Asphalt pavement crack filling device

A technology of asphalt pavement and asphalt, which is applied in the field of asphalt pavement crack filling device, which can solve the problems of pavement damage, increased workload, and reduced filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

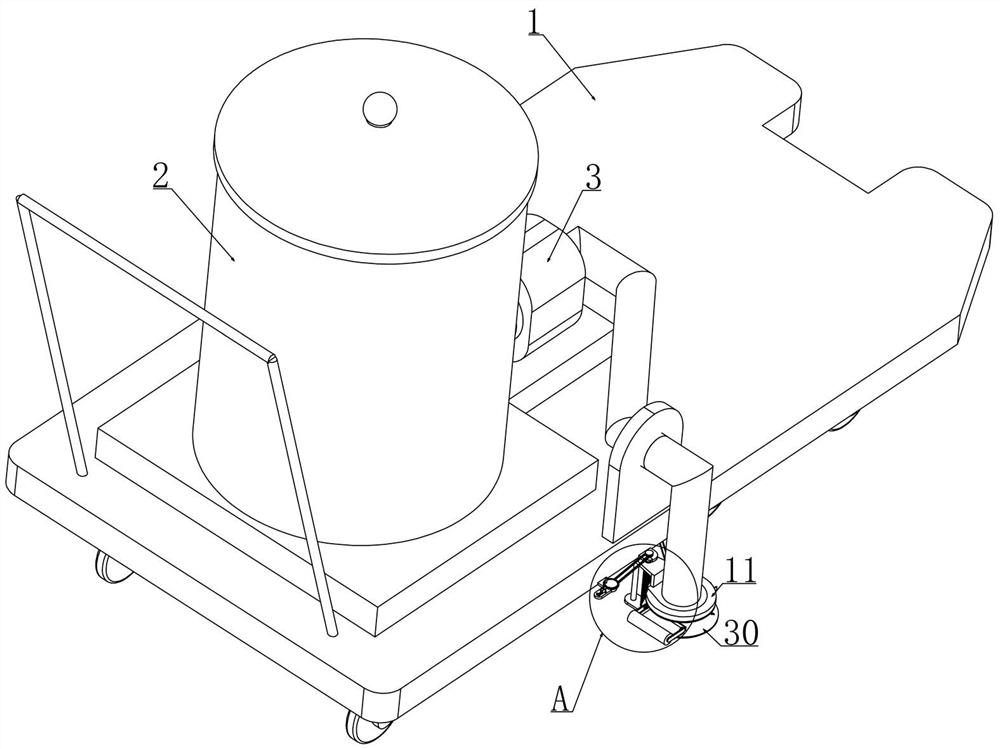

[0041] Embodiment 1, this embodiment provides a kind of asphalt pavement crack filling device, refer to the attached Figure 5 As shown, it includes a trolley 1, and a hot melt box 2 is fixedly installed on the trolley 1 near the handrail, which provides asphalt (asphalt mortar) or joint glue with a temperature that meets the requirements, and there is a paddle-type forced stirring inside. The mixer 43 and grid-type heat conduction coil are used to ensure that the asphalt material is evenly heated. The mixer 43 is driven by a dedicated asphalt mixer 43 drive motor and the drive motor of the asphalt mixing ball is connected to a battery fixed on the cart 1, and the electric There is a controller connected permanently, and the heat transfer oil is indirectly heated by a small gas-fired heating furnace (this is the existing technology, so I won’t go into details here), and the temperature can be automatically adjusted. Thinning), start the agitator 43 to stir the asphalt material...

Embodiment 2

[0044] Embodiment 2, on the basis of embodiment 1, with reference to appended Figure 5 As shown, the conveying system includes an asphalt pump 3 that communicates with the bottom of the hot melt tank 2 and is fixedly installed on the trolley 1, and the asphalt pump 3 is driven by a drive device, which is generally a dedicated drive motor for the asphalt pump 3 drive, And this driving motor is also electrically connected with the controller and connected with the battery, and the asphalt pump 3 is connected with the nozzle 4, and because the melted joint glue has a higher temperature, the general pipeline is easy to be damaged, and in the transmission process If the joint glue melts in it, it will be clogged and the whole device cannot be used. Therefore, we use an electric heating discharge hose for the pipeline connecting the asphalt pump 3, the nozzle 4, and the hot melt tank 2. Electricity is used as the heating condition, and it is equipped with a temperature control sens...

