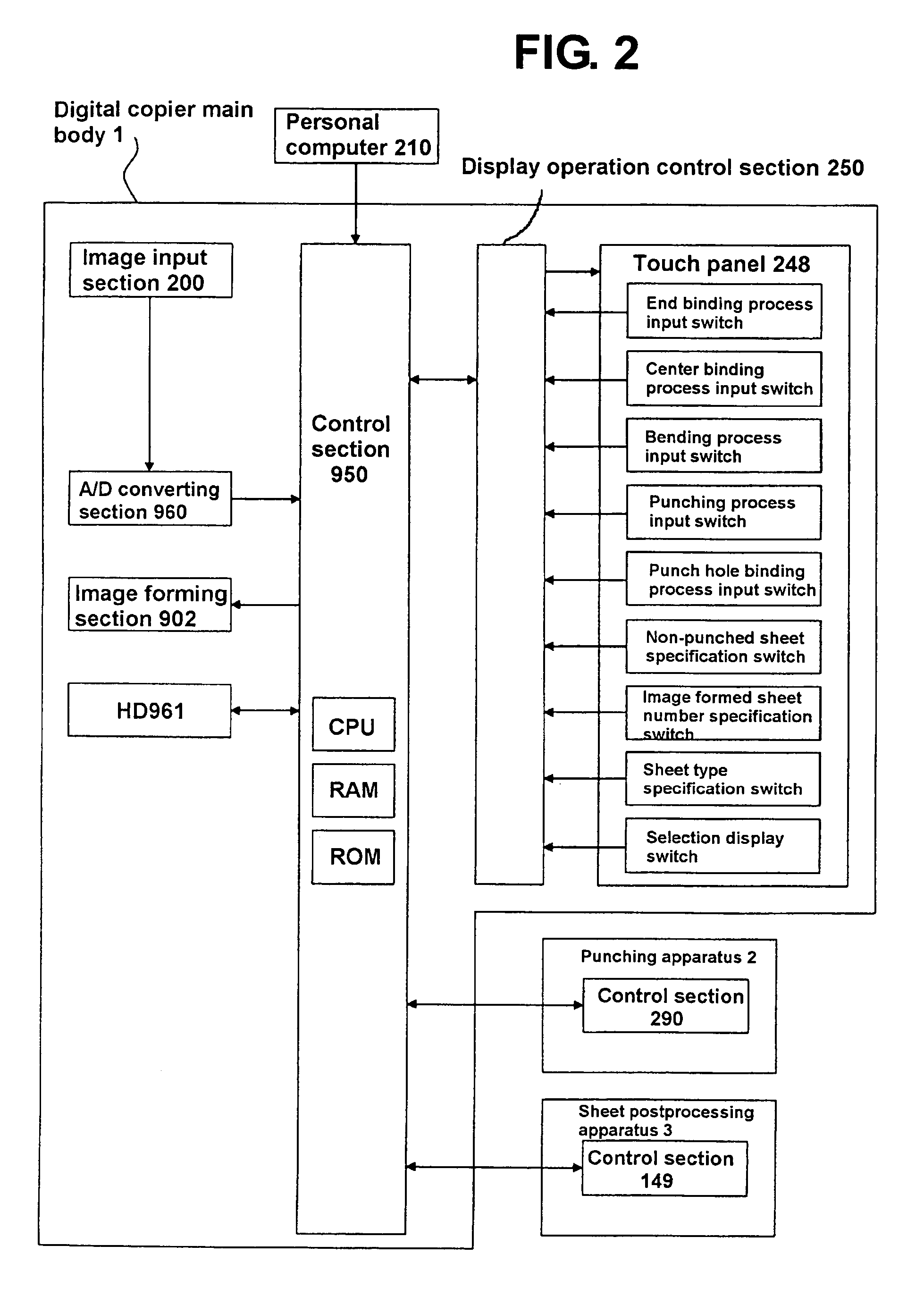

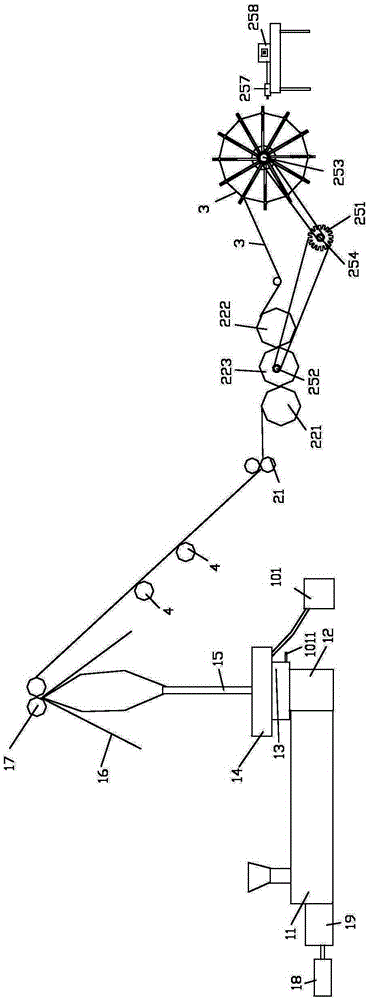

InactiveUS20050152725A1Reduce consumptionReduce noiseFunction indicatorsElectrographic process apparatusPunchingSheet material

A sheet post-processing apparatus includes a loading section for loading a sheet, and a punching device for punching the sheet loaded in the loading section at a punching position. A sheet bundle forming device is provided for forming a sheet bundle of the sheet punched by the punching device and a sheet not punched by the punching device. A binding device drives a staple into the sheet bundle at the punching position as a bound position to bind the sheet bundle.

Owner:NISCA KK

Floating gate memory with split-gate read transistor and split gate program transistor memory cells and method for making the same

InactiveUS20060221682A1Disturb conditionEliminates reverse tunnelingRead-only memoriesDigital storageEngineeringTransistor

Variations in memory array and cell configuration are shown, which eliminate punch-through disturb, reverse-tunnel. Several configurations are shown which range from combined and separate source lines for each row of cells, a two transistor cell containing a read transistor and a program transistor connected by a merged floating gate, and a two transistor cell where the program transistor has an extra implant to raise the Vt of the transistor to protect against punch-through disturb. A method is also described to rewrite disturbed cells, which were not selected to be programmed.

Owner:TAIWAN SEMICON MFG CO LTD

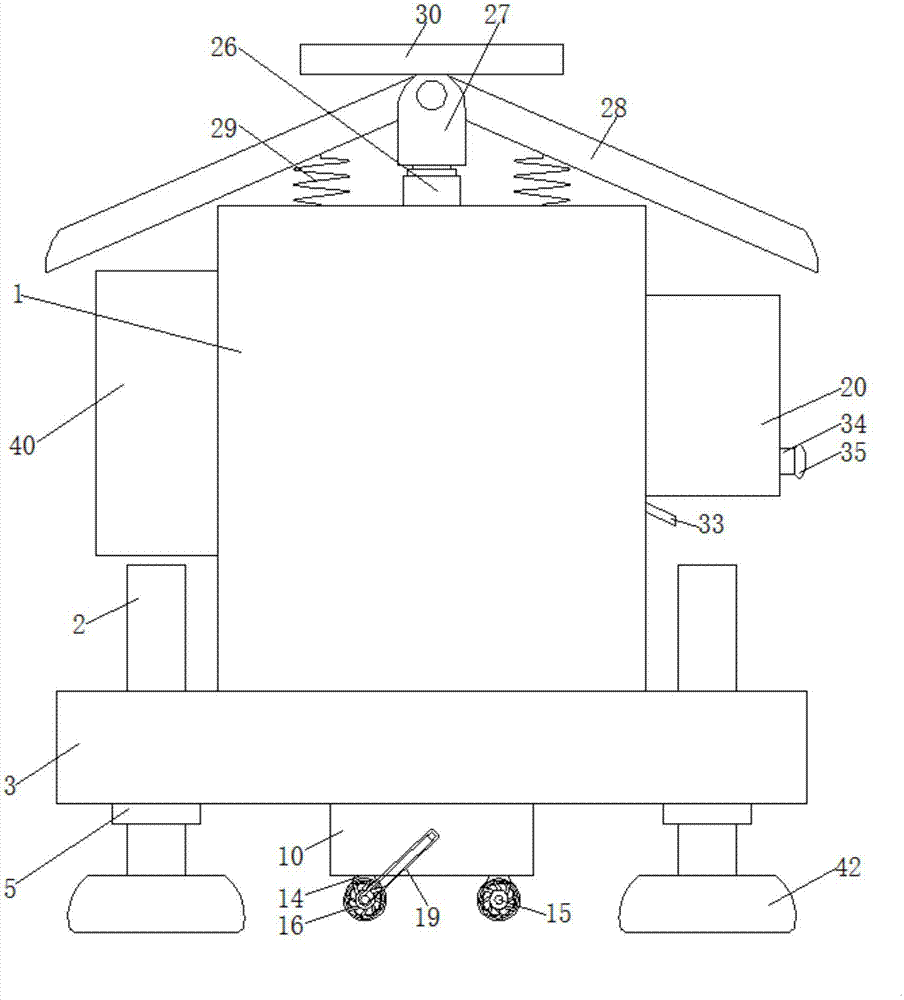

Electric power cabinet for outdoor construction engineering

InactiveCN107425453AAvoid damageAchieve moisture resistanceSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDrive wheelArchitectural engineering

The invention provides a power cabinet for outdoor construction engineering, which includes a power cabinet body, supporting legs and a horizontal plate. A rain shield is arranged above the power cabinet body, and a cooling slot hole is provided on one side of the power cabinet body and embedded in the cooling slot. The dust-proof net in the hole, the bottom of the power cabinet body is equipped with a driving wheel to facilitate the movement of the power cabinet. The power cabinet for outdoor construction can solve the problem of poor dustproof effect of the traditional power cabinet for construction.

Owner:GANZHOU YANSHUNFEI TECH CO LTD

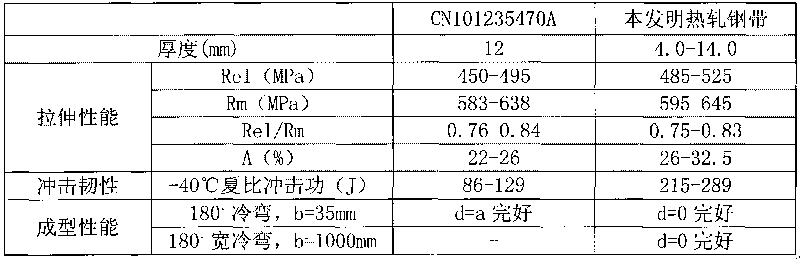

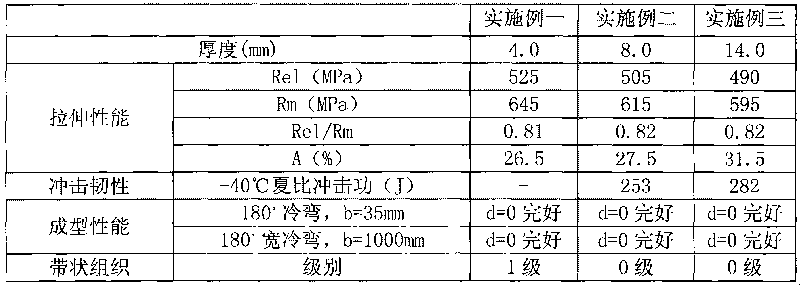

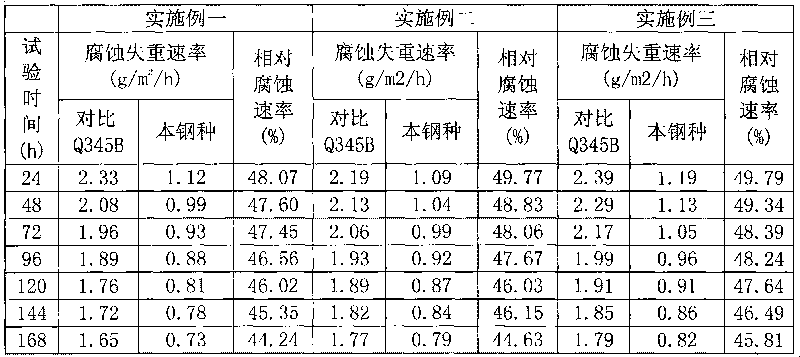

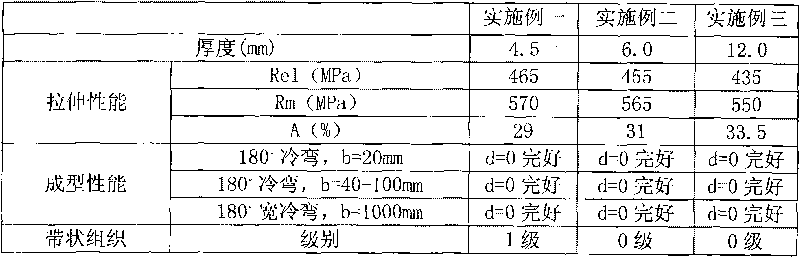

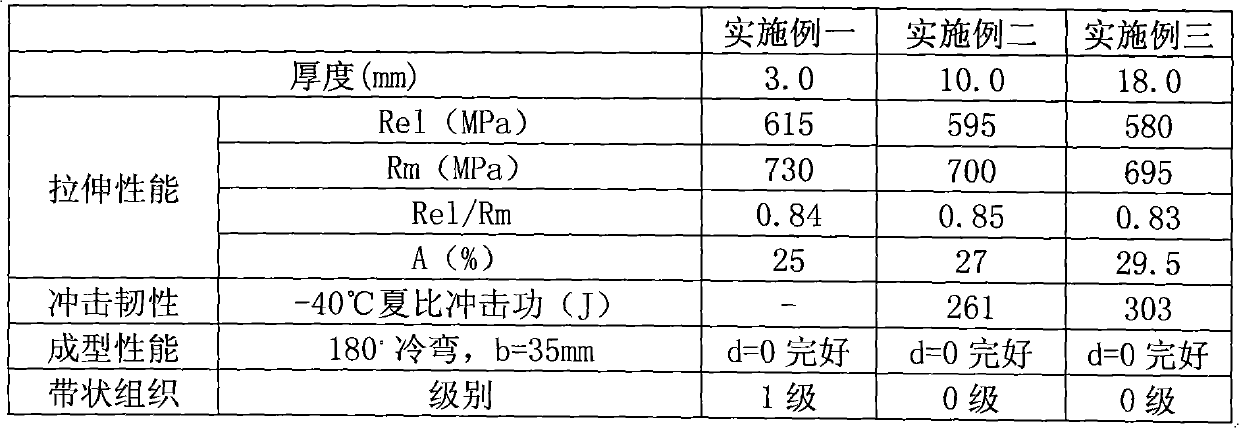

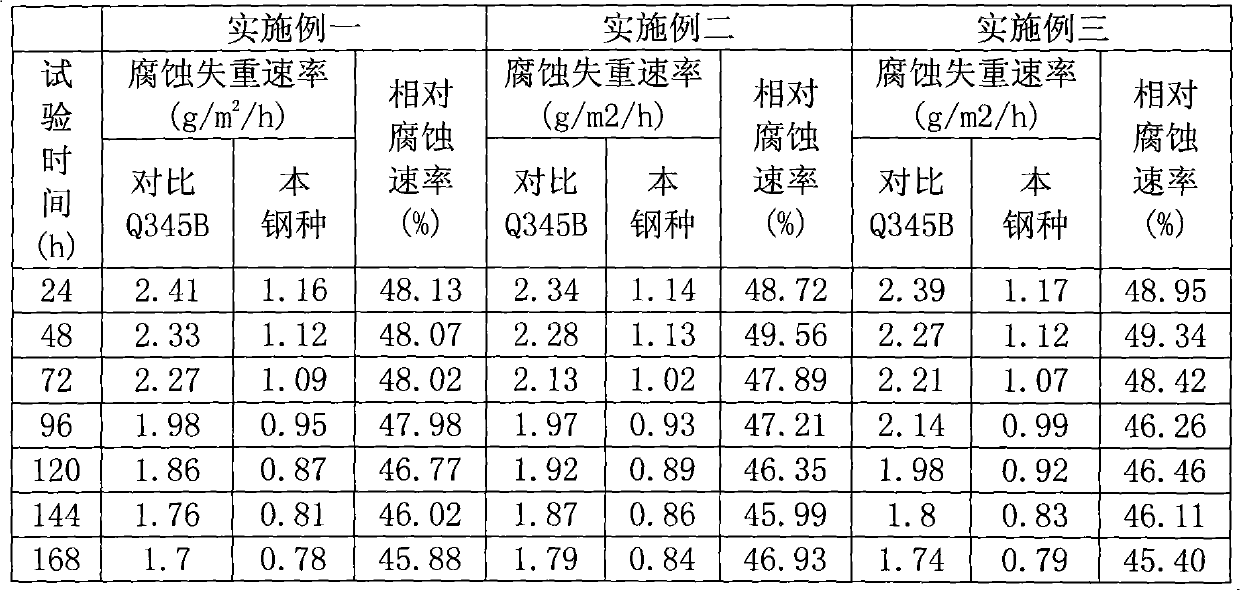

High-strength weather-resisting hot rolled steel strip and manufacturing method thereof

ActiveCN101736203ALow costLow content of harmful elementsManufacturing convertersMetal rolling arrangementsBand shapeMechanical property

The invention relates to a high-strength weather-resisting hot rolled steel strip and a manufacturing method thereof. The hot rolled steel strip comprises the following chemical components in percentage by weight: C is more than 0 and is less than or equal to 0.10, Si is more than or equal to 0.15 and is less than or equal to 0.45, Mn is more than or equal to 0.70 and is less than or equal to 1.40, P is more than 0 and is less than or equal to 0.020, S is more than 0 and is less than or equal to 0.008, Cr is more than or equal to 0.35 and is less than or equal to 1.00, Ni is more than or equal to 0.15 and is less than or equal to 0.55, Cu is more than or equal to 0.25 and is less than or equal to 0.50, Nb+V+Ti is more than 0 and is less than or equal to 0.22, and the balance of Fe and other unavoidable impurities. The manufacturing method of the hot rolled steel strip comprises the following steps: A. continuous casting billet preparation is realized by hot metal pretreatment desulfuration, top and bottom combined blown converter smelting, LF refining and thick plate blank continuous casting; B. controlled rolling and controlled cooling technology are adopted to process the continuous casting billet into the hot rolled steel strip, finish rolling temperature is 790-890 DEG C, water cooling is quickly carried out to 450-650 DEG C for reeling, and then the obtained product is cooled to room temperature. The steel strip processed by the manufacturing method of the high-strength weather-resisting hot rolled steel strip has low hazardous element content and banded structure rank, higher comprehensive mechanical property, weather resisting performance and favourable formability.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

