Constant pressure oil outlet valve

A technology of oil outlet valve and oil outlet valve seat, which is applied in the direction of engine components, fuel injection pumps, machines/engines, etc., can solve the problem of ineffective control of the initial pressure of throttling fuel, low sensitivity of component action coordination, unsatisfactory and Perfection and other issues to achieve the effect of avoiding excessive enhancement, novel design and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the specific embodiments of the accompanying drawings.

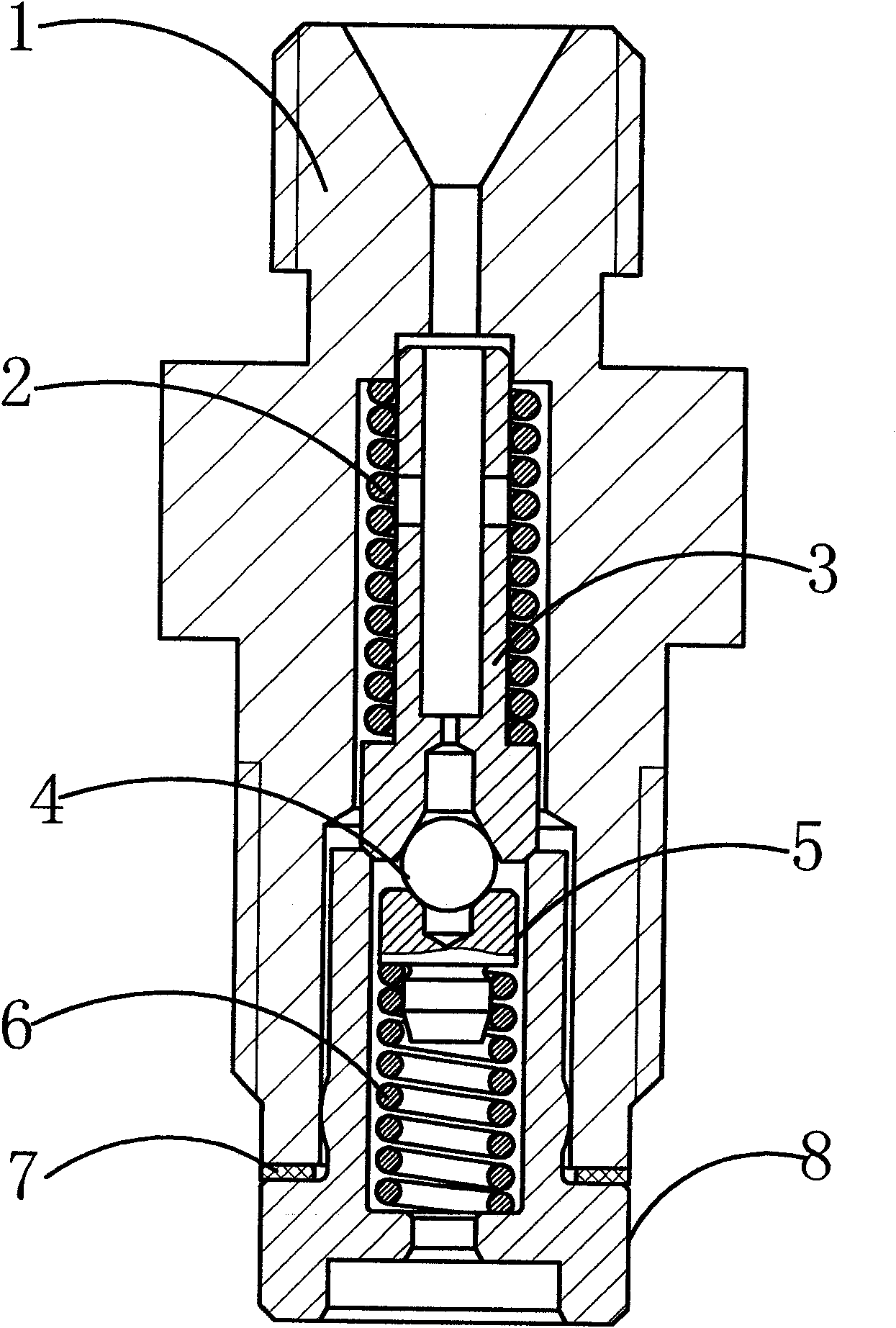

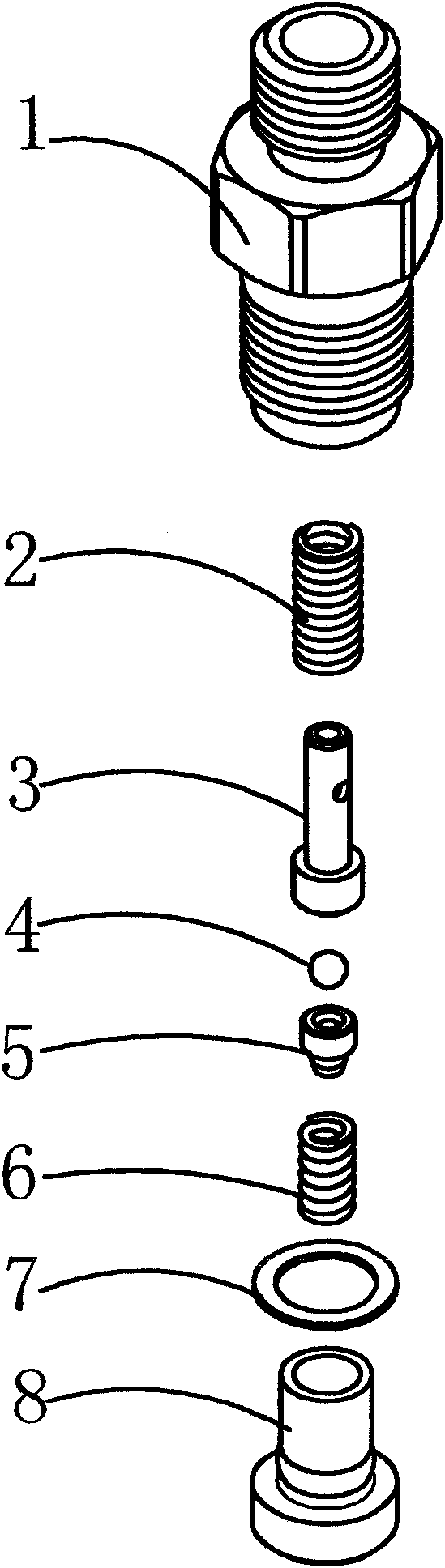

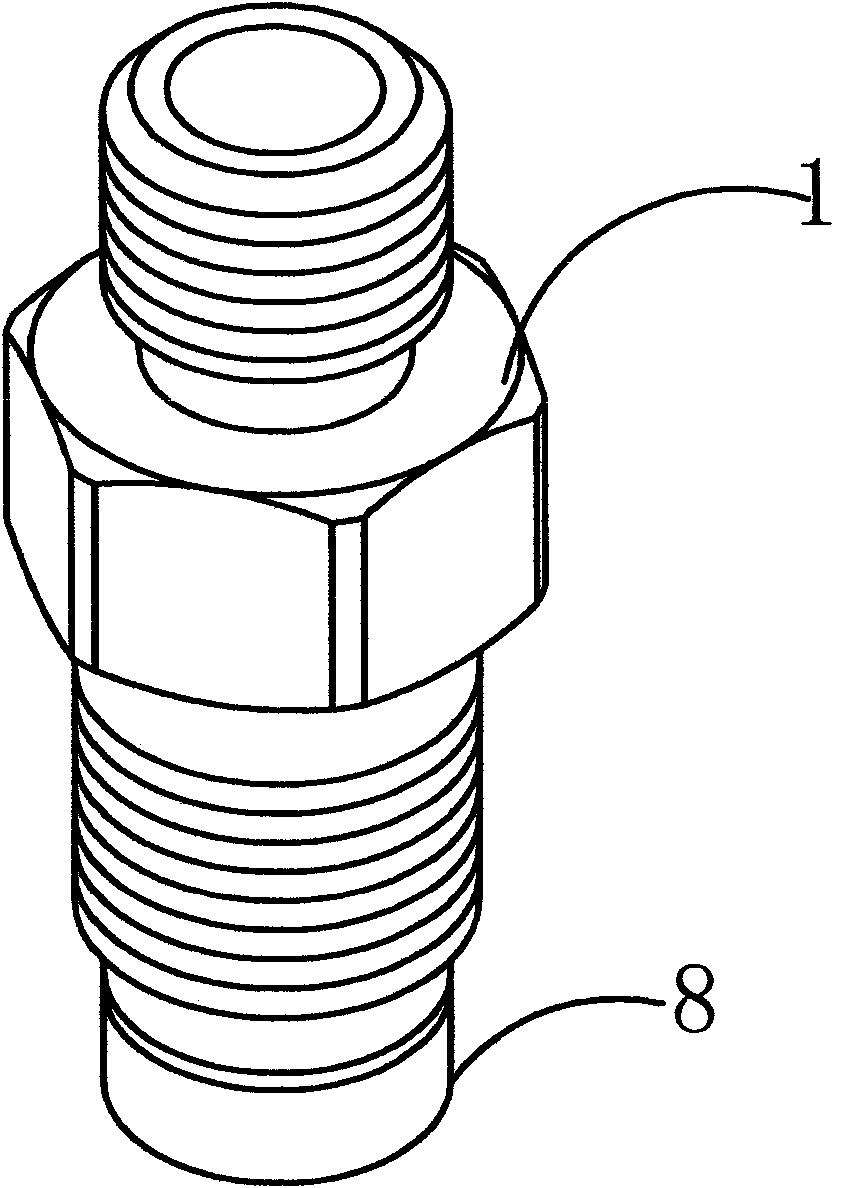

[0016] Figure 1 to Figure 4 It is a schematic diagram of the structure of the present invention.

[0017] The reference signs are: oil outlet valve tight seat 1, lift limiting chamber 1a, oil outlet valve spring 2, oil outlet valve core 3, outer spherical surface 3a, oil inlet 3b, oil discharge orifice 3d, Protruding rafter column 31, groove 32, steel ball 4, spring seat 5, pressure relief valve spring 6, sealing gasket 7, oil outlet valve seat 8, inner spherical surface 8a.

[0018] Such as Figure 1 to Figure 4 As shown, the equal-pressure oil outlet valve of the present invention includes an oil outlet valve tight seat 1, an oil outlet valve spring 2 installed in the oil valve tight seat 1, an oil outlet valve core 3, and an oil outlet valve seat 8 and assembled in sequence The steel ball 4, the spring seat 5, and the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com