Patents

Literature

407results about How to "Improve assembly stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

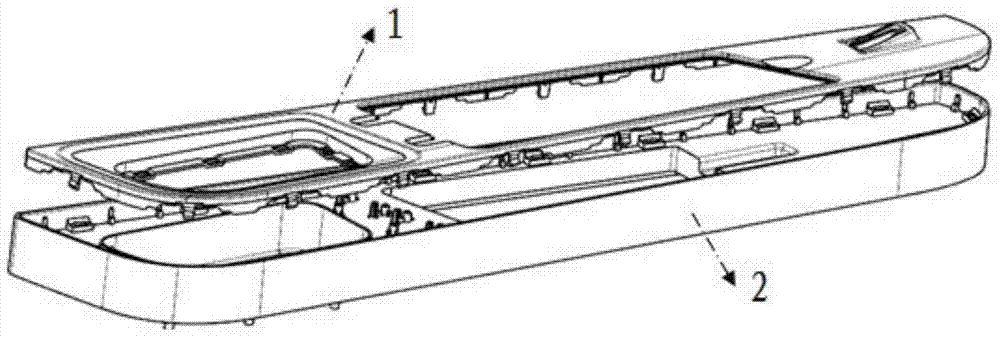

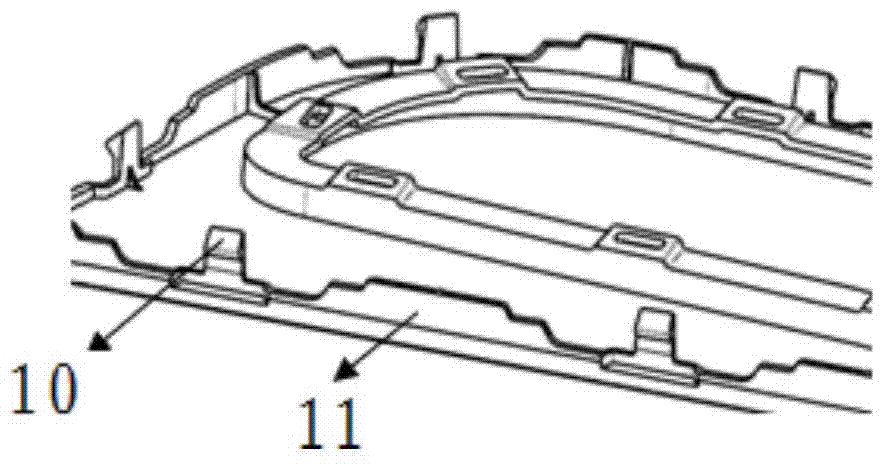

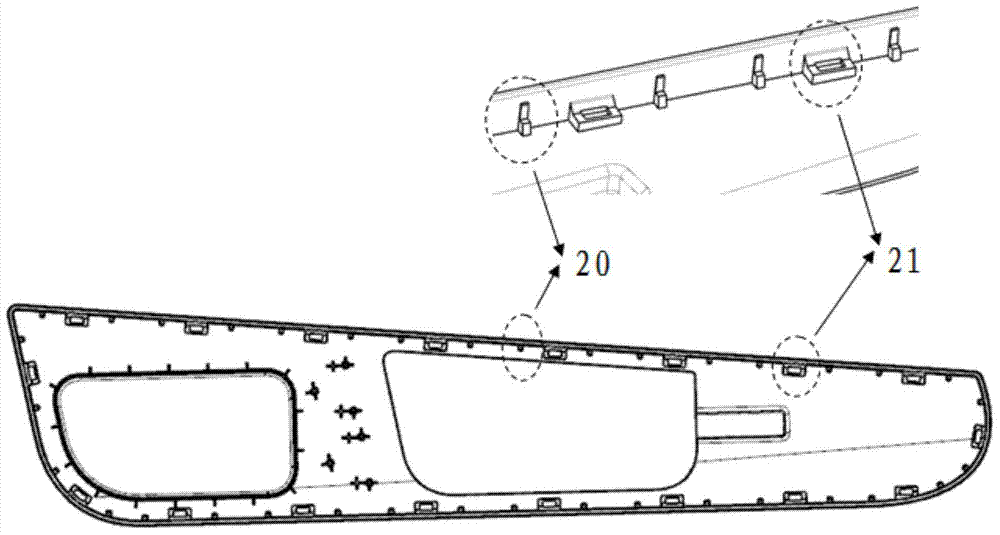

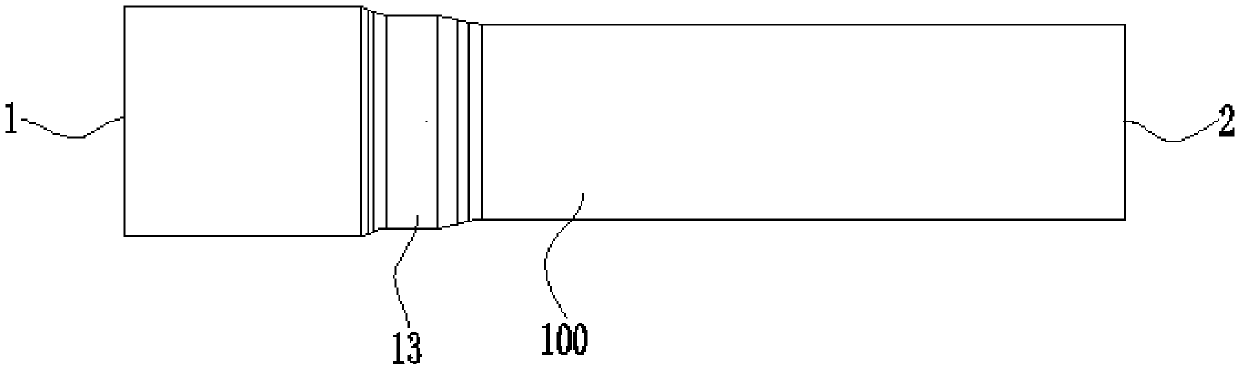

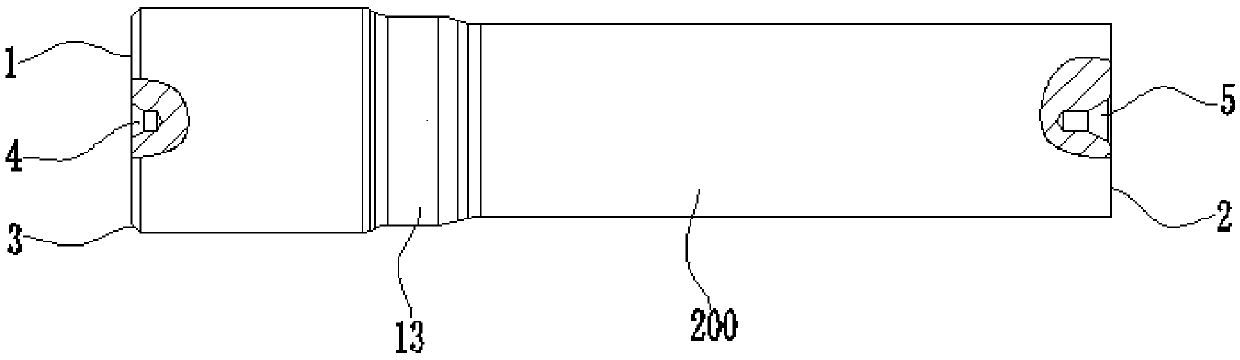

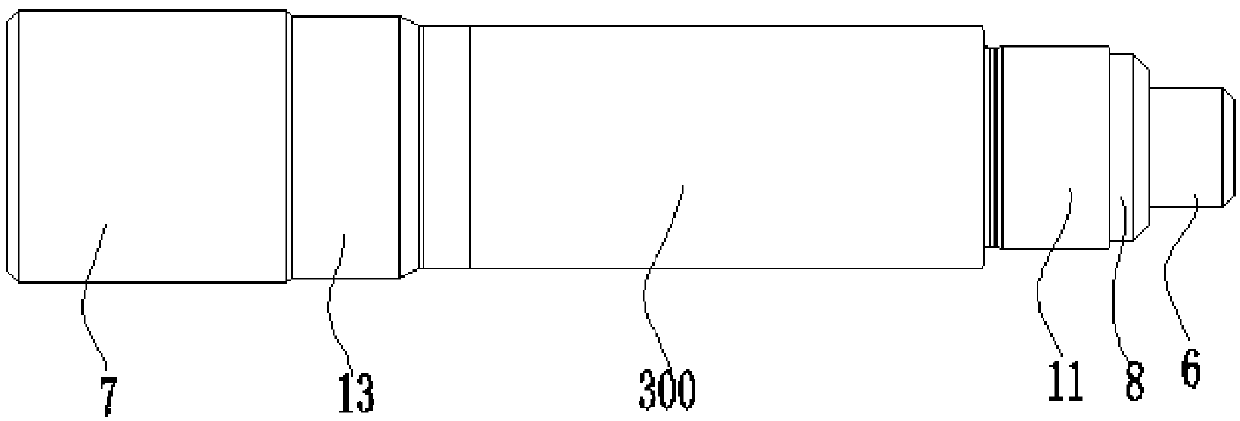

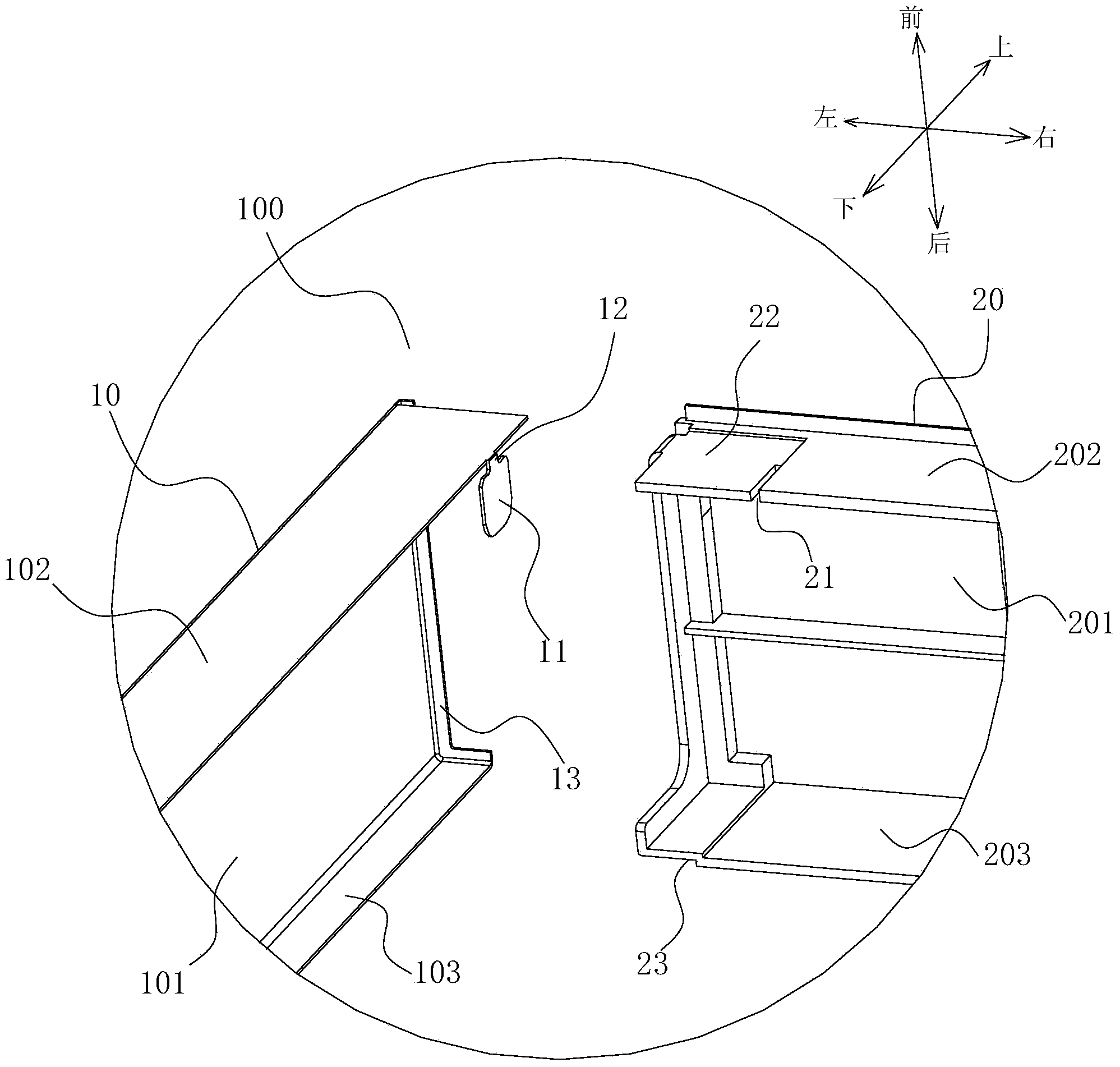

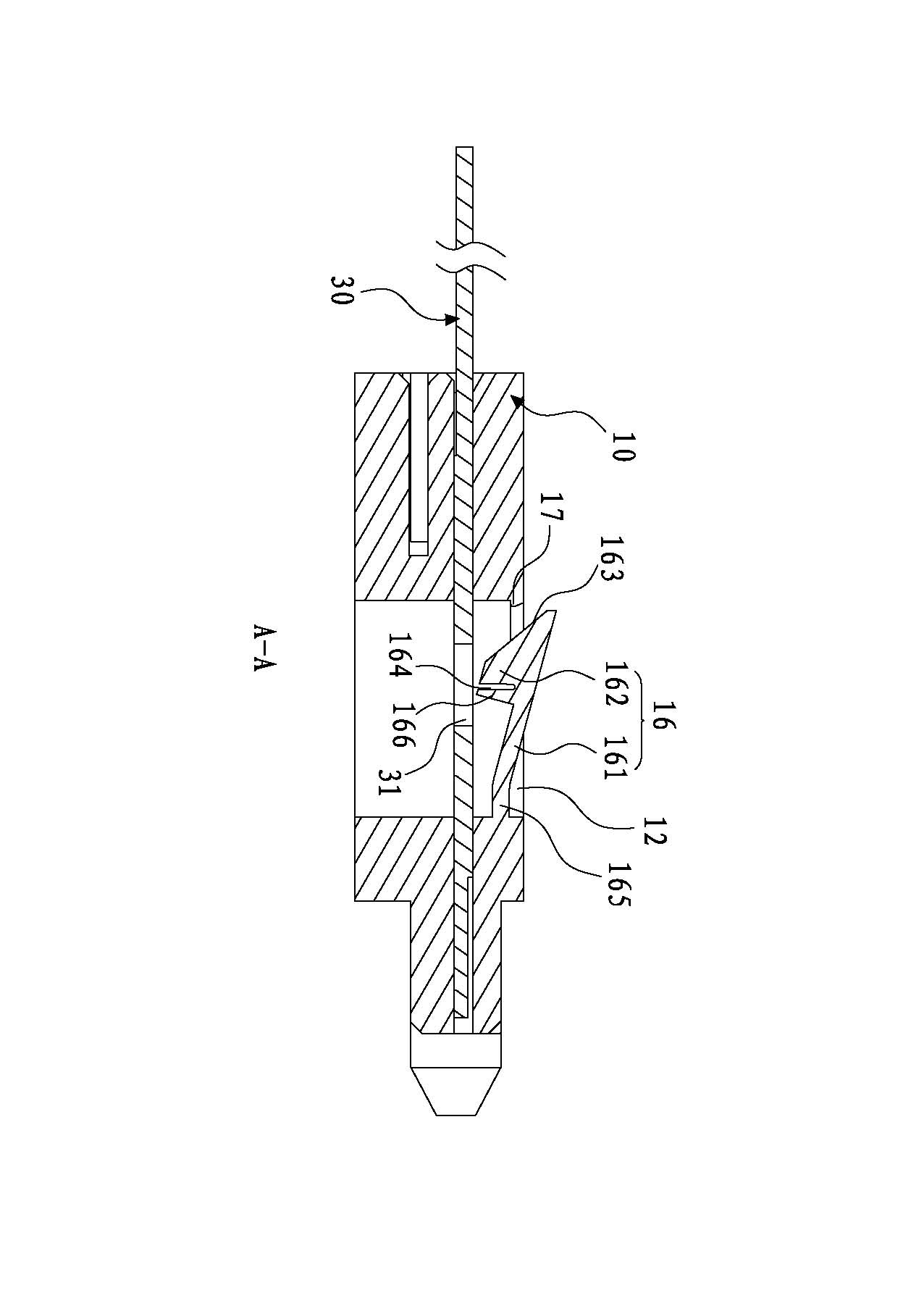

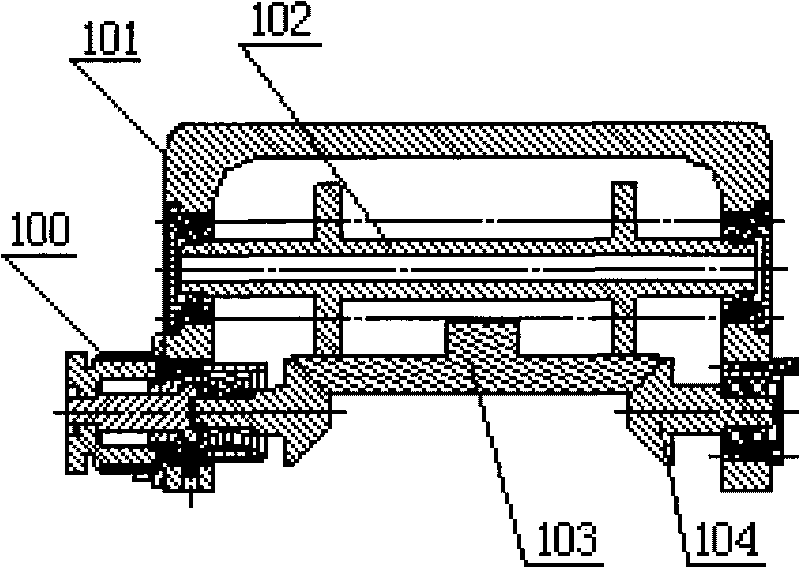

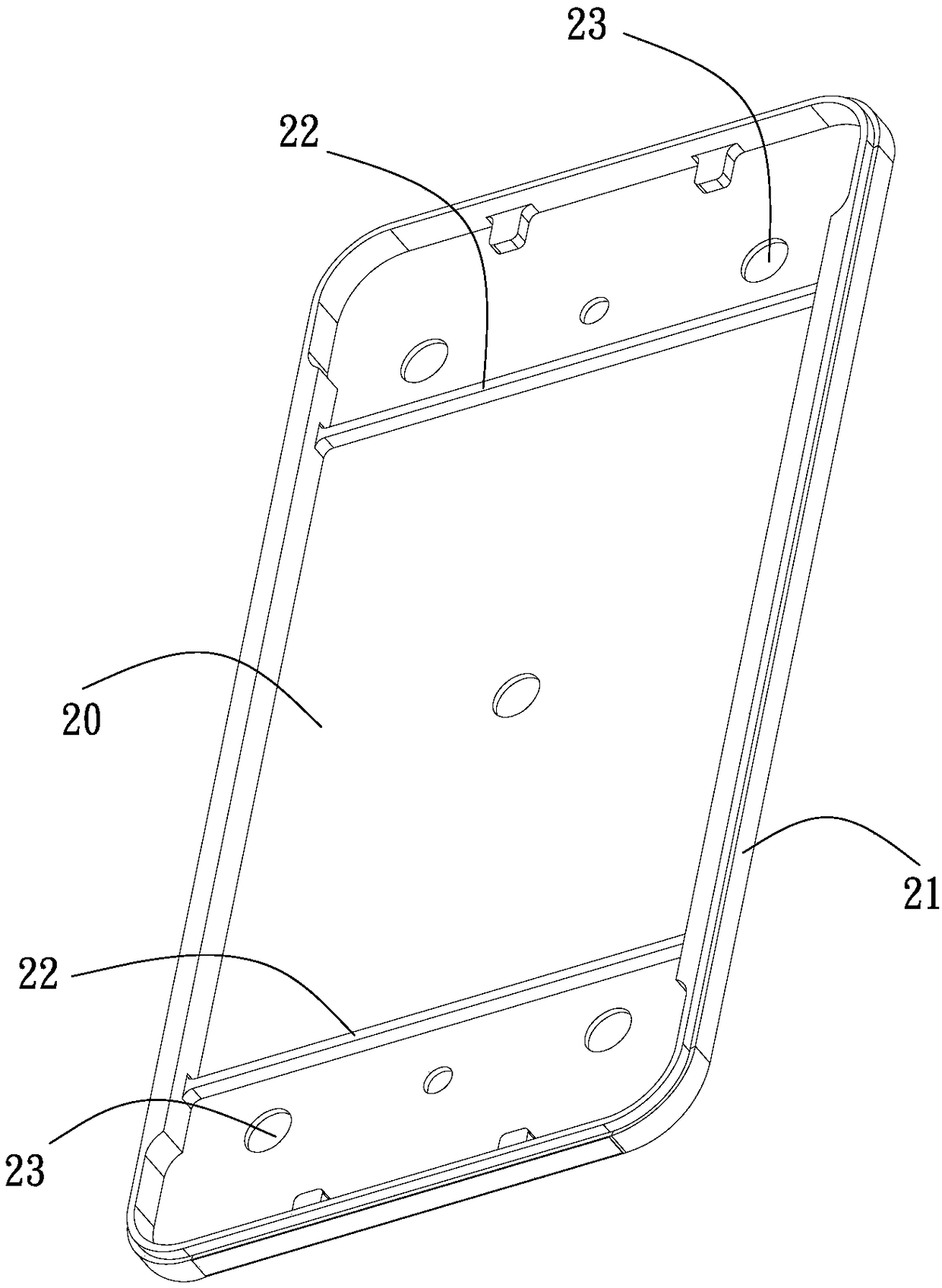

Large plastic plate matching structure based on cantilever buckles

The invention relates to a large plastic plate matching structure based on cantilever buckles. The large plastic plate matching structure comprises a cover plate (1) and a basal plate (2), the buckles (10) and cover plate turning edges (11) are arranged on the periphery of the cover plate at intervals, and the inner side wall of the basal plate is provided with clamping groove bosses (21) matched with the buckles and limiting bosses (20) used for supporting the cover plate turning edges. When the cover plate turning edges are turned to the upper portion of the side wall of the basal plate, the lower end faces of the cover plate turning edges abut against the top surfaces of the limiting bosses. Each clamping groove boss comprises a rectangular cavity (210) extending in the Z direction, the top surface of each limiting boss is a vertical limiting surface (201), and circumferential direction limiting surfaces (202) perpendicular to the vertical limiting surfaces are arranged at the upper ends of the vertical limiting surfaces. The limiting bosses are utilized, the clamping groove bosses are matched with the cover plate turning edges, and the buckles are used for multi-point horizontal surface matching; compared with an existing method that cover plate turning edges and grooves in the side wall of the basal plate are directly buckled and the turning edges directly abut against the bottom surface of the basal plate, better assembly stability is achieved.

