Leather belt wheel for driving belt and belt driving apparatus

A technology of belt drive and pulley, applied in the direction of transmission, belt/chain/gear, hoisting device, etc., can solve the problems of insufficient utilization and increase the manufacturing cost of flat wheel, so as to avoid friction loss and improve durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

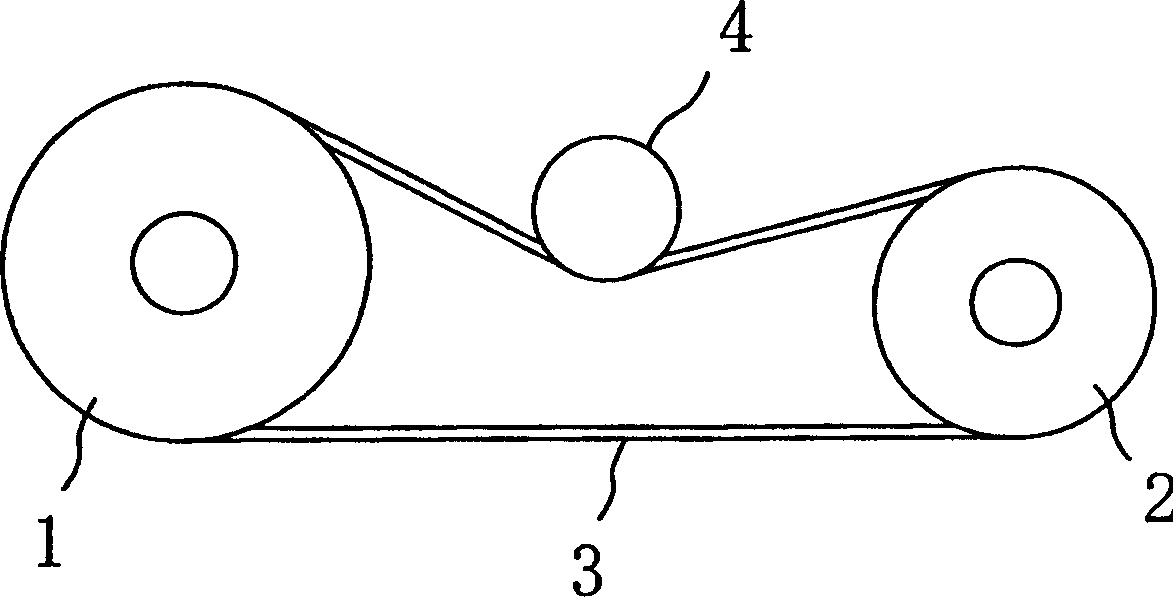

[0031] exist figure 1 In the belt drive shown, 1 represents the driving pulley (flat edge pulley), and 2 represents the driven pulley (flat edge pulley). These two pulleys 1 and 2 are wound with a flat transmission belt 3, and the flat edge pulley 3 is connected to the pulley 4 crimping.