Embodiment 3

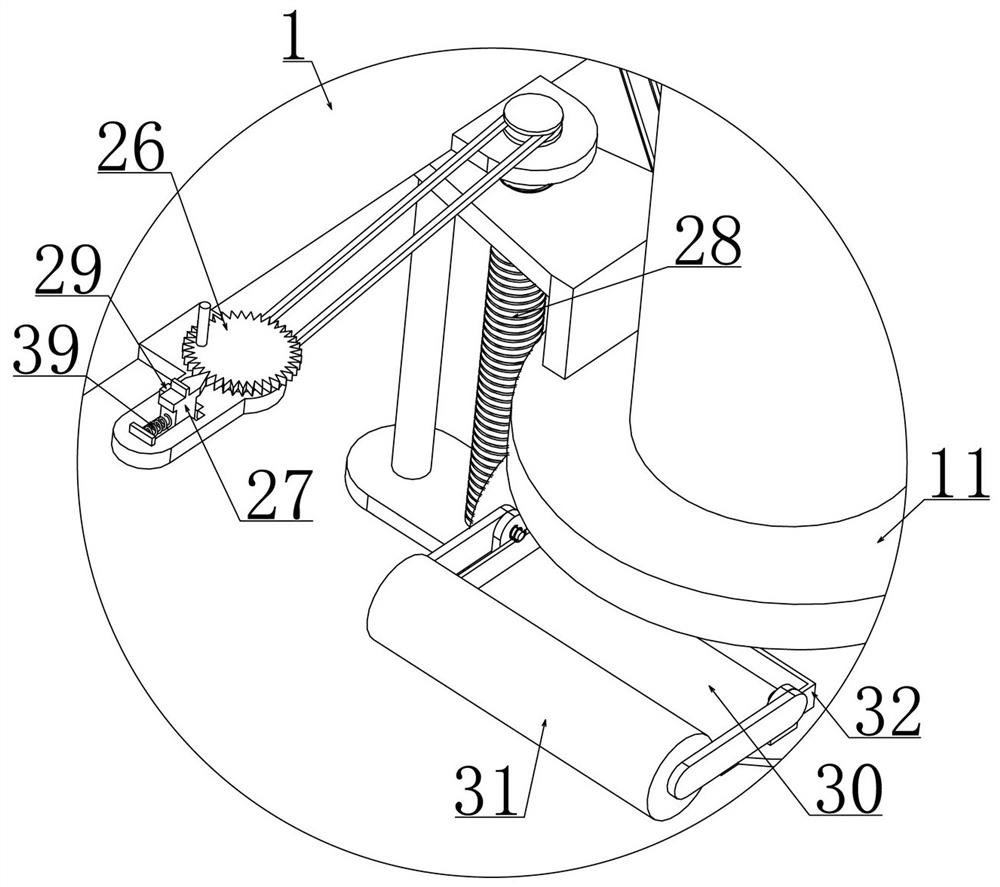

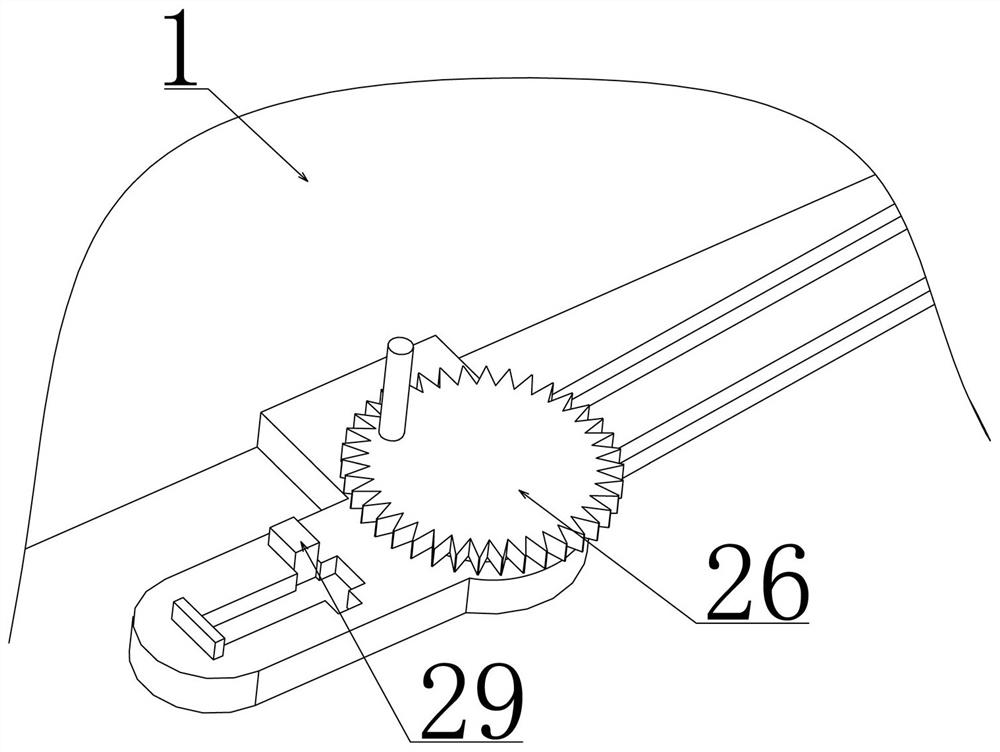

[0046] Embodiment 3, on the basis of embodiment 2, with reference to appended Figure 7 , attached Figure 8 , attached Figure 9 And attached Figure 11 As shown, the flow control device includes an installation cylinder 11 arranged on the upper end of the nozzle 4 and communicated with the electric heating discharge hose, and the top wall of the installation cylinder 11 is rotatably installed with a drive plate 12, and the lower end of the drive plate 12 is provided with six etc. The side-shaped chute 13, in addition, the bottom wall of the installation cylinder 11 is also provided with straight grooves 14 corresponding to the six sides of the chute 13 at equal intervals, and the straight grooves 14 are tangent to the inner wall of the nozzle 4, and the six straight grooves 14 is slidably installed with a flow control plate 15, and each flow control plate 15 is slidably matched with a part of a side of the hexagonal chute 13, so that when we rotate the drive plate 12, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com