Disposable isolation bedding manufacturing process and equipment

A technology for manufacturing equipment and isolation beds, which is applied in the direction of textiles and papermaking, bed sheets, non-woven fabrics, etc. It can solve problems such as low efficiency, rough edges, and low work efficiency, so as to improve work efficiency, save manufacturing costs, and have good heat sealing effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In order to press various complex flower-shaped patterns on the product according to customer needs, there is no need to use sewing machines, needles and threads, the trouble of frequent needle and thread changes, and the broken joints of traditional thread stitching. Shearing and sealing can also play the role of decoration while sewing, ensuring the adhesion and at the same time achieving the waterproof effect, making the surface of the product have a three-dimensional relief effect, improving the working speed, and the product effect is more high-end and beautiful. The quality is more guaranteed, the sealed edge does not crack, does not damage the edge of the cloth, and there is no burr, curling phenomenon, and no preheating is required when manufacturing products, reducing costs;

[0060] This embodiment adopts the following technical solutions:

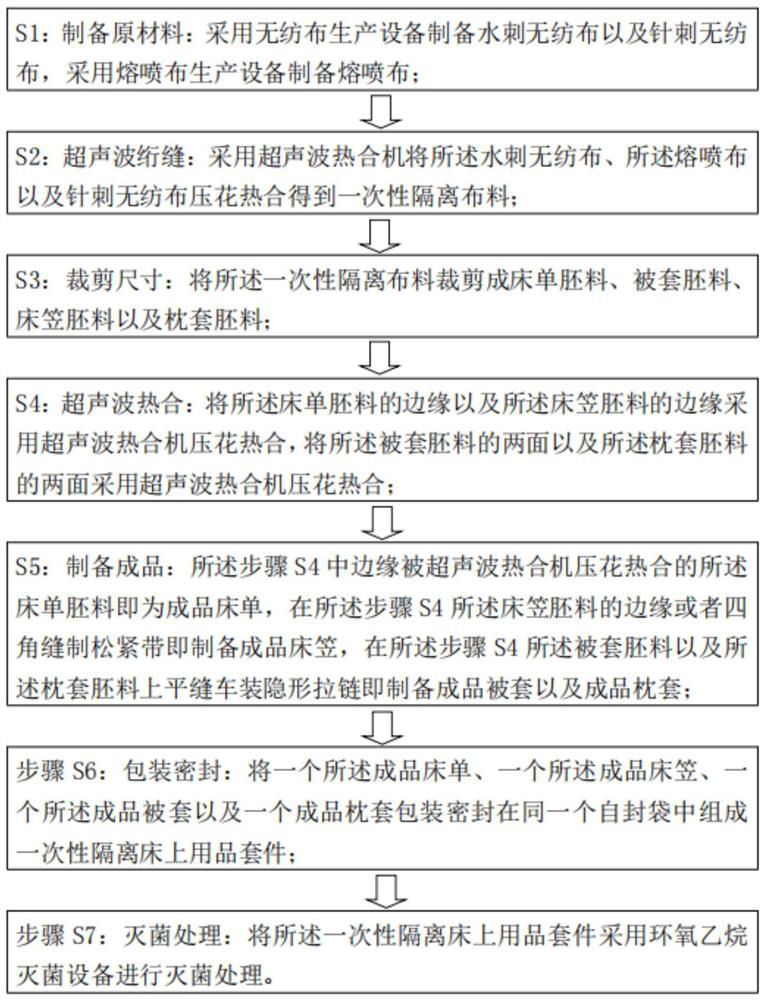

[0061] A manufacturing process of disposable isolation bedding, such as figure 1 shown, including the following steps: ...

