Method and mechanism for accurately controlling heat-seal temperature of heating wire

A technology of precise control and electric heating wire, which is applied in the direction of electric heating devices, electrical components, bag making operations, etc., can solve the problems of inaccurate intermittent time, inability to output accurate voltage, unstable film sealing, etc., to improve product quality and heat sealing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

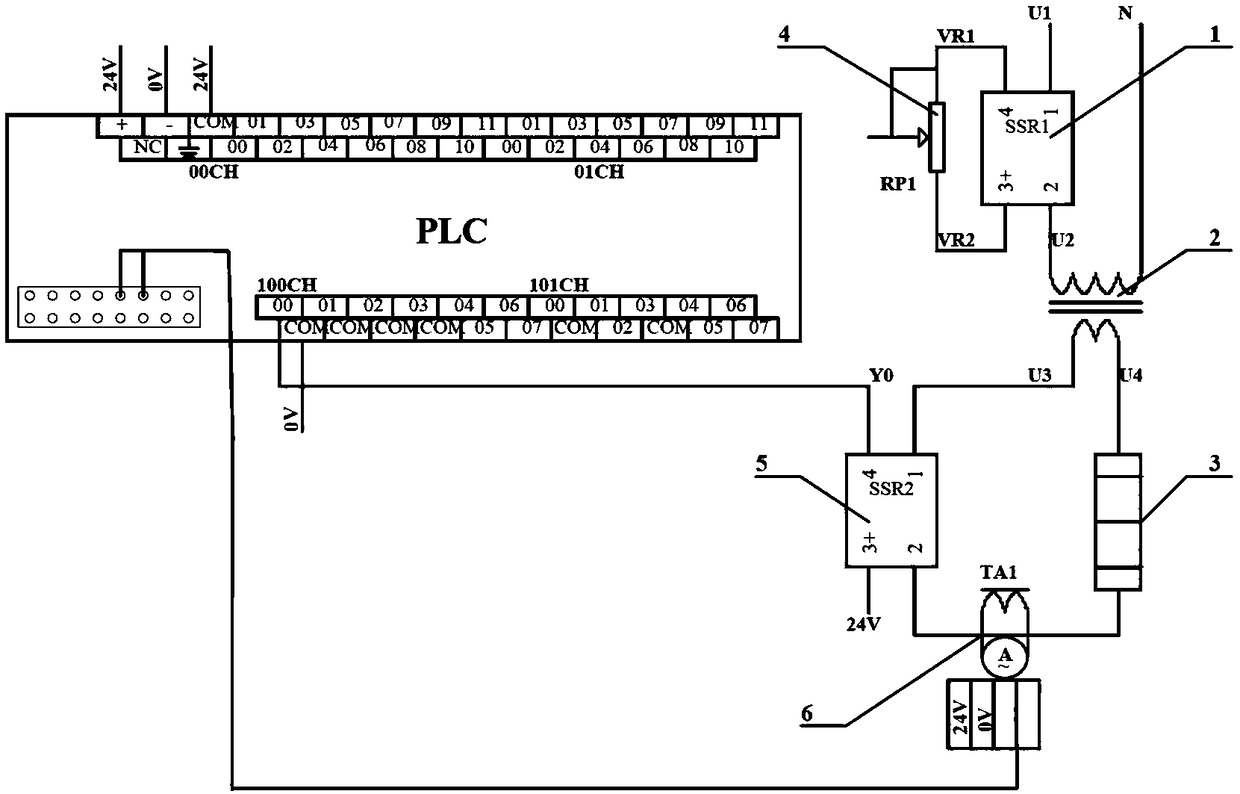

[0014] Such as figure 1 As shown, a control method for precisely controlling the sealing temperature of the heating wire includes:

[0015] 1), generate the first base voltage 2, the second variable voltage and superimpose and connect the heating wire, the first base voltage is a constant current DC voltage, and the first adjustment potentiometer 4 is set to adjust the voltage variablely, And the first solid state relay 1 carries out on-off control to the output of the first basic voltage; the second variable voltage is a PWM DC voltage, and the second solid state relay 5 is set to carry out on-off control on the output of the second variable voltage; the second solid state relay The output end of a Hall current sensor 6 is connected to the heating wire 3 in series;

[0016] 2), with a PLC controller, the PID module and the PWM controller that the PLC controller contains, the PLC controller is connected to the control terminal of the first solid state relay, the second solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com