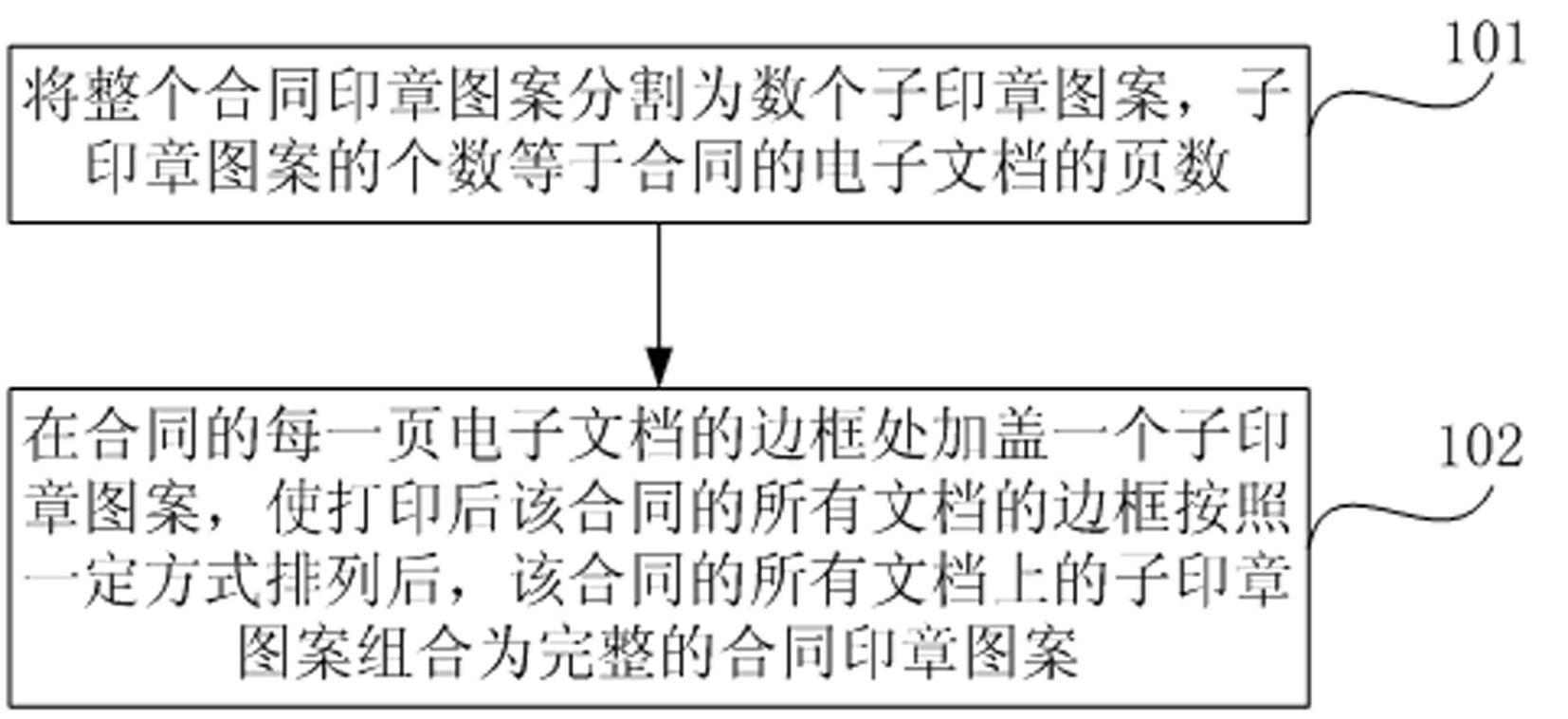

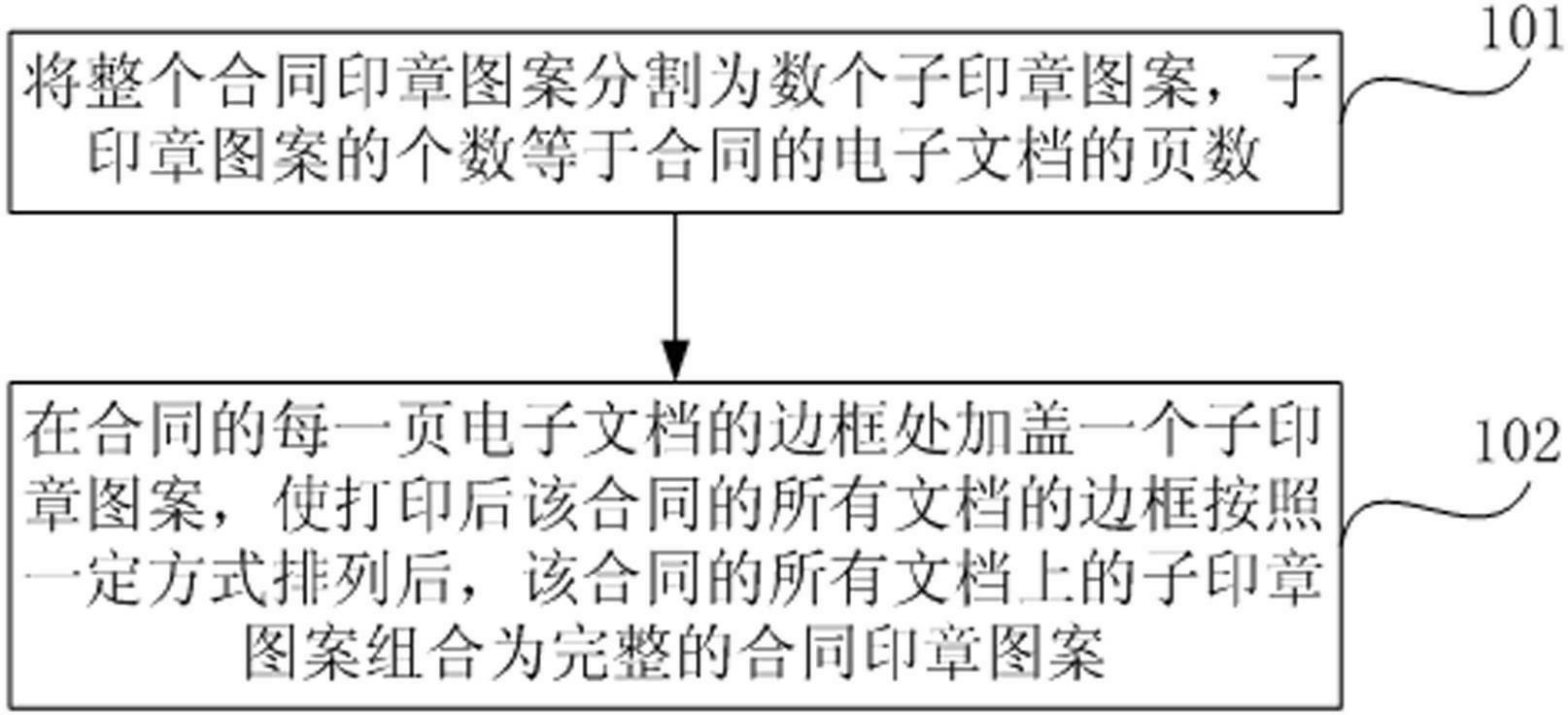

Method and device for electronic document anti-counterfeit

InactiveCN102663324APrevent forgeryImprove securityDigital data protectionElectronic documentDocument preparation

The invention relates to a method and a device for electronic document anti-counterfeit. The method for electronic document anti-counterfeit comprises the steps that : a whole contract stamp pattern is segmented into a plurality of sub-stamp patterns, and the number of the sub-stamp patterns is equal to the page number of the electronic document of a contract; the sub-stamp pattern is stamped additionally at the border of each page of the electronic document of the contract; after all the borders of all the printed pages of the contract document are arranged in a certain mode, the complete contract stamp pattern is formed through combining all the sub-stamp patterns which are on the contract document. With the method and the device for traditional anti-counterfeit in the invention, illegal stamp operation of a tradition contract is avoided; the influence of human factors is reduced and a contract process is made to be circulated more efficiently; contract manufacturing cost and energy are saved; the most important matter is that the method and the device effectively assist in preventing forgery of the electronic document contract and improving security of the electronic document contract.

Owner:北京思特奇信息技术股份有限公司

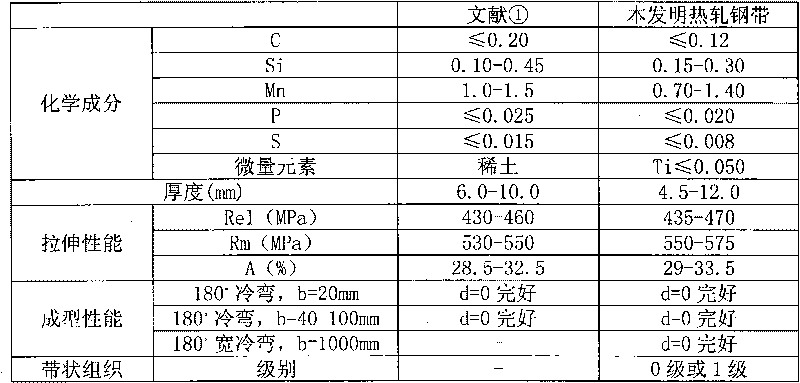

Hot rolled band for container and method for manufacturing same

ActiveCN101736198ALow costLow content of harmful elementsManufacturing convertersMetal rolling arrangementsChemical compositionRoom temperature

The invention relates to a hot rolled band for a container and a method for manufacturing the same. The hot rolled band comprises the following chemical components in percentage by mass: more than 0 and less than or equal to 0.12 percent of C, more than or equal to 0.15 and less than or equal to 0.30 percent of Si, more than or equal to 0.70 and less than or equal to 1.40 percent of Mn, more than 0 and less than or equal to 0.020 percent of P, more than 0 and less than or equal to 0.008 percent of S, more than 0 and less than or equal to 0.050 percent of Ti, and the balance of Fe and inevitable impurities. The method for manufacturing the hot rolled band comprises the following steps: A, preparing continuous casting slabs through molten iron pretreatment and desulfuration, smelting of a top-bottom blowing converter, LF refinement and slab continuous casting; and B, adopting a controlled rolling and controlled cooling process to machine the continuous casting slabs into the hot rolled band, wherein a final rolling temperature is between 810 and 910 DEG C, quickly cooling the hot rolled band in water to the temperature of between 450 and 650 DEG C, reeling the hot rolled band up and then cooling the hot rolled band to the room temperature. The band machined by the method for manufacturing the hot rolled band for the container has the characteristics of lower cost, harmful element content and banded structure level, higher comprehensive mechanical properties and good molding property.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

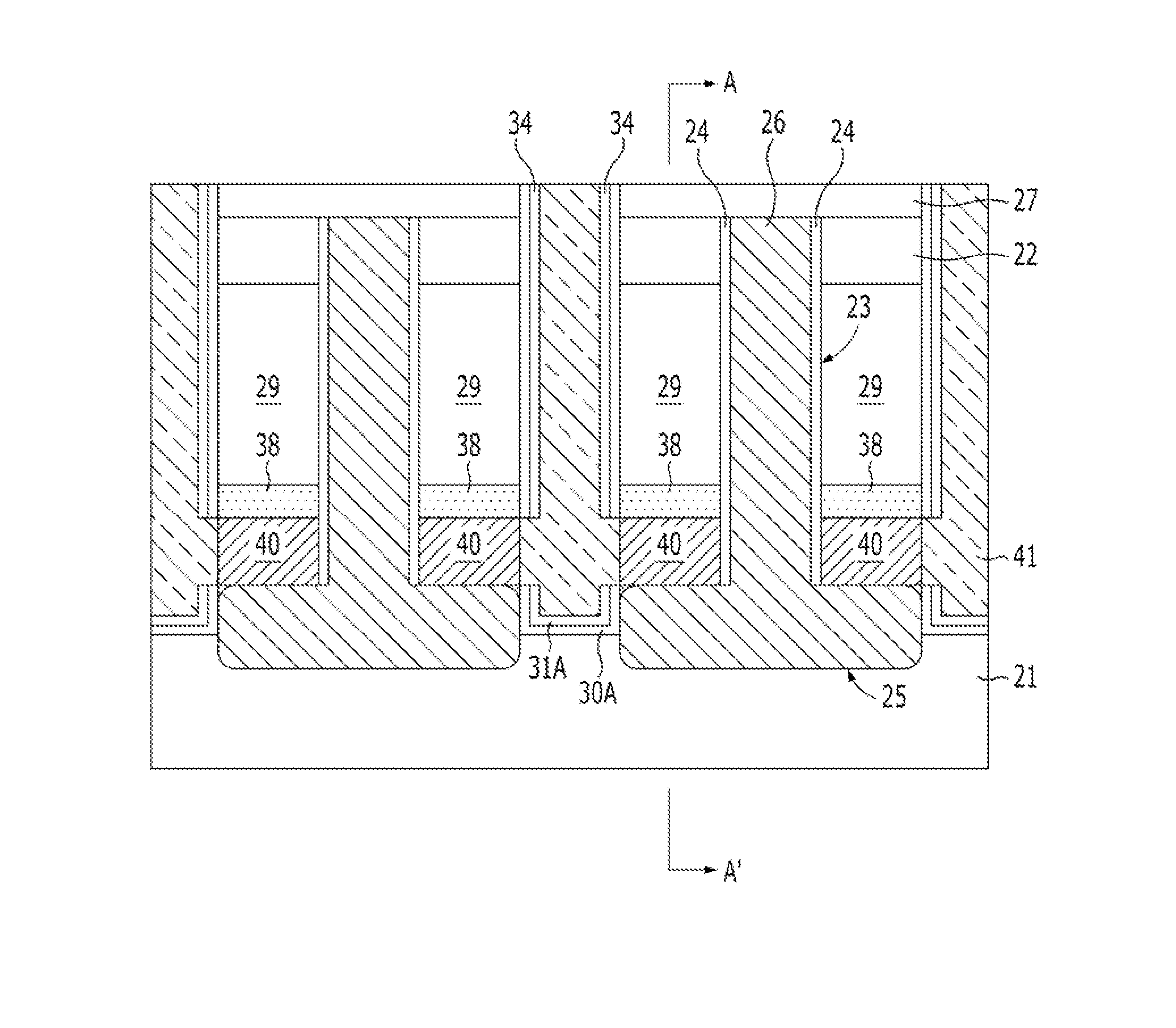

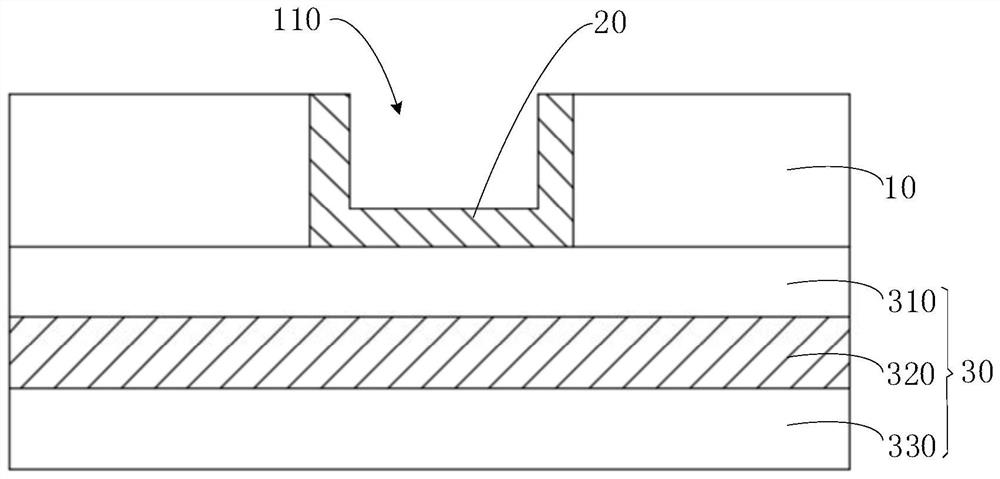

Semiconductor device with buried bit line and method for fabricating the same

ActiveUS20140061746A1Preventing pattern leaningHigh aspect ratio etching processTransistorSolid-state devicesBit lineDevice material

A method for fabricating a semiconductor device includes etching a semiconductor substrate to form bulb-type trenches that define a plurality of active regions in the semiconductor substrate; forming a supporter in each of the bulb-type trenches; dividing each active region, of the plurality of active regions, into a pair of body lines by forming a trench through each active region; and forming a bit line in each body line of the pair of body lines.