Owner:BAOSTEEL DEV CO LTD

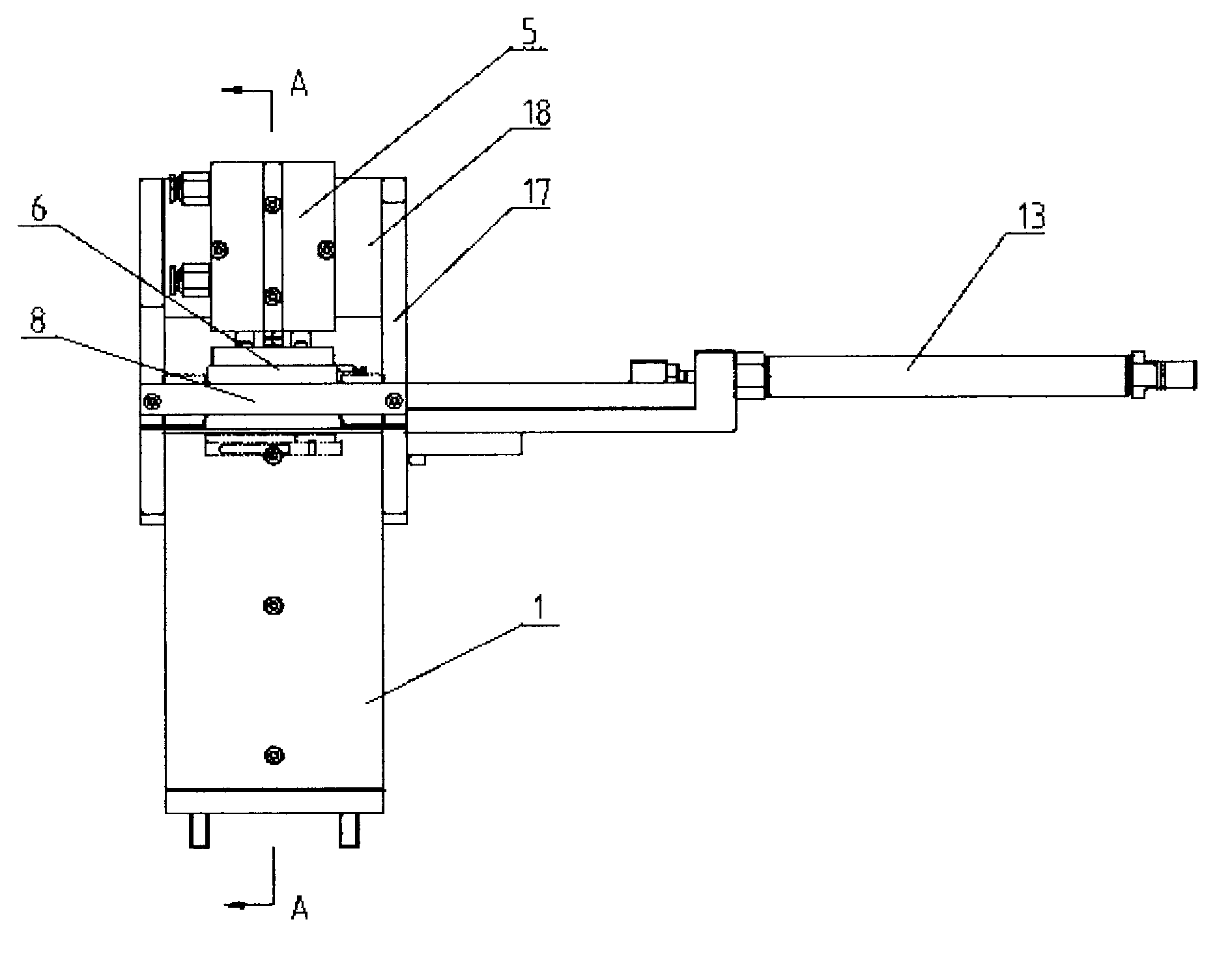

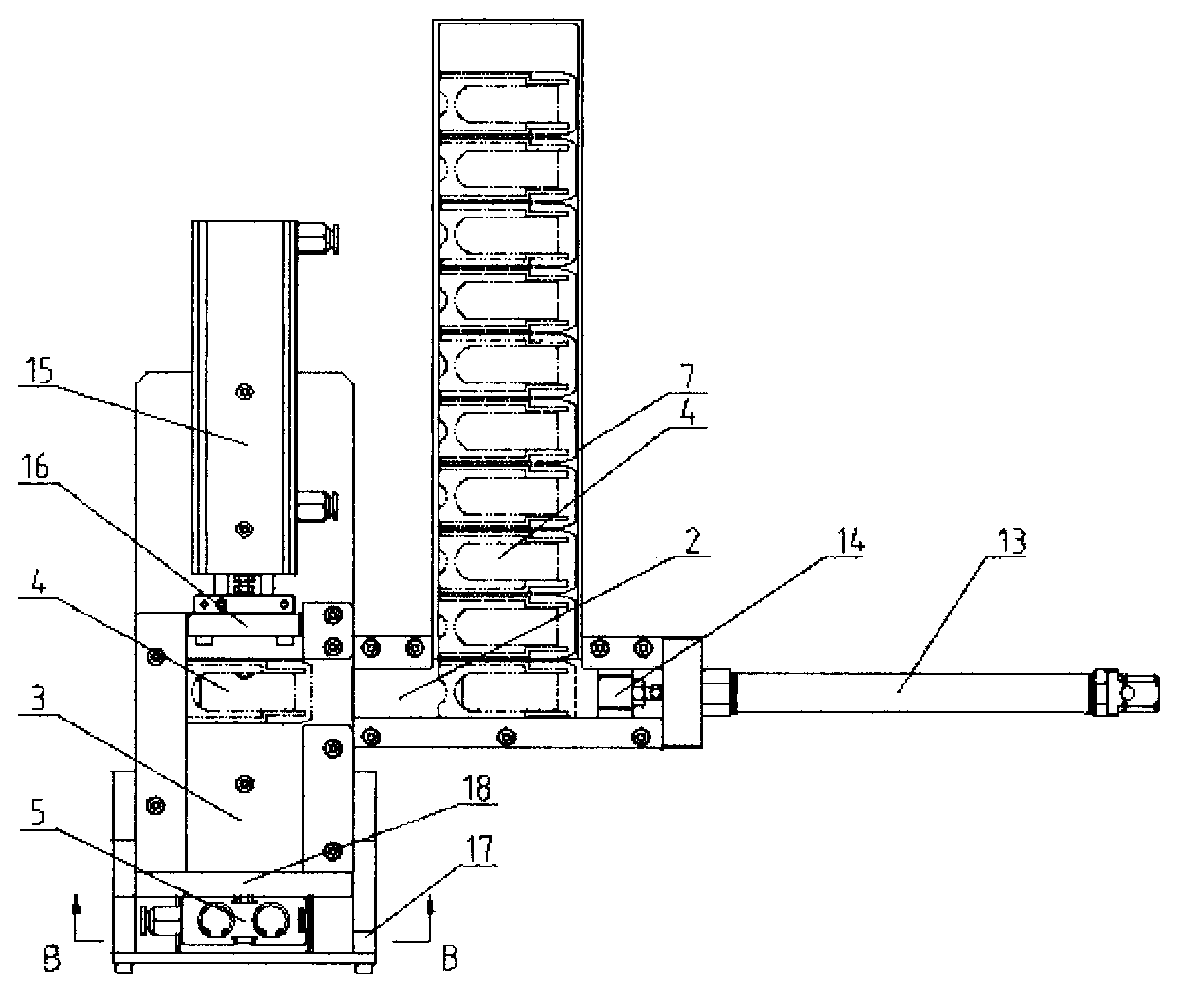

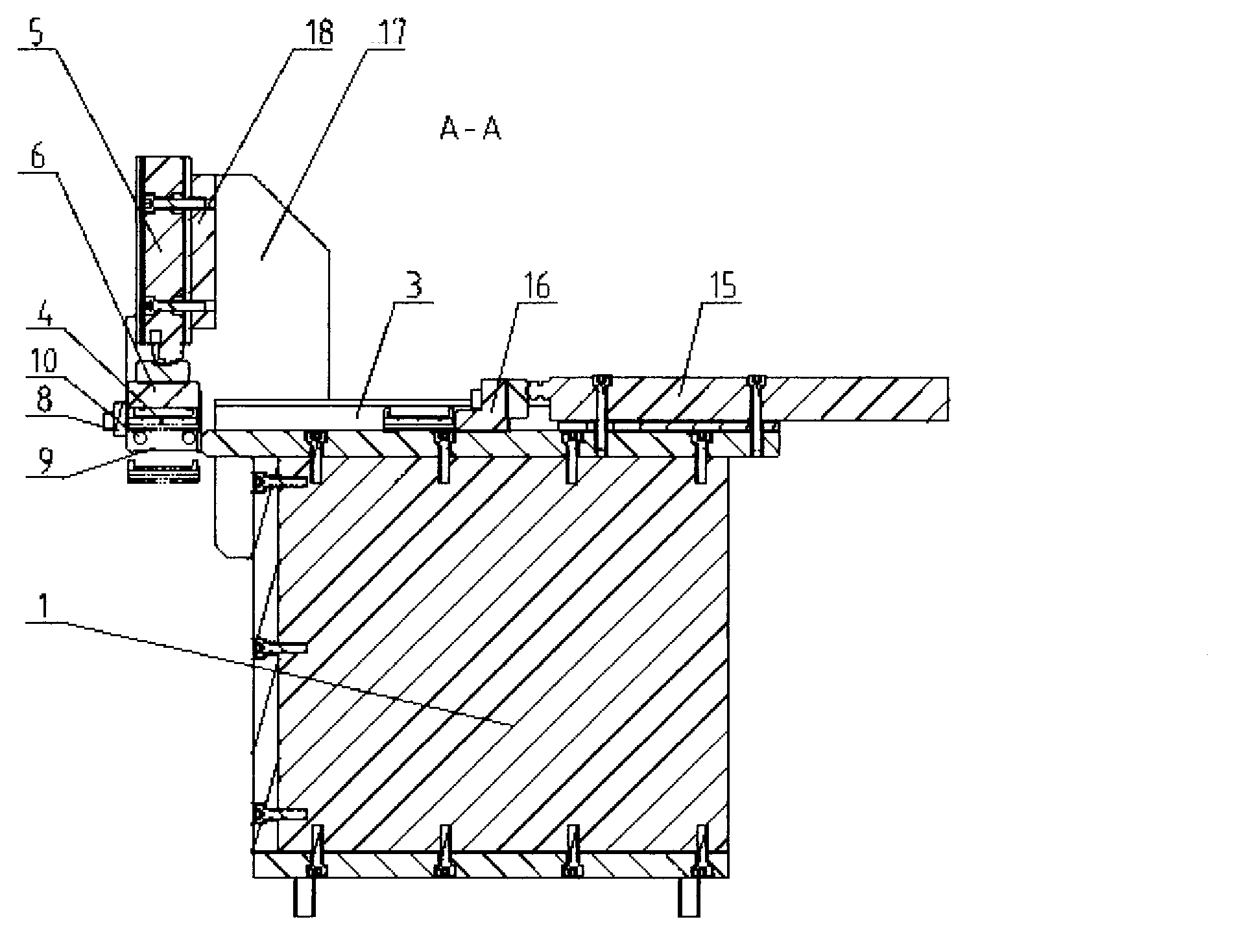

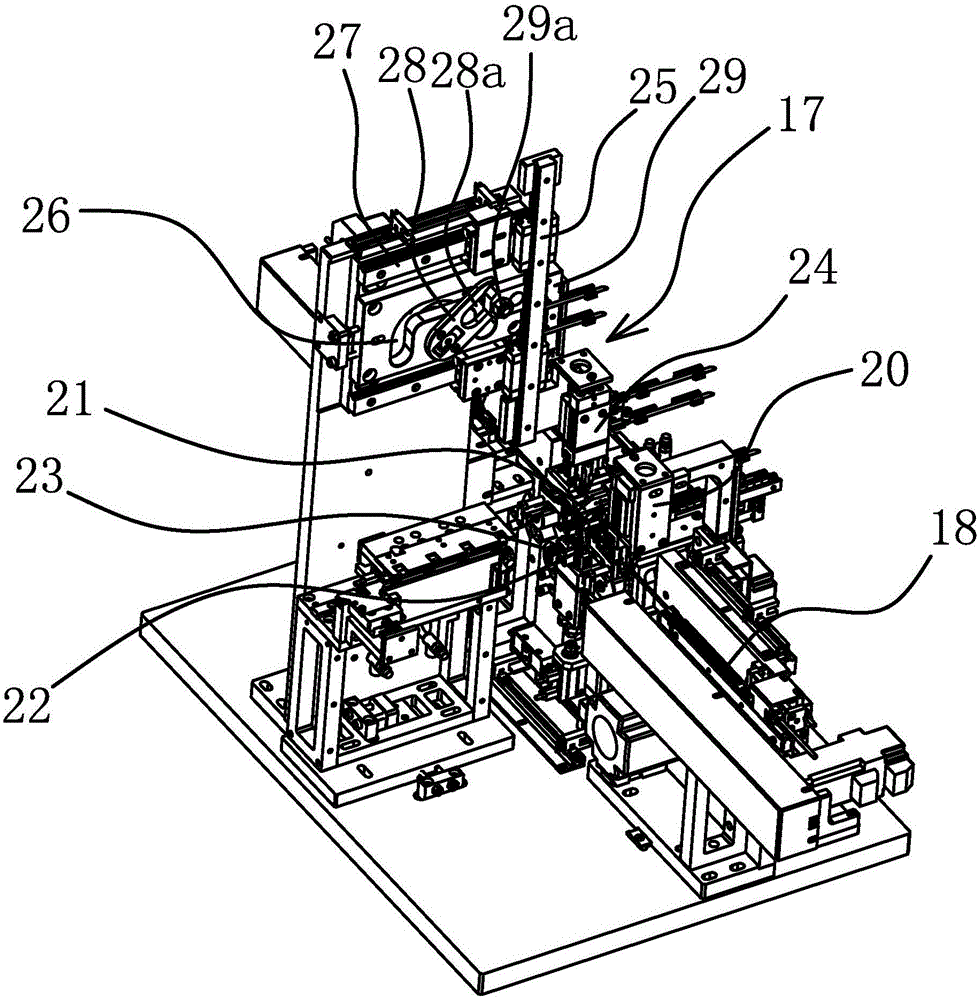

Shell feeding device of lockset spring assembly assembling machine

ActiveCN102794630ARealize mechanized operationImprove assembly qualityAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses a shell feeding device of a lockset spring assembly assembling machine. The shell feeding device comprises a rack and a material pressing mechanism, wherein the rack is provided with a feeding rail and a material pushing rail; the tail end of the feeding rail is communicated with the front end of the material pushing rail; the front end of the material pushing rail is located below the material pressing mechanism, and the tail end of the feeding rail is provided with a feeding mechanism capable of conveying a shell into the material pushing rail; the tail end of the material pushing rail is provided with a material pushing mechanism capable of conveying the shell to be below the material pressing mechanism; the material pressing mechanism comprises a material pressing cylinder fixed on the rack and a material pressing plate fixed on the material pressing cylinder; and the rack is further provided with a fixing mechanism capable of fixing the shell which is conveyed to be below the material pressing plate. The shell feeding device disclosed by the invention has a high mechanical degree, can replace artificial assembling and has a high feeding speed, and can improve the assembling quality and stability of a lockset spring assembly.

