Plug-in type cable head disassembling tool

A plug-in cable head and tool technology, which is applied in the direction of connecting/terminating cable equipment, switchgear, electrical components, etc., can solve the problems of uneven stress distribution, tilting, and cable terminal offset of the cable terminal. To achieve the effect of reducing assembly and disassembly staff, easy to use, and solving small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

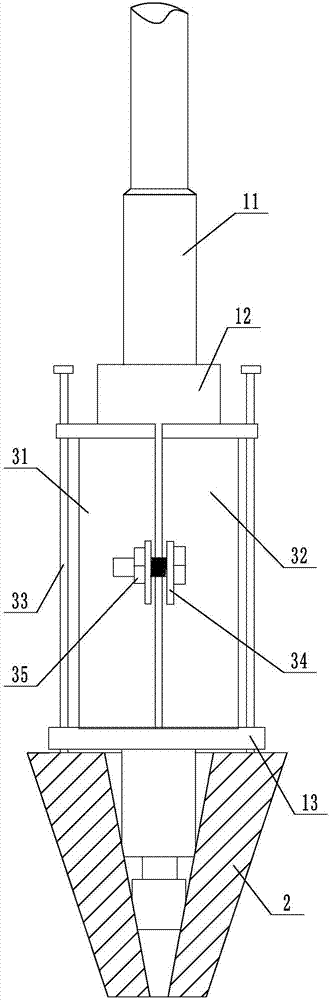

[0026] Such as Figure 1 to Figure 4 as shown,

[0027] The cable plug is prior art, including cable 11, upper deck 12 and lower deck 13, the upper deck is connected with the lower deck, and the cable is inserted in the upper deck and the lower deck.

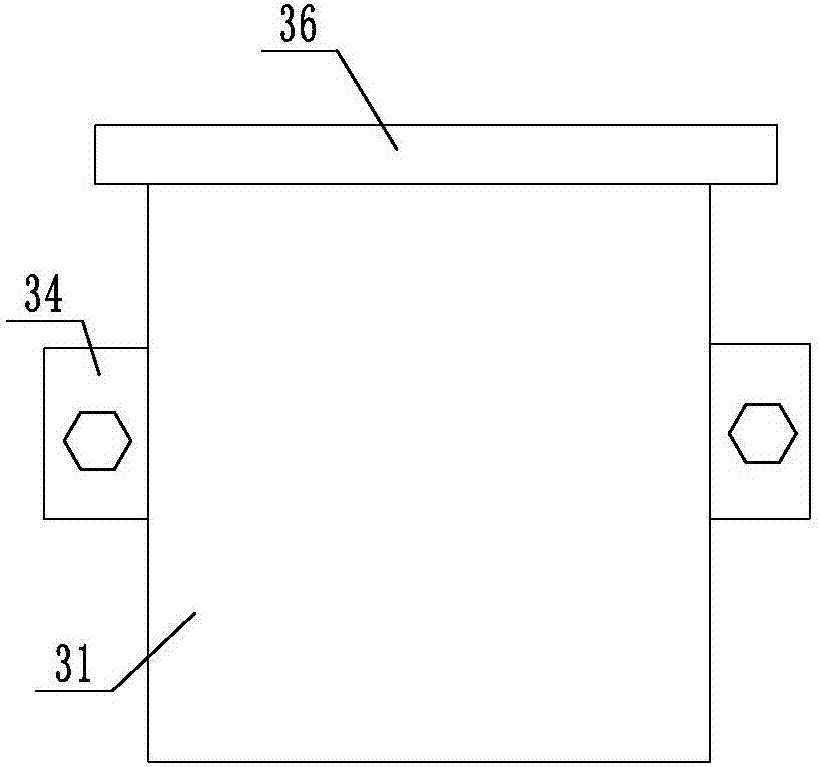

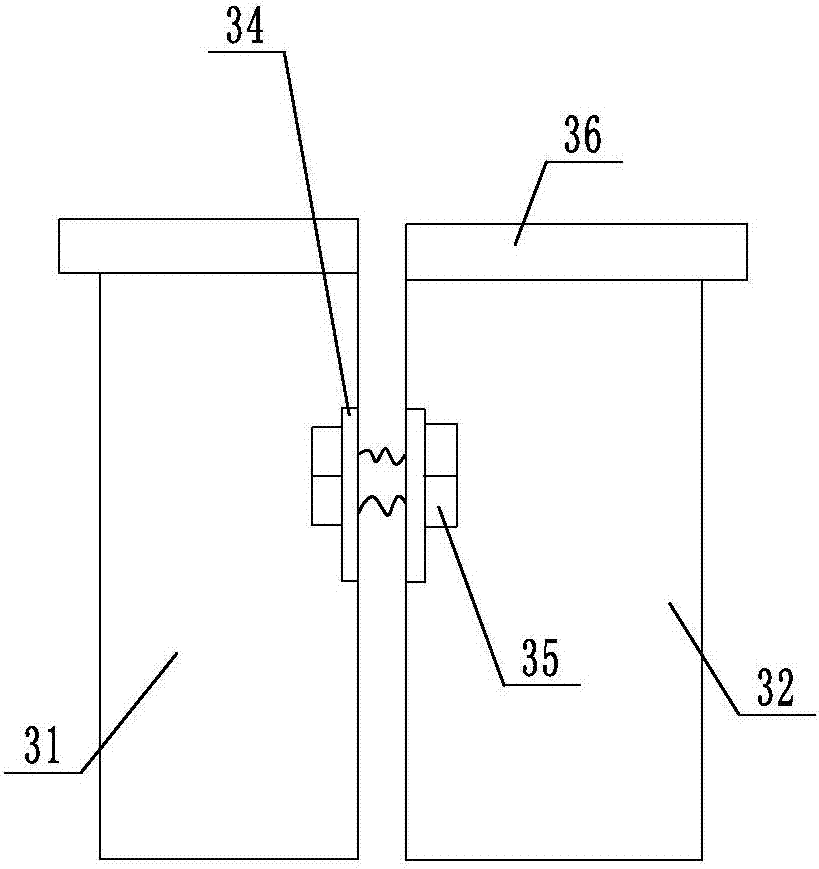

[0028] A lead screw assembly is provided on the upper deck, and the lead screw assembly includes a left half ring 31, a right half ring 32, a lead screw 33, a locking plate 34, a bolt 35 and a lead screw pressure plate 36, the left half ring and the right half ring There are locking plates on the rings, and the left half ring and the right half ring are connected together by bolts and nuts at the locking plates.

[0029] The diameter of the ring surrounded by the left half ring and the right half ring is larger than the diameter of the upper clamping platform, and the ring is sleeved on the outside of the upper snap ring.

[0030] The upper side of the left half ring and the right half ring is provided with a lead screw pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com