Owner:SK HYNIX INC

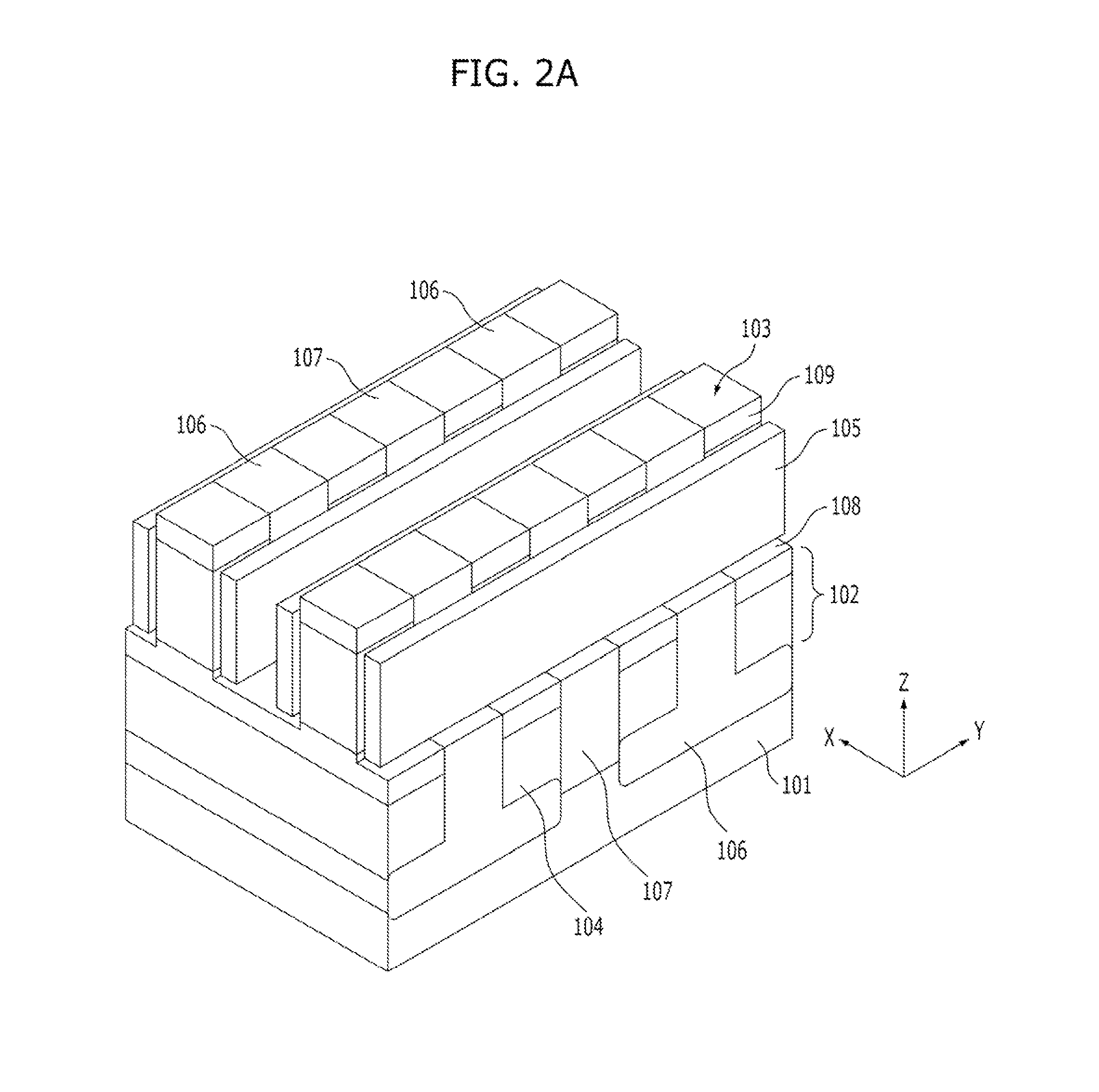

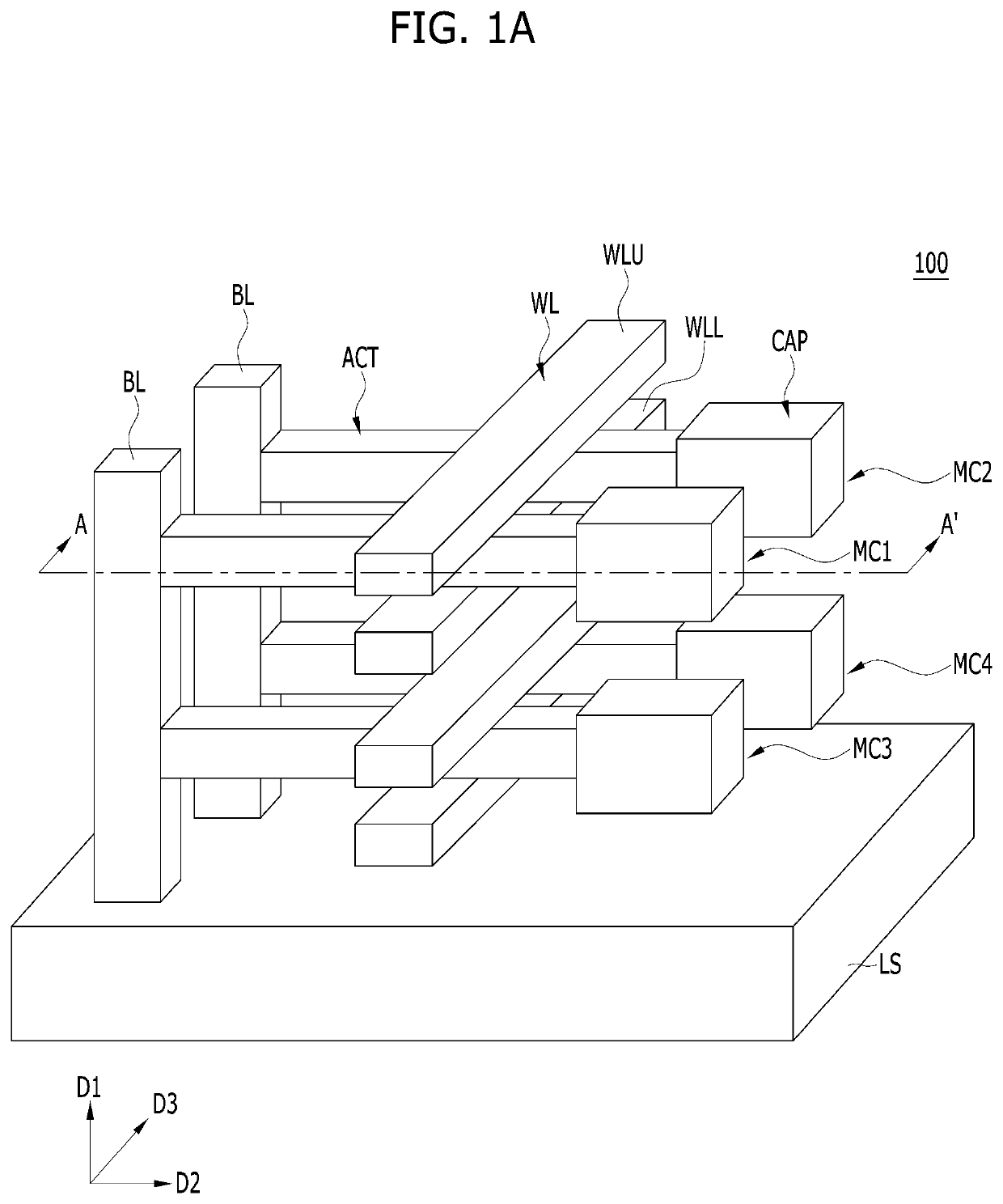

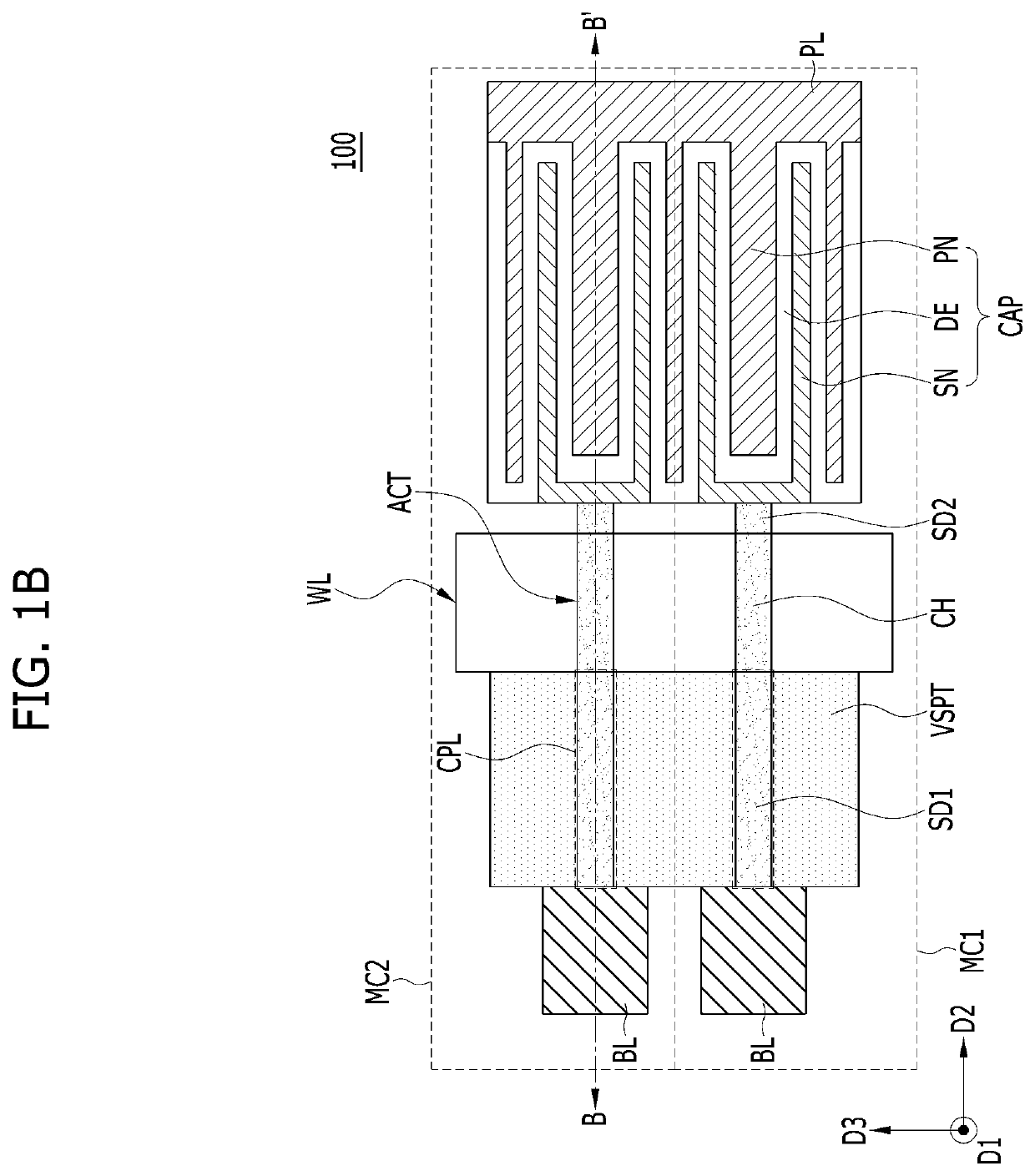

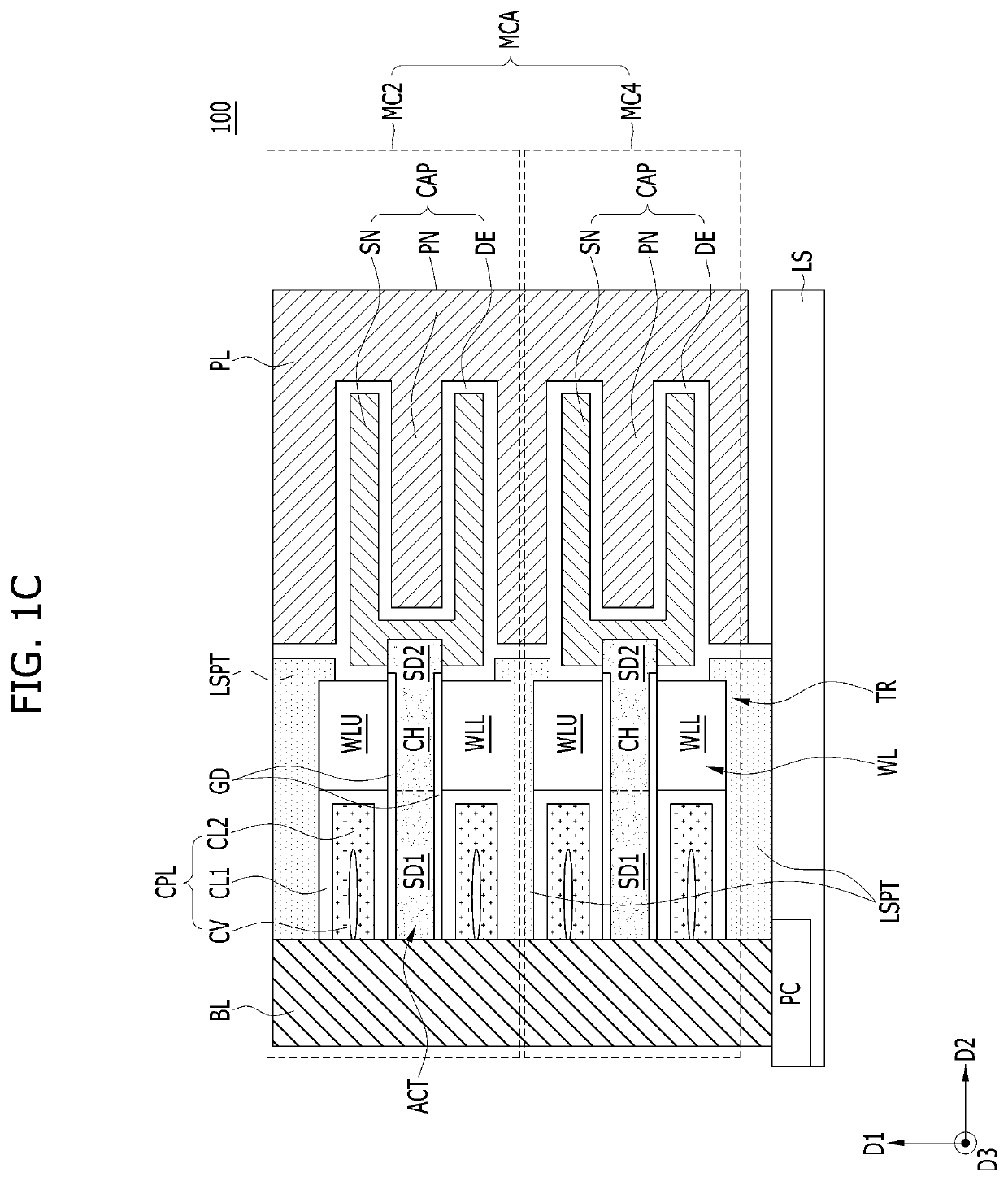

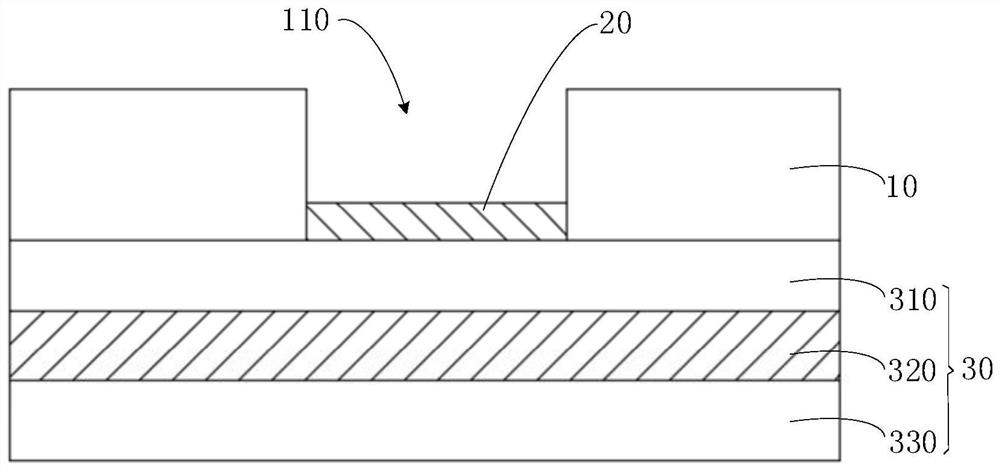

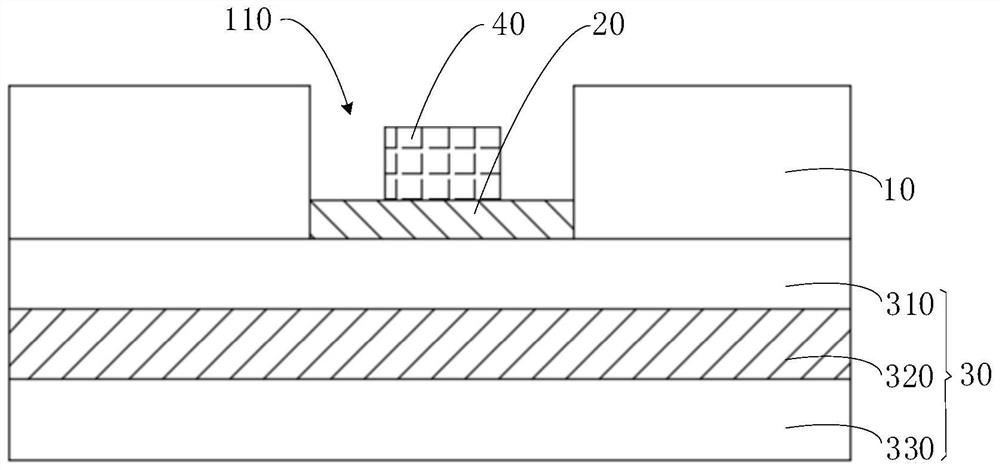

Semiconductor device

PendingUS20220013524A1Lateral migration can be suppressedAvoid stampingTransistorSemiconductor/solid-state device detailsBit lineMemory cell

According to the disclosure, highly integrated memory cells and a semiconductor device having the same are provided. According to an embodiment, a semiconductor device comprises a plurality of memory cells vertically stacked on a base substrate, each of the plurality of memory cells includes, a bit line vertically oriented from the base substrate, a capacitor horizontally spaced apart from the bit line, an active layer horizontally oriented between the bit line and the capacitor, a word line positioned on at least one of a top surface and bottom surface of the active layer and horizontally extending in a direction crossing the active layer, and a capping layer positioned between the word line and the bit line and including, at least, a low-k material and an air gap.