Owner:CHANGZHOU INST OF NUMERICAL CONTROL TECH +1

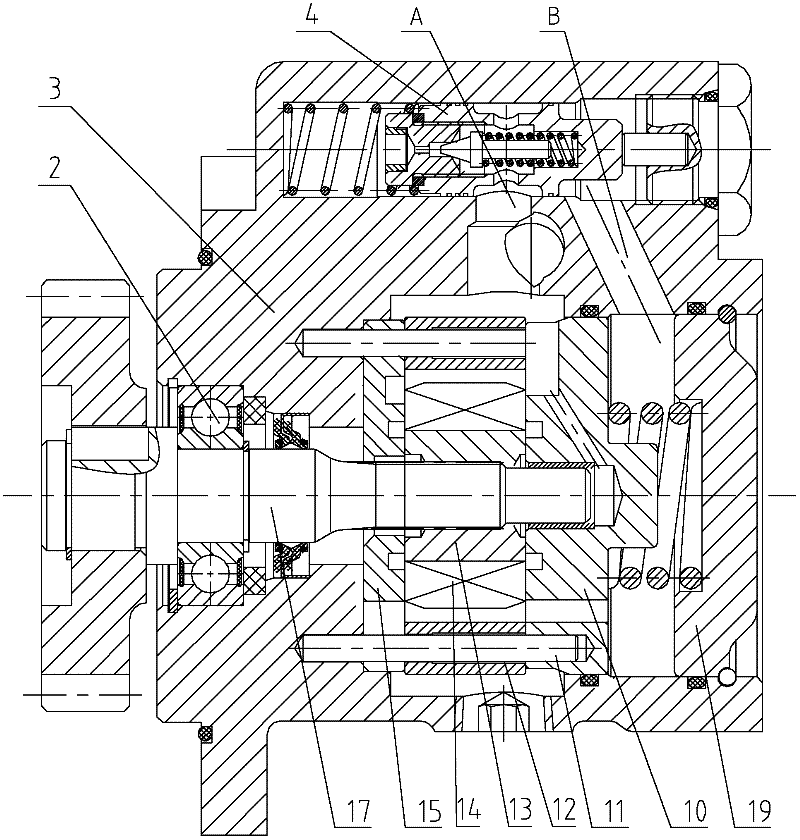

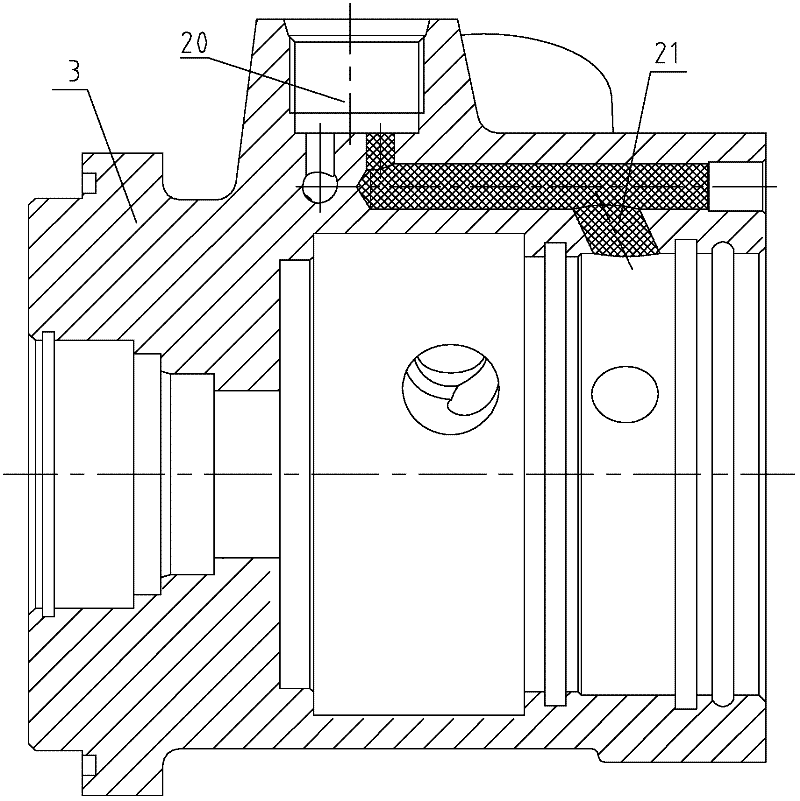

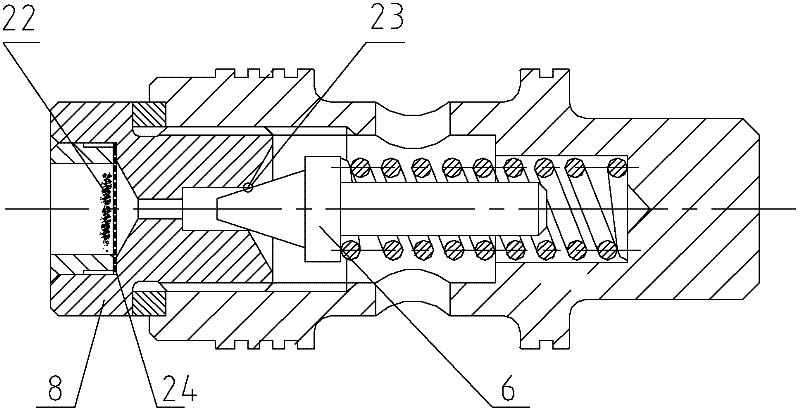

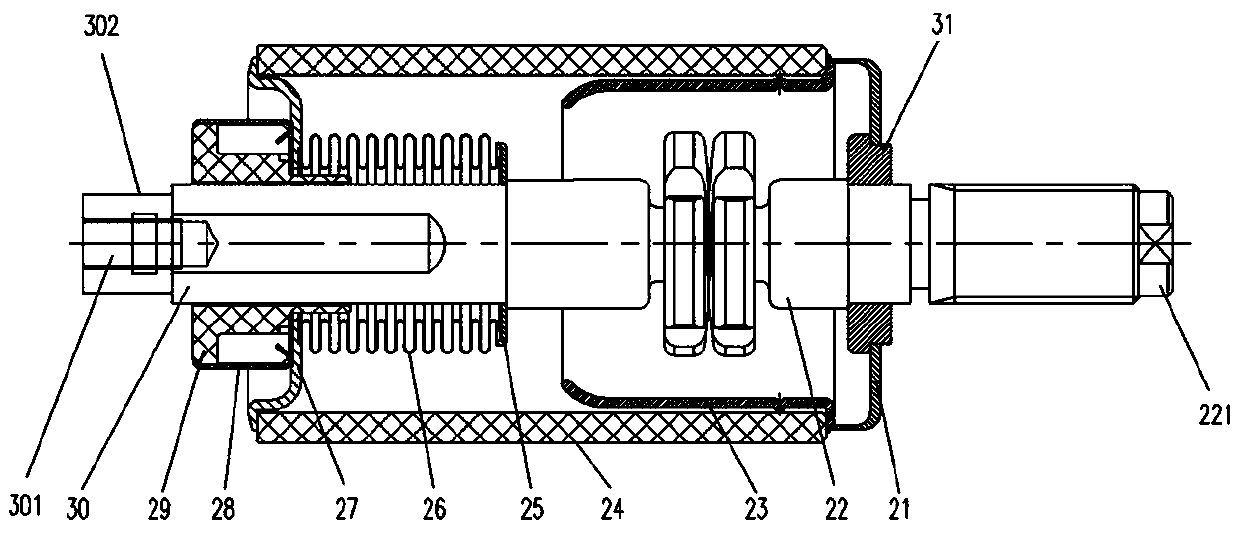

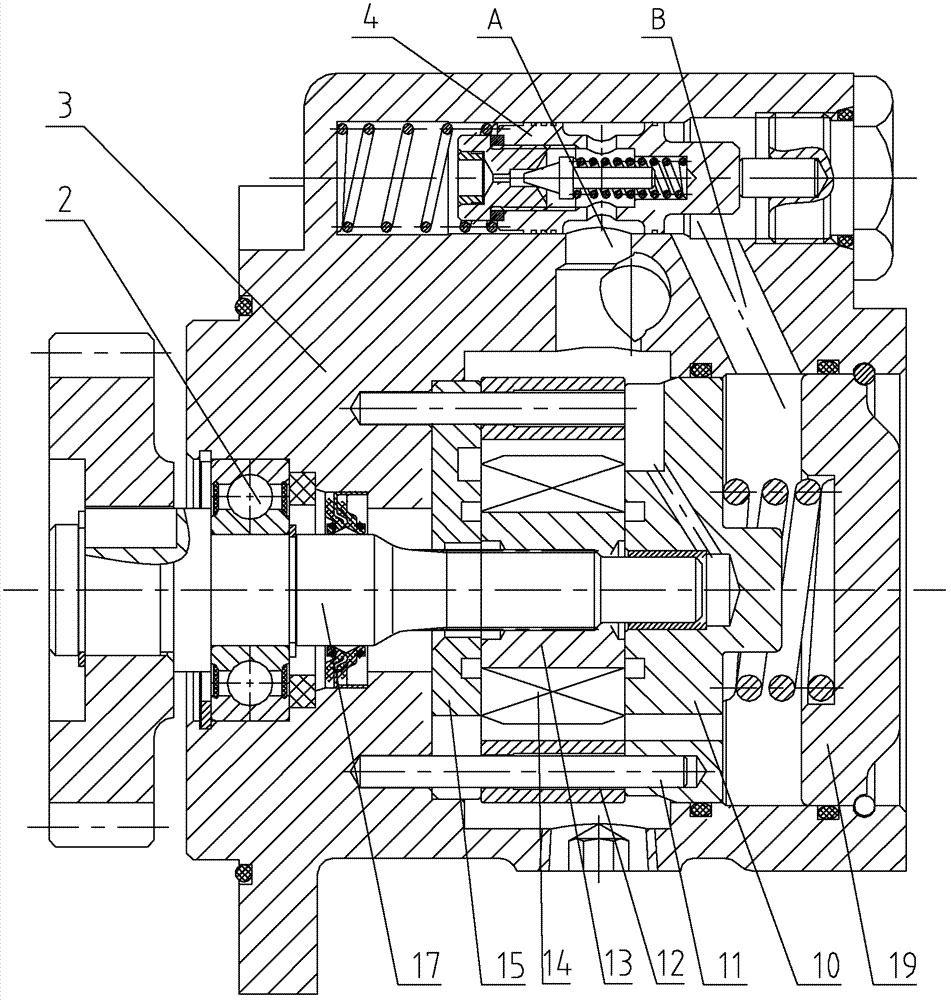

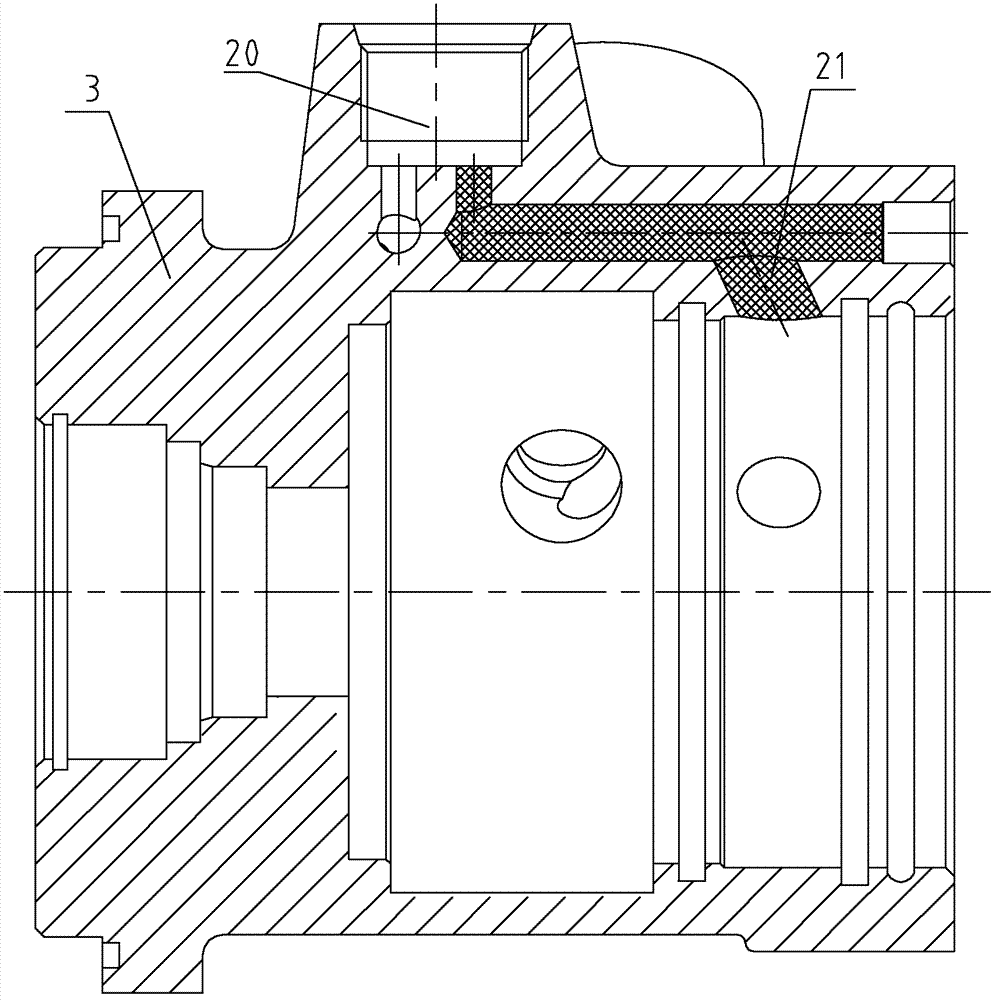

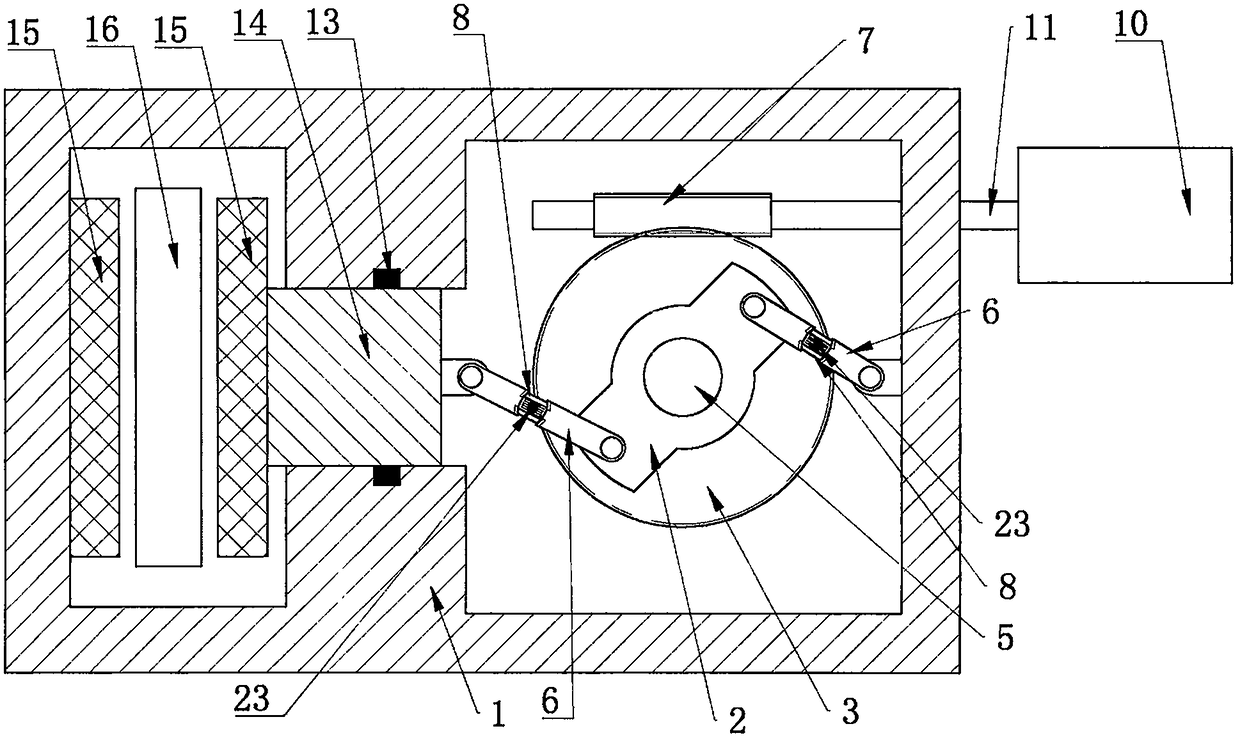

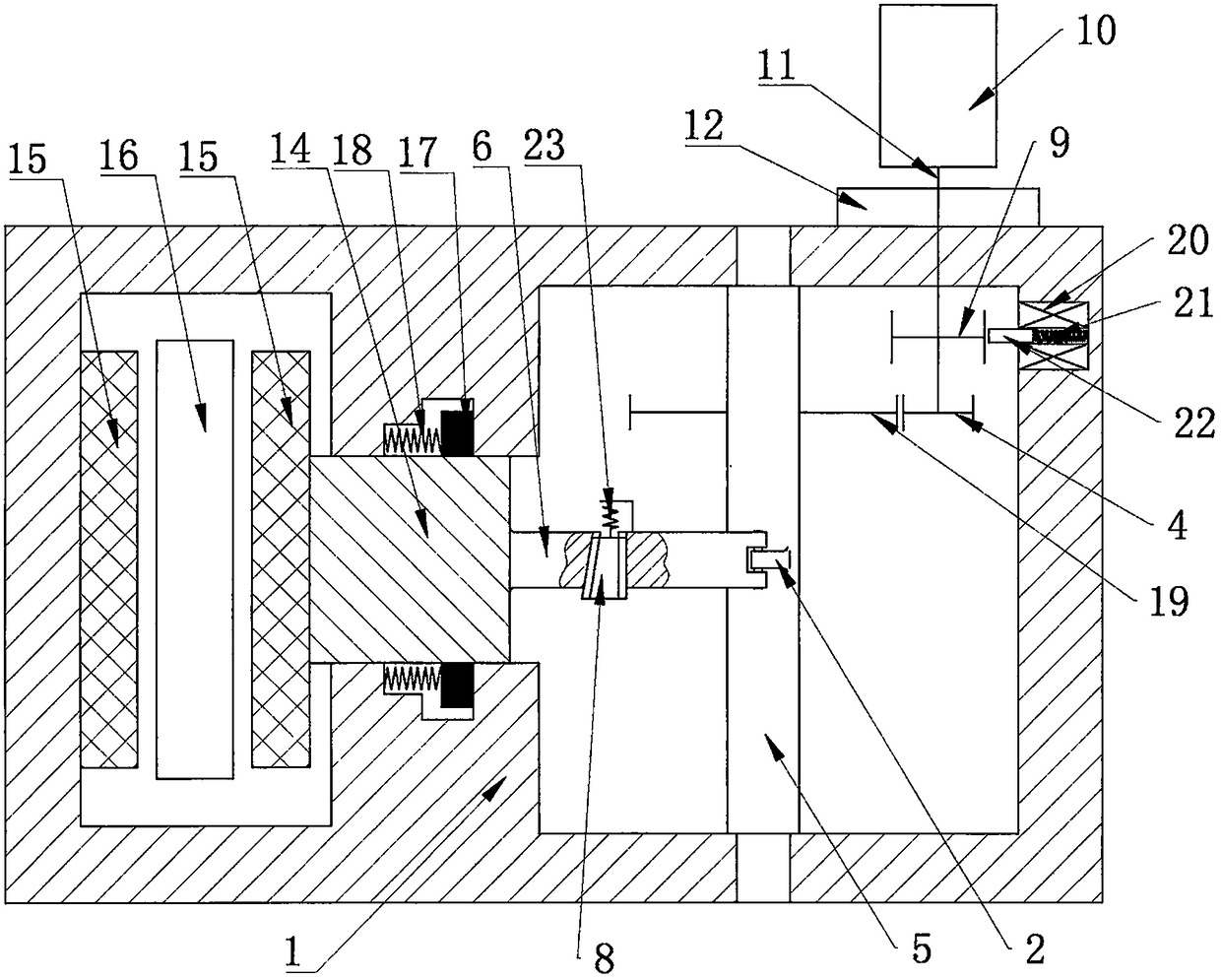

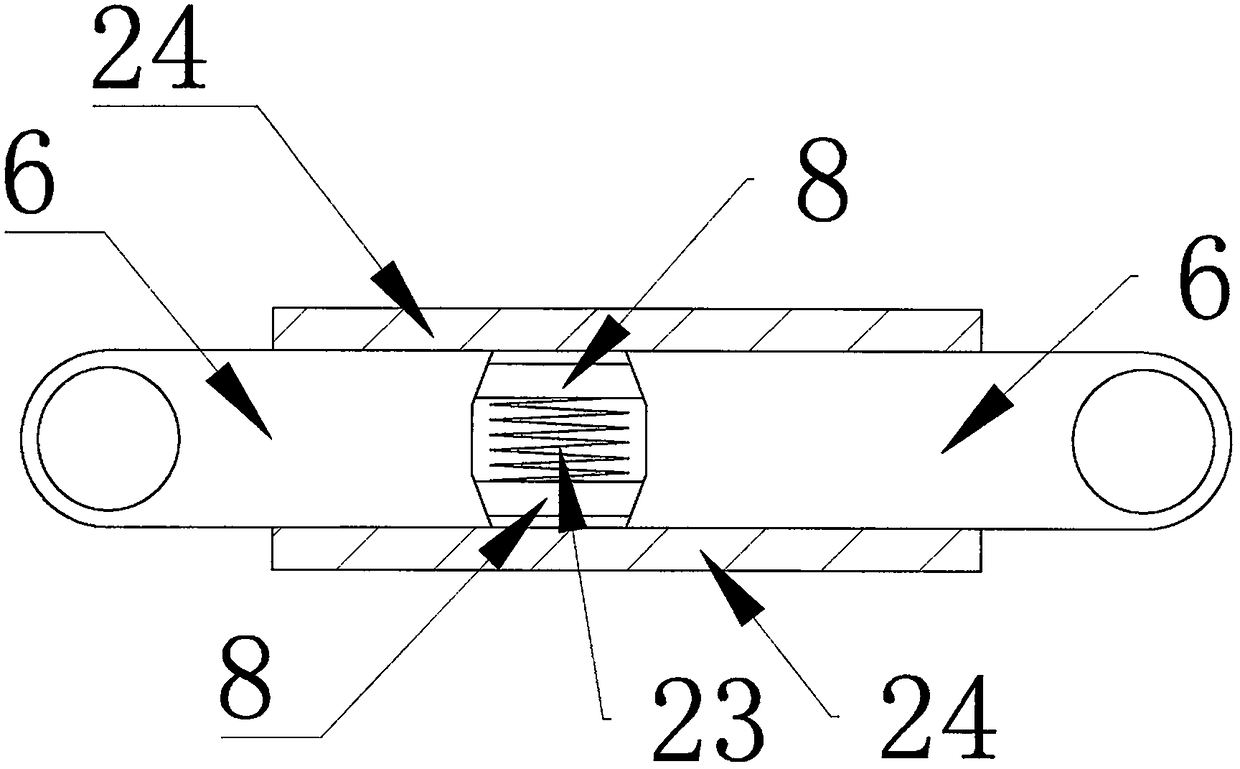

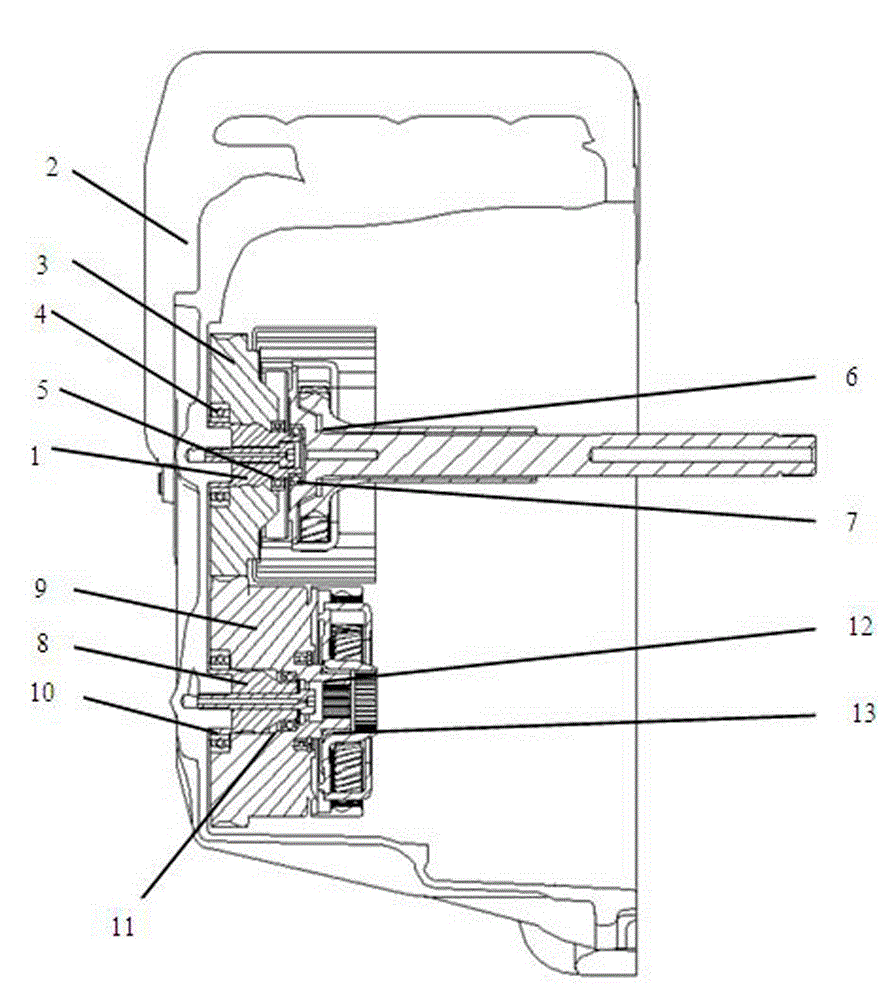

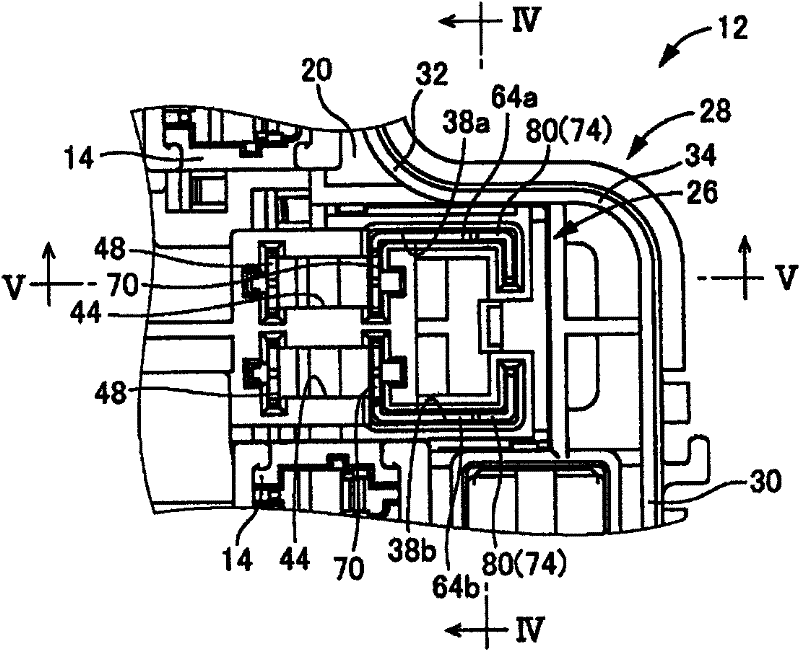

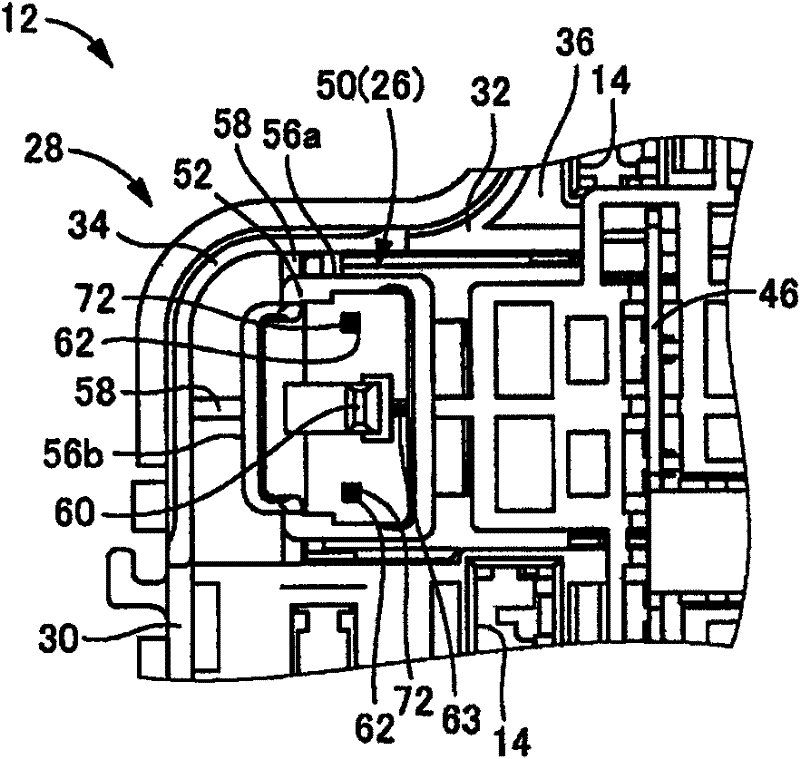

Power steering pump

ActiveCN102536802AExtended service lifeImprove filtering effectSpecific fluid pumpsRotary piston pumpsSafety controlOil distribution

The invention discloses a power steering pump. The power steering pump is characterized in that a pump shaft is connected in series with a front oil distribution disc, a blade assembly and a front oil distribution disc into a whole so as to be installed in a pump body cavity, the front oil distribution disc and a front wall of the pump body cavity form an oil-out front cavity in an enclosed mode, and a pump body is provided with a valve hole on the side of an outer circle of the pump body cavity; the valve hole is communicated with the oil-out front cavity, the valve hole is internally provided with a flow safety control valve, and the oil-out front cavity is communicated with an oil outlet at the front of the pump body through a high-pressure oil channel; the outer circle of the blade assembly and an inner wall of the pump body cavity form a pump body back cavity in an enclosed mode, and the valve hole is communicated with the pump body back cavity through a return oil channel; and blades are driven by the pump shaft to rotate so as to finish an oil absorption and draining process, and the flow safety control valve controls oil mass discharged from the oil-out front cavity through the oil outlet to keep constant. The power steering pump provided by the invention has the advantage of shortening a high-pressure oil flow channel with smoothness in transition, reducing flow pressure loss, and avoiding that the power steering pump is failed due to serious heating because the flow channel in the traditional structure is long and bent by adopting a high pressure structure of the pump body front cavity.

