Film blowing and heat sealing integrated machine

An all-in-one, film blowing machine technology, used in envelope/bag manufacturing machinery, paper/cardboard containers, thin material handling, etc., can solve the problems of high cost, high noise, inconvenient portability, etc., and reduce the floor space. , Cost saving, good heat sealing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

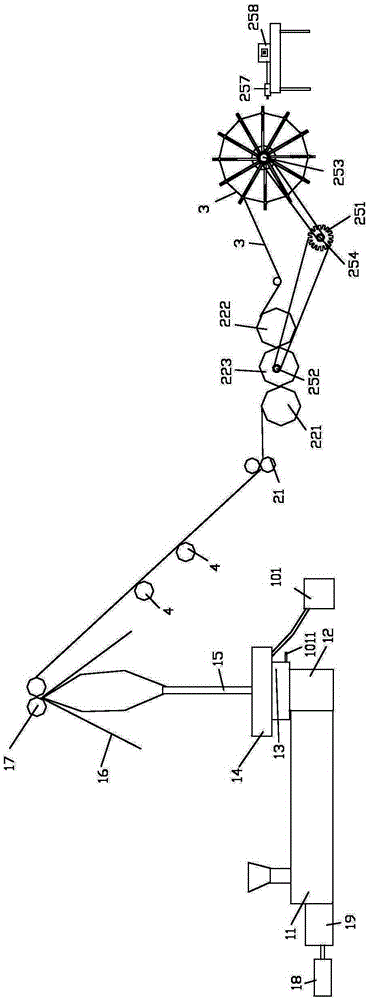

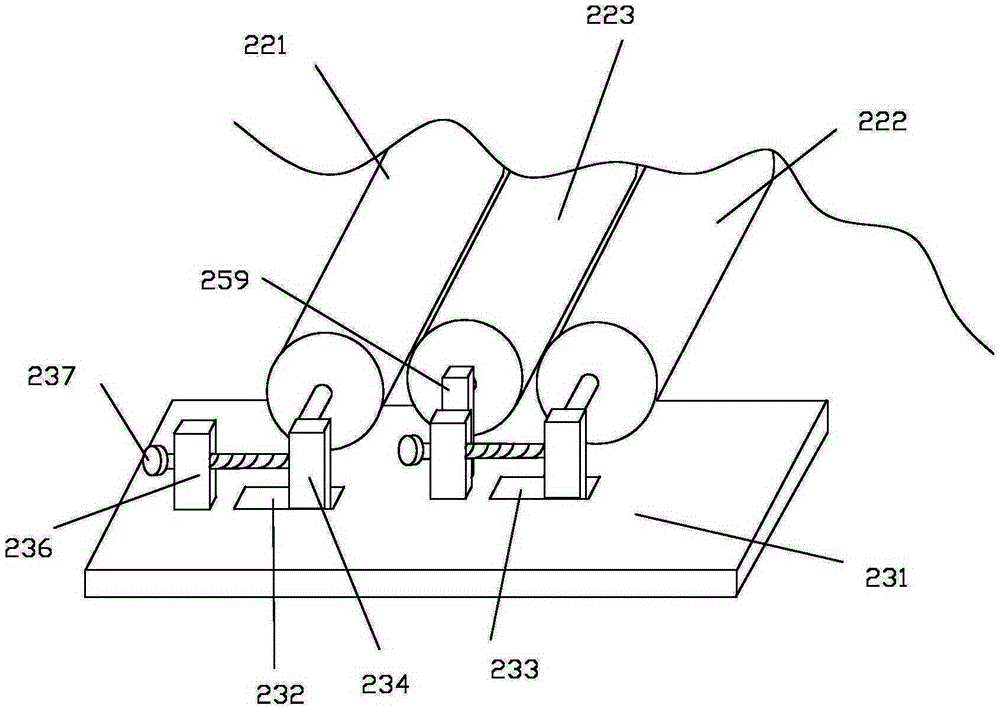

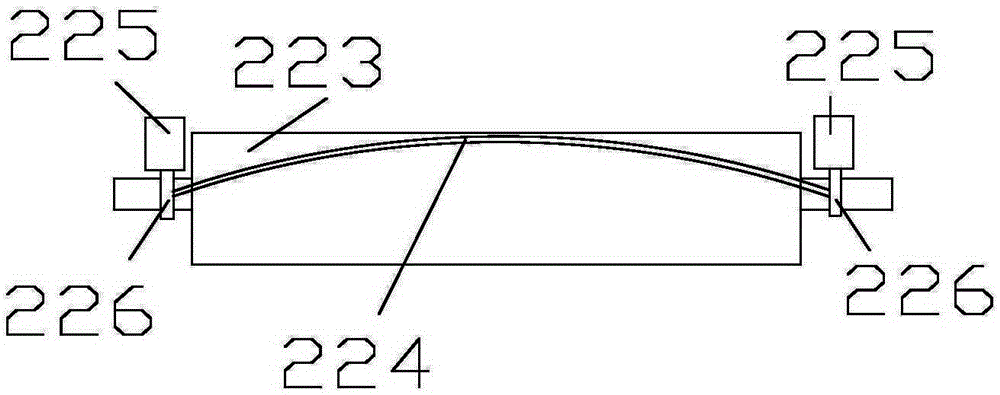

[0036] Such as figure 1 As shown, this embodiment discloses a blown film heat bonding machine, including a blown film machine body, which is an existing equipment, including an extruder 11, a filter device 12, a die head 13, an air ring 14, a mandrel 15, Herringbone plate 16, first traction device 17, motor 18, speed reducer 19, blower 101. Motor 18 is connected with one end of reducer 19, and the other end of reducer 19 is connected with one end of extruder 11, and die head 13 is arranged on the other end of extruder 11 through filtering device 12, and one side of die head 13 is provided with Air nozzle 1011. A filter screen is provided in the filter device 12 . The air ring 14 is installed on the die head 13, and the air blower 101 is connected with the air ring 14 through a pipe. The middle part of the die head 13 is coaxially equipped with a mandrel 15, a her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com