Owner:SK HYNIX INC

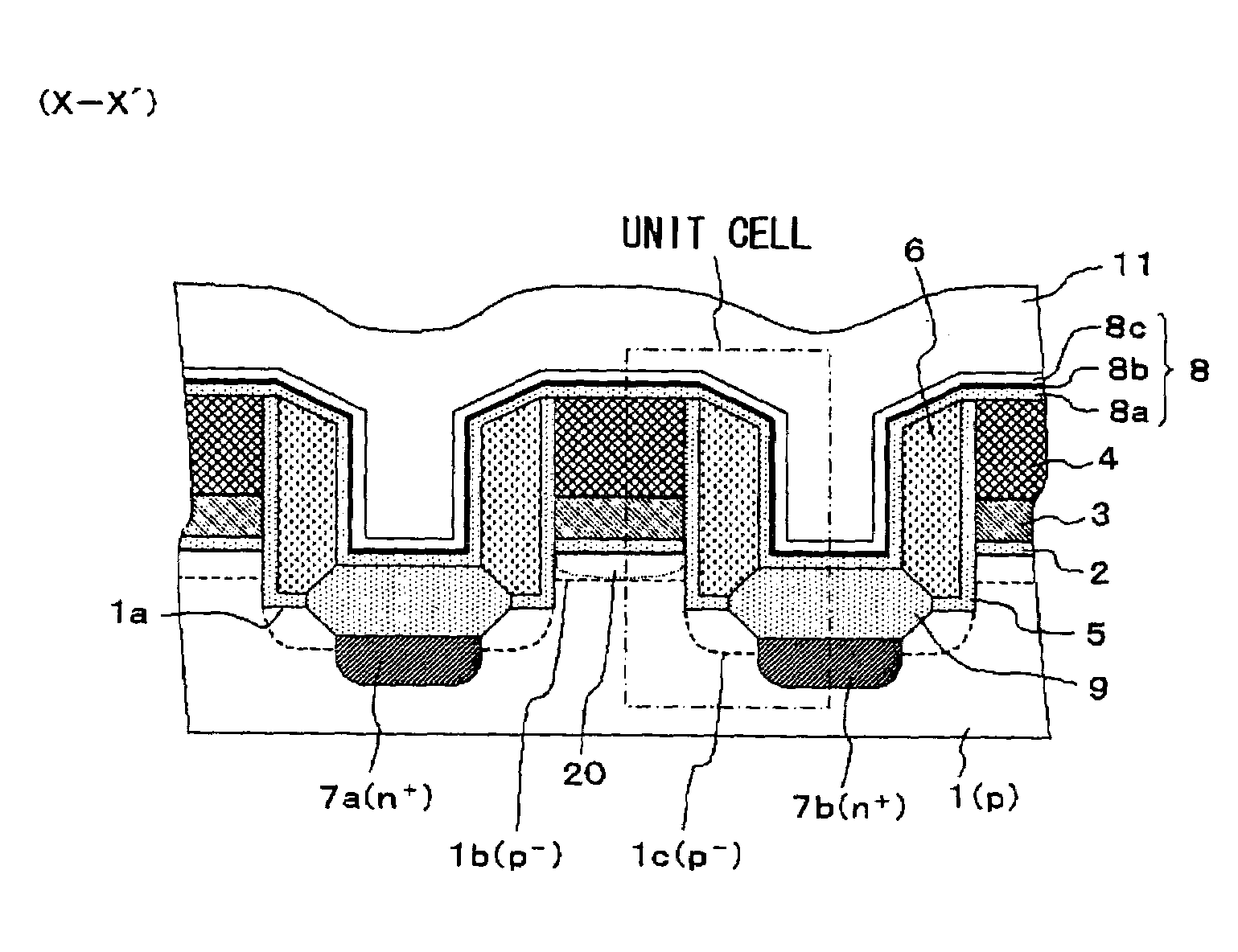

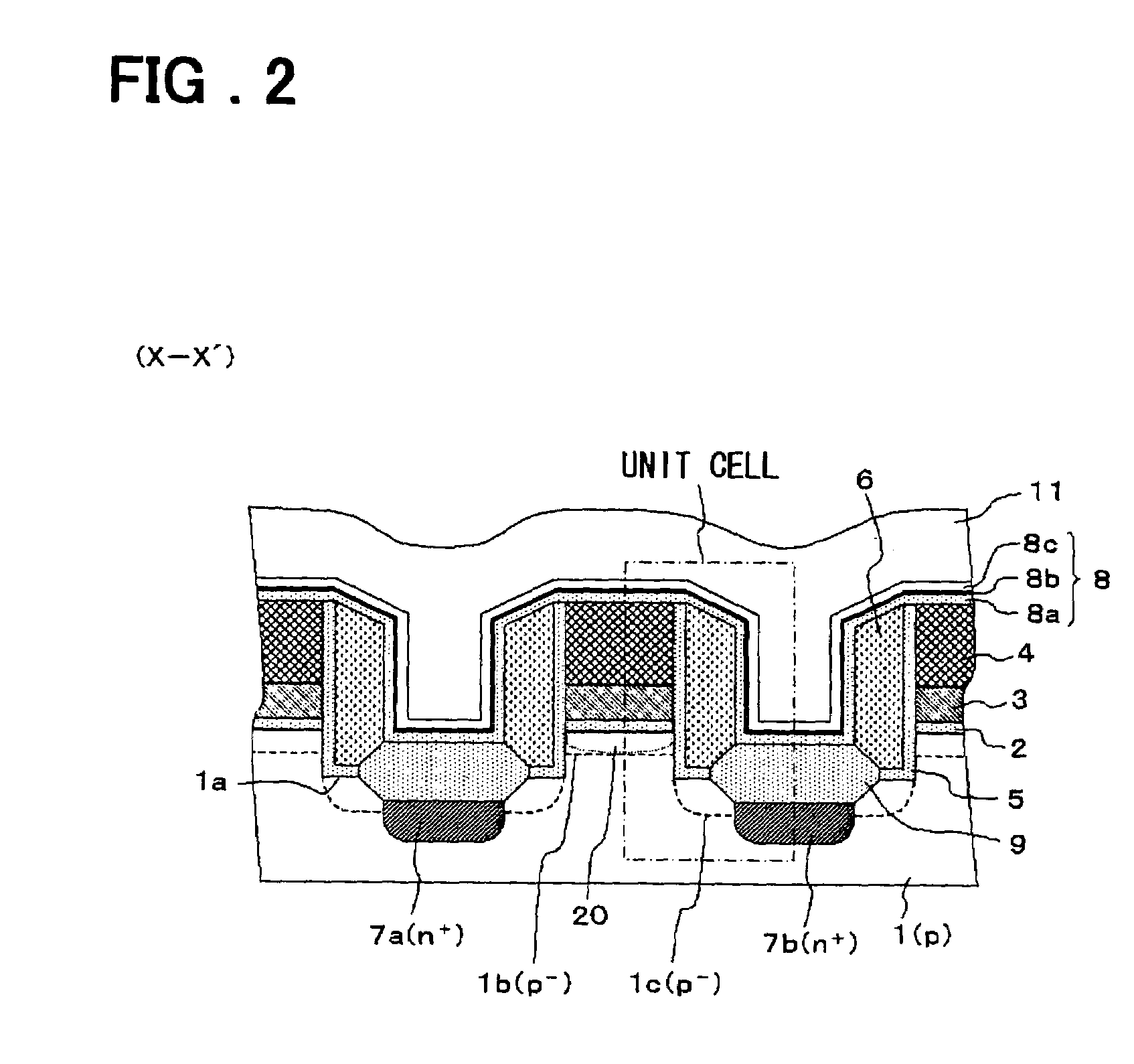

Semiconductor memory device

ActiveUS7619278B2Reduce leakageEffective expansionTransistorSolid-state devicesMiniaturizationEngineering

A semiconductor-memory device that reduces leak off due to miniaturization of memory cells, and comprises as a single unit cell: a substrate 1 having a trench section 1a; a selector gate 3 that is located via an insulating film 2 on the substrate adjacent to the trench section 1a; a first well 1b that is formed on the surface of the substrate 1 below the selector gate 3; a floating gate 6 that is located via an insulating film 8a on the surface of the bottom section and sidewall section of the trench section 1a; a second well 1c that is formed on the surface of the bottom section of the trench section 1a below the floating gate 6; a first diffusion area 7a that is formed on the surface of the bottom section of the trench section 1a; and a control gate 11 located via an insulating film 8 on top of the floating gate 6; and where the area near the sidewall surface and bottom surface of the trench section 1a forms a channel in the selector gate 3; and the impurity density of the first well 1b is not more than the impurity density of the second well 1c.

Owner:RENESAS ELECTRONICS CORP

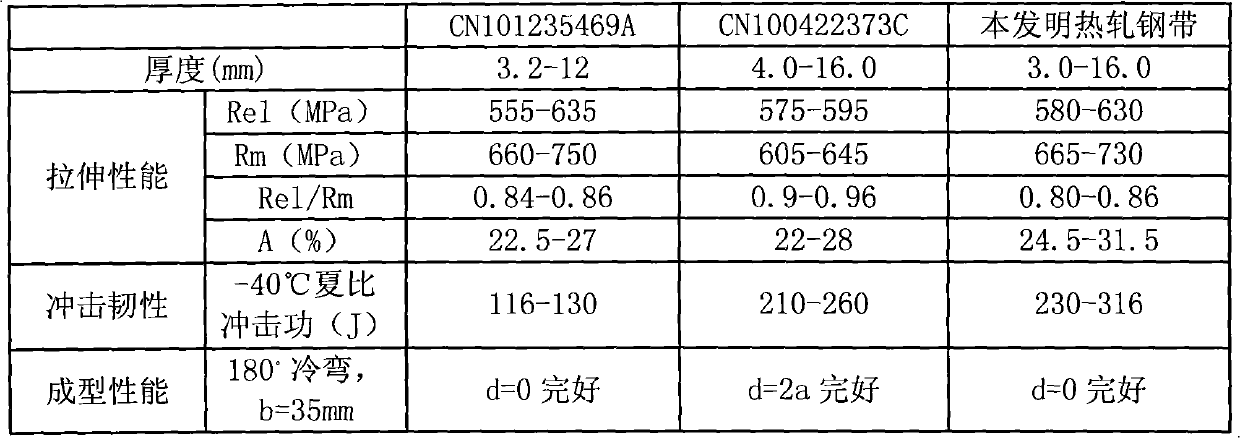

High-strength weather-resistant hot rolled steel strip and manufacturing method thereof

InactiveCN101768704ALow costLow content of harmful elementsMetal rolling arrangementsWeather resistanceAtmospheric air

The invention relates to a high-strength weather-resistant hot rolled steel strip and a manufacturing method thereof, and the hot rolled steel strip comprises the following components by mass percent: 0<C<=0.10, 0.15<=Si<=0.45, 1.20<=Mn<=1.85, 0<P<=0.020, 0<S<=0.008, 0.35<=Cr<=1.00, 0.15<=Ni<=0.55, 0.25<=Cu<=0.50, and 0<Nb+V+Ti<=0.22. The manufacturing method of the steel strip has the following steps: A, manufacturing continuously cast bloom by molten iron pretreatment desulfurization, smelting by a top and bottom blowing converter, LF refining and continuous casting of thick slabs; and B, processing the continuously cast bloom into the hot rolled steel strip by using controlled rolling and controlled cooling technologies with the finishing rolling temperature of 790-890 DEG C, rapidly cooling the temperature to 450-650 DEG C by water, reeling and cooling to room temperature. Steel strips which are processed by the manufacturing method of 550MPa high-strength good mouldability weather-resistant hot rolled steel steeps have less harmful element content and lower banded structure level, higher comprehensive mechanical property, weather resistance and good mouldability.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

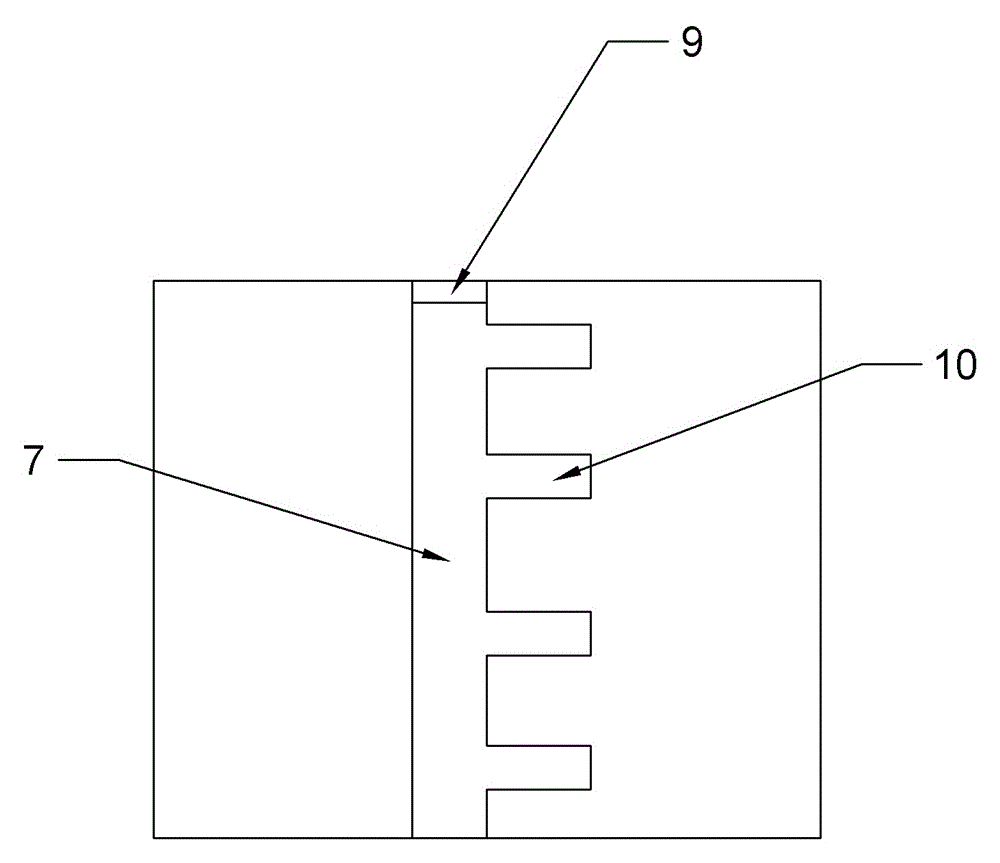

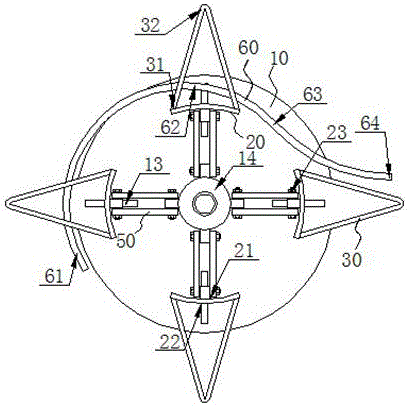

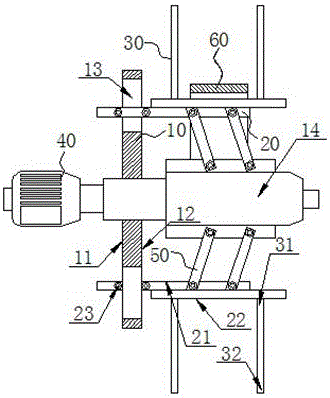

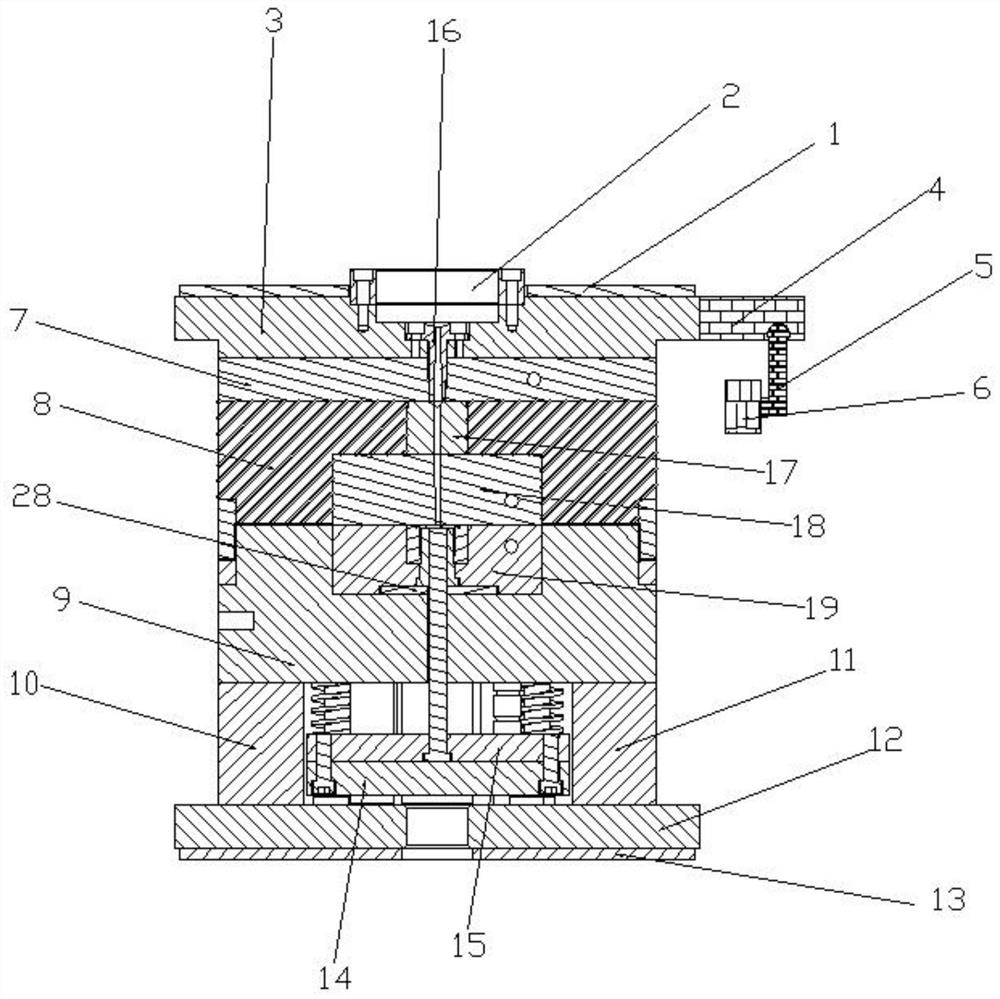

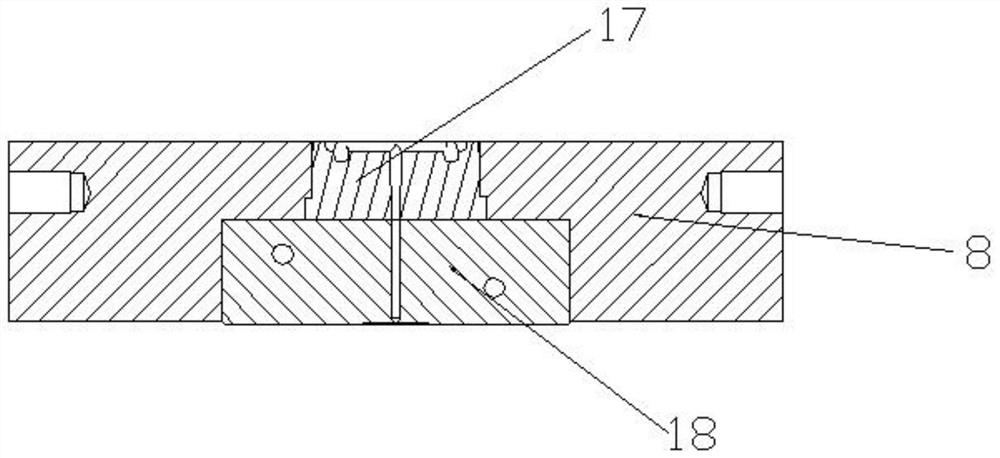

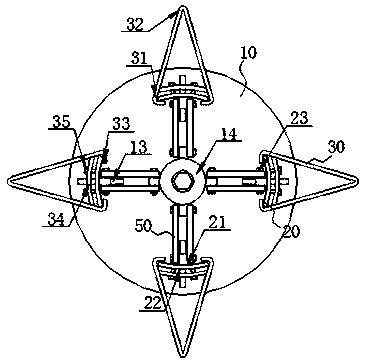

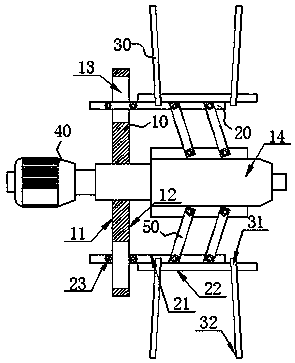

Vehicle spoke roundness trimming device

The invention relates to the stamping detection filed, and especially relates to a vehicle spoke roundness trimming device, which comprises a foundation base, a mounting base and a central spindle used for positioning and clamping a central hole of a spoke, wherein the mounting base is located on the foundation base and the mounting base is fixedly connected to the foundation base; the central spindle is located at the geometrical center of the mounting base; a top portion of the mounting base is provided with a mounting surface cooperated with an arc surface of the spoke; an edge of the mounting surface is provided with an arc baffle plate; and a heating mechanism is set above the mounting surface. According to the invention, the arc degree is trimmed through heating and rotation, thus the out-of-roundness degree of the spoke is lowered; and the spoke is avoided from being molten again and stamped, thus lowering the production cost.