Owner:QUANXING MACHINING GRP

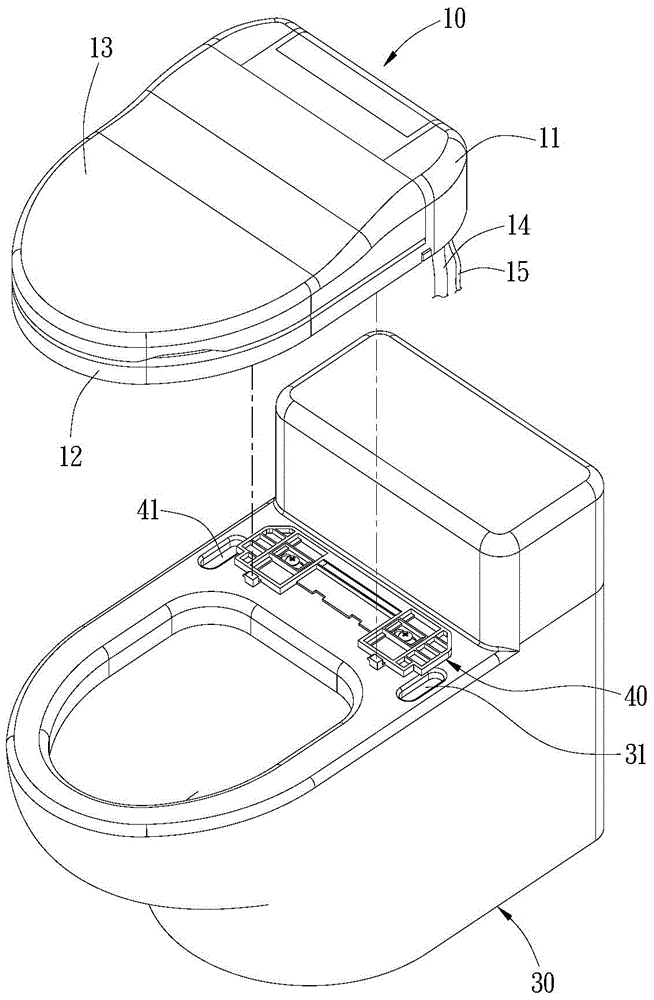

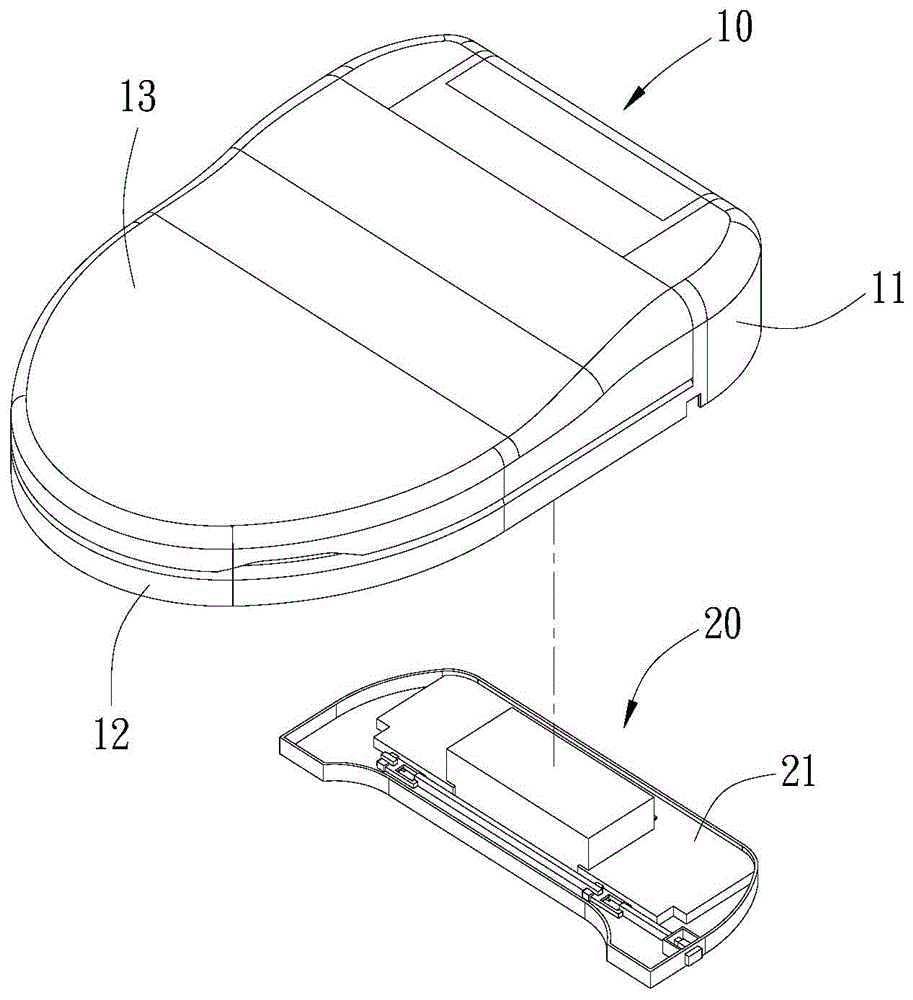

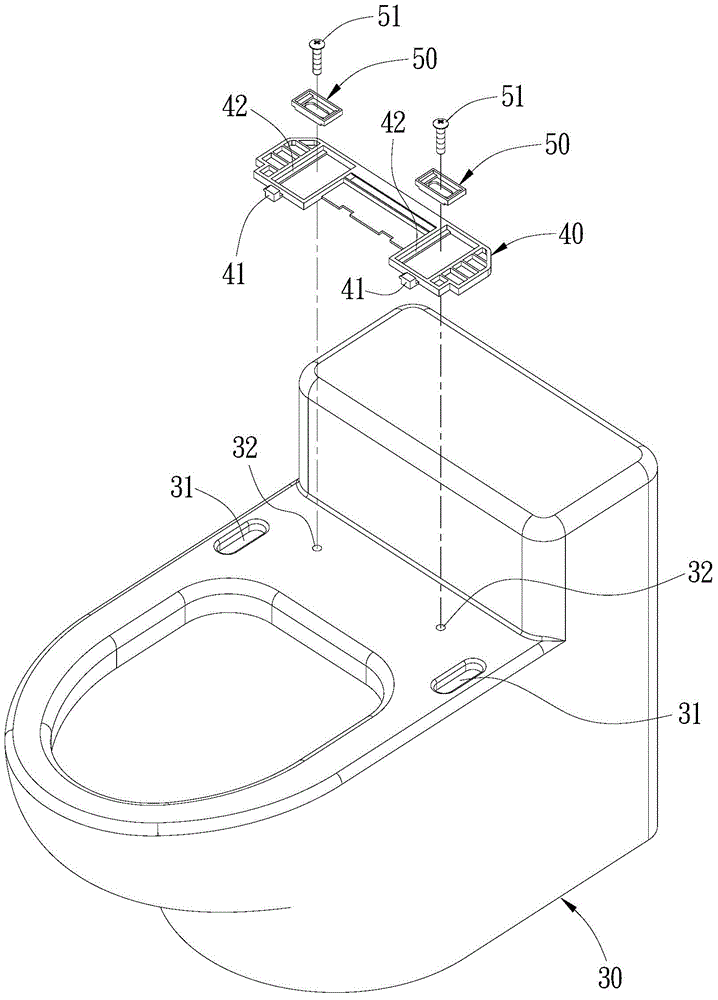

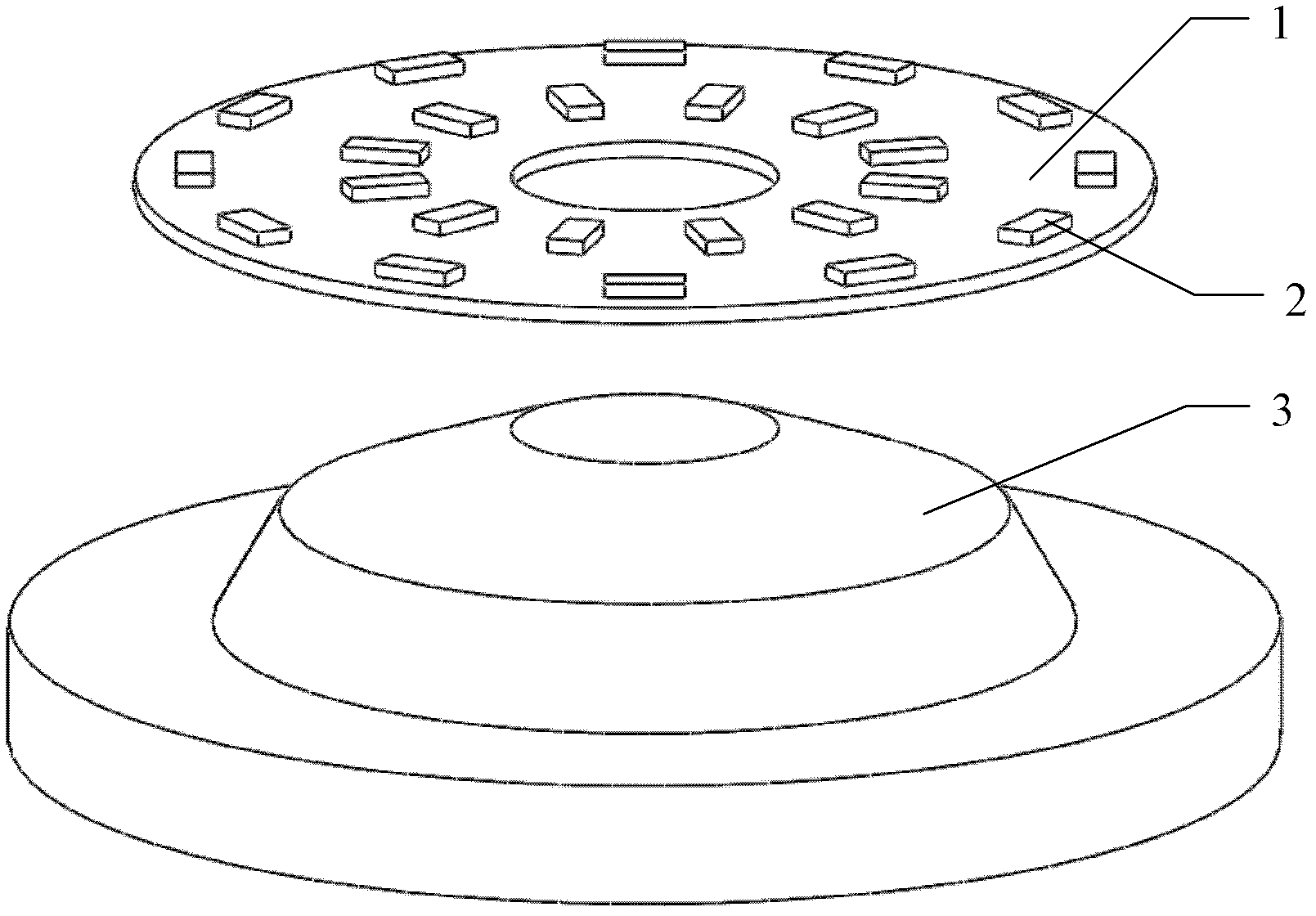

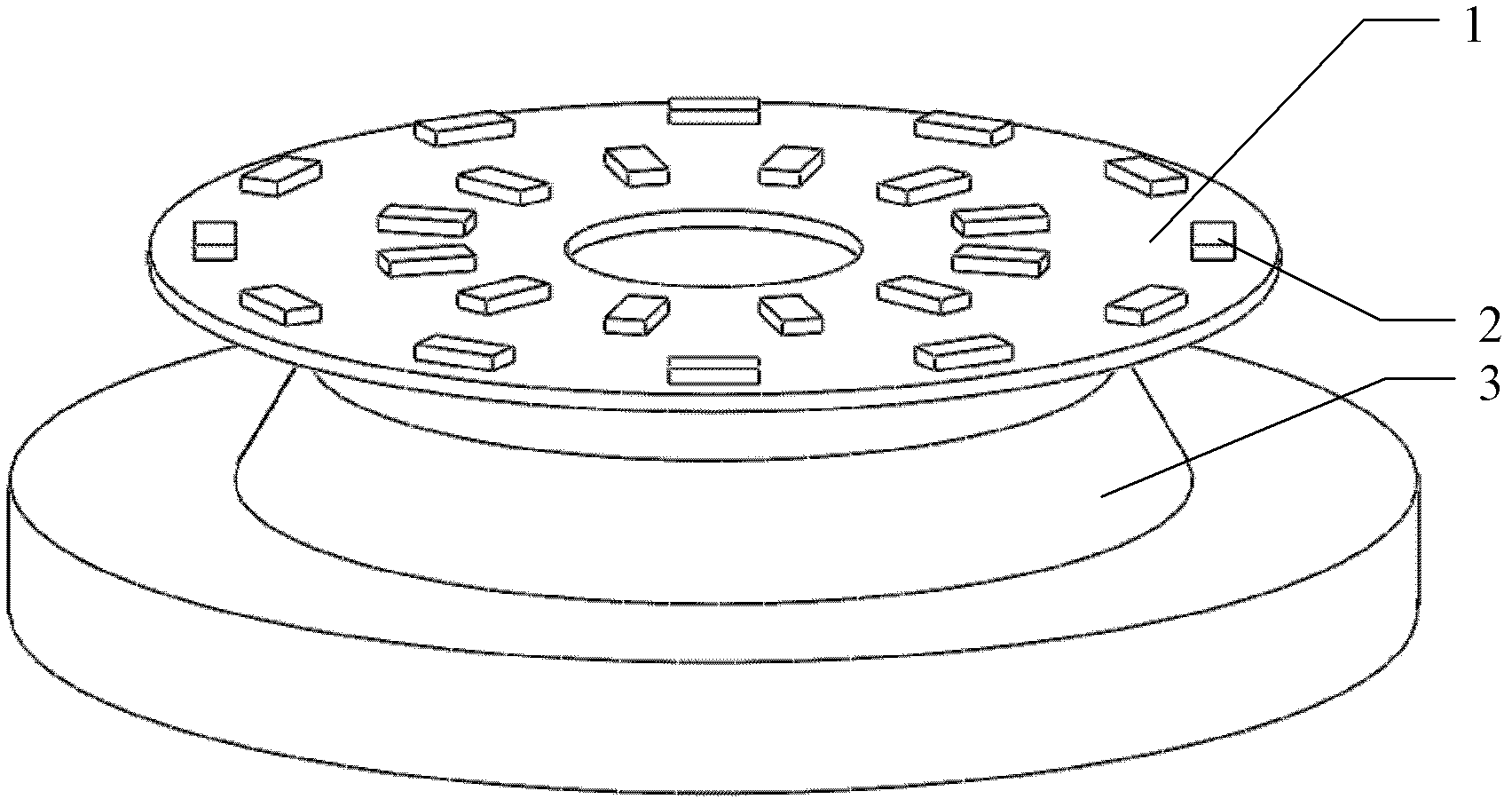

Intelligent toilet structure

InactiveCN105019528APrevent accidental touchPrevent fettersVibration dampersBathroom coversAffixElectric wire

A toilet seat contains: a toilet seat, a connecting assembly, a body, and a fixing plate. The toilet seat includes a support, a holder, and a cover; the support has an electronic controlling element, at least one inlet pipe, and an electric wire. The connecting assembly is connected with the support and includes an elongated affix piece, a retaining member, and a pressing member; the affix piece has two penetration portions and two recesses. The retaining member has two cutouts defined on two ends thereof to correspond to the two penetration portions and has two locking portions proximate to the two cutouts. The body includes two accommodating orifices and two connection orifices. The fixing plate is mounted on the two connection orifices and includes two opposite lockers extending outwardly therefrom and inserting through the two penetration portions and the two cutouts to retain with the two locking portions.

Owner:GLOBE UNION INDAL

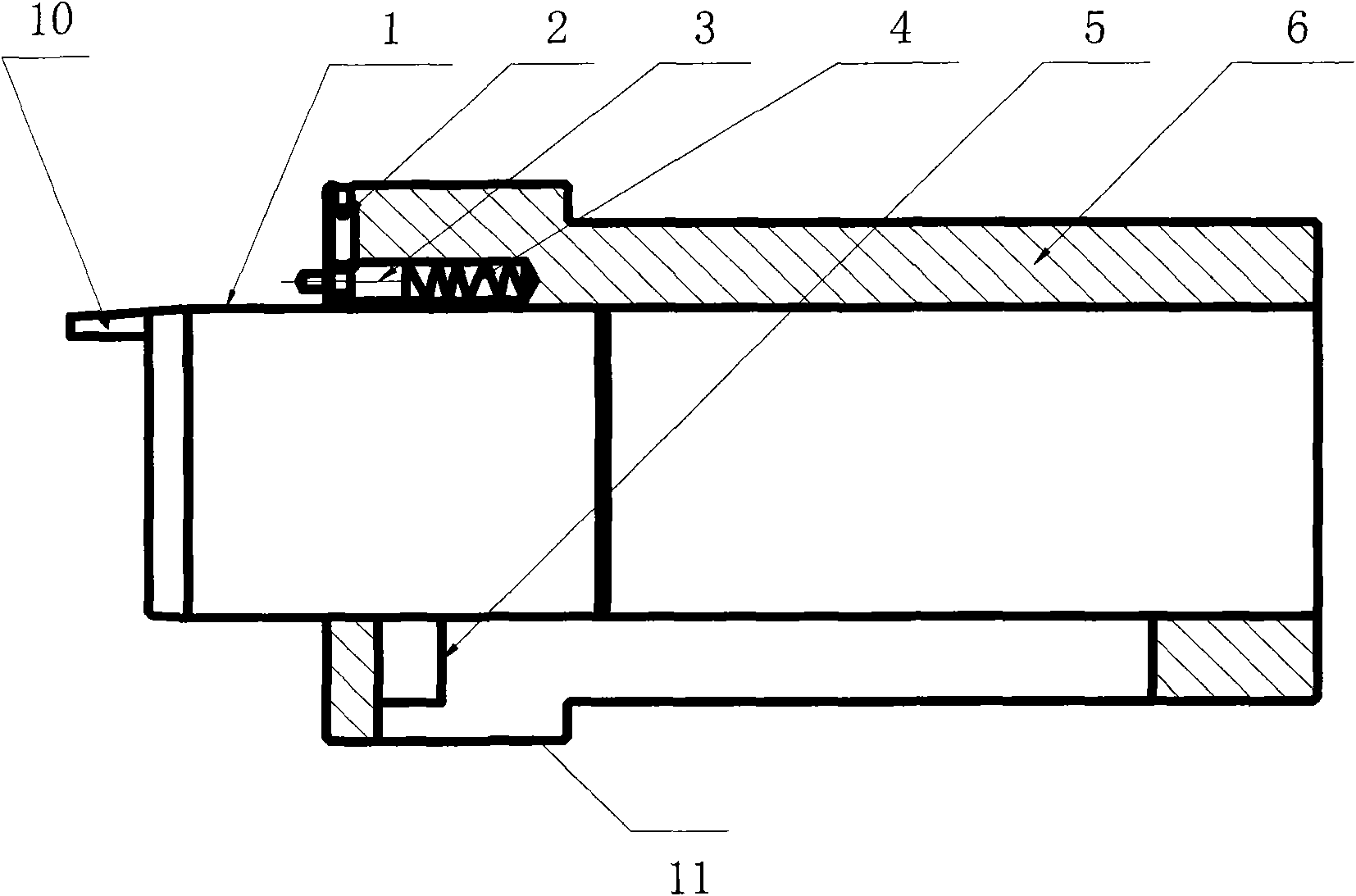

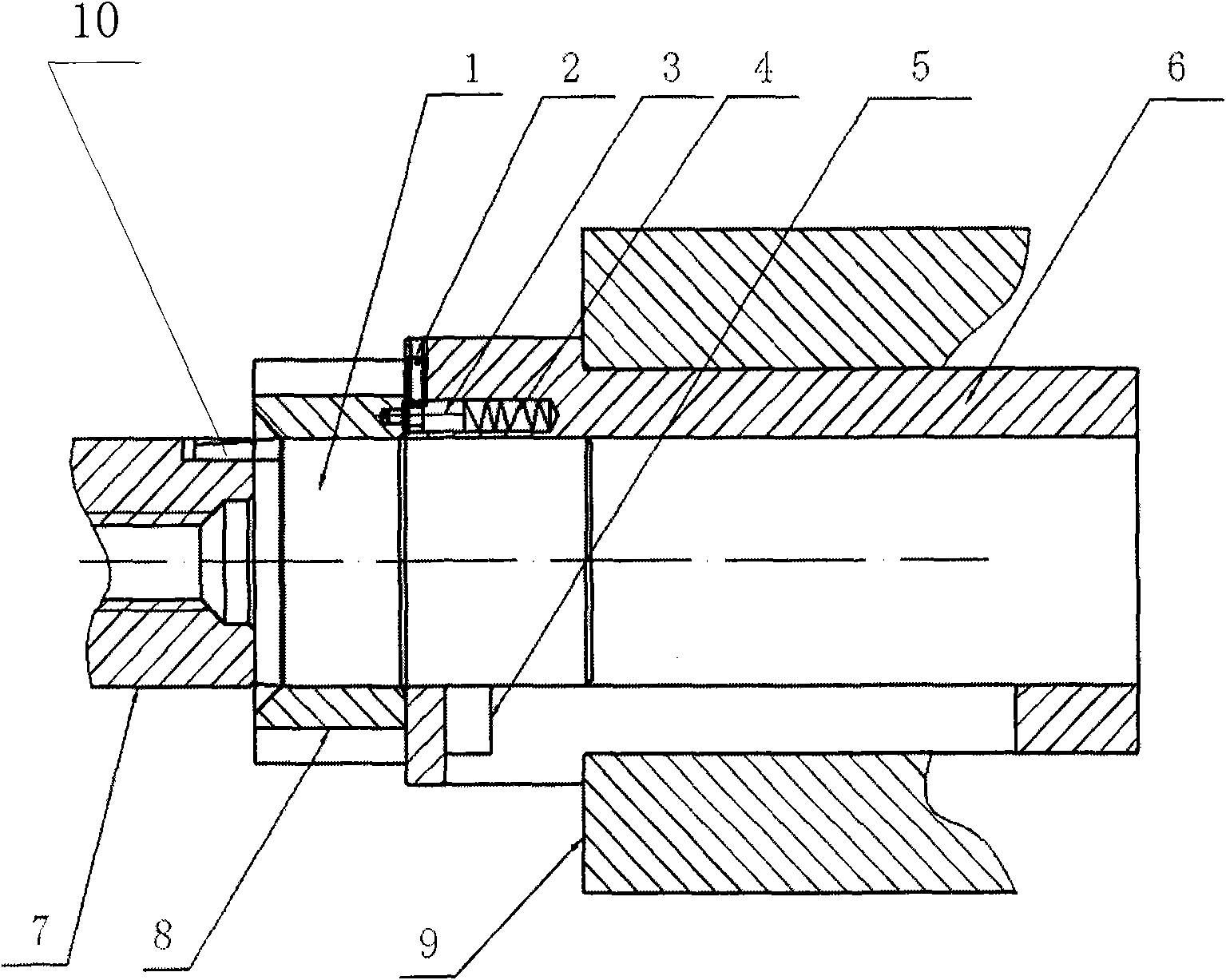

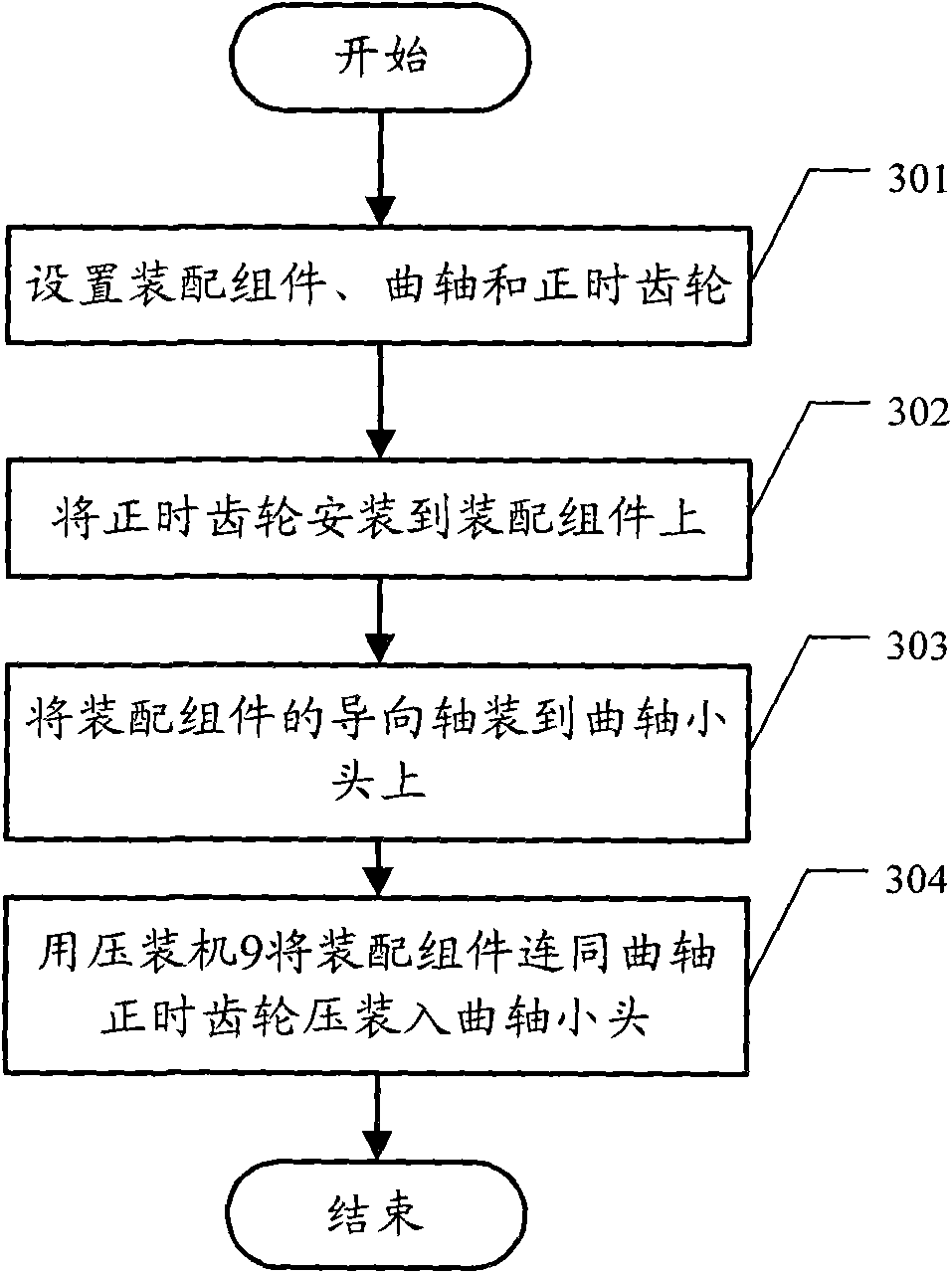

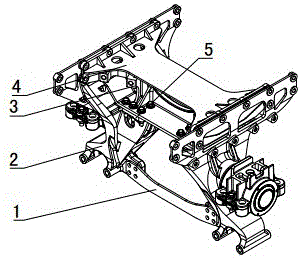

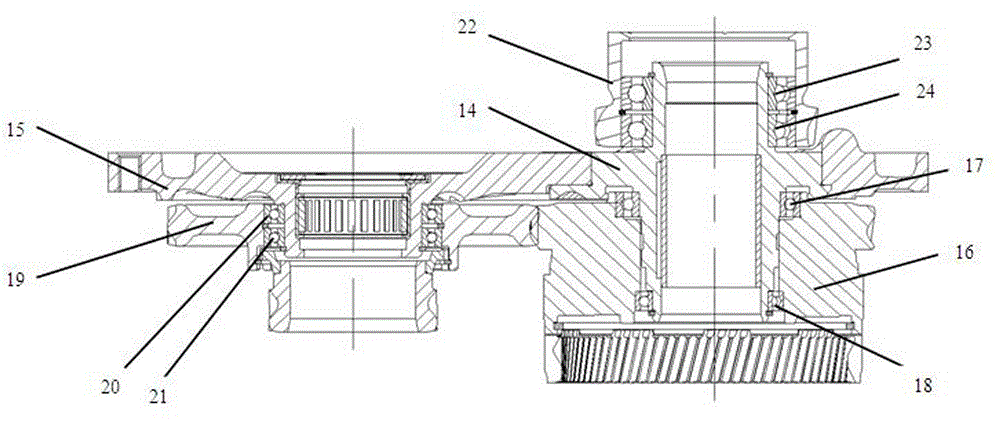

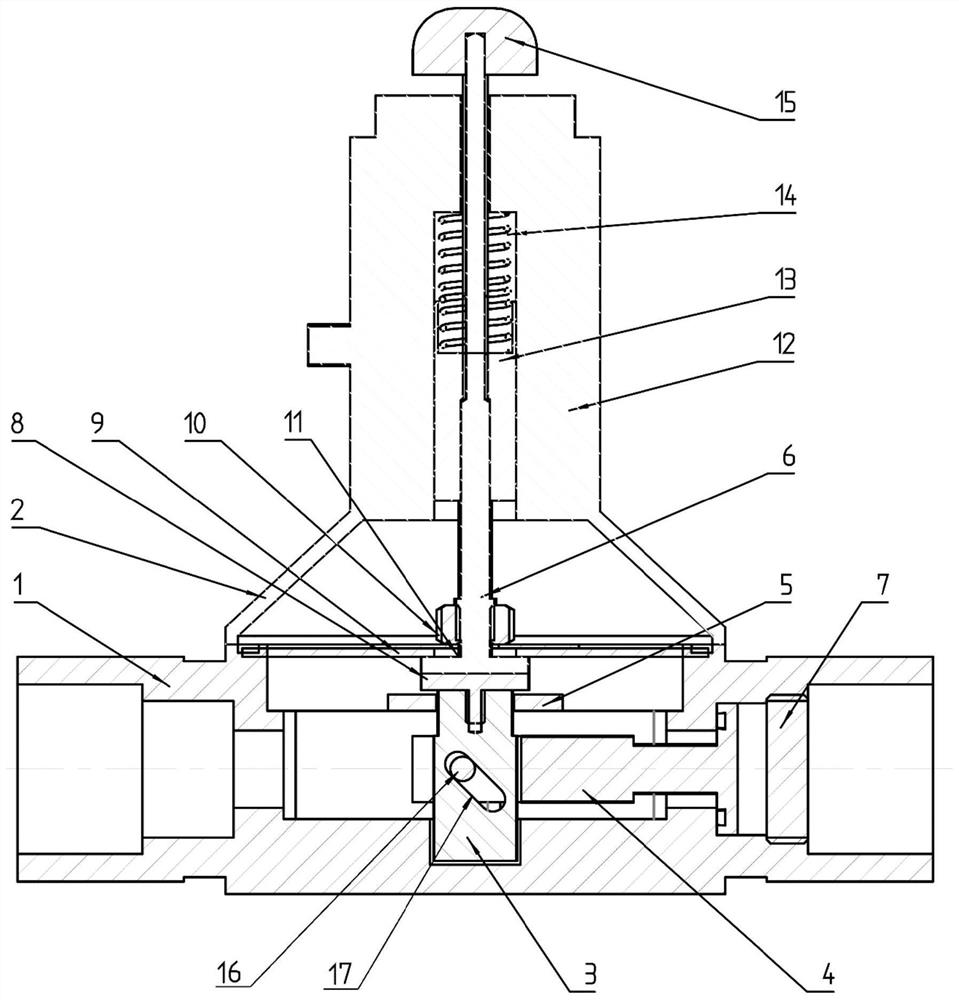

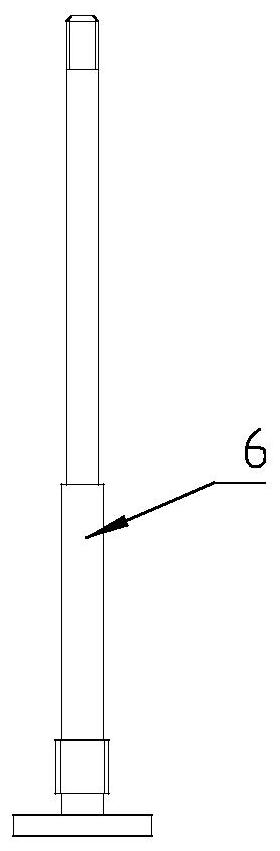

Assembly component and assembly method for crankshaft timing gear

ActiveCN101856785AReduce the difficulty of pressingImprove assembly stabilityMetal working apparatusGear wheelEngineering

The invention discloses an assembly component and an assembly method for a crankshaft timing gear. The assembly component comprises a guide shaft and a guide sleeve which is axially and glidingly sleeved on the guide shaft. The method comprises the following steps of: setting the assembly component consisting of the guide shaft and the guide sleeve, and setting a crankshaft and a timing gear according to the assembly component; arranging the timing gear on the guide sleeve of the assembly component; arranging the guide shaft on the small head of the crankshaft; and pressing the assembly component and the crankshaft timing gear into the small head of the crankshaft together by using a press so as to finish the assembly of the crankshaft timing gear. The assembly component and the assembly method can overcome the defects of high pressing difficulty, poor assembly stability, low precision and the like in the prior art to relieve the pressing difficulty and improve the assembly stability and the precision.