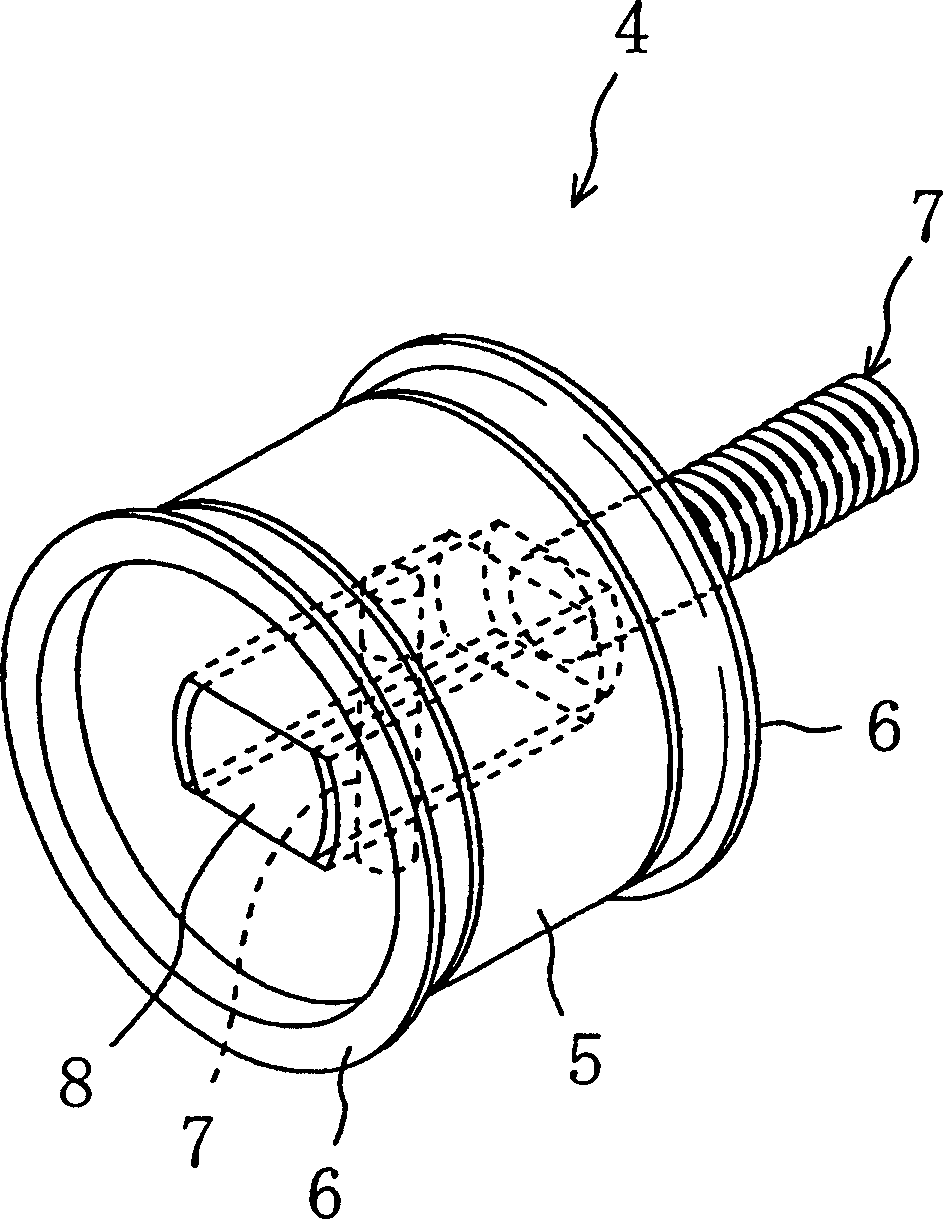

[0032] pulley 4 as figure 2 As shown, it has: a pulley body 5 with a flat transmission belt 3 wound around it, transmission parts 6 and 6 arranged on both sides of the pulley body 5, a supporting mechanism that supports the pulley body 5 and transmission parts 6 and 6 and enables them to swing freely 7. The support mechanism 7 is composed of a support rod 8 and a pivot 9 .

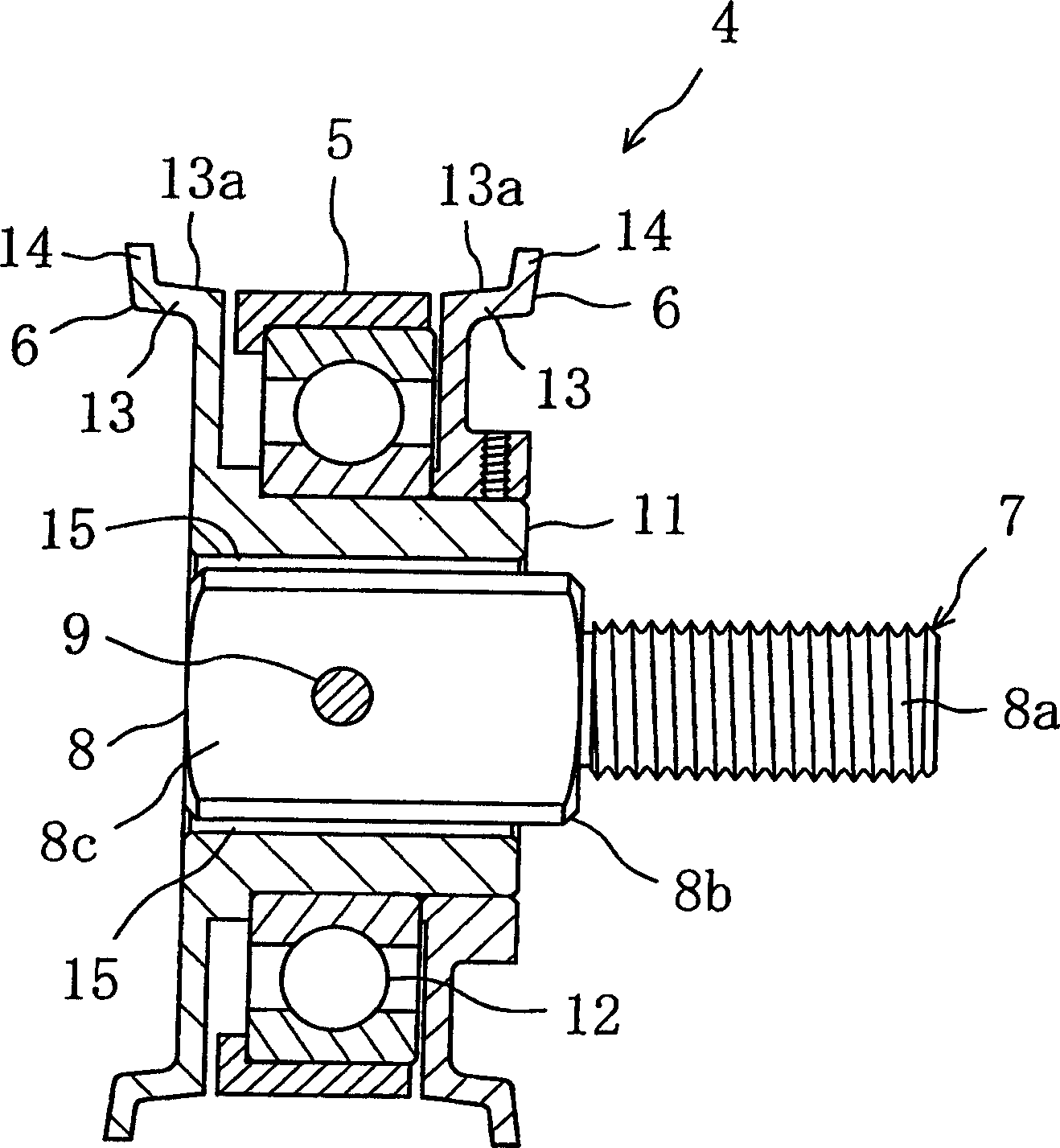

[0033] Such as image 3 As shown, the pulley body 5 is supported by the cylindrical shaft member 11 by the bearing 12, and is freely rotatable. The transmission member 6 on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com