Owner:CHONGQING ZETIAN AUTO PARTS

Sheet post-processing apparatus and image forming apparatus

InactiveUS7236737B2Reduce consumptionReduce noiseFunction indicatorsElectrographic process apparatusPunchingSheet material

A sheet post-processing apparatus includes a loading section for loading a sheet, and a punching device for punching the sheet loaded in the loading section at a punching position. A sheet bundle forming device is provided for forming a sheet bundle of the sheet punched by the punching device and a sheet not punched by the punching device. A binding device drives a staple into the sheet bundle at the punching position as a bound position to bind the sheet bundle.

Owner:NISCA KK

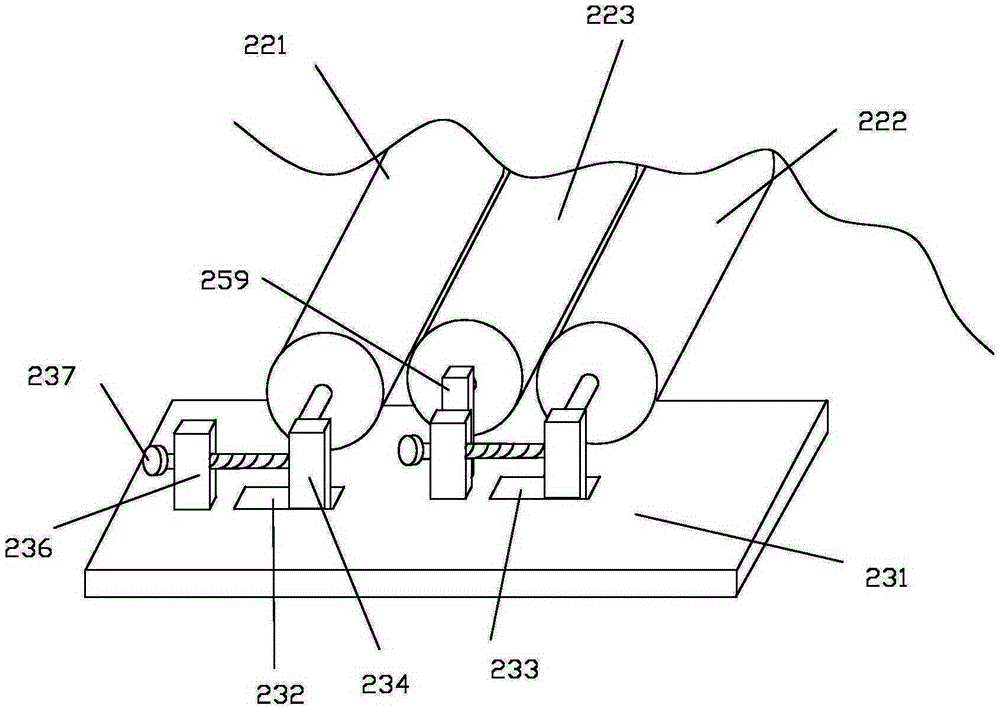

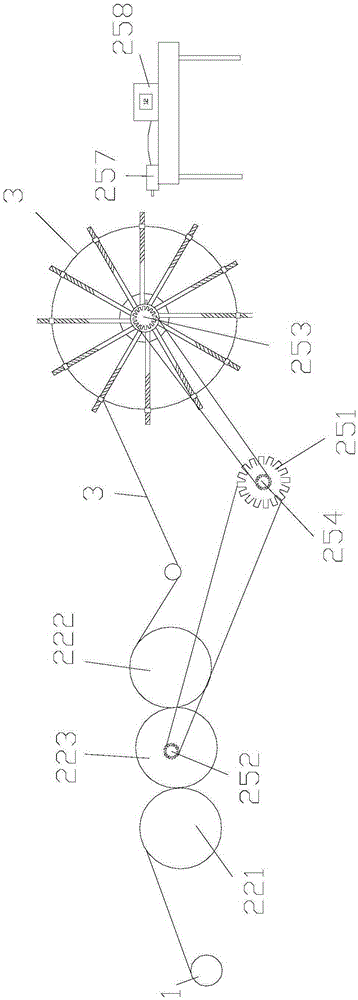

Film blowing and heat sealing integrated machine

InactiveCN105383094ASmall footprintLow costEnvelopes/bags making machineryWebs handlingSmall footprintFilm blowing machine

The invention relates to a film blowing and heat sealing integrated machine which comprises a film blowing machine body, wherein the film blowing machine body comprises an extruder, a filtering device, a die head, an air ring, a mandrel, a herringbone plate and a first draft gear; the die head is arranged at the extruding end of the extruder, the air ring is arranged on the die head, the mandrel is coaxially arranged in the middle of the die head, the herringbone plate is arranged above the mandrel, and the first draft gear is arranged above the herringbone plate; and the integrated machine also comprises a heat sealing machine body, wherein the heat sealing machine body comprises a second draft device and a heat sealing roll assembly, the second draft device is used for carrying out second time of traction on a film pulled by the first draft device, and the heat sealing roll assembly is used for carrying out heat sealing on the film pulled by the second draft device. The integrated machine has the advantages that occupation area is small, manufacture cost is low, maintenance rate is low, heat sealing stationarity is good, noise is low, and a prepared film bag is convenient to take and easy to open.

Owner:ANQING XINSHUN PLASTIC CO LTD

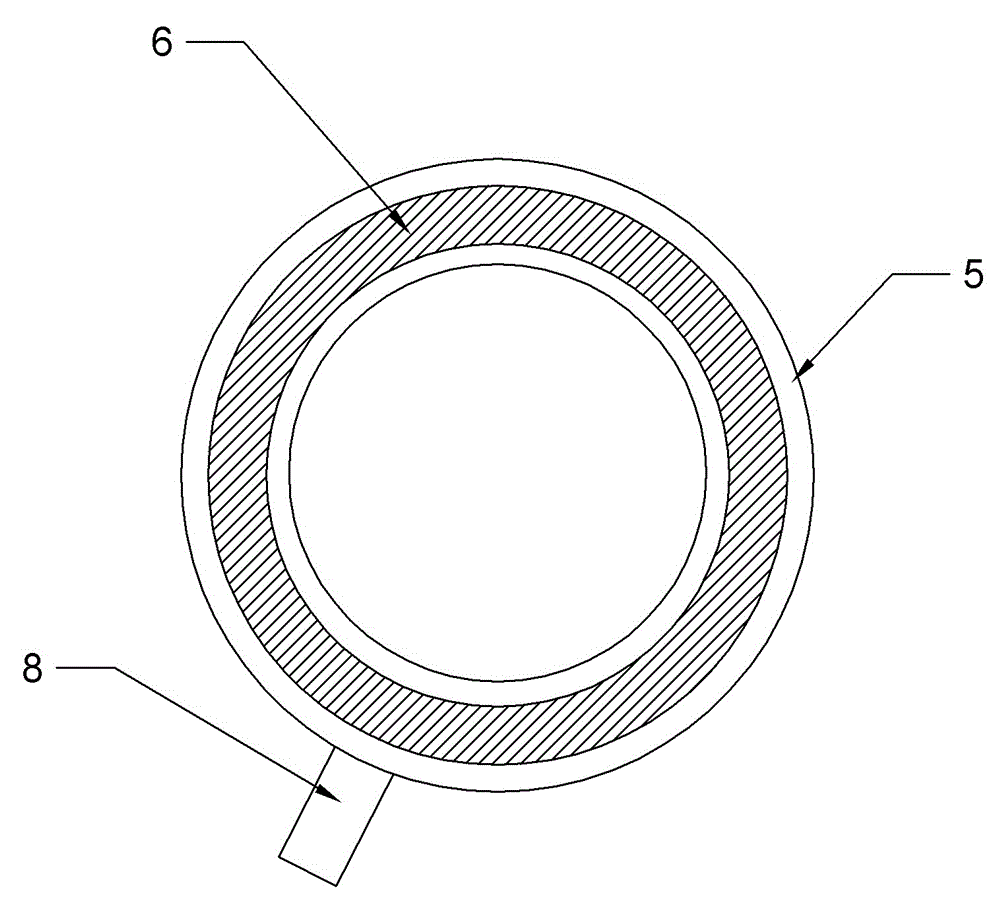

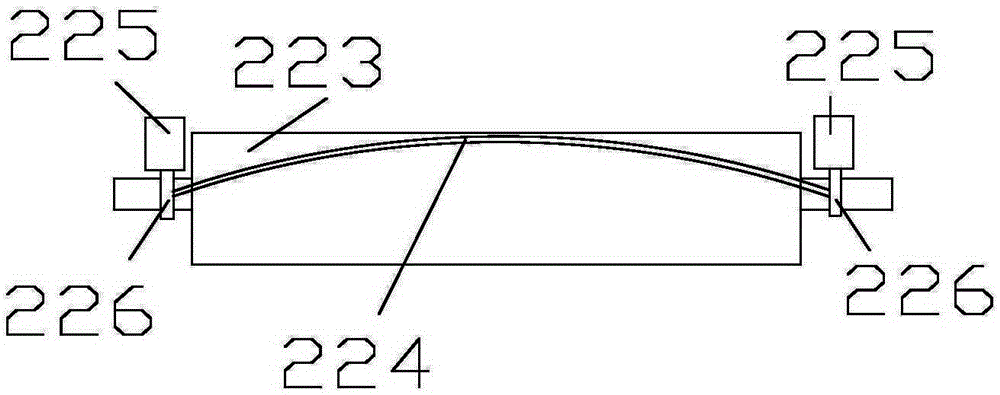

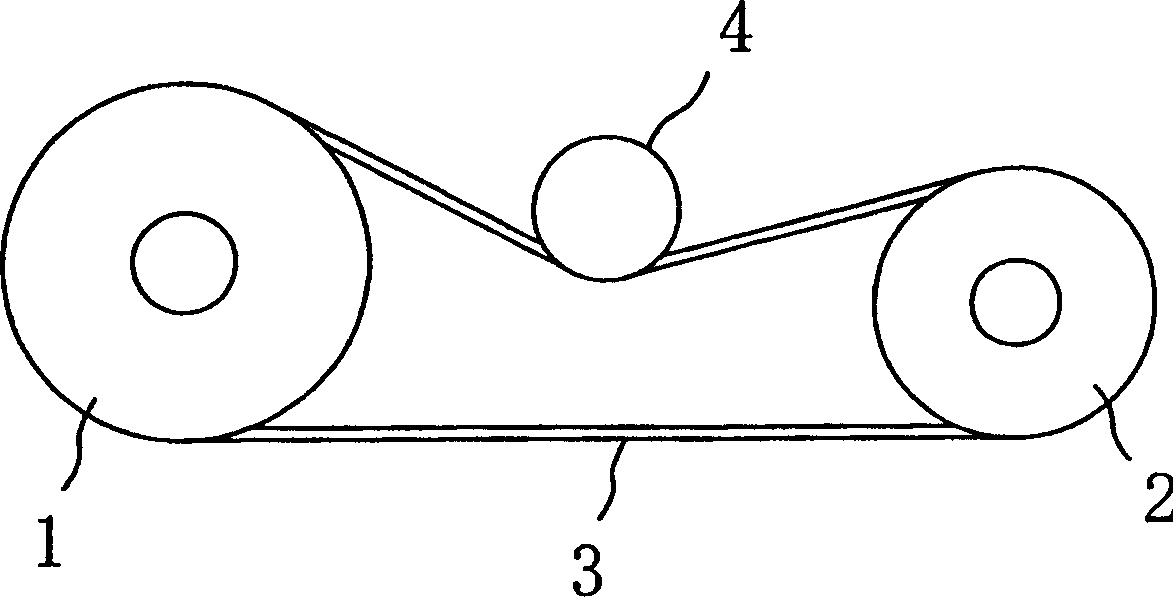

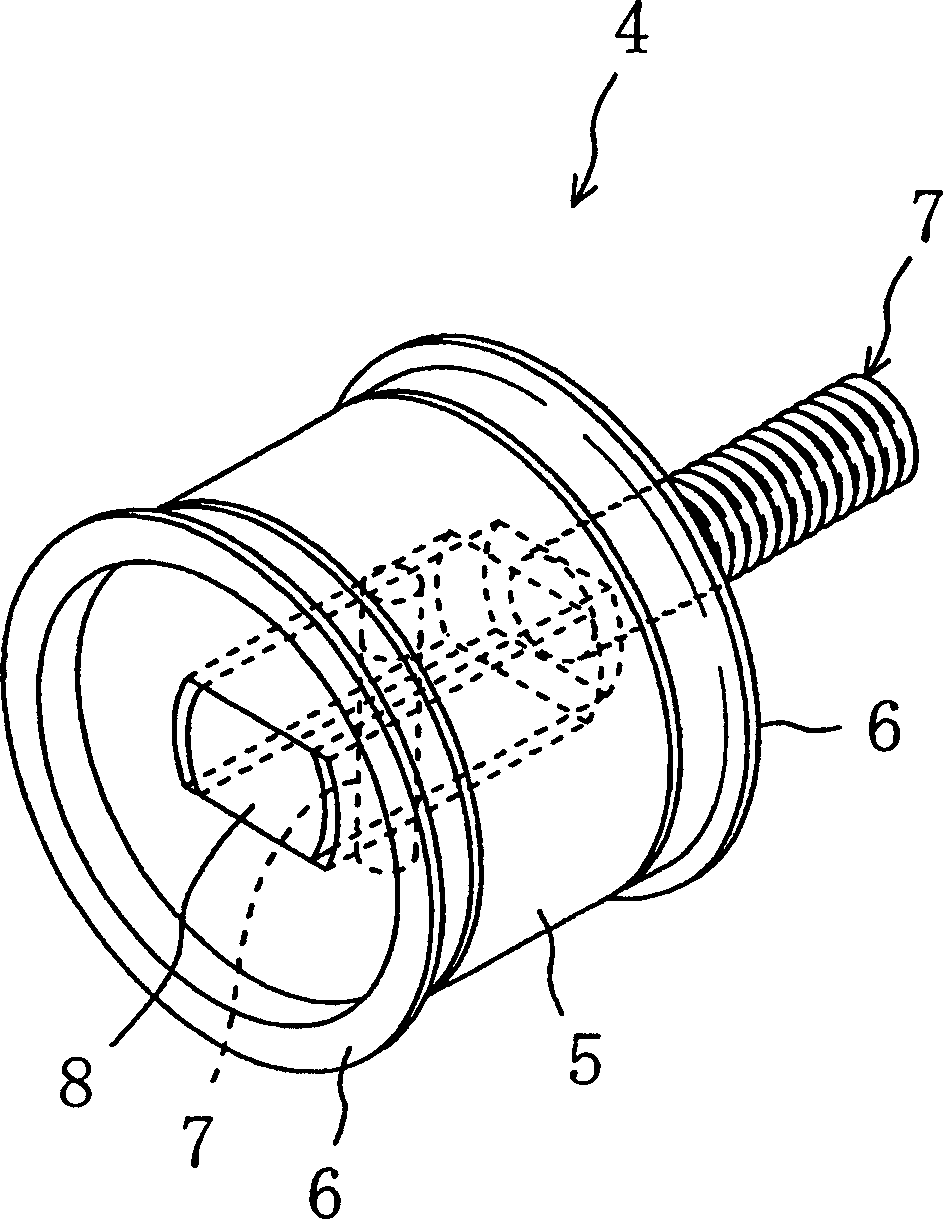

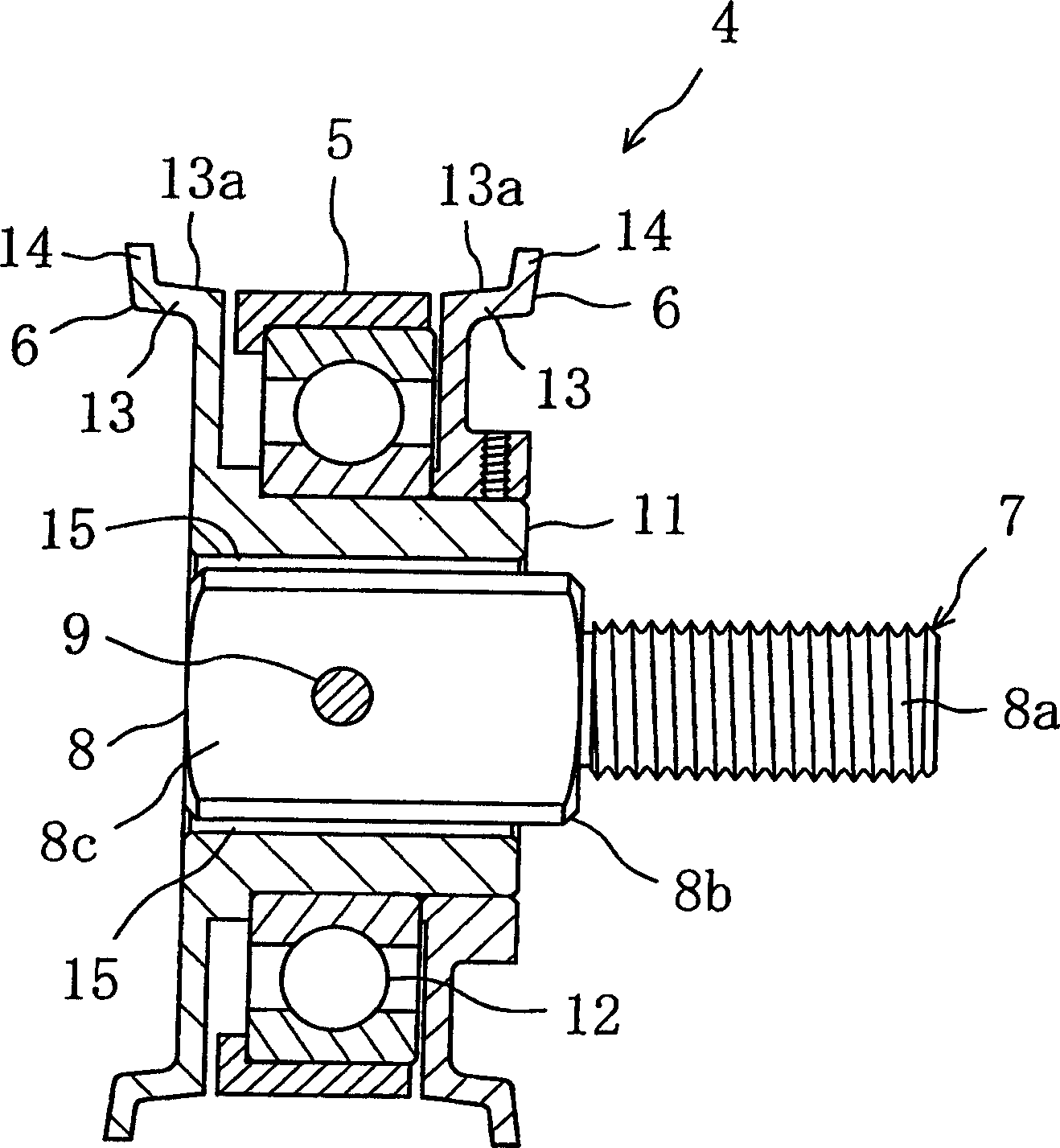

Leather belt wheel for driving belt and belt driving apparatus

A pulley body 5 is provided at its both sides with power transmission members 6, 6. When a flat belt 3 becomes misaligned relative to the center of the pulley body 5 and comes into contact with one of the power transmission members 6, a running force of the flat belt 3 is utilized to displace the pulley body 5 diagonally relative to the flat belt 3, thus producing a force for returning the flat belt 3 to its original state.