Owner:GUANGXI YUCHAI MASCH CO LTD

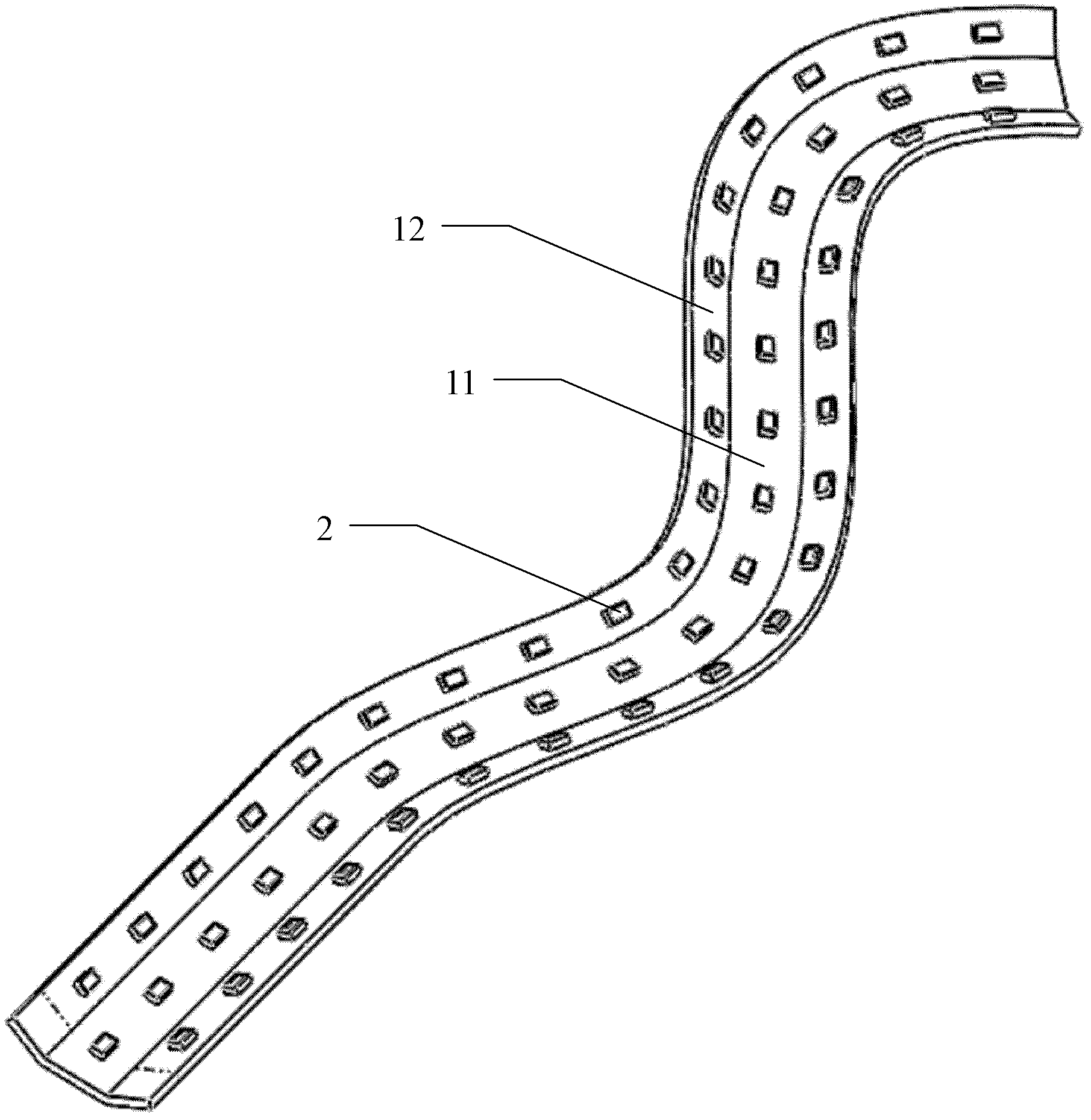

Three-dimensional metal-based Printed Circuit Board (PCB) assembly structure, corresponding light-emitting lamp and manufacturing method

InactiveCN102595788AImprove reliabilityImprove performancePrinted circuit assemblingPlanar light sourcesCircuit reliabilityComputer module

The invention relates to a three-dimensional metal-based Printed Circuit Board (PCB) assembly structure assembly structure in a light-emitting lamp, which consists of a single continuous metal-based circuit board and a plurality of light-emitting components on the upper surface of the metal-based circuit board. Each light-emitting component is connected with the metal-based circuit board by a circuit; parts on the metal-based circuit board, which are provided with the light-emitting components, are not positioned on the same plane or curved surface; and the metal-based circuit board is of a three-dimensional structure. The invention also relates to the light-emitting lamp with the assembly structure and a manufacturing method of the assembly structure. Due to the adoption of the three-dimensional metal-based PCB circuit board assembly structure which is of the structure, the corresponding light-emitting lamp and the manufacturing method, the heat conduction contact surface is larger; a single module assembly has simple and practical structure; the process is simplified; the three-dimensional metal-based PCB circuit board assembly structure is convenient and rapid to process, is beneficial to mass mechanical production, has low cost, has high circuit reliability and stable and reliable performance and is firm and durable; the assembly stability and the mechanical strength of a circuit board assembly are improved; and the three-dimensional metal-based PCB circuit board assembly structure is difficult to deform and has wide application range.

Owner:蔡子丰

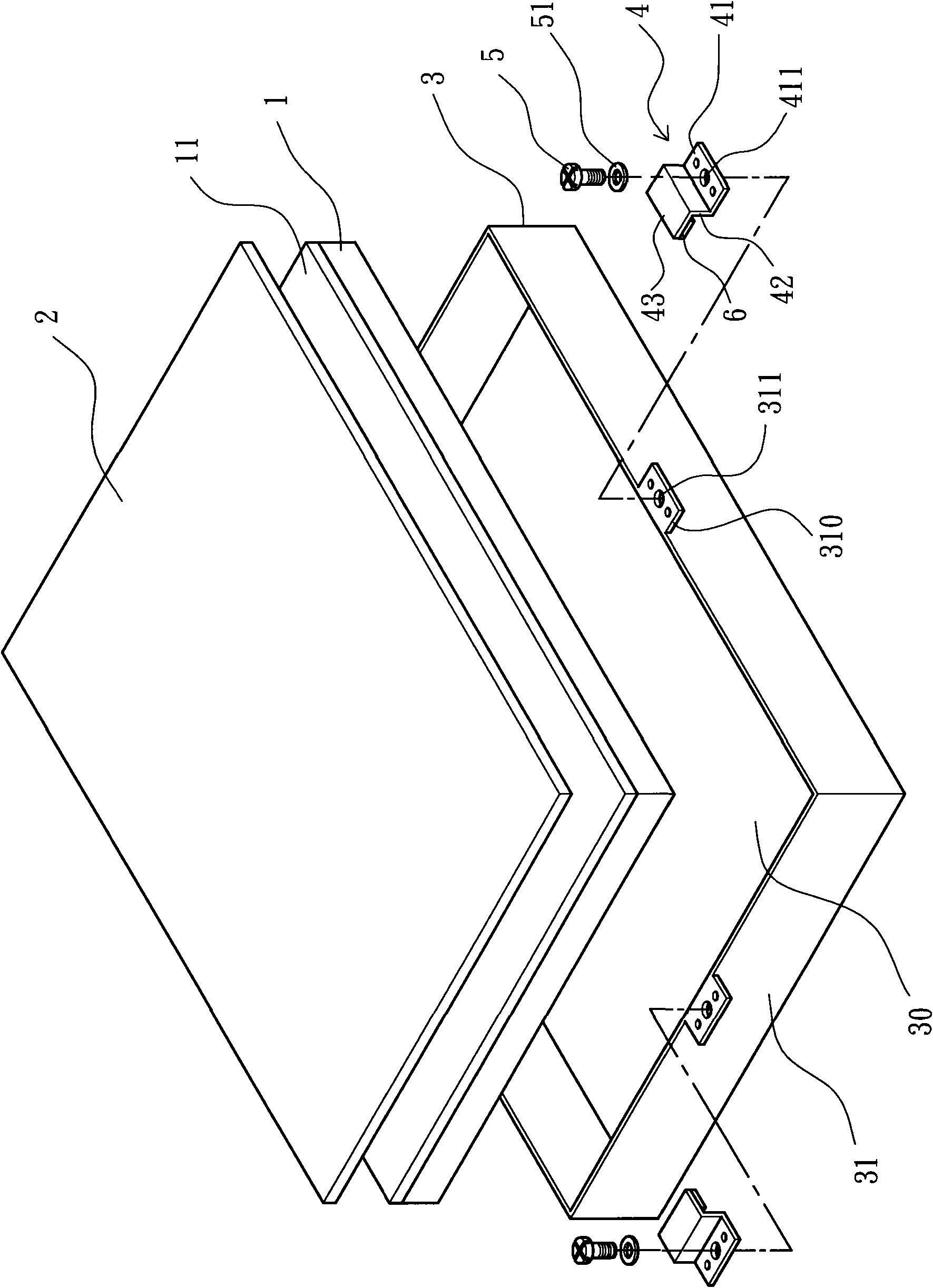

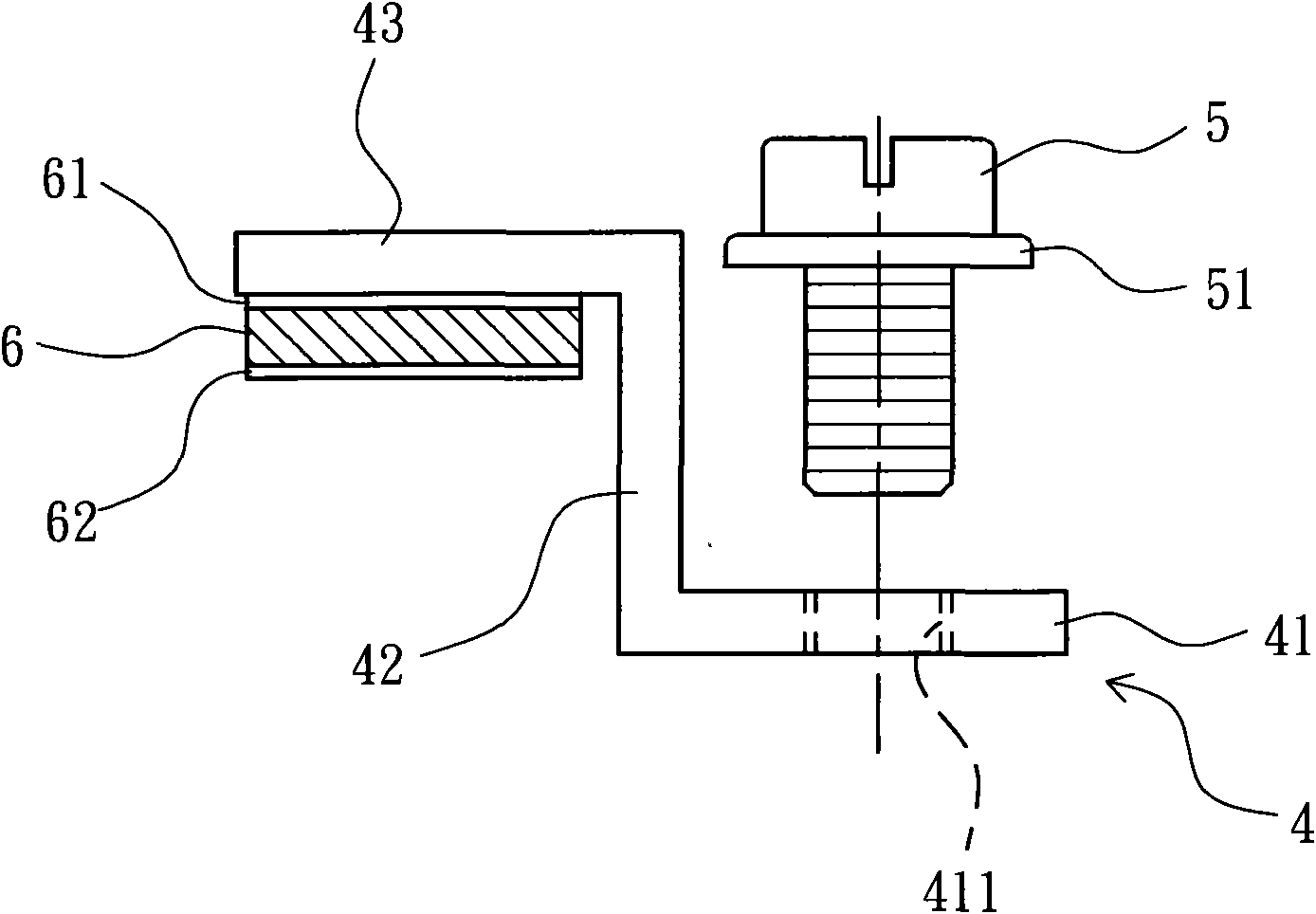

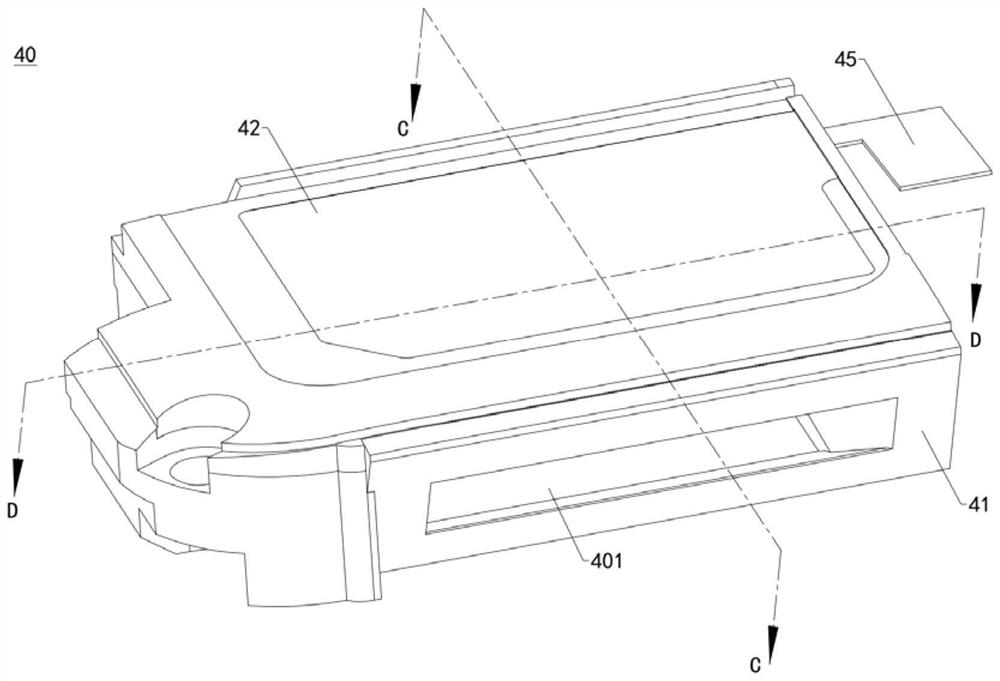

Display device

InactiveCN101566745AWon't looseAvoid damageStatic indicating devicesInput/output processes for data processingDisplay deviceEngineering

The invention discloses a display device which comprises a display module, an auxiliary panel and a fixed structure, wherein the fixed structure is used for assembling the auxiliary panel on the display module. The fixed structure comprises a frame and a plurality of positioning sheets arranged on the frame. The frame defines a holding space for holding and bearing the display module and the auxiliary panel. Each of the positioning sheets is correspondingly matched with a screwing component to stably screw the auxiliary panel on the frame. Each of the positioning sheets is further provided with a buffer shock absorbing sheet with adhesive layers on both sides to adhere on the auxiliary panel. By the method, the invention can stably assemble the auxiliary panel on the frame by using screwing pressure and viscosity to absorb the shock so as to prevent the auxiliary panel from shifting relative to the frame.

Owner:CORETRONIC PROJECTION KUSN CORP

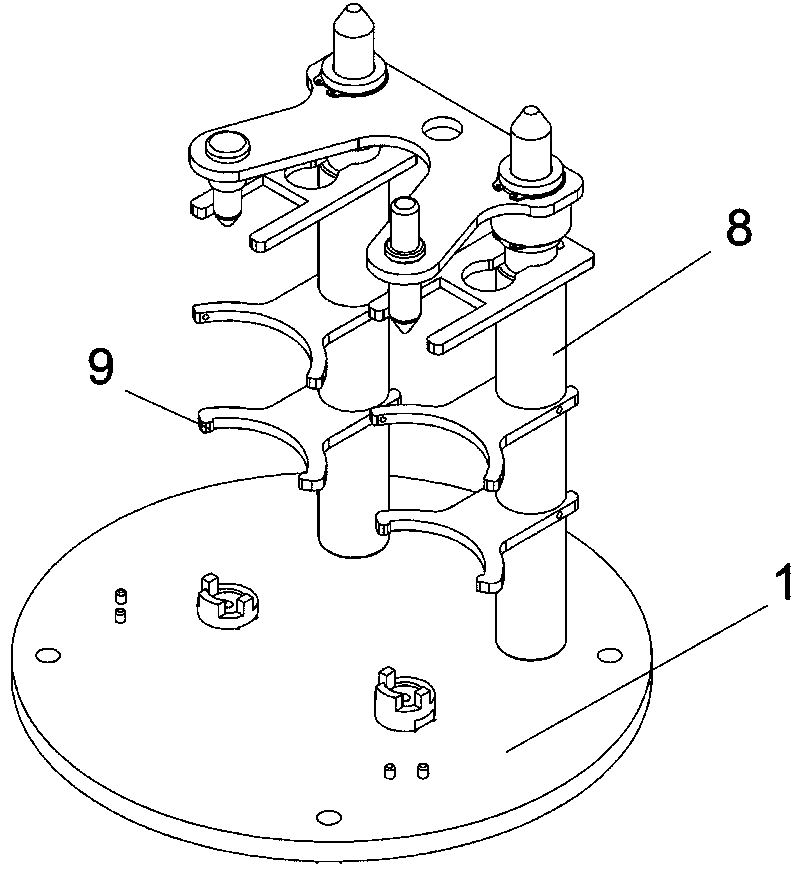

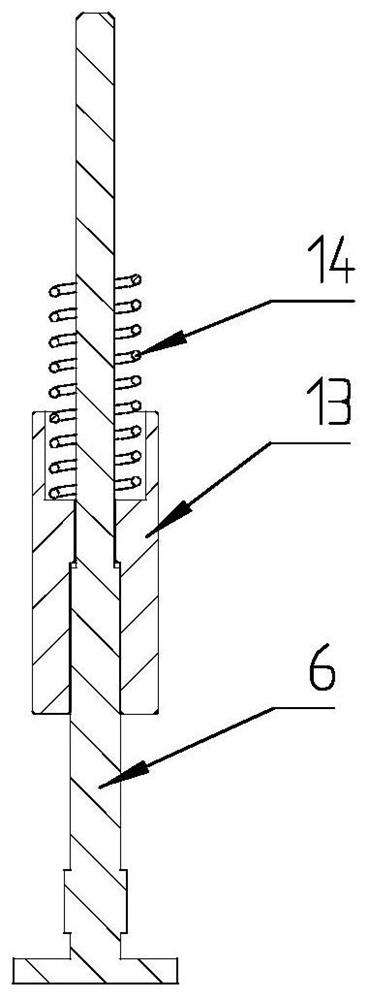

Vacuum arc-extinguishing chamber assembling calibration clamp

ActiveCN108962648AGuaranteed coaxialityImprove coaxialityElectric switchesVacuum arcElectrical and Electronics engineering

The invention relates to a vacuum arc-extinguishing chamber assembling calibration clamp. The vacuum arc-extinguishing chamber assembling calibration clamp comprises a calibration unit used for calibrating a single vacuum arc-extinguishing chamber. The calibration unit comprises a movable end positioning pin and a static tube core positioning structure which are coaxially arranged in an up and down direction. The movable end positioning pin is used for inserting and connecting to the threaded hole of a movable tube core in a coaxial and positioning mode. The static tube core positioning structure is used for assembling with a static tube core in the coaxial and positioning mode. A righting structure used for righting the vacuum arc-extinguishing chamber is arranged above the static tube core positioning structure. During vacuum arc-extinguishing chamber assembling, the static tube core positioning structure and the static tube core are installed in the coaxial and positioning mode. Themovable end positioning pin is coaxially inserted and connected to the threaded hole of the movable tube core. The coaxiality of the static tube core and the movable tube core is guaranteed, the righting structure can carry out righting and positioning on a static cover plate, a porcelain shell and other components, and a problem that the coaxiality of the vacuum arc-extinguishing chamber can not be guaranteed in the prior art is solved.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +2

Washing machine shaft and machining method thereof

ActiveCN109623298ALow costImprove organizationOther washing machinesTextiles and paperPulp and paper industryMachining

The invention discloses a washing machine shaft and a machining method thereof, and belongs to the technical field of shaft machining. The machining method is characterized in that a cold extrusion process is adopted to machine a rod material to enable the rod material to be formed into a stepped shaft, for the stepped shaft obtained after milling and drilling machining, the two end faces are milled, chamfering is performed, and a center hole is punched so that the stepped shaft can be clamped by adopting a double-centre tool method. According to the washing machine shaft and the machining method thereof, through the unified positioning reference, the machining precision is improved, in addition, the production cost is also reduced, the production efficiency is improved, the operation is simple and convenient, the machining quality is stable, and the batch production is facilitated.

Owner:安徽一众精密轴业有限公司

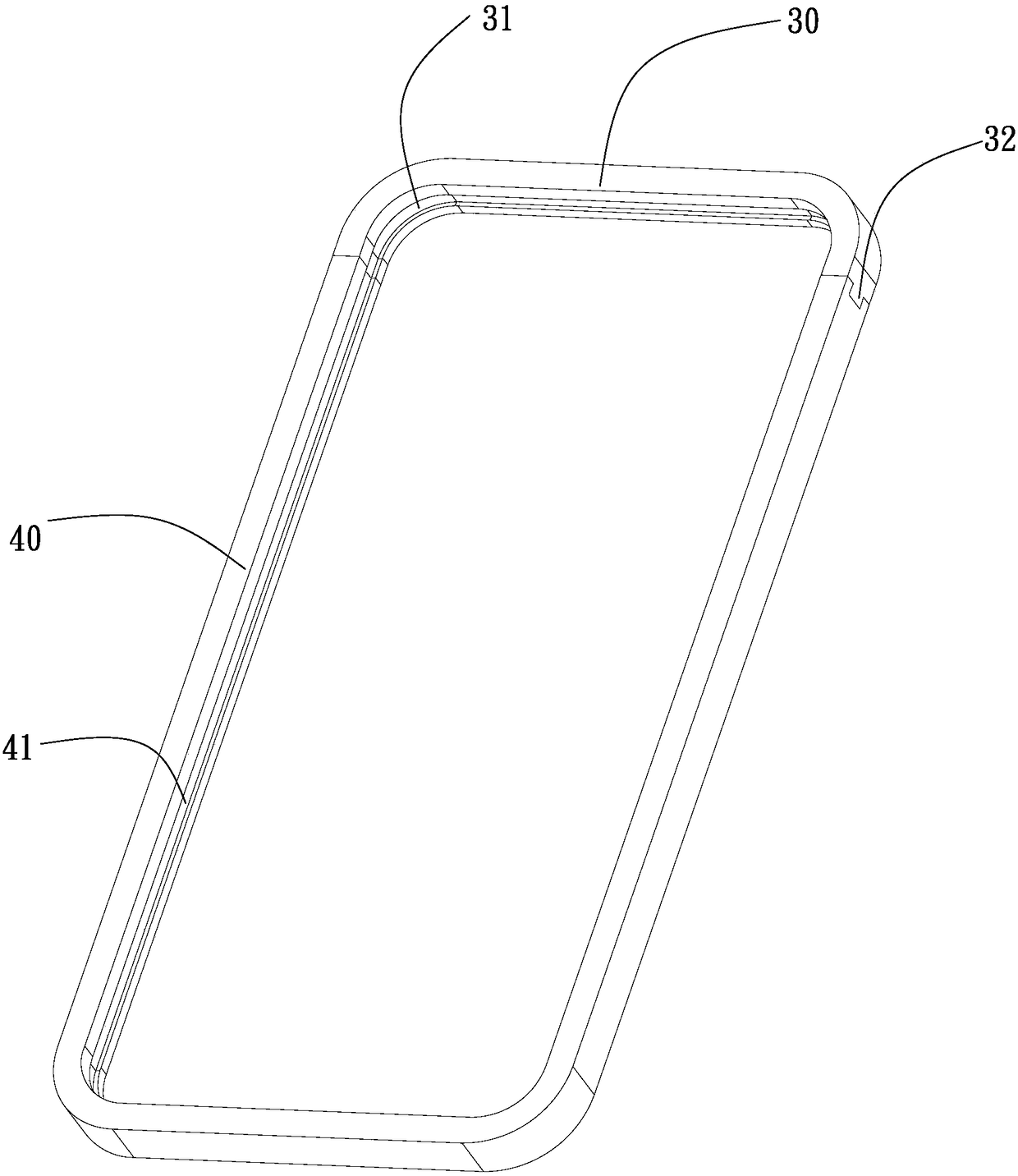

Doorframe and refrigeration equipment door body with doorframe

ActiveCN103628777ASimple structureStable structureDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

The invention discloses a doorframe and refrigeration equipment door body with the doorframe. The doorframe comprises a left upright post, a right upright post, an upper end cover and a lower end cover, wherein a plugging tongue is arranged on at least one end of at least one of the left upright post and the right upright post; the upper end cover is connected with the upper ends of the left upright post and the right upright post; the lower end cover is connected with the lower ends of the left upright post and the right upright post; plugging slots matched with the plugging tongue are formed in the upper end cover and the lower end cover. According to the doorframe provided by the embodiment of the invention, due to the fact that the plugging tongue is arranged on at least one end of at least one of the left upright post and the right upright post, correspondingly, the plugging slots matched with the plugging tongue are formed in the upper end cover and the lower end cover, the plugging tongue and the plugging slots are very simple in structure, the plugging tongue is inserted into the plugging slots, and the doorframe can be assembled by bending the plugging tongue, the doorframe is convenient to assemble, the production efficiency is improved, the assembled plugging tongue is not easy to loose from the plugging slots, and the doorframe is more stable and firmer.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

