Multi-mode large and small turbocharger diesel engine sequential supercharging structure

A turbocharger and sequential supercharging technology, applied in the direction of machines/engines, mechanical equipment, combustion engines, etc., can solve problems that do not involve improving the idling performance of turbocharged diesel engines, so as to reduce fuel consumption, reduce emissions, and improve The effect of air intake efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

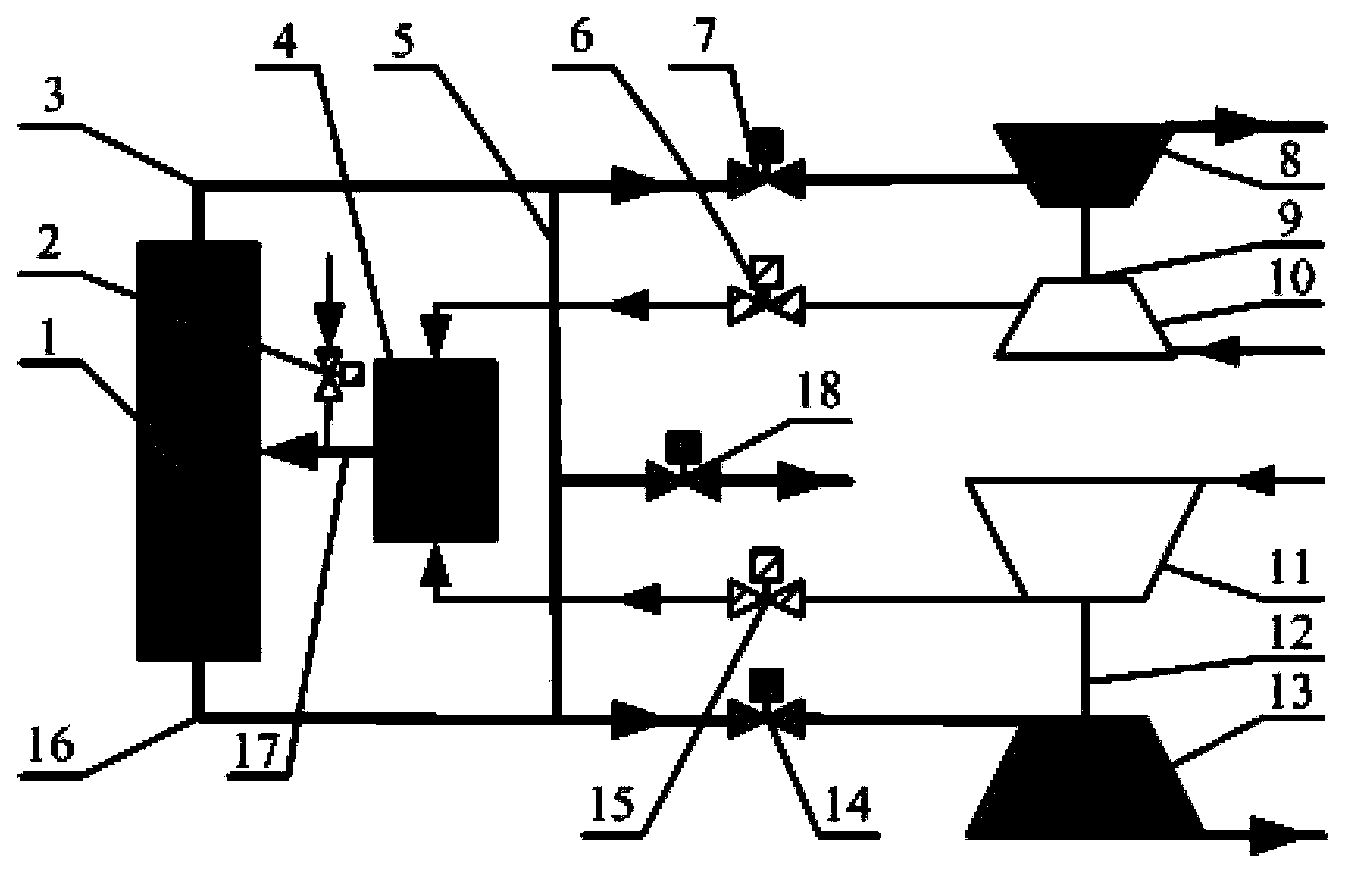

[0013] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0014] combine figure 1 , the multi-mode diesel engine size turbocharger sequence supercharging structure involved in the present invention is composed of diesel engine 1, supercharger 9, 12, intercooler 4, diesel engine intake and exhaust pipes 3, 16, 17, control valves, etc., The sizes of the two superchargers are different. One end of the intake valve 2 is connected to the atmosphere, and the other end is connected to the intake pipe 17 . One end of the exhaust valve 18 is connected to the atmosphere, and the other end is connected to the exhaust communication pipe 5 . Gas valve A7 one end links to each other with small supercharger turbine 8, and the other end links to each other with A column exhaust pipe 3. One end of the air valve A6 is connected with the small supercharger compressor 10 , and the other end is connected with the intercooler 4 . One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com