Owner:BANDO CHEM IND LTD

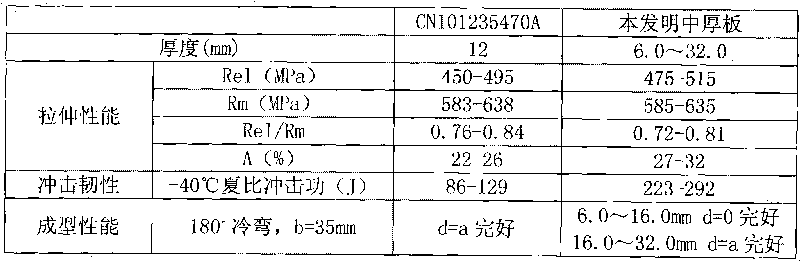

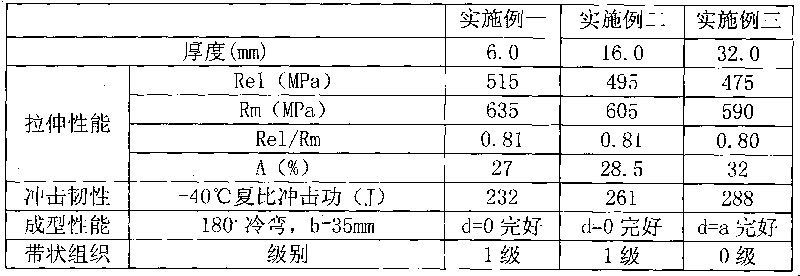

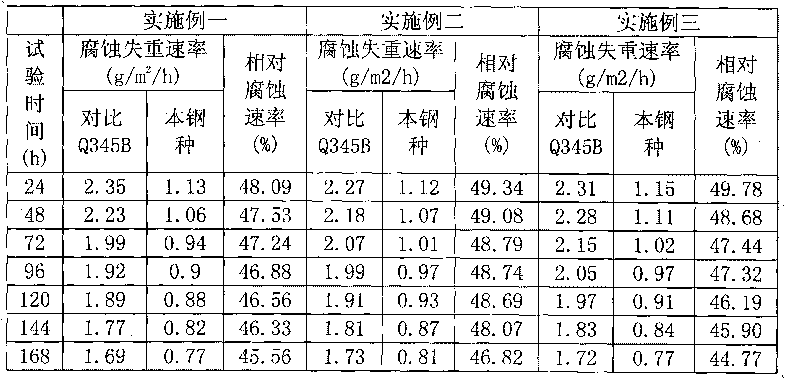

High-strength atmospheric corrosion-resistant medium plate and manufacturing method thereof

ActiveCN101736204AHigh strengthImprove impact toughnessManufacturing convertersMetal rolling arrangementsMechanical propertyImpurity

The invention relates to a high-strength atmospheric corrosion-resistant medium plate and a manufacturing method thereof. The medium plate comprises the following chemical components in percentage by mass: more than 0 and less than or equal to 0.12 percent of C, more than or equal to 0.15 percent and less than or equal to 0.45 percent of Si, more than or equal to 0.70 percent and less than or equal to 1.40 percent of Mn, more than 0 and less than or equal to 0.020 percent of P, more than 0 and less than or equal to 0.008 percent of S, more than or equal to 0.35 percent and less than or equal to 1.00 percent of Cr, more than or equal to 0.15 percent and less than or equal to 0.55 percent of Ni, more than or equal to 0.25 percent and less than or equal to 0.50 percent of Cu, more than 0 and less than or equal to 0.22 percent of Nb and V and Ti and the balance of Fe and inevitable impurities. The manufacturing method of the medium plate comprises the steps of: A, preparing continuously cast blank through the preprocessing and desulfuration of molten iron, the smelting in a top-bottom blowing converter, LF refining and the continuous casting of a thick plate blank; and B, machining the continuously cast blank to make the medium plate by adopting a TMCP process with a finishing temperature of 790 and 890 DEG C, quickly cooling the medium plate with water to 550 to 650 DEG C for reeling, and then cooling the medium plate to room temperature. The medium plate machined by using the manufacturing method of the atmospheric corrosion-resistant high-strength medium plate has low harmful element content and level of banded structures, high comprehensive mechanical property, atmospheric corrosion resistant performance and excellent formability.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

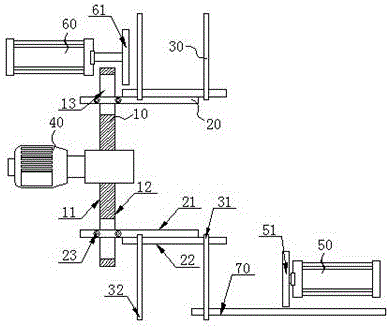

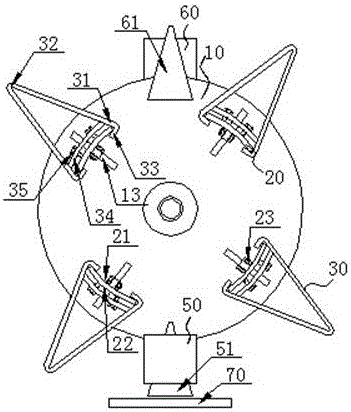

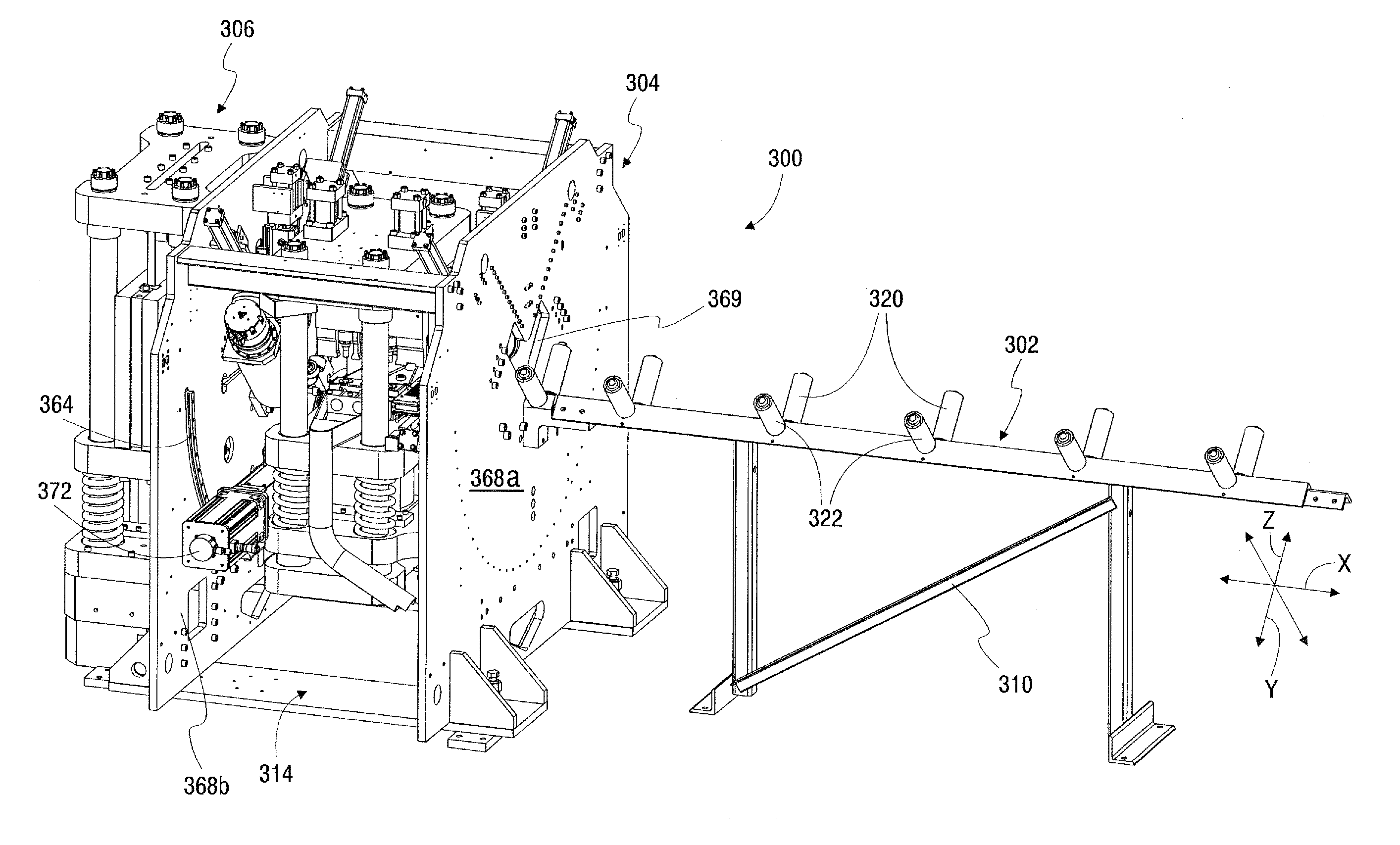

Automatic machining device of car damper support

InactiveCN106734686AAvoid stampingReduce the risk of accidentsMetal-working feeding devicesVehicle componentsCircular discEngineering

The invention discloses an automatic machining device of a car damper support. The automatic machining device comprises a piece taking rotation disc, a clamping feeding air cylinder and a clamping retreating air cylinder; the piece taking rotation disc is provided with a plurality of piece taking operation support arms, and each piece taking operation support arm is provided with two V-shaped piece taking connecting rods; the piece taking connecting rod fixed ends of the V-shaped piece taking connecting rods are provided with limiting overturning edges, installation fixing baffles and installation fixing bolts, the limiting overturning edges are located on one sides of the piece taking operation support arms, the installation fixing baffles are located on the other sides of the piece taking operation support arms, the installation fixing bolts are in threaded connection with the installation fixing baffles, and one end of each installation fixing bolt abuts against the corresponding piece taking operation support arm; and piston rod free ends of the clamping feeding air cylinder and the clamping retreating air cylinder both face motion zones of the V-shaped piece taking connecting rods. By means of the automatic machining device, car damper support assemblies in different specifications and shapes can be effectively grabbed to be subject feeding operation.

Owner:WUHU YUANSHAN MACHINERY MFG CO LTD

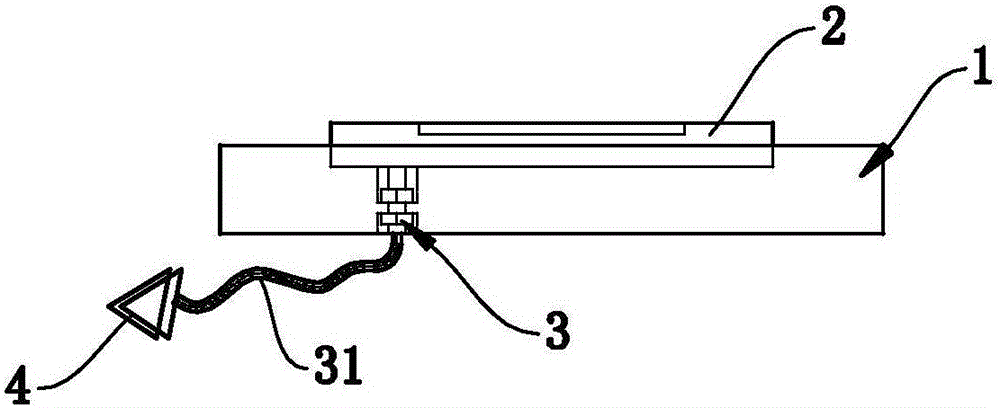

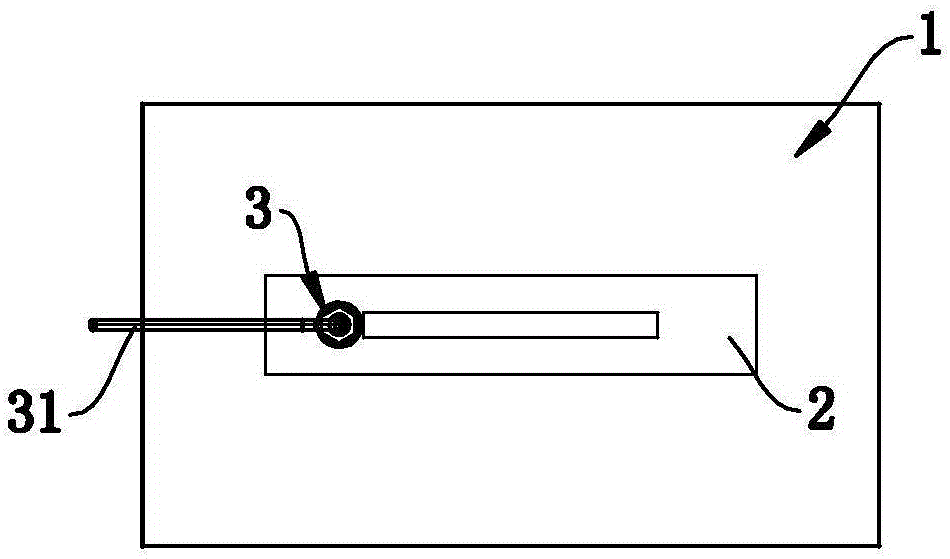

Display device and electronic equipment

PendingCN111627340AAvoid stampingImprove effectivenessDigital data processing detailsIdentification meansEngineeringMechanical engineering

The invention discloses a display device and electronic equipment, belonging to the technical field of display. According to a main technical scheme in the invention, the display device comprises a first machine shell, a second machine shell, a flexible display screen and at least one elastic assembly, wherein the first end of the first machine shell is provided with an opening; the first end of the second machine shell is provided with an opening; the opening of the second machine shell is inserted into the opening of the first machine shell, and the second machine shell is in sliding connection with the first machine shell to allow the second machine shell to slide out of / into the first machine shell; the first end of the flexible display screen is connected with the outer surface of thefirst side of the first machine shell, and the second end of the flexible display screen bypasses the end, deviating from the opening of the second machine shell, of the second machine shell and is connected with a winding assembly in the first machine shell so as to allow the flexible display screen to slide out of / into the first machine shell along with the second machine shell; and the elasticassembly can provide elastic force for the second machine shell, so when the second machine shell slides out of the first machine shell, the outer surface, close to the first side of the first machine shell, of the second machine shell is flush with the outer surface of the first side of the first machine shell.

