Hot rolled band for container and method for manufacturing same

A manufacturing method and container technology, applied in the direction of metal rolling, manufacturing converters, etc., can solve the problems of increasing the manufacturing cost of steel strips, affecting the stable production and safe use of containers, and the mechanical properties and molding fluctuations of finished products, so as to achieve good forming performance , the content of harmful elements and the effect of low levels of banded tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The good formability hot-rolled steel strip thickness of this embodiment container is 4.5mm, and the mass percentage ratio of chemical composition is:

[0036] C: 0.069 Si: 0.23 Mn: 1.21 P: 0.010 S: 0.003

[0037] Ti: 0.023, the rest is Fe and unavoidable impurities.

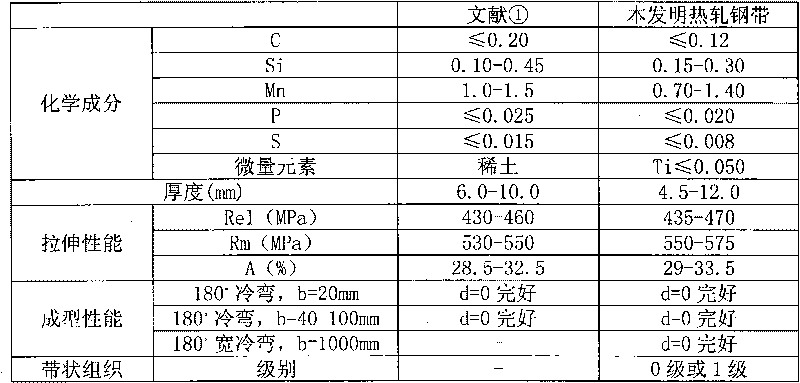

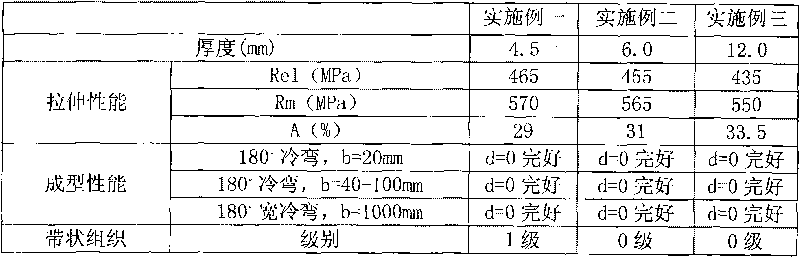

[0038] Table 2 shows the test results of the mechanical properties, formability and strip structure of the hot-rolled steel strip in this embodiment.

[0039] Table 2

[0040]

Embodiment 2

[0042] The good formability hot-rolled steel strip thickness of this embodiment container is 6.0mm, and the mass percentage ratio of chemical composition is:

[0043] C: 0.071 Si: 0.26 Mn: 1.29 P: 0.011 S: 0.003

[0044] Ti: 0.025, the rest is Fe and unavoidable impurities.

[0045] Table 2 shows the test results of the mechanical properties, formability and strip structure of the hot-rolled steel strip in this embodiment.

Embodiment 3

[0047] The good formability hot-rolled steel strip thickness of this embodiment container is 12.0mm, and the mass percentage ratio of chemical composition is:

[0048] C: 0.055 Si: 0.19 Mn: 1.38 P: 0.009 S: 0.002

[0049] Ti: 0.029, the rest is Fe and unavoidable impurities.

[0050] Table 2 shows the test results of the mechanical properties, formability and strip structure of the hot-rolled steel strip in this embodiment.

[0051] Manufacturing method embodiment one

[0052] What the present embodiment made was the steel strip embodiment one, and the manufacturing method of the present embodiment comprises the following steps in sequence:

[0053] A preparation of continuous casting slab

[0054] Through hot metal pretreatment desulfurization, 180-ton top-bottom compound blowing converter smelting, LF refining and slab continuous casting, the mass percentage ratio of the chemical composition of the continuous casting billet obtained is:

[0055] C: 0.069 Si: 0.23 Mn: 1.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com