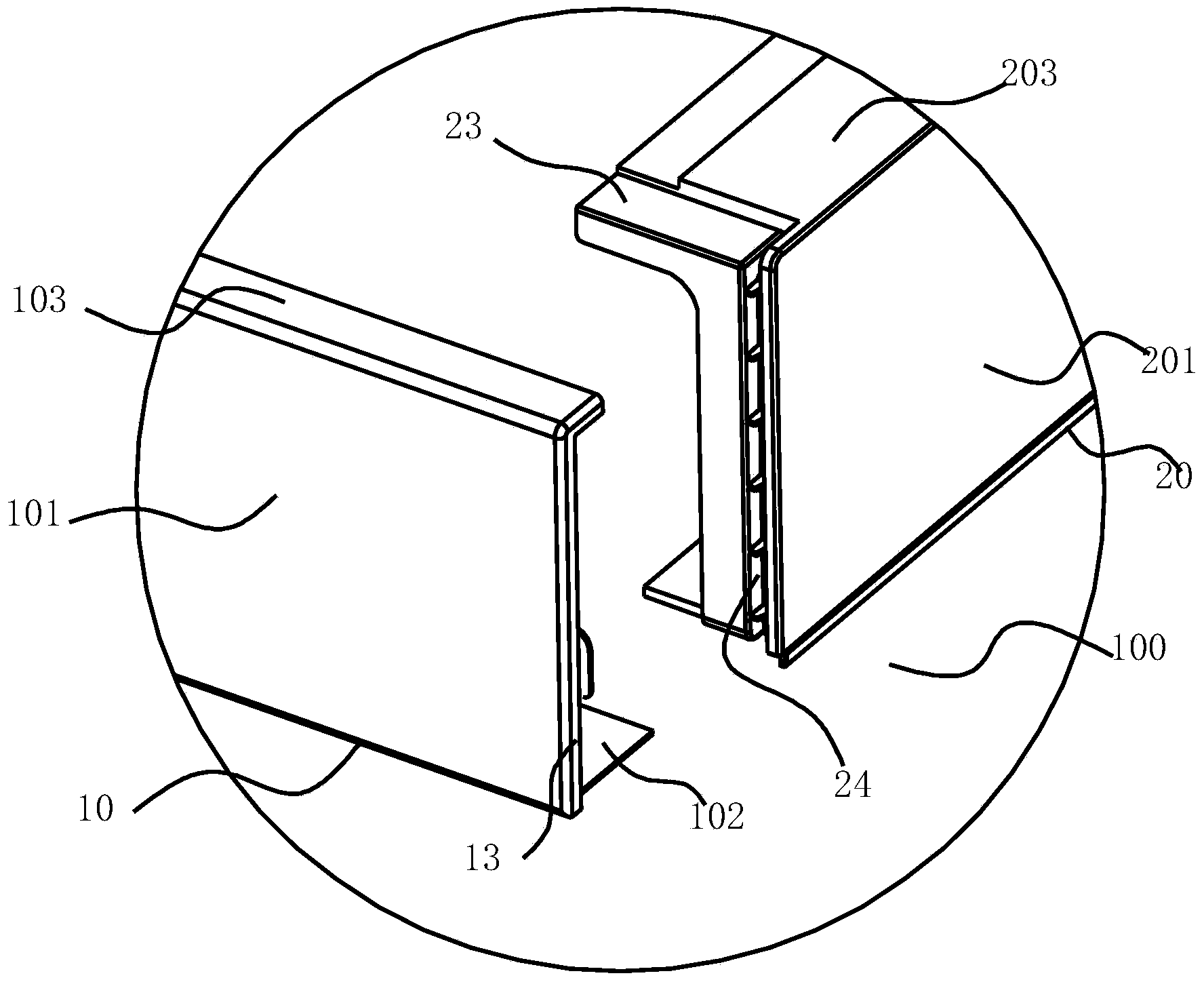

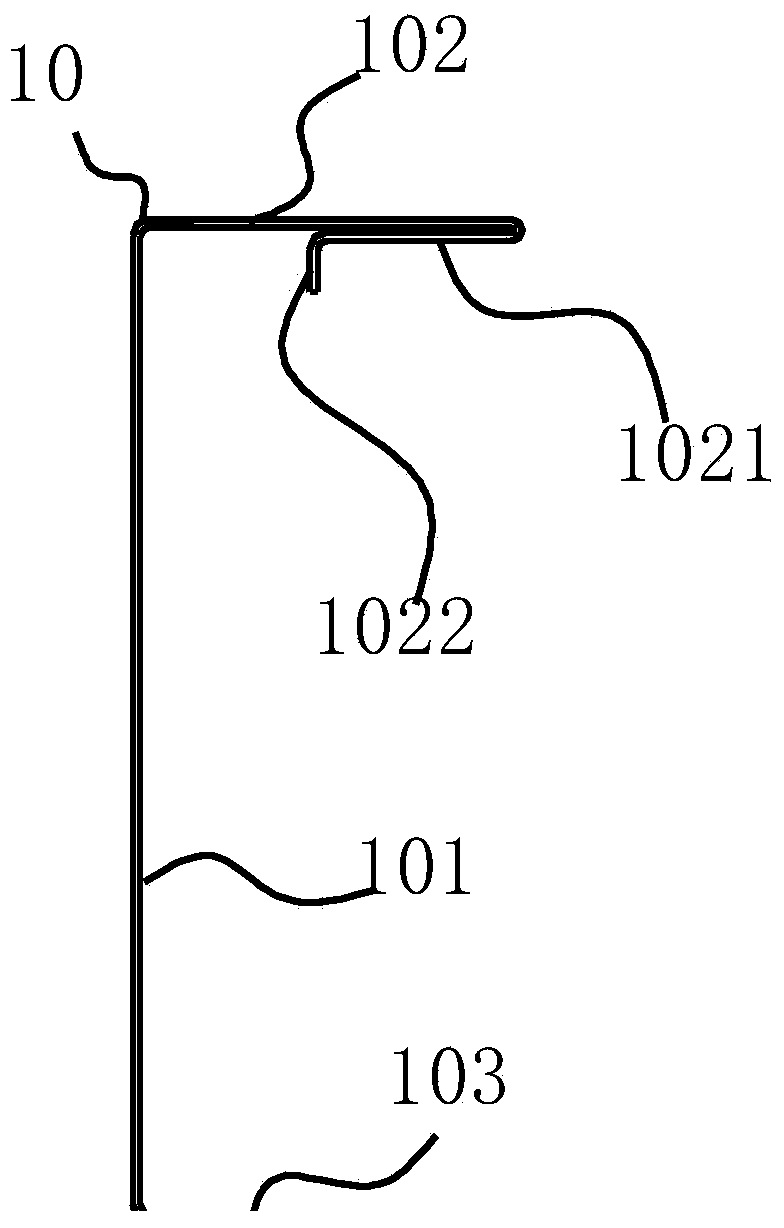

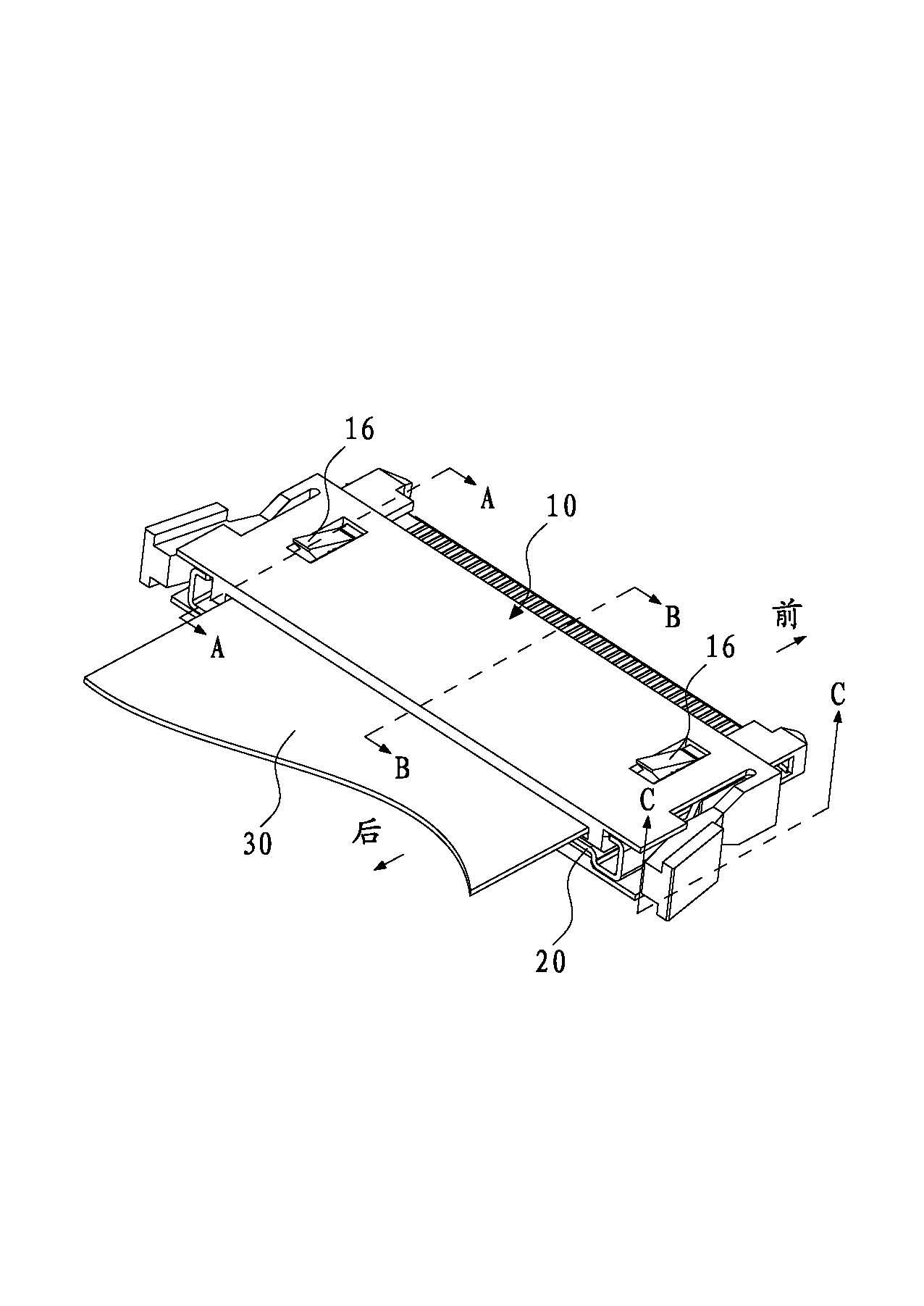

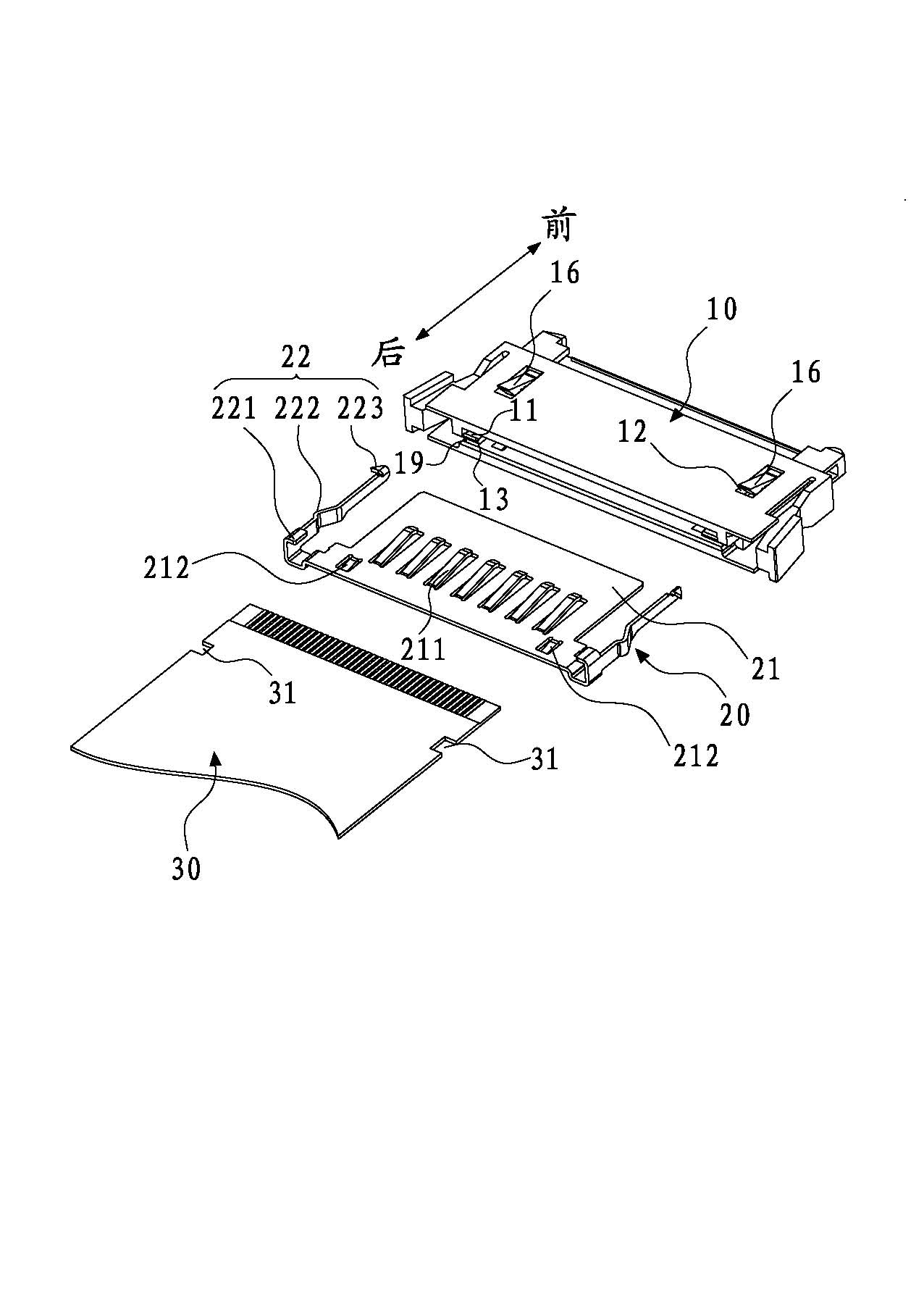

Electric connector for flat conductor

InactiveCN102629723AFirm and not easy to fall outSimple structureCouplings bases/casesFixed connectionsElectrical conductorEngineering

Owner:DONGGUAN YUQIU ELECTRONICS CO LTD

Power steering pump

ActiveCN102536802BExtended service lifeImprove filtering effectSpecific fluid pumpsRotary piston pumpsEngineeringHigh pressure