Owner:BOE TECH GRP CO LTD

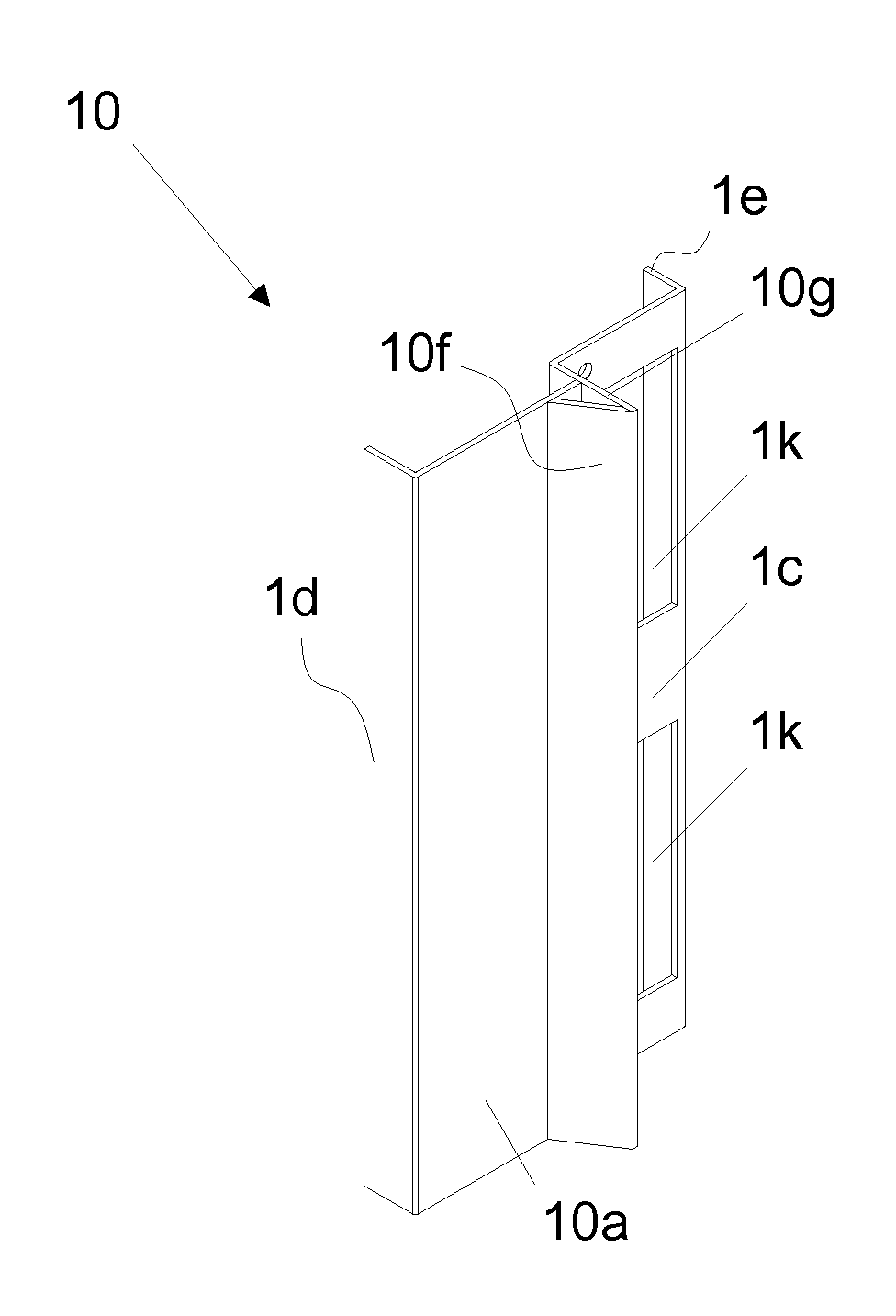

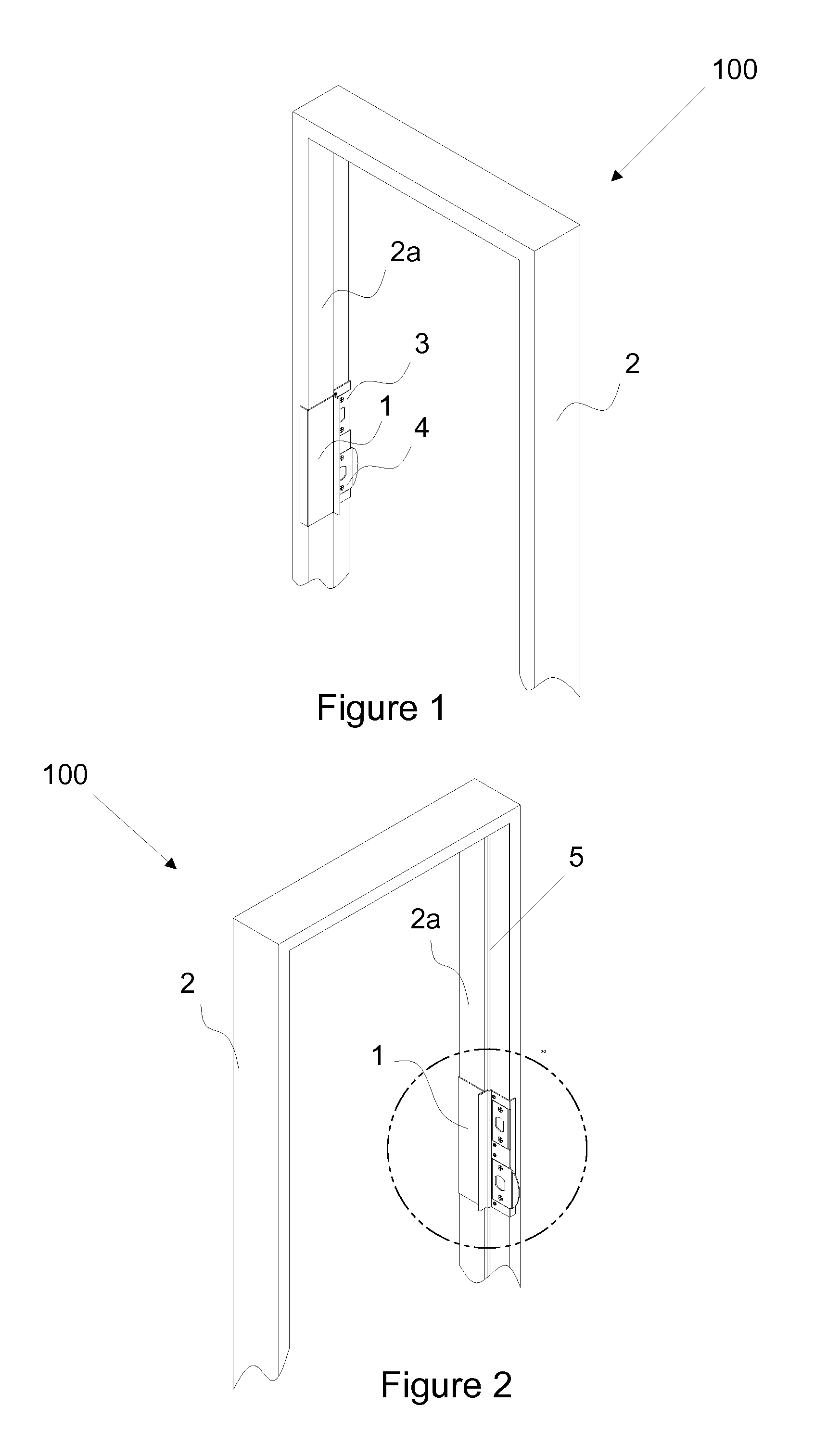

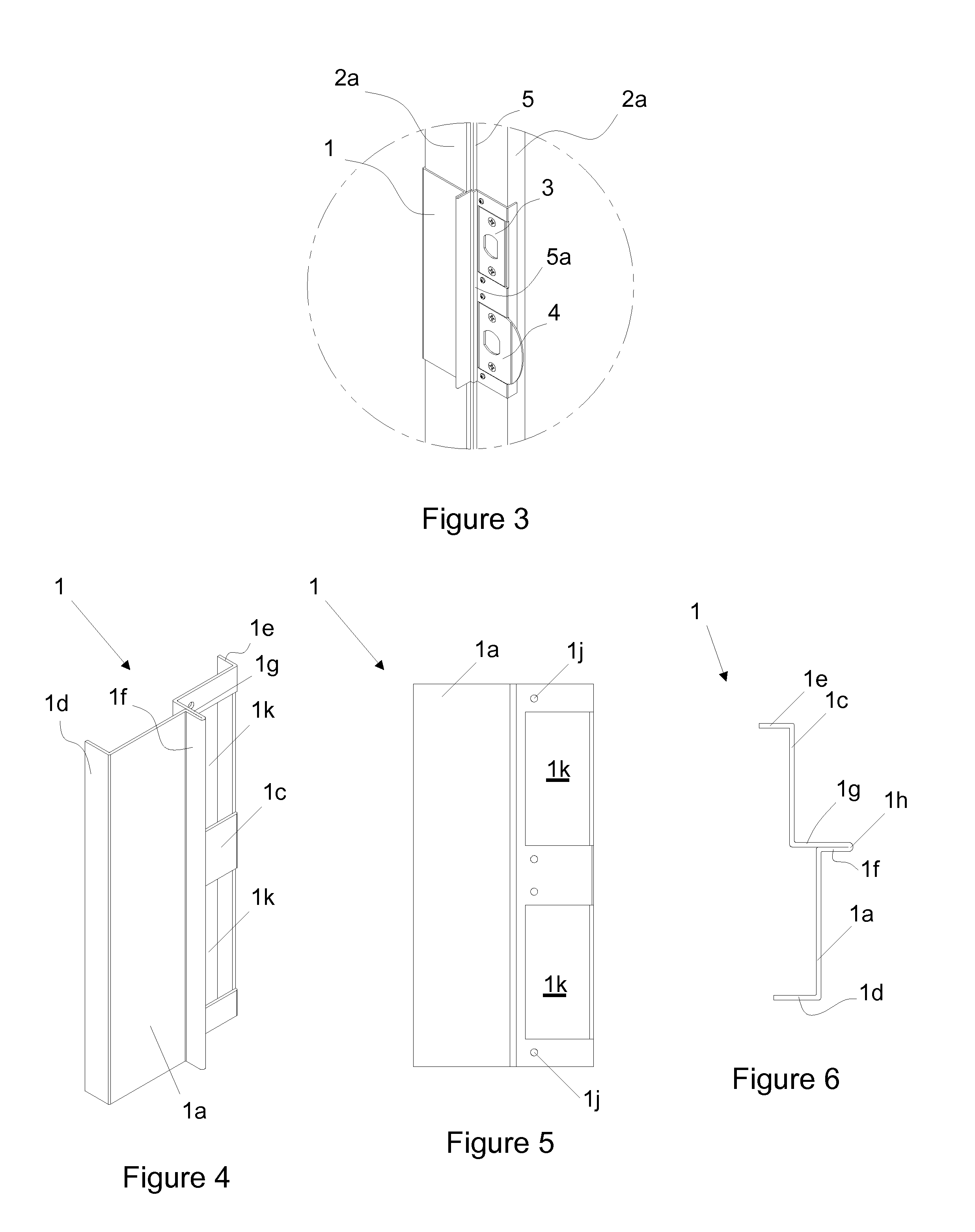

Safe and Secure Door Plate

InactiveUS20140346787A1Enhanced effectivenessImprove efficiencyBuilding locksWing fastenersEngineeringProtected area

A door plate provides better safety and security. The plate cannot be kicked in or provide access to a door to be picked. The door plate, in conjunction with a doorjamb, makes one strong unit. The door plate wraps the vulnerable area of the doorjamb with its steel property thus becomes more impervious to splitting the edge of the doorjamb or any part of the protected area of the wrapping.

Owner:MARTIN JR PAUL T +1

Machining and feeding mechanism of suspension frame assembly of electric vehicle

ActiveCN106743544AReduce the risk of accidentsFeeding height adjustment is stableConveyor partsElectric vehicleMachining

The invention discloses a machining and feeding mechanism of a suspension frame assembly of an electric vehicle. The mechanism includes a pick-up rotating disk, a plurality of pick-up operation support arms are arranged on the pick-up rotating disk, and two V-shaped pick-up connection rods are arranged on each pick-up operation support arm; a plurality of support arm mounting and adjusting grooves are formed in the pick-up rotating disk, and each support arm mounting and adjusting groove is internally provided with the corresponding pick-up operation support arm; the axis of a pick-up operation surface of the pick-up rotating disk is coaxially provided with a rotary fixation adjustment shaft, and the rotary fixation adjustment shaft is connected with each pick-up operation support arm through two mutually parallel fixation adjustment connection rods; The mechanism further includes an S-shaped feeding chute arranged between the two corresponding V-shaped pick-up connection rods on each pick-up operation support arm. The machining and feeding mechanism of the suspension frame assembly of the electric vehicle can effectively catch the suspension frame assembly of the electric vehicle and carry out feeding operation, and the feeding height of a stamping feeding mechanism is steadily adjusted.

Owner:QUANJIAO DONGRUN ELECTRONICS TECH

Display module, manufacturing method of display module, display panel and display device

The invention provides a display module, a manufacturing method of the display module, a display panel and a display device. The display module comprises a supporting layer, a bearing layer and a display function layer, and the supporting layer comprises a through hole; the bearing layer is positioned in the through hole, is fixedly connected with the side wall of the through hole and blocks one end of the through hole; the display function layer is arranged on the side, where the through hole is blocked, of the supporting layer; the bearing layer is in contact with the display function layer,and the bearing layer is used for supporting the display function layer. According to the display module provided by the invention, a die mark phenomenon can be avoided.

Owner:BOE TECH GRP CO LTD +1

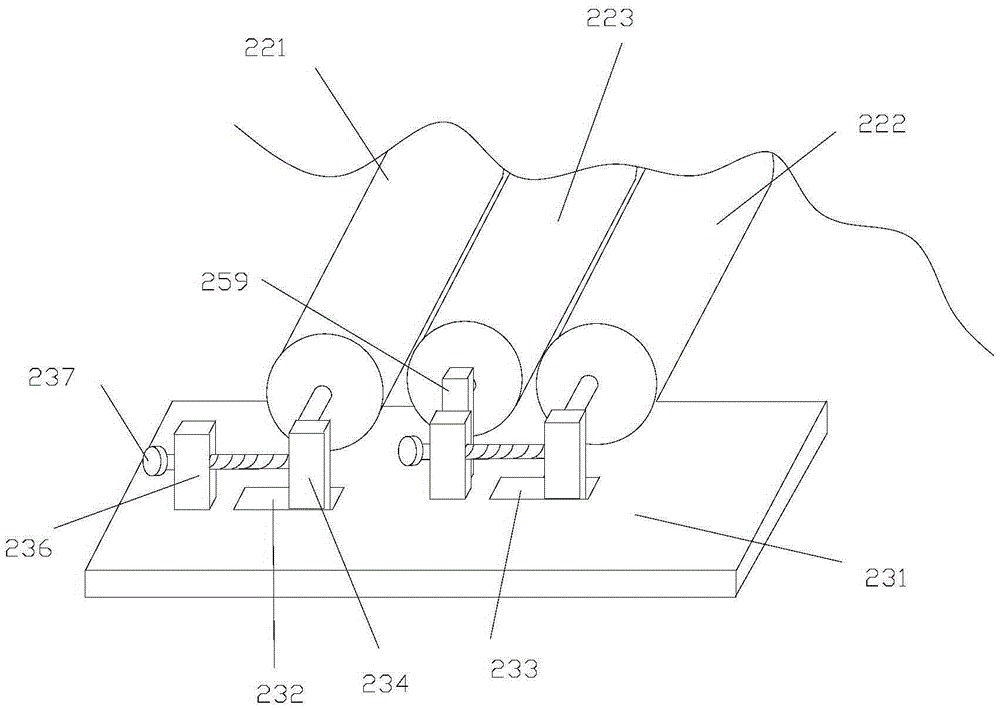

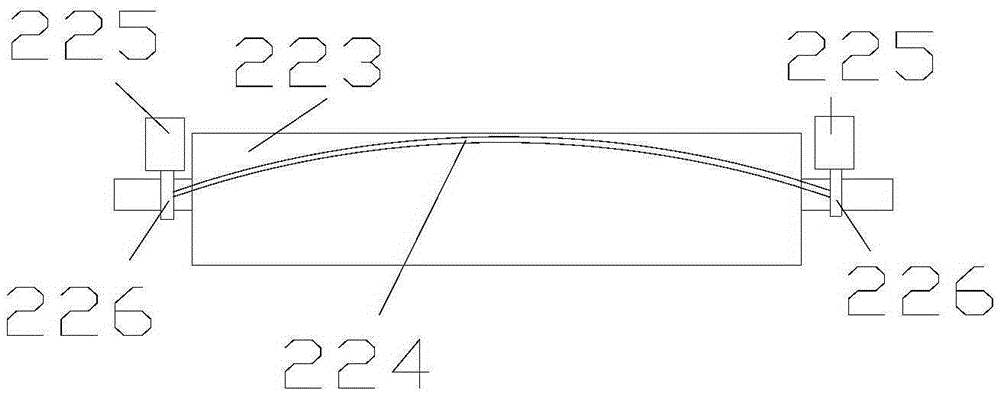

Rolling type film heat sealing machine

InactiveCN105398089AAvoid stampingGood thermal stabilityEnvelopes/bags making machineryWebs handlingEngineeringResistance wire

The invention discloses a rolling type film heat sealing machine which comprises a feeding roll and further comprises a heat sealing roll assembly. The heat sealing roller assembly is used for conducting heat sealing on a film fed by the feeding roll. The heat sealing roll assembly comprises a first traction roll, a second traction roll and a heat sealing roll arranged between the first traction roll and the second traction roll. The first traction roll and the second traction roll are arranged in parallel. The heat sealing roll is driven by a transmission mechanism to rotate and is further provided with an electric resistance wire. The electric resistance wire extends to the other end of the heat sealing roll from one end of the heat sealing roll to be connected with an external power source. The rolling type film heat sealing machine has the beneficial effects that the maintenance rate is low, the heat sealing stability is good, noise is small and a manufactured film bag is convenient to carry and easy to open.

