Automatic machining device of car damper support

An automobile shock absorber and automatic processing technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of prone to industrial accidents, irregular and special-shaped structures, and high danger, and achieves improved efficiency and equipment. Degree of automation, avoidance of stamping operations, and reduced risk effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

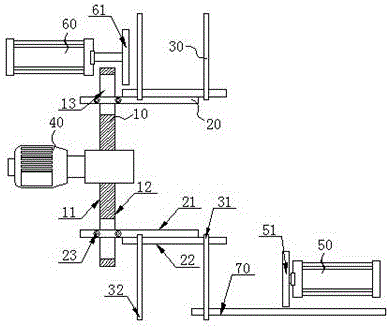

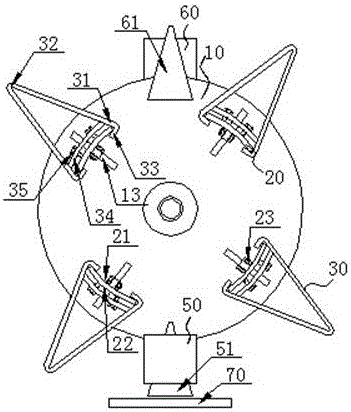

[0016] refer to Figure 1 to Figure 2 , Figure 1 to Figure 2 It is a structural schematic diagram of a specific embodiment of the present invention.

[0017] Such as Figure 1 to Figure 2 As shown, an automatic processing device for an automobile shock absorber bracket includes a pick-up rotary disc 10, a clamping feed cylinder 50 arranged below the pick-up rotary disc 10 and a clamping feed cylinder 50 arranged on the pick-up rotary disc 10 above the clamping and returning material cylinder 60, the free end of the piston rod of the clamping feeding cylinder 50 is provided with a clamping feeding push plate 51, and the free end of the piston rod of the clamping and returning material cylinder 60 is provided with a clamping Return material pushing plate 61; The two sides of described pick-up rotary disc 10 are respectively driving connection surface 11 and pick-up work surface 12, and the pick-up work face 12 of described pick-up rotary disc 10 is provided with several pick-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com