Owner:QUANXING MACHINING GRP

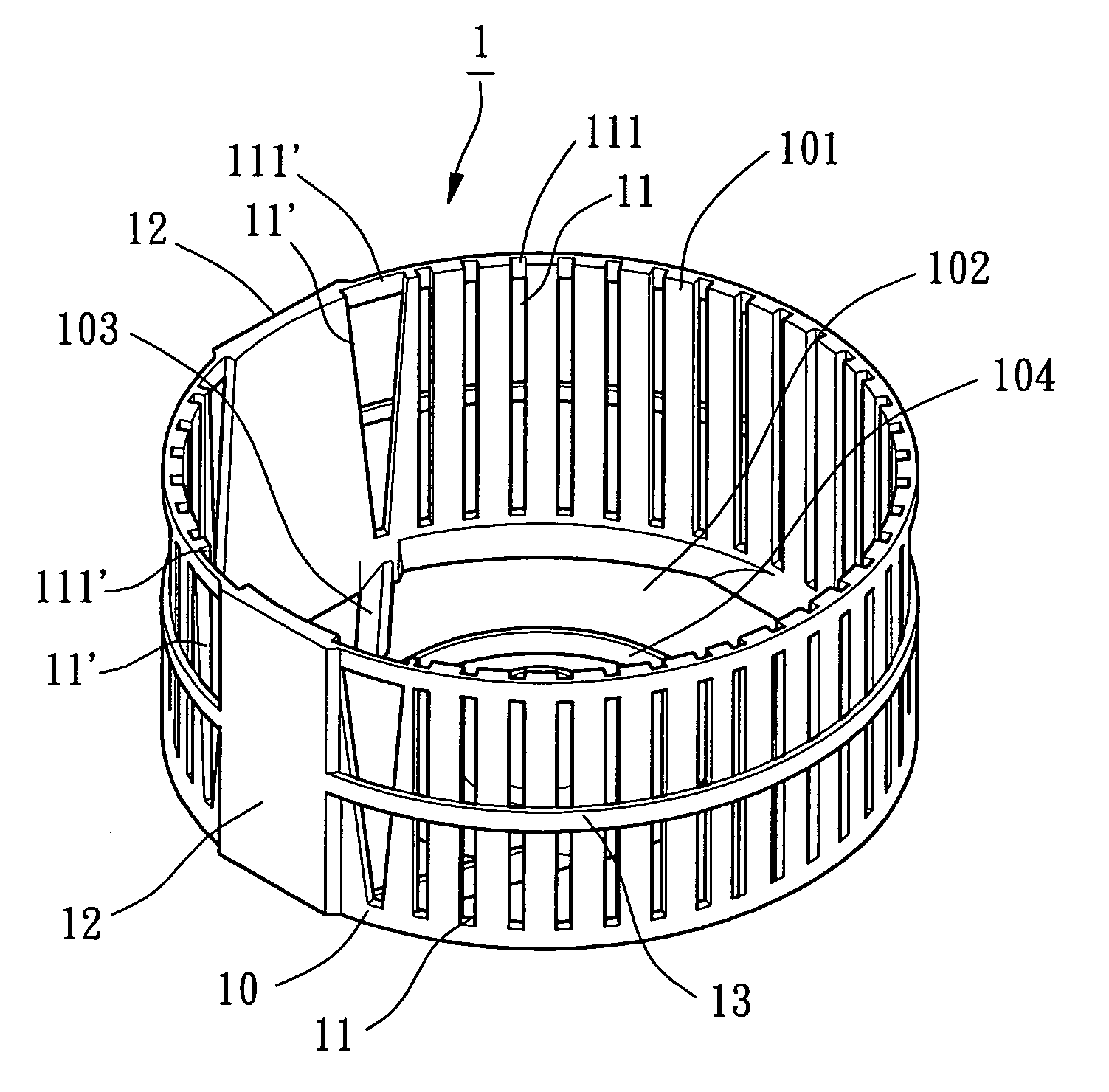

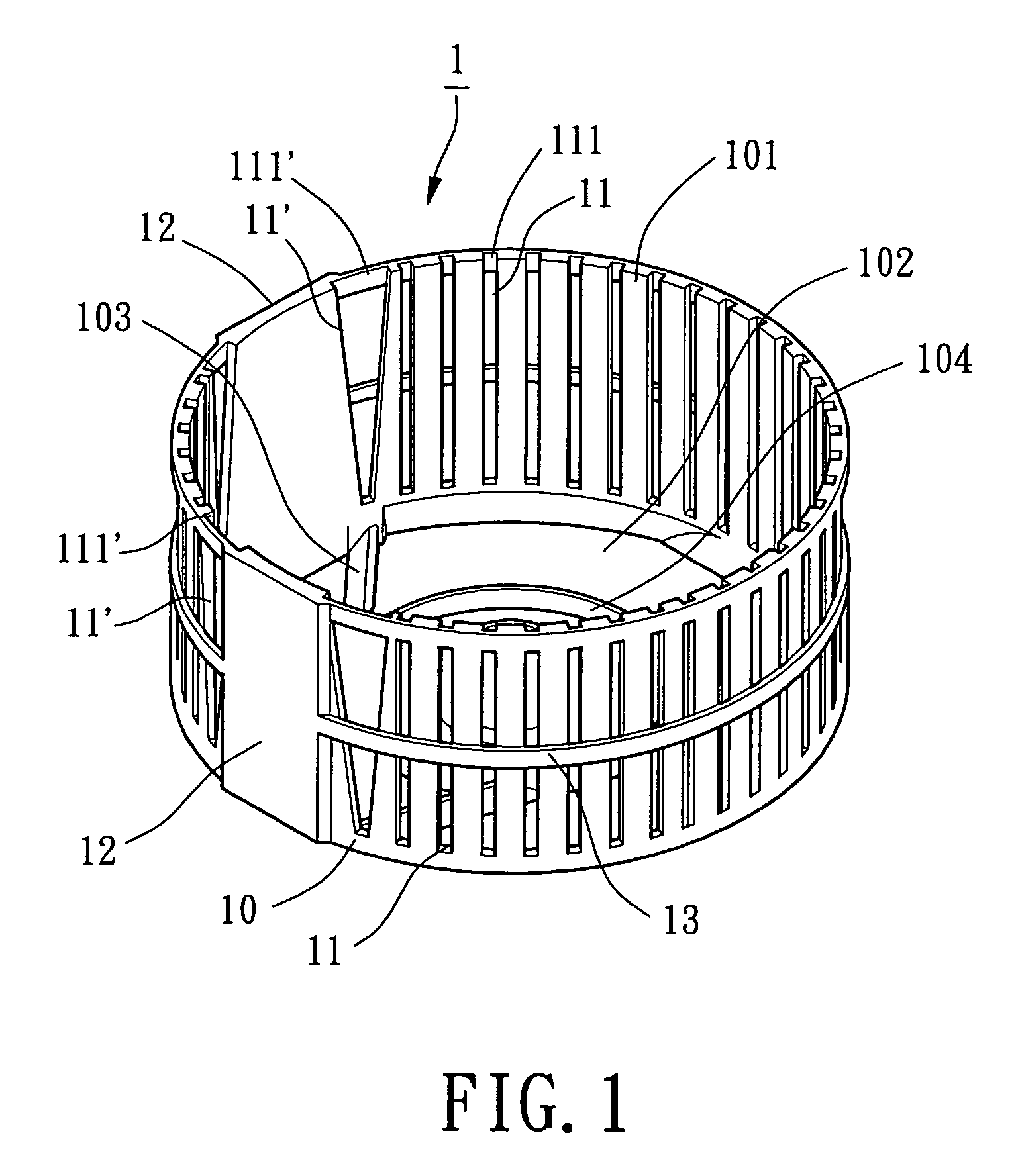

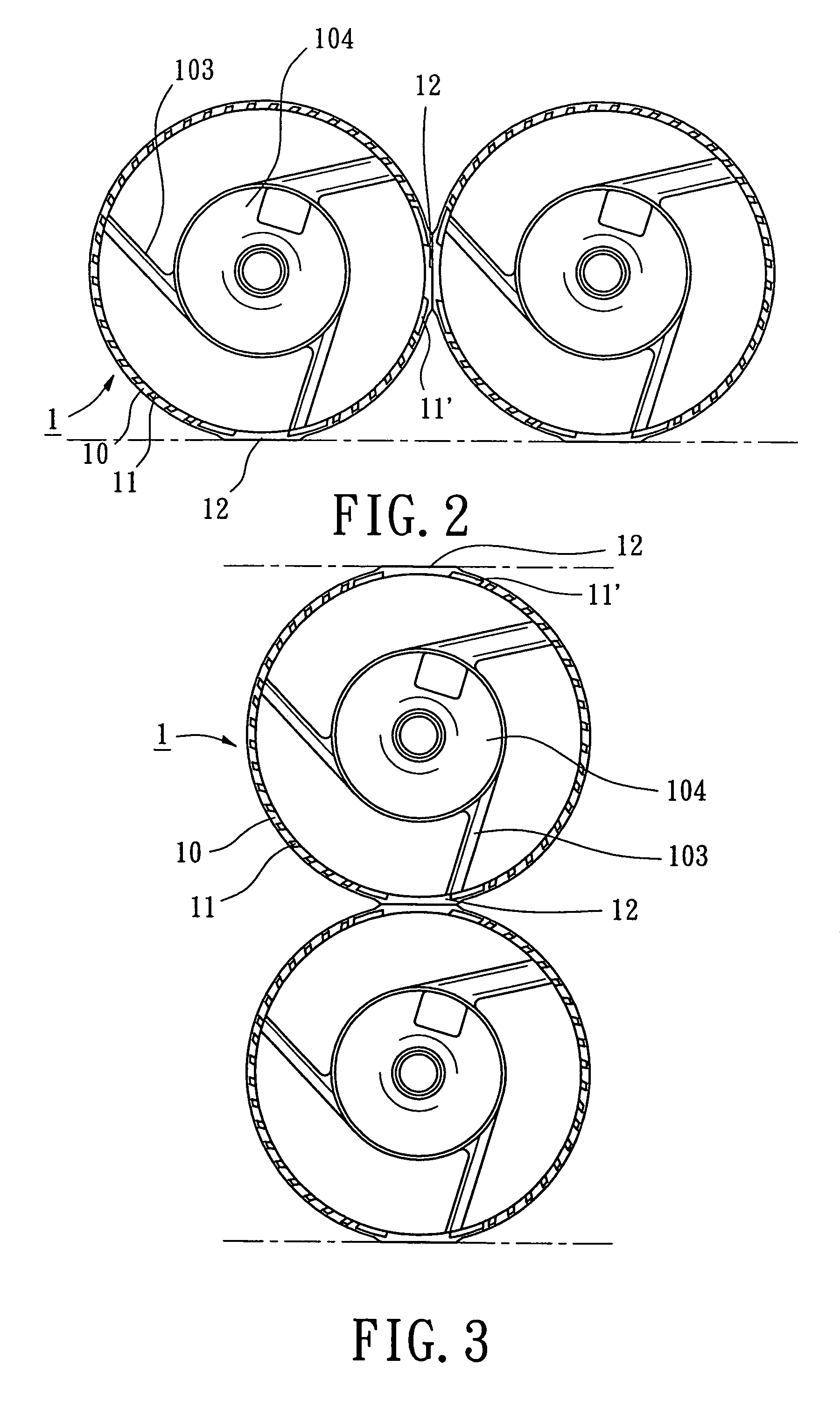

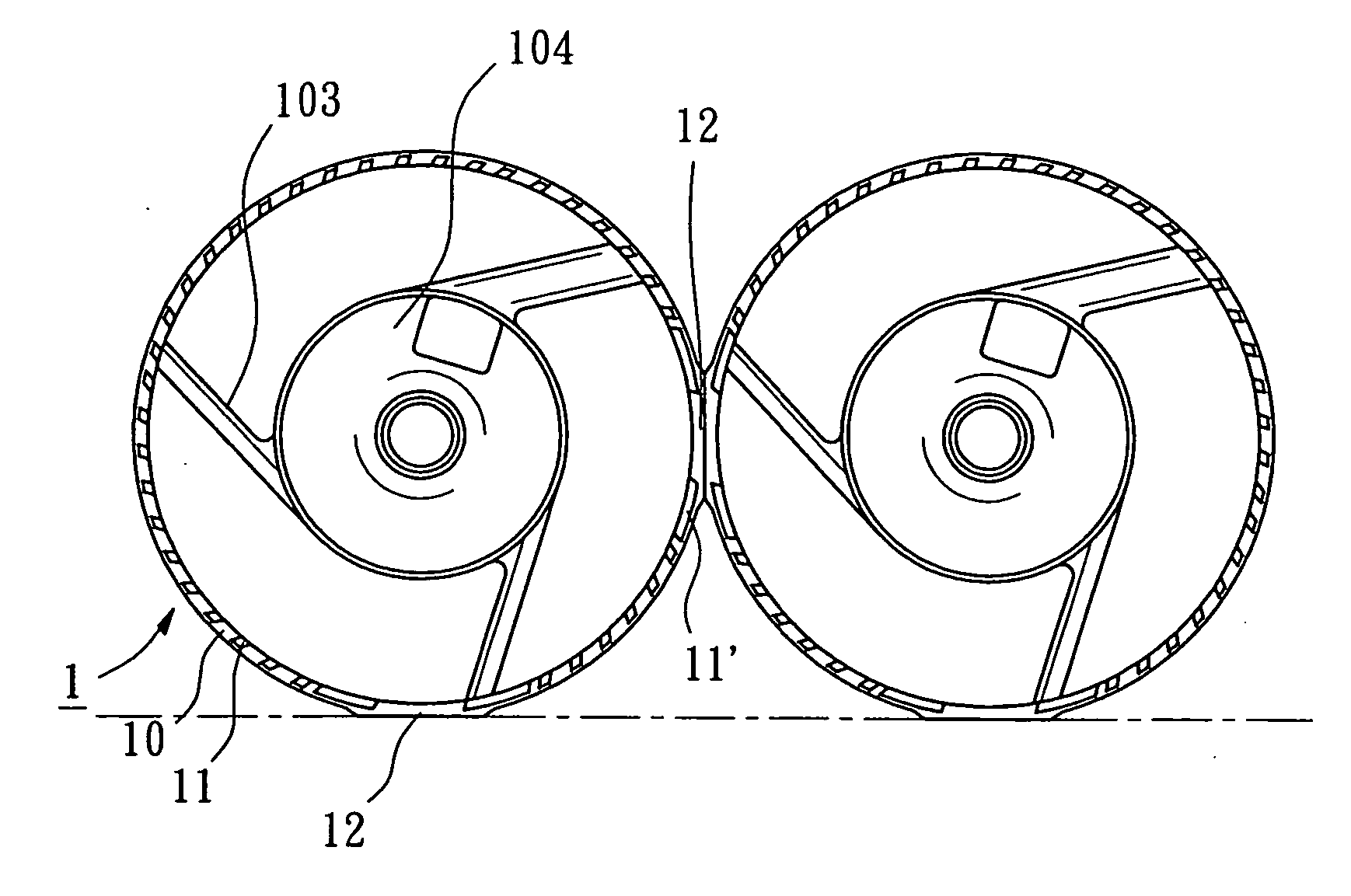

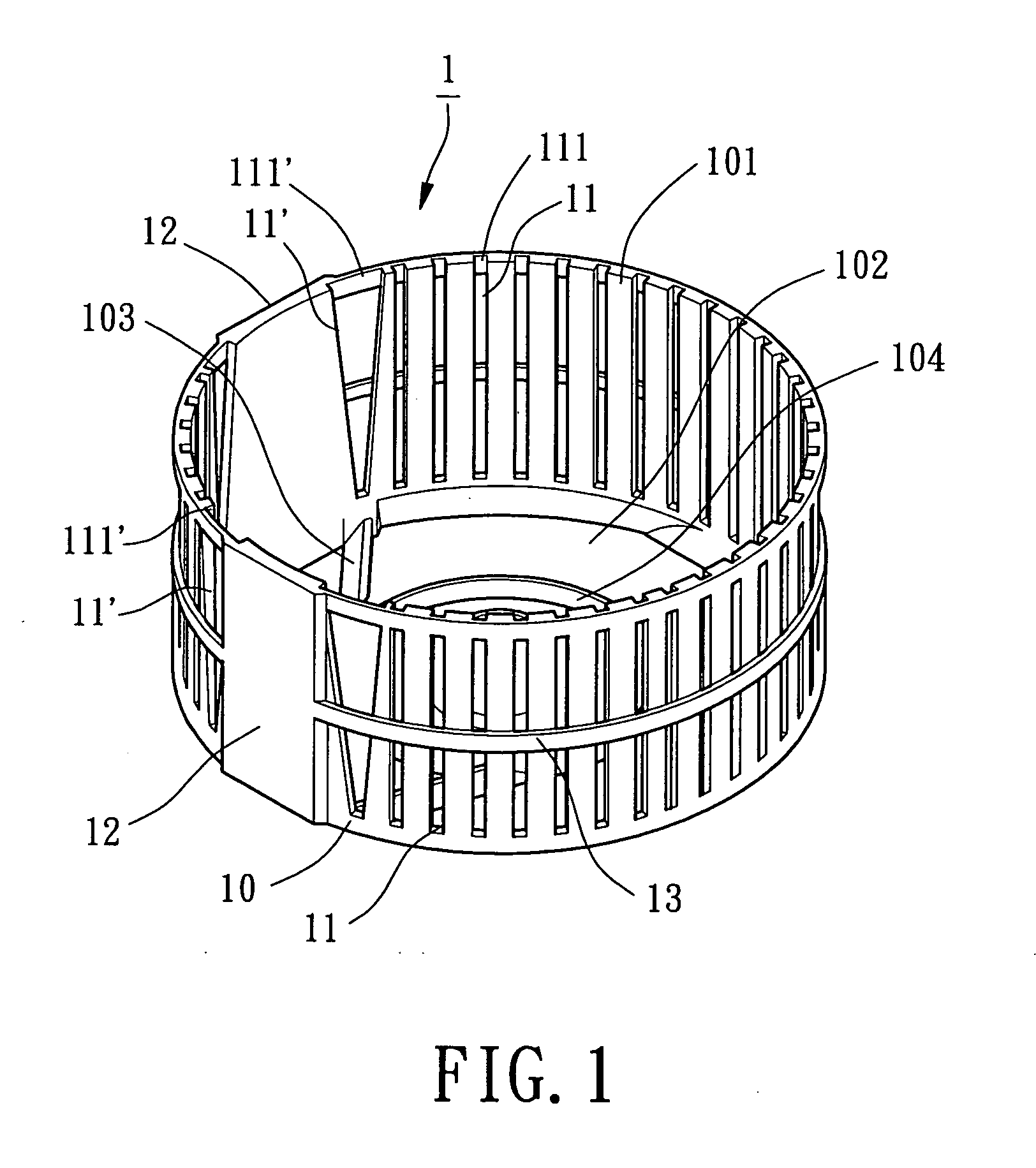

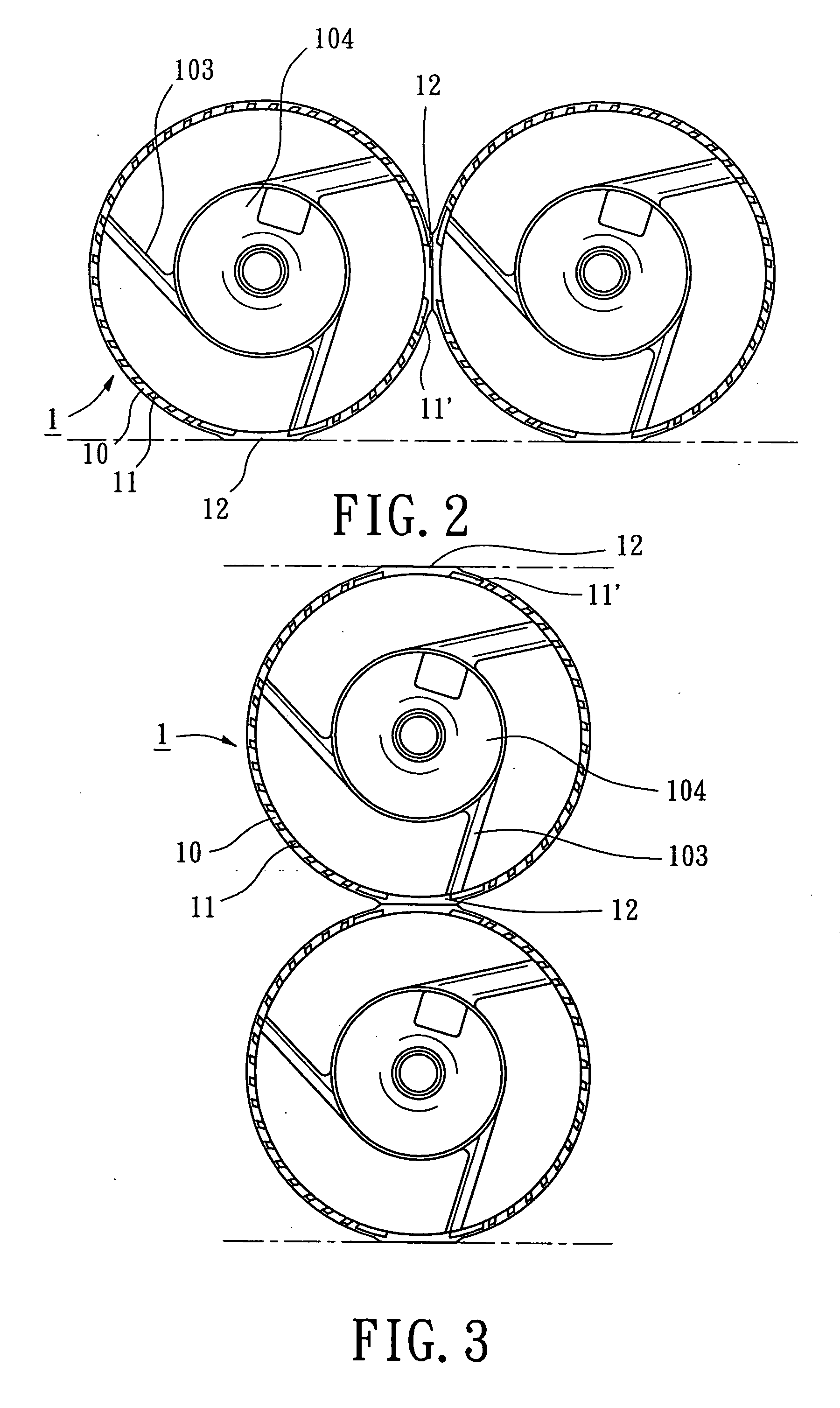

Housing for axial flow heat-dissipating fan

InactiveUS7080970B2Improve assembly stabilityIncrease assembly flexibilityPump componentsCombination enginesEngineeringComputer fan