Embodiment 2

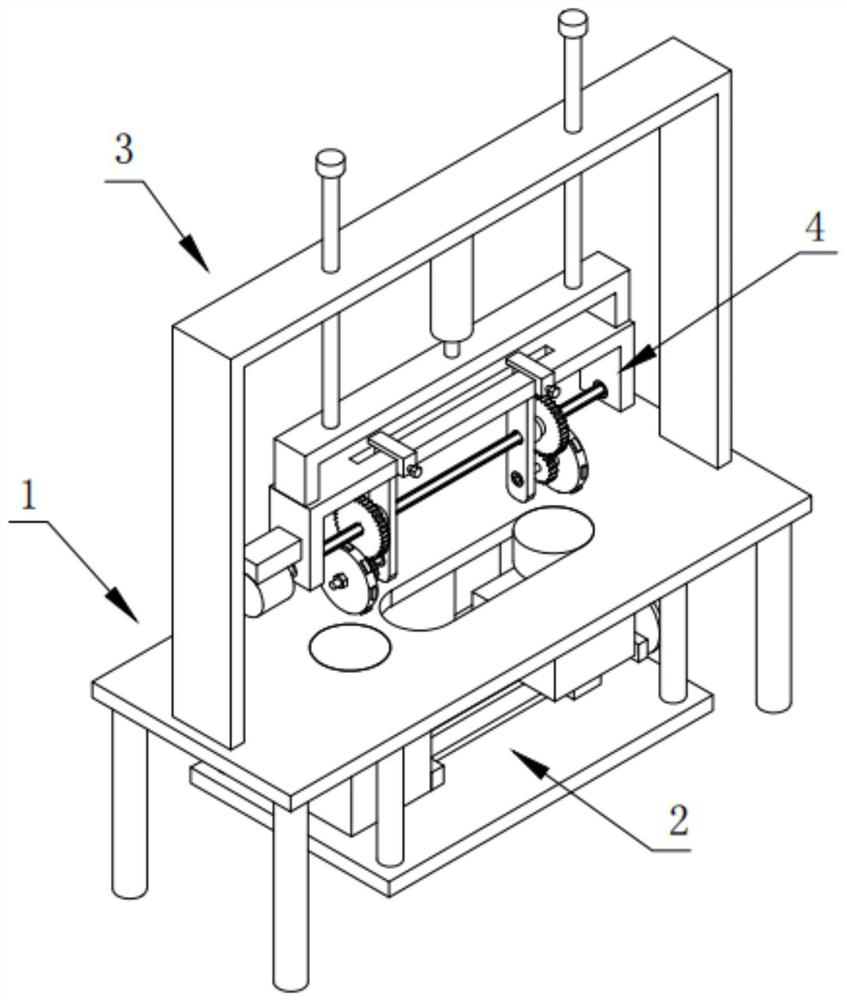

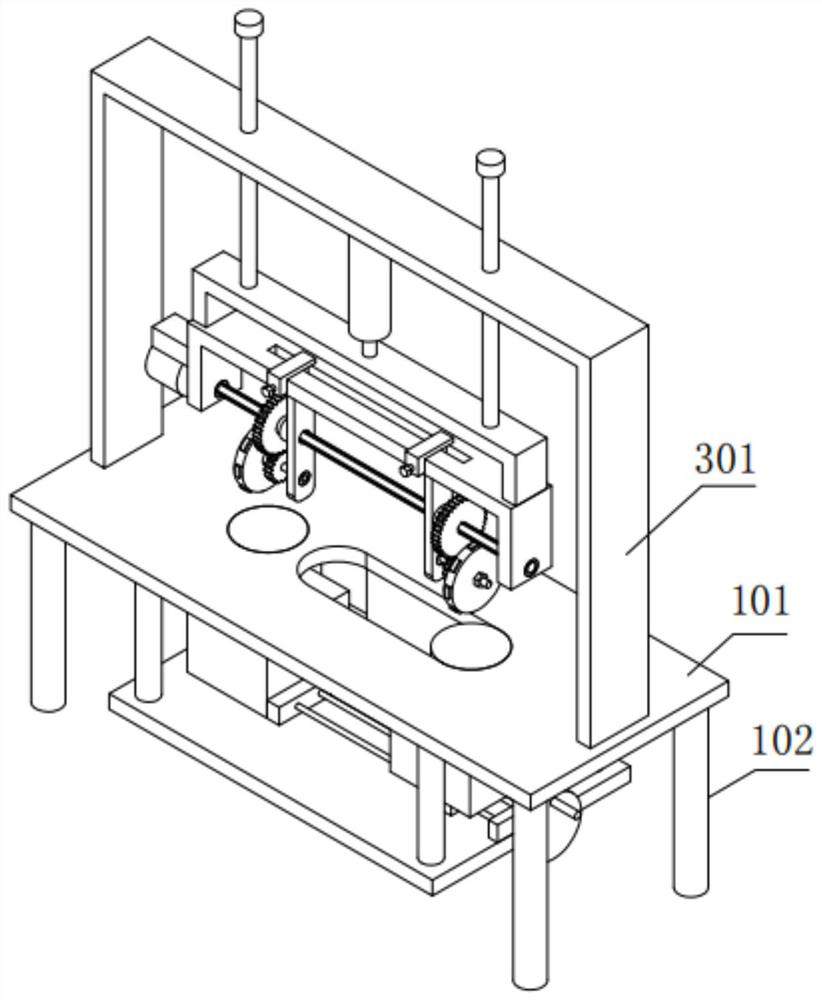

[0072] like figure 2 As shown, the present embodiment provides a disposable isolation bedding manufacturing equipment, which is composed of an ultrasonic heat sealing machine, the ultrasonic heat sealing machine has a frame 1, and an ultrasonic generating mechanism 2 and a lifting mechanism 3 are installed on the frame 1. The lifting mechanism 3 A pressing mechanism 4 is installed on it;

[0073] Among them, such as Figure 2-3 As shown, the frame 1 is used as the main body of the ultrasonic heat sealing machine. In order to make the frame 1 simple in structure and easy to assemble, the frame 1 is composed of a support plate 101 and a leg 102. In order to make the frame 1 suitable for installing a pressing mechanism 4. The support plate 101 is provided with a circular hole 104 and a waist-shaped hole 103 . In order to enable the rack 1 to accommodate the installation of the ultrasonic generating mechanism 2 , the outriggers 102 are fixedly installed at the bottom of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com