Owner:ANQING XINSHUN PLASTIC CO LTD

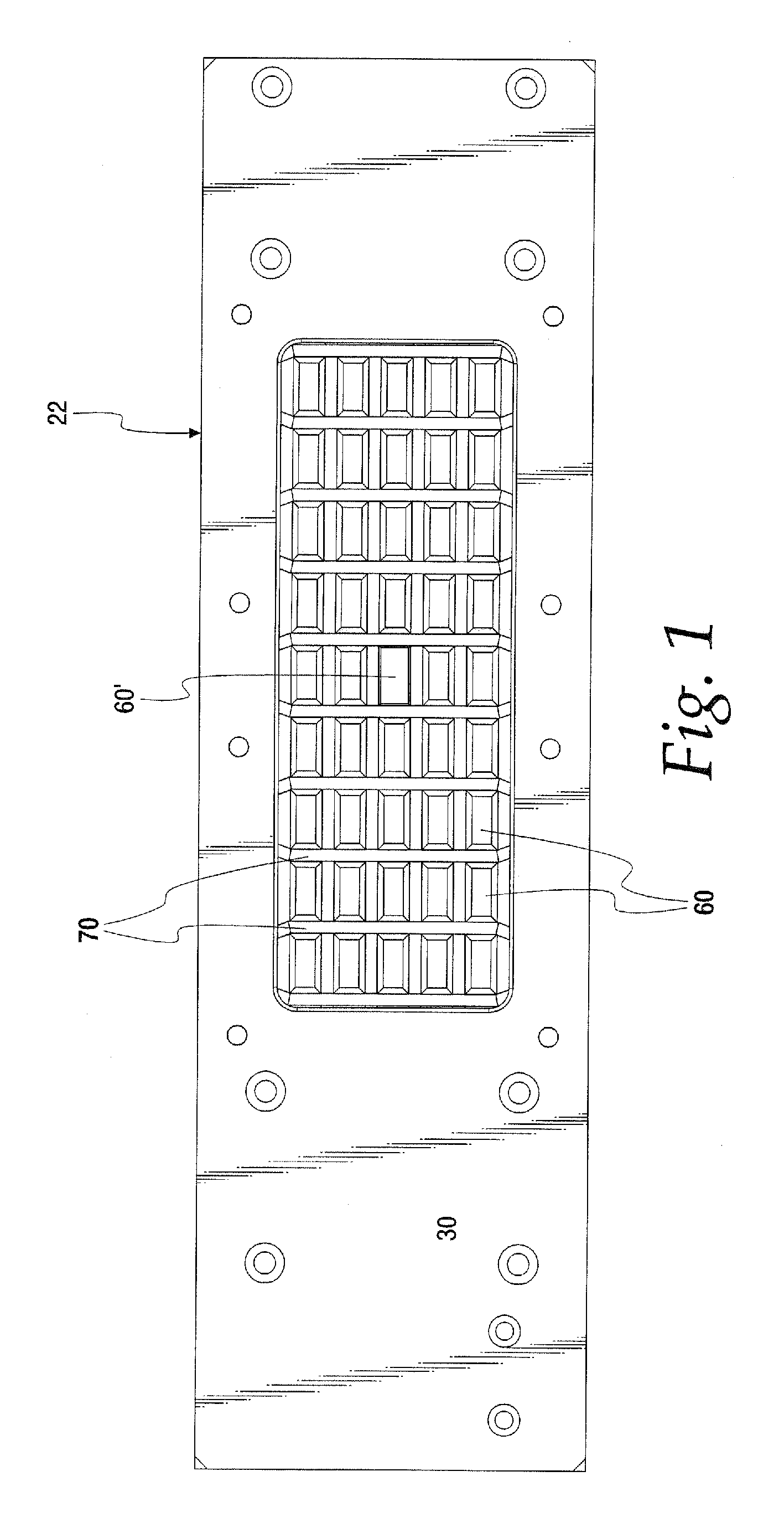

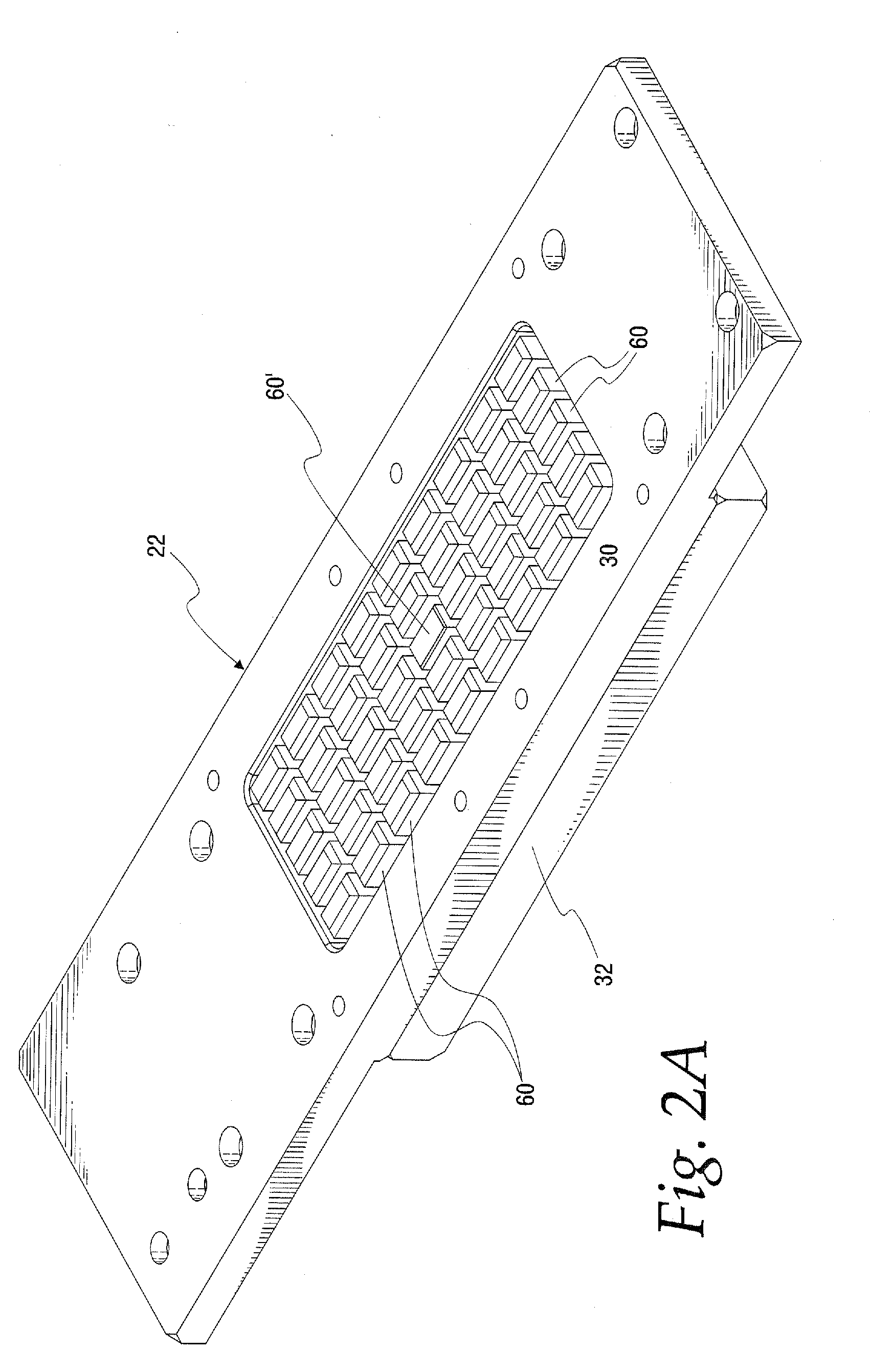

Adjustable Character Stamp

InactiveUS20110100237A1Easy to controlEasy to operateMechanical working/deformationRotary pressesEngineeringMechanical engineering

An adjustable stamp for stamping characters on a workpiece, including a base plate with a platen, a plurality of stamps each having a raised character on one side, a stamp holder, and a support securing the stamps to the holder in an array while allowing limited free motion of the stamps relative to each other in the stamping and retract directions. The support is mounted to the base plate for movement in a plane substantially perpendicular to the stamping direction to selectively position one of the stamps over the platen. The base plate and the workpiece may be pressed together, whereby the raised character of the one stamp is stamped into the workpiece by the platen pressing against the opposite side of the one stamp, with the free motion of the other stamps preventing their raised characters from being stamped into the workpiece.

Owner:PEDDINGHAUS

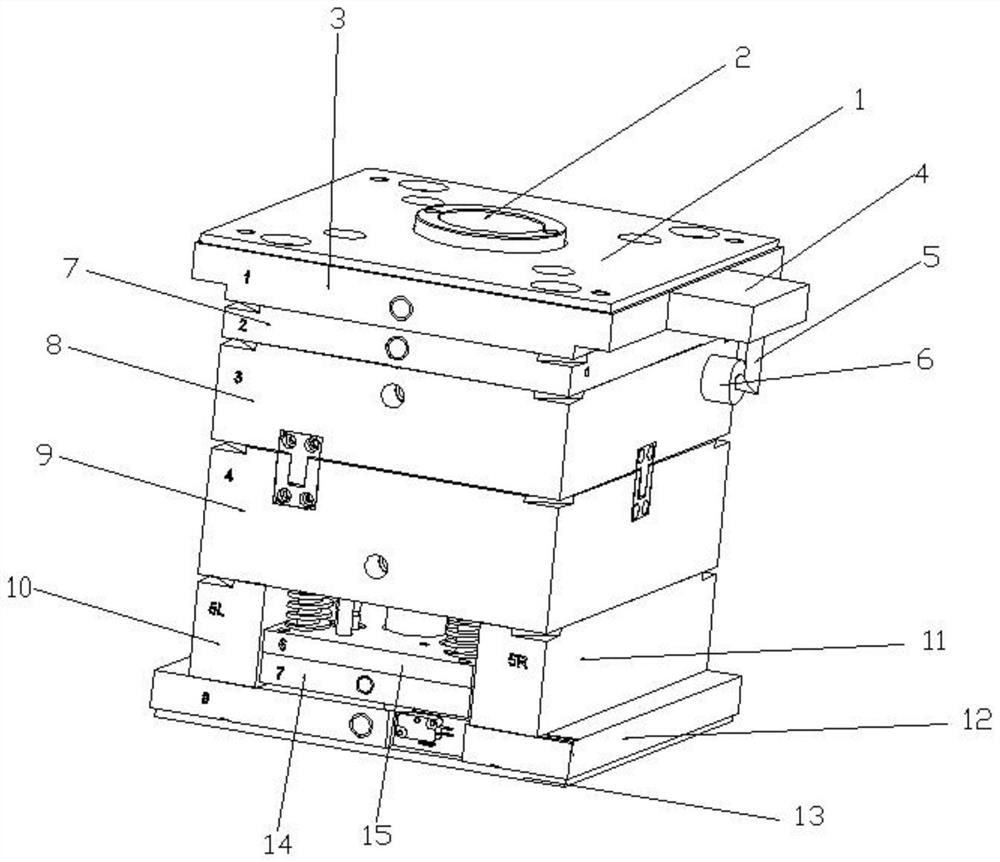

Injection molding device for processing plastic protective cap and working method thereof

The invention discloses an injection molding device for processing a plastic protective cap and a working method thereof. A support plate is fixedly connected to the right side of an upper fixed template, one end of a support frame is rotatably connected to the bottom of the right side of the support plate, a powerful fan is fixedly connected to the other end of the support frame, a first mountinggroove matched with a sprue bushing is formed in the center of the top of the upper fixed template, the sprue bushing is fixedly mounted in the first mounting groove through screws, the upper fixed template is movably connected with a runner plate and a fixed template, the fixed template is positioned on the lower side of the runner plate, a fixed die core is fixedly mounted in the middle of thebottom end of the fixed template through screws, a runner block is movably mounted in the middle of the top end of the fixed template, and the runner block is extruded and fixed to the fixed templatethrough the top of the fixed die core. By the adoption of the structure, the plastic protective cap is easy to demold, unnecessary flash is prevented, a mechanism is convenient to disassemble, and repair and maintenance are facilitated.

Owner:宁国市锦鼎橡塑制品有限公司

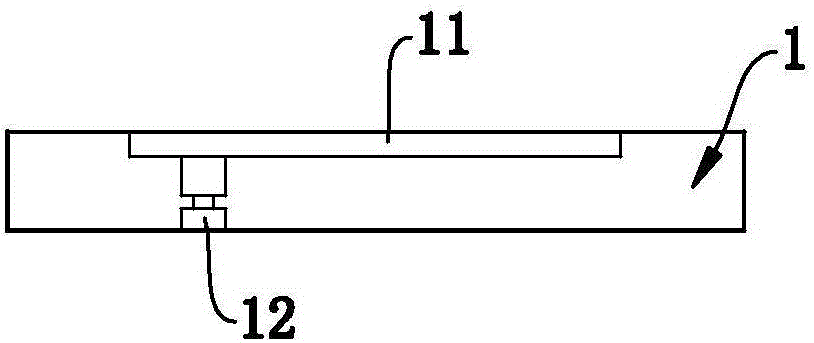

Mold insert core monitoring system, mold system and using method of mold system

InactiveCN106113430AReduce the frequency of exceptionsPlacement monitoringControl systemDisplay device

The invention discloses a mold insert core monitoring system and belongs to the technical field of injection molds. The mold insert core monitoring system comprises a mold plate. An insert core is installed on the first side of the mold plate in a separable mode. A limit switch used for detecting the insert core is arranged on the second side of the mold plate. The limit switch corresponds to the insert core and is electrically connected with a control system of a mold. The limit switch is also connected with a signal display device. The invention further discloses a mold system comprising the mold insert core monitoring system. The invention further discloses a using method of the mold system. The mold system is adopted by the using method. The using method of the mold system comprises the step of installing the insert core on a manipulator, the step of installing the insert core on the mold plate, and the step of mold assembly. By the adoption of the mold insert core monitoring system, the mold system and the using method of the mold system, the installation condition of the insert core can be effectively monitored, the mold is well protected, and unnecessary mold repairing cost is reduced; and the anomaly frequency of the mold is reduced, the stability of product quality is improved, the working efficiency is improved, and normal shipment of products is guaranteed.

Owner:GOERTEK INC

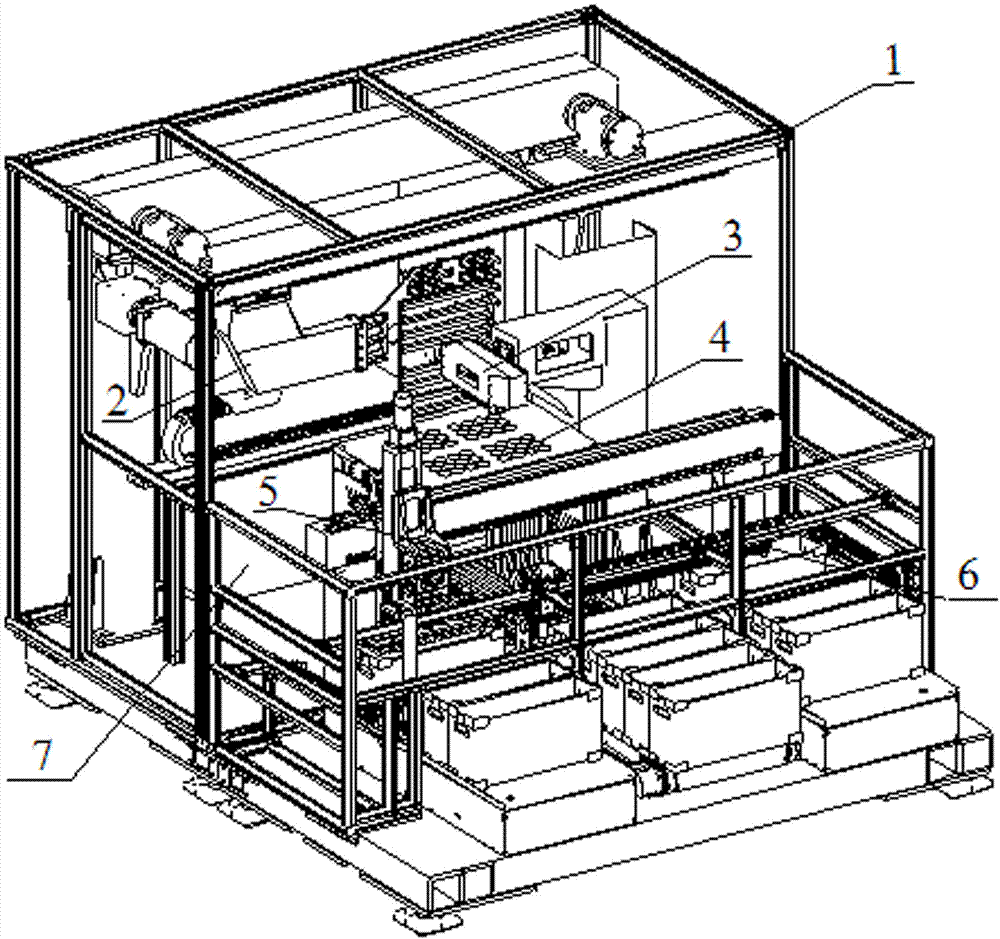

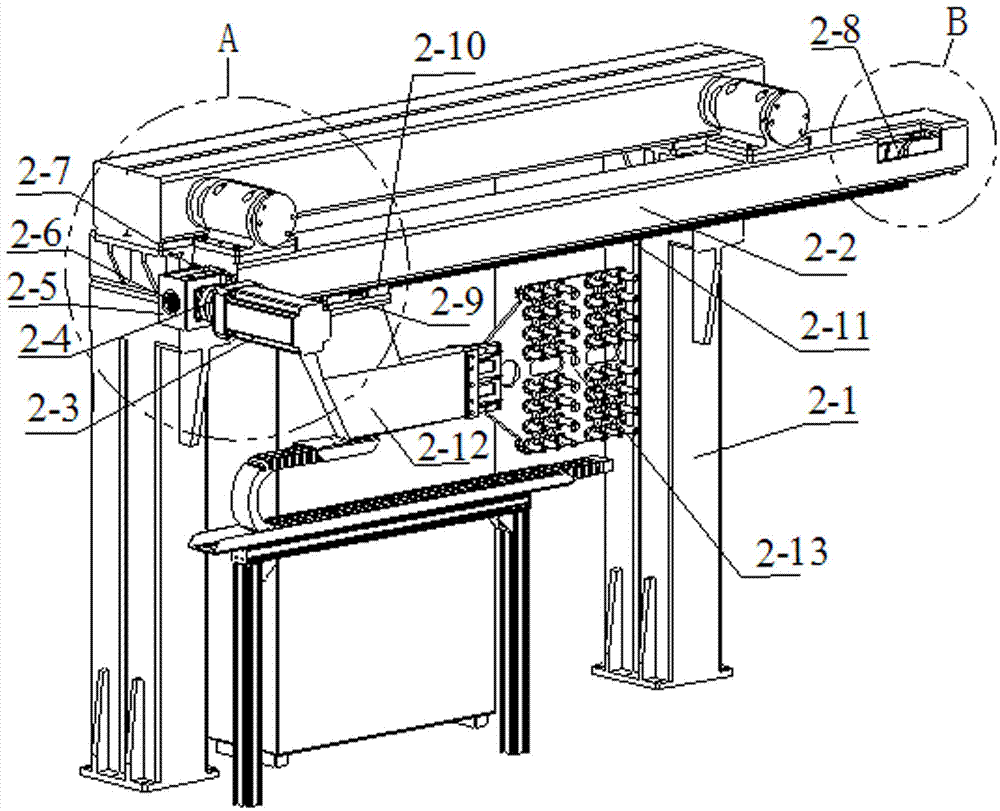

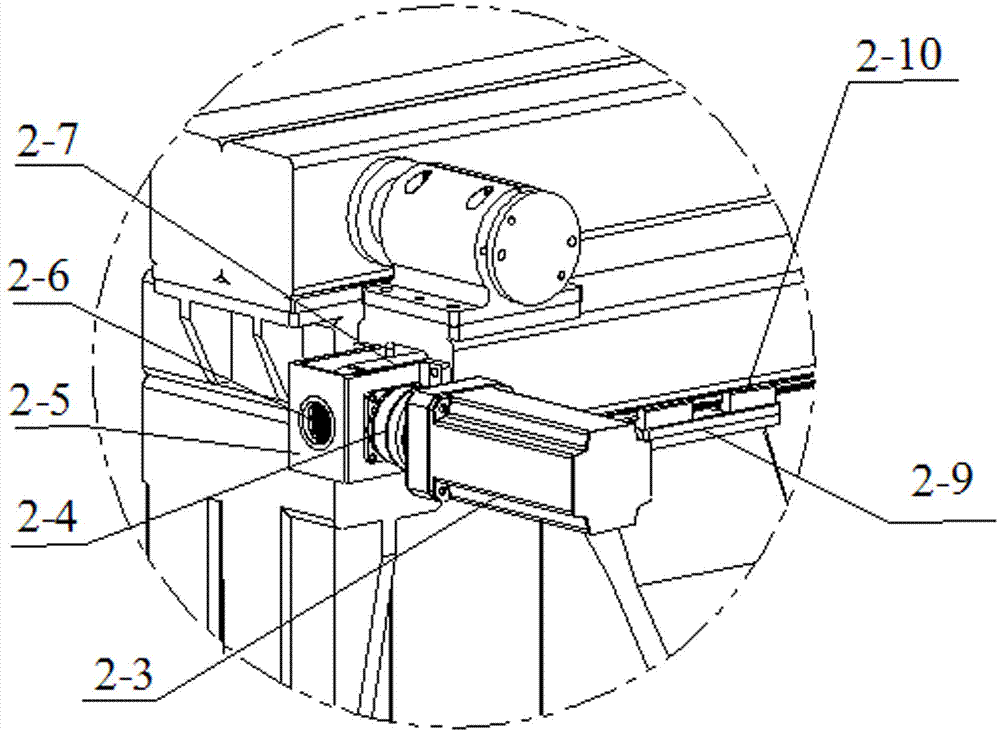

A system for automatically taking out and packing blood collection tubes for medical use

Owner:NINGBO WELLLIH ROBOTS TECH CO LTD

A punching and feeding mechanism for automobile beam welding sub-assembly

ActiveCN106583574BSmooth feedingEasy to adjustMetal-working feeding devicesVehicle componentsEngineeringWelding

The invention discloses a stamping feeding mechanism of automobile beam welding subassemblies. The stamping feeding mechanism comprises a part taking rotary disc, and a plurality of part taking operation support arms are arranged on the part taking rotary disc; two V-shaped part taking connecting rods are arranged on each part taking operation support arm; a plurality of support arm mounting adjusting grooves are formed in the part taking rotary disc; each part taking operation support arm is arranged in the corresponding support arm mounting adjusting groove; a rotating fixing adjusting shaft is coaxially arranged at the axis part of a part taking working plane of the part taking rotary disc as well; the rotating fixing adjusting shaft is connected with each part taking operation support arm through two parallel fixing adjusting connecting rods; and limiting folding edges, mounting fixing baffles and mounting fixing bolts are arranged at part taking connecting rod fixing ends of the V-shaped part taking connecting rods. The stamping feeding mechanism is applicable to processing of the automobile beam welding subassemblies of different specifications and shapes, and adjustment of the feeding height of the stamping feeding mechanism is stable.

Owner:宁波宏科汽车部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com