Owner:SUNONWEALTH ELECTRIC MACHINE

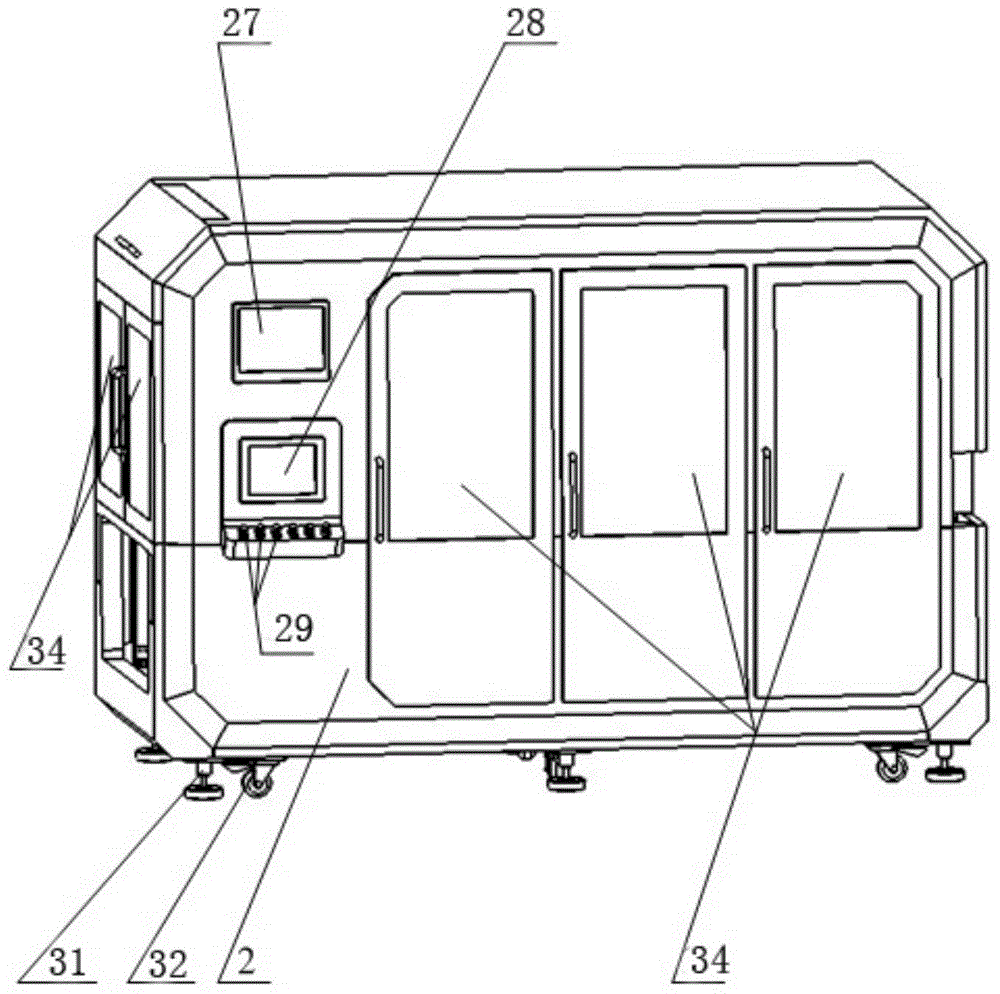

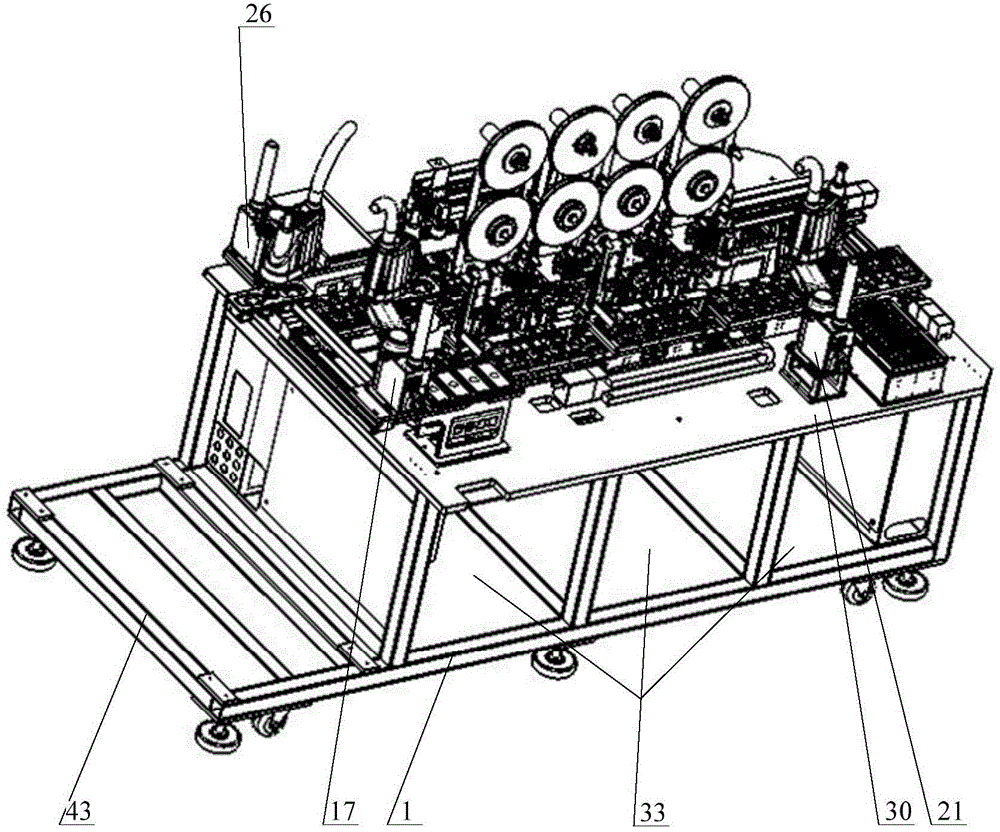

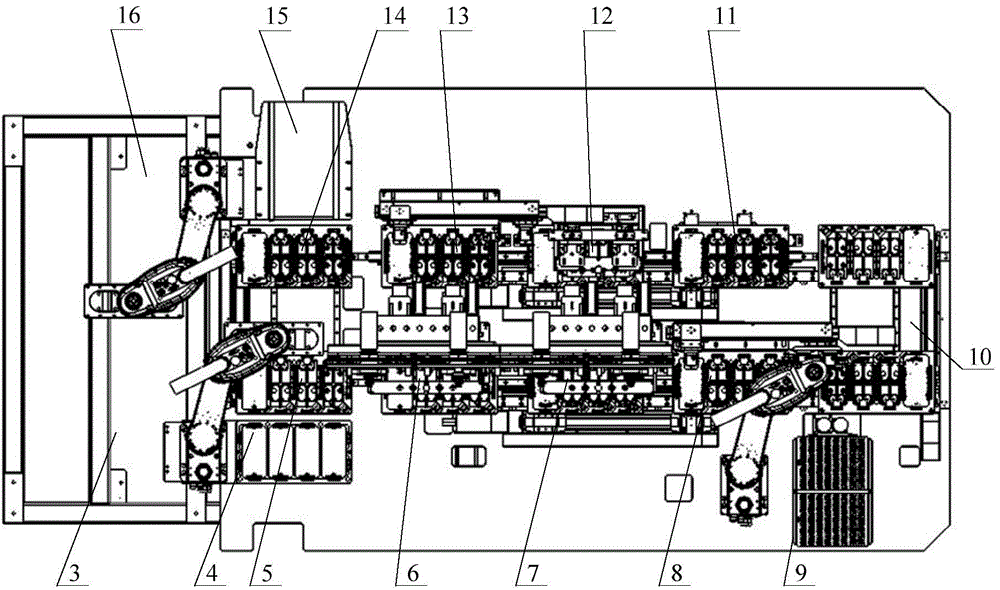

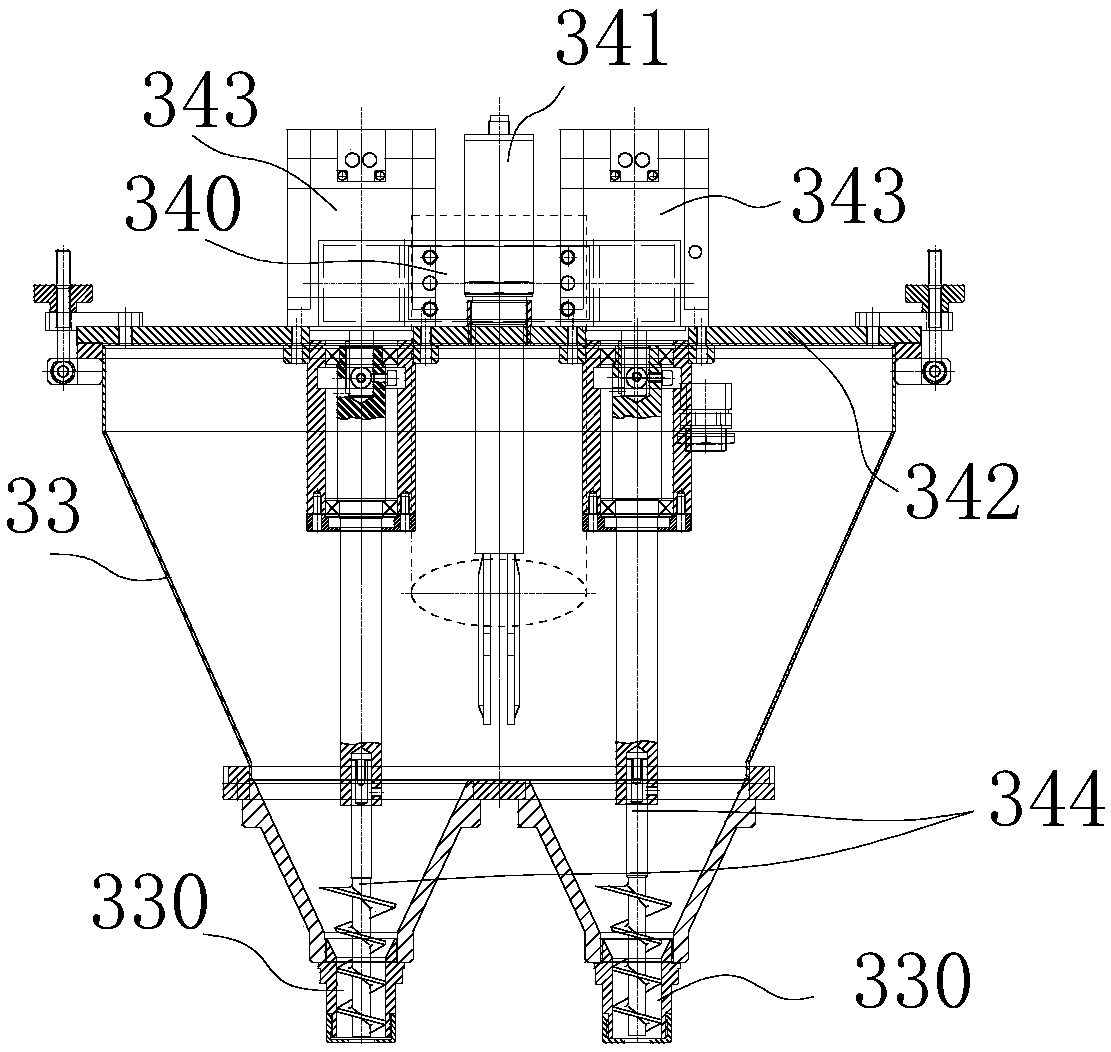

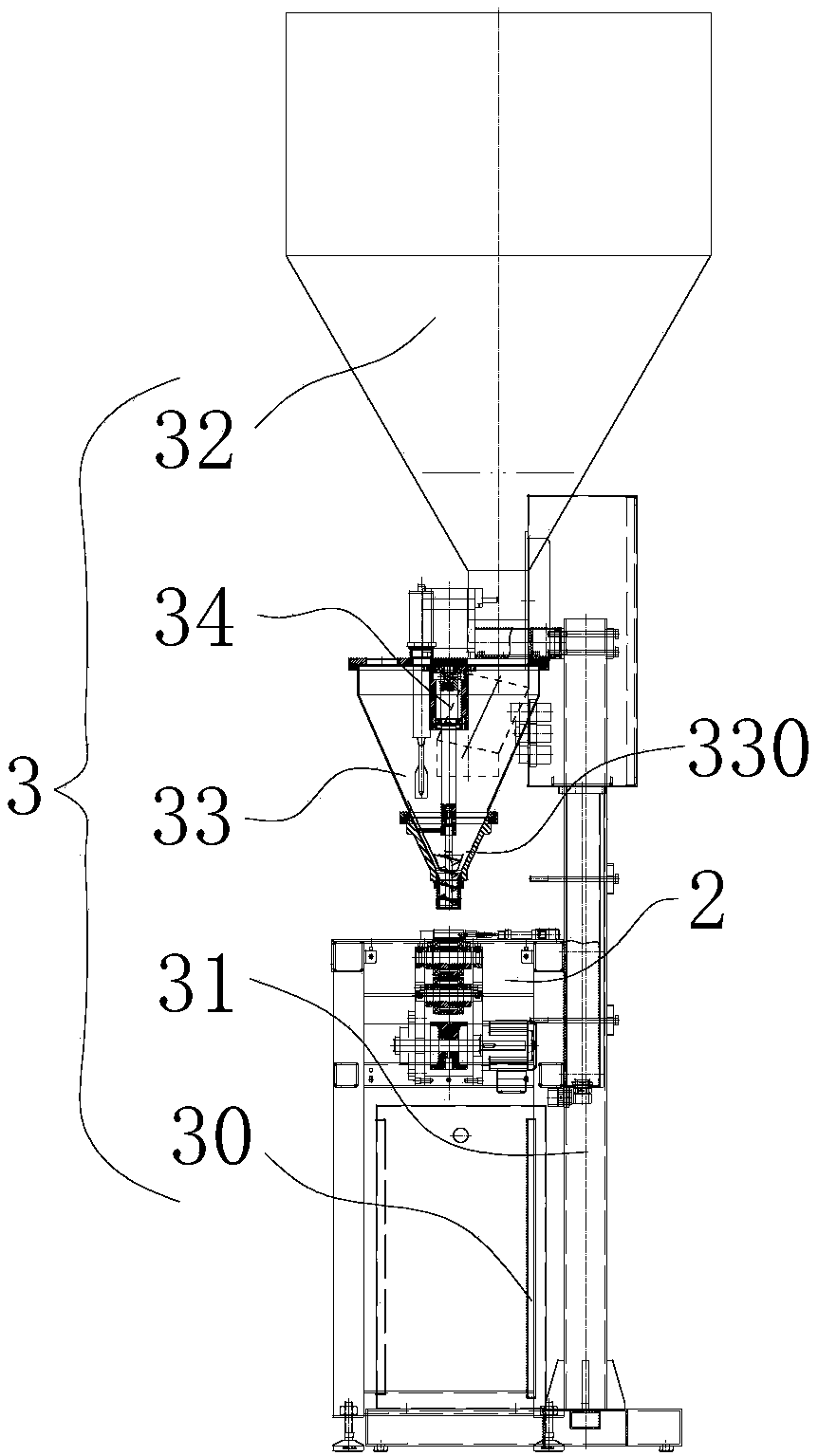

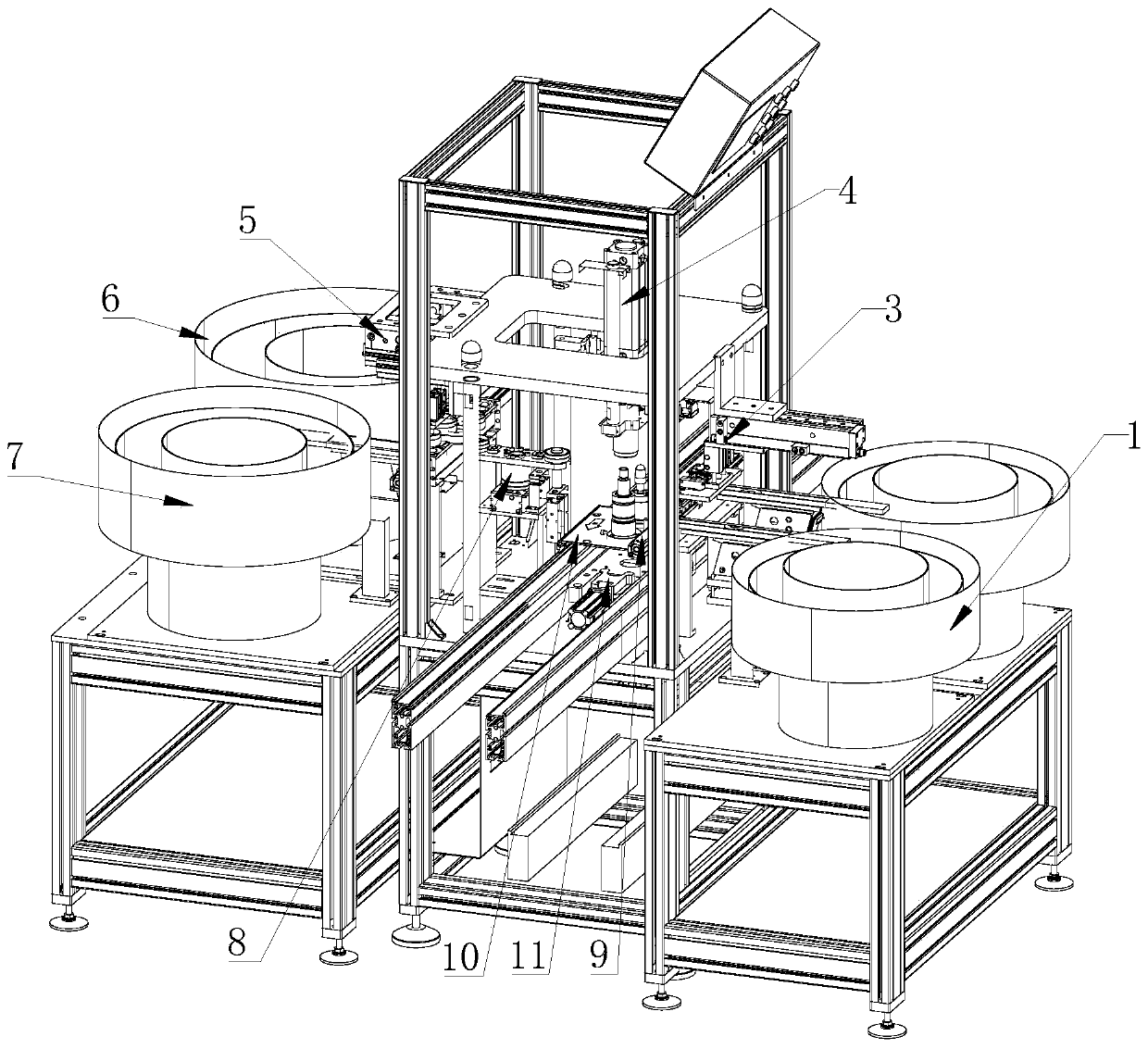

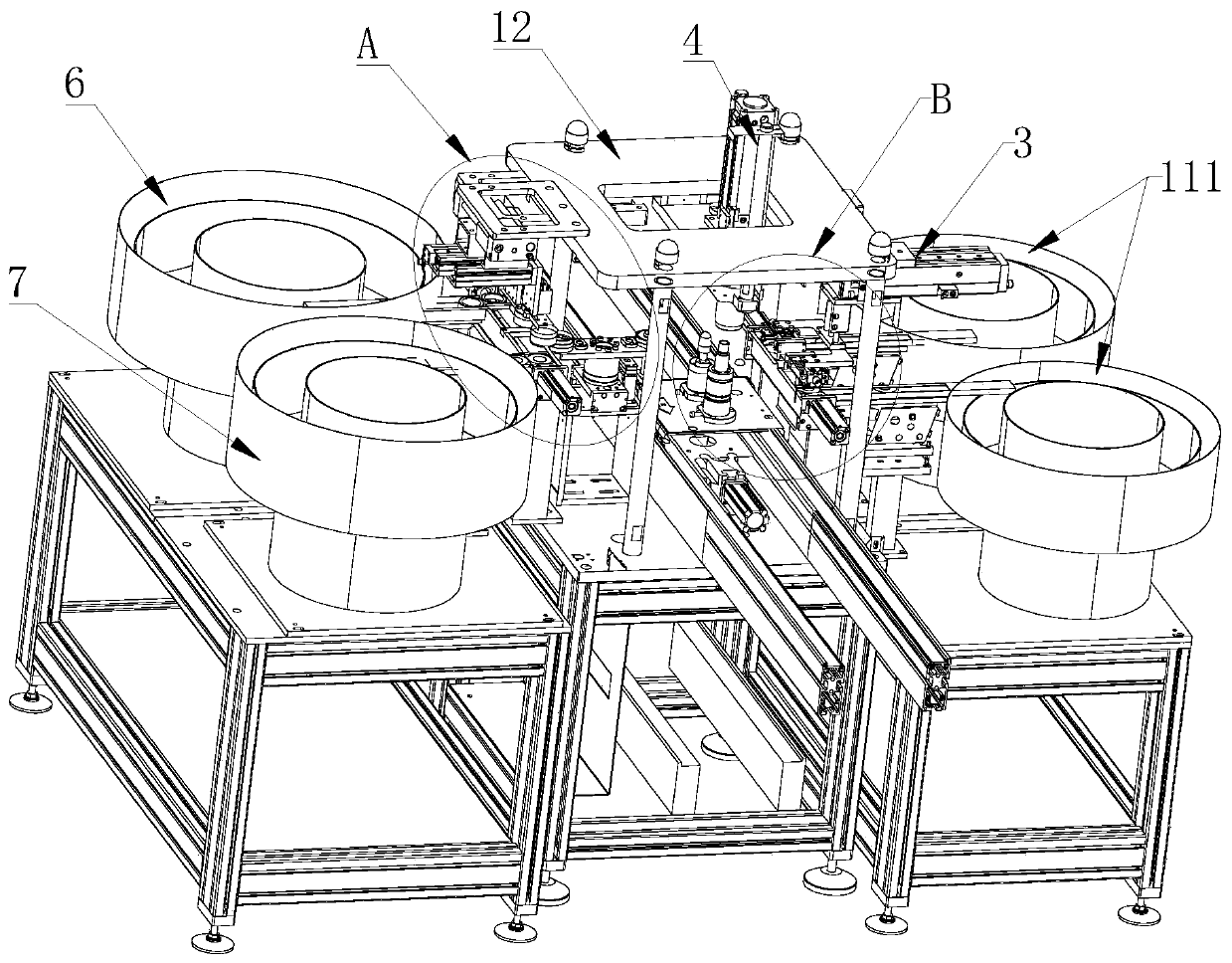

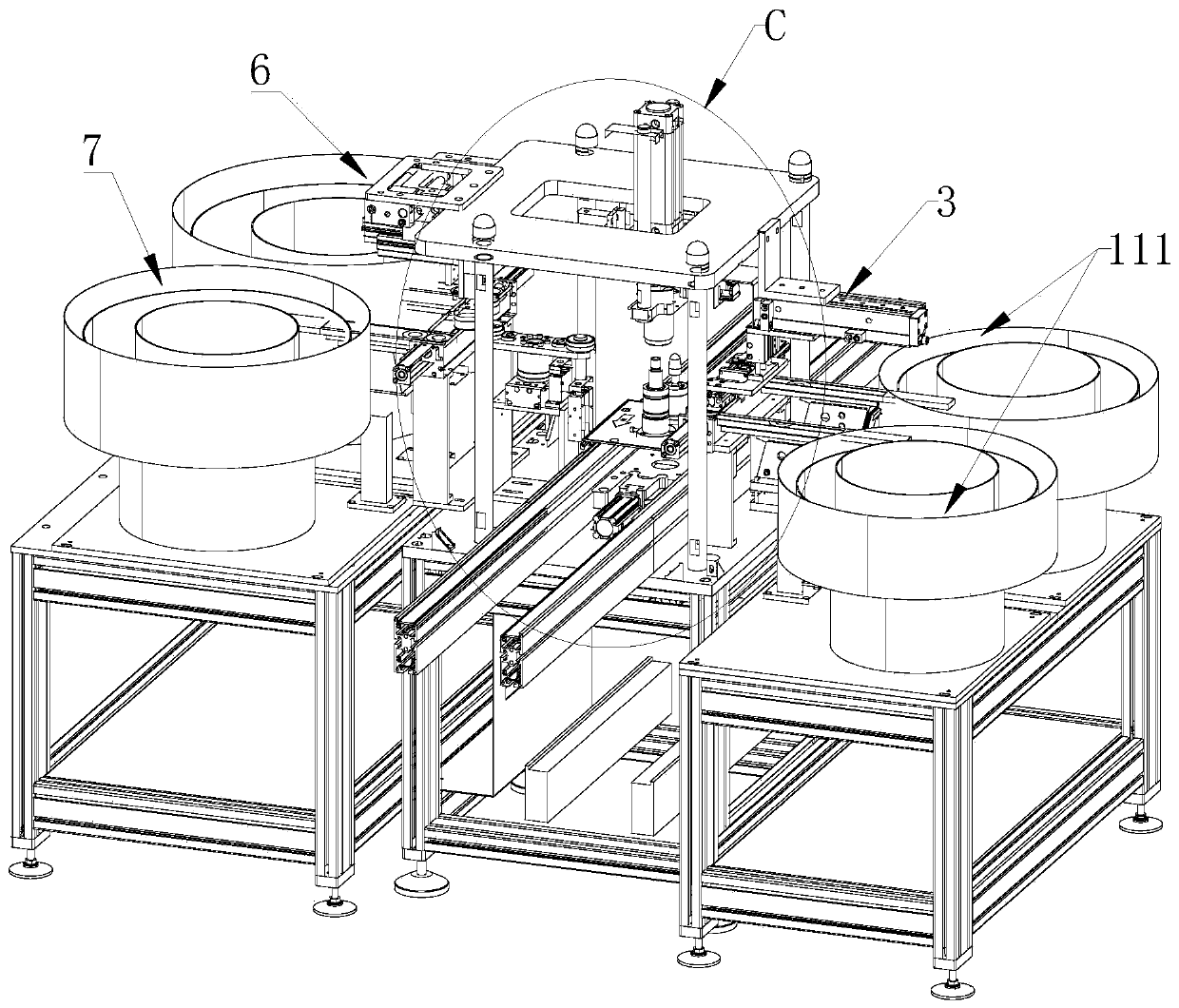

Full-automatic efficient precision assembling machine

ActiveCN105805114ACompact structureShorten the production lineFastening meansProduction lineHot melt

The invention discloses a full-automatic efficient precision assembling machine. The full-automatic efficient precision assembling machine comprises a rack, a workbench arranged on the rack, a feeding supporting disc station, a product locating station, a feeding station, an assembling hot melt adhesive station, a to-be-assembled piece assembling station, a to-be-assembled piece supporting disc placing station, a jig transferring station, a pressure maintaining station, a detection station, a material taking station, an unqualified product receiving station and a qualified product supporting disc station, wherein the feeding supporting disc station, the product locating station, the feeding station, the assembling hot melt adhesive station, the to-be-assembled piece assembling station, the to-be-assembled piece supporting disc placing station, the jig transferring station, the pressure maintaining station, the detection station, the material taking station, the unqualified product receiving station and the qualified product supporting disc station are sequentially distributed around the workbench. Product locating jigs are transferred among the stations through a supporting and conveying mechanism, and devices on all the stations are connected with a PLC. The assembling machine is compact in structure, can achieve efficient and precise assembly of products and pieces to be assembled and integrates the feeding, hot melt achieve gluing, to-be-assembled piece gluing, detection and discharging processes, and the product assembling production line can be shortened.

Owner:SUZHOU YIMEIDE TECH CO LTD

Loudspeaker module and electronic equipment

The invention provides a loudspeaker module which comprises a first shell, a loudspeaker inner core and a waterproof breathable film, the first shell is provided with a containing groove, the loudspeaker inner core is installed in the containing groove, the loudspeaker inner core comprises a voice diaphragm, a front voice cavity is formed between the voice diaphragm and the first shell, and the side, away from the front voice cavity, of the voice diaphragm is a rear voice cavity. The first shell is further provided with a resonance groove, the bottom of the resonance groove is provided with a communication hole, the resonance groove is communicated with the front sound cavity through the communication hole, and the waterproof breathable film covers an opening, facing the rear sound cavity, of the resonance groove and is used for isolating the resonance groove from the rear sound cavity so as to balance air pressure of the front sound cavity and the rear sound cavity when the loudspeaker module does not work. The problem that the sound production quality of the loudspeaker module is affected due to the fact that the sound film deviates due to different air pressures of the front sound cavity and the rear sound cavity is avoided, and the sound quality of the loudspeaker module is improved. The invention further provides electronic equipment.

Owner:HUAWEI TECH CO LTD

Electronic mechanical wire control brake

ActiveCN108591306ASimple structureWork reliablyAxially engaging brakesBrake actuating mechanismsMotor driveControl system

The invention relates to an electronic mechanical wire control brake which comprises a motor, a transmission mechanism, a connecting rod, a rotating rod, a piston, a friction limiting device and the like. The connecting rod is provided with a wedge-shaped adjusting mechanism. The motor drives the rotating rod to move through the transmission mechanism. The rotating rod moves to drive the connecting rod provided with the wedge-shaped adjusting mechanism to move, the piston and brake calipers are driven to move to the opposite direction, friction pads are pressed with the same force from the twosides of a braking disc, and the efficient braking effect is achieved. The brake is simple in structure, reliable in work and high in braking efficiency, the braking gap can be adjusted automatically, the influence caused by abrasion of the friction pads is compensated, the design of a control system is simplified, and the brake can be used for traveling braking and parking braking.

Owner:ZHEJIANG NORMAL UNIVERSITY

Housing for axial flow heat-dissipating fan

InactiveUS20050281665A1Improve assembly stabilityIncrease assembly flexibilityPump componentsCombination enginesEngineeringMechanical engineering

Owner:SUNONWEALTH ELECTRIC MACHINE

Polyester film for electrical insulation

InactiveCN1242026AExcellent formabilityGood apparent densityPlastic/resin/waxes insulatorsSynthetic resin layered productsElectricityApparent density

A polyester film for electrical insulation is characterized in that the apparent density of the film is 1.37-0.85 g / cm<3>; the tension elastic modulus is 2.0-4.5 GPa. A film which includes little low polymer, low cost, excellent heat resistance, impact endurance test resistance, forming processing performance, good assembly stability and better identify performance can be made. In addition, the film can reduce leakage current when being used on motor for insulation.

Owner:TORAY IND INC

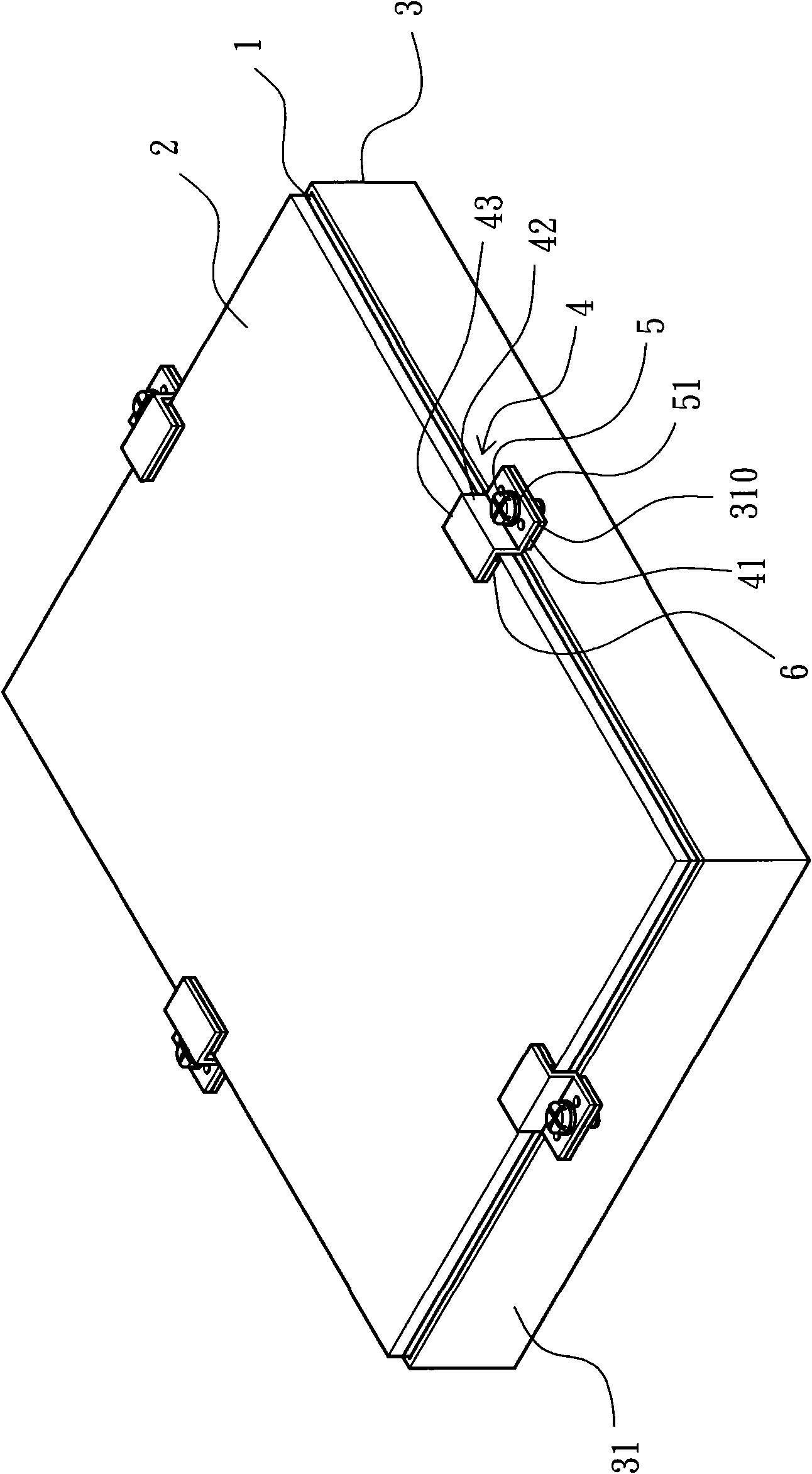

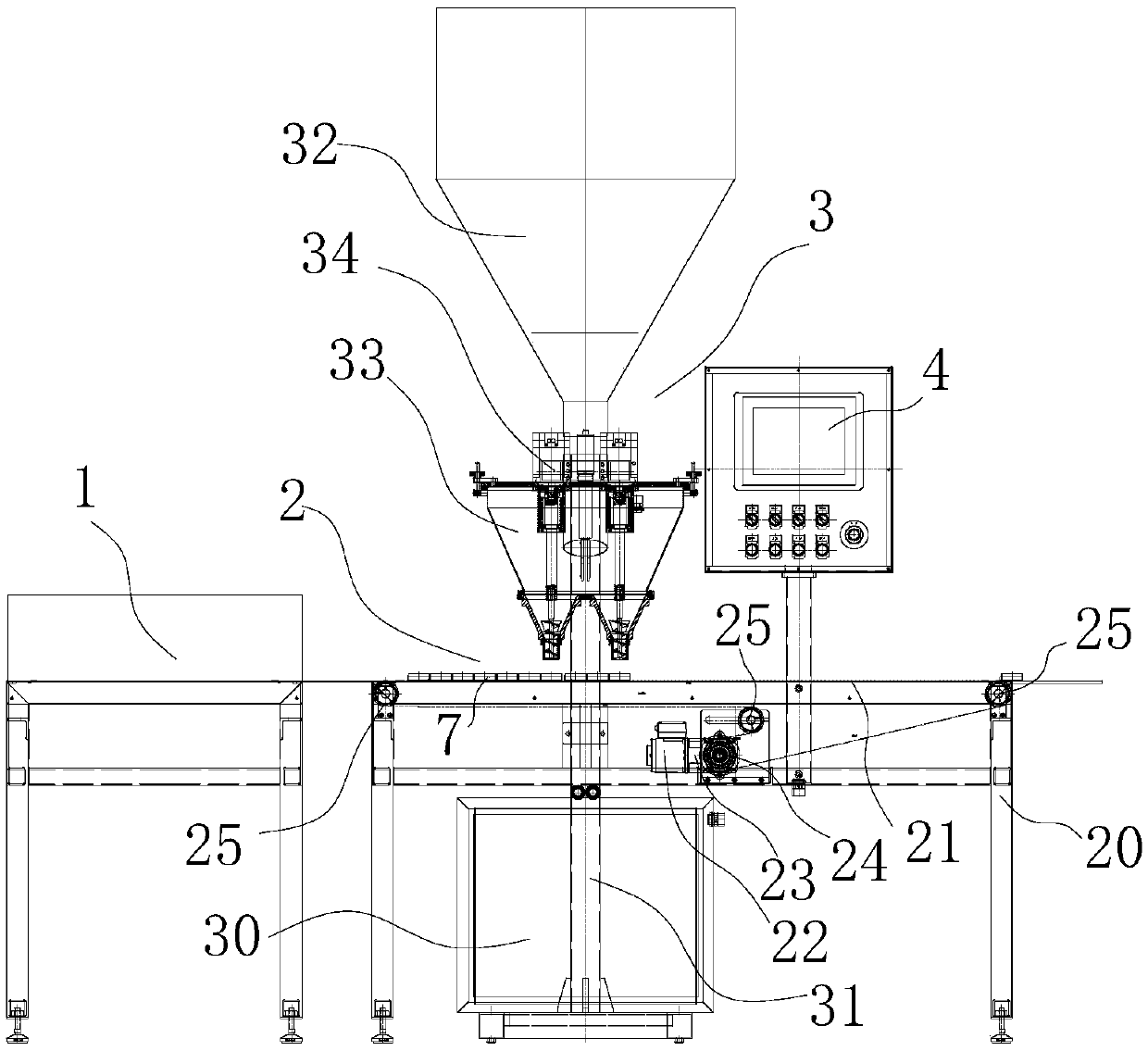

Double-ended filling conveying line

InactiveCN109625486AAvoid pollutionImprove filling efficiencyPackaging automatic controlPackaging machinesParticulatesLiquid state

The invention provides a double-ended filling conveying line which is used for applying particulate matters, powder and semi-fluid substances or liquid-state substances to production and package. Thedouble-ended filling conveying line comprises a conveying mechanism, a filling, containing and clearing-up machine, at least one group of filling machines, and a display control screen, wherein the filling, containing and clearing-up machine is used for orderly pushing cleared-up to-be-filled cavities onto a conveyor belt of the conveying mechanism; at least one group of filling machines is arranged at the upper side of the conveyor belt of the conveying mechanism, and each group of filling machines simultaneously fills one or two to-be-filled cavities on the conveyor belt every time; a control system of the display control screen is separately connected to the filling, containing and clearing-up machine, the conveying mechanism and each group of filling machines separately, and separatelyorderly controls pushing to-be-filled cavities, controls start and stop of conveying mechanism linkage, regulates conveying speed, controls start and stop of unloading of each group of filling machines, and regulates unloading amount of each unloading hole; and two or more filling machines are arranged on one conveyor belt, so that two or more filling machines can simultaneously fill, and therefore, filling efficiency is effectively improved.

Owner:珠海瑞创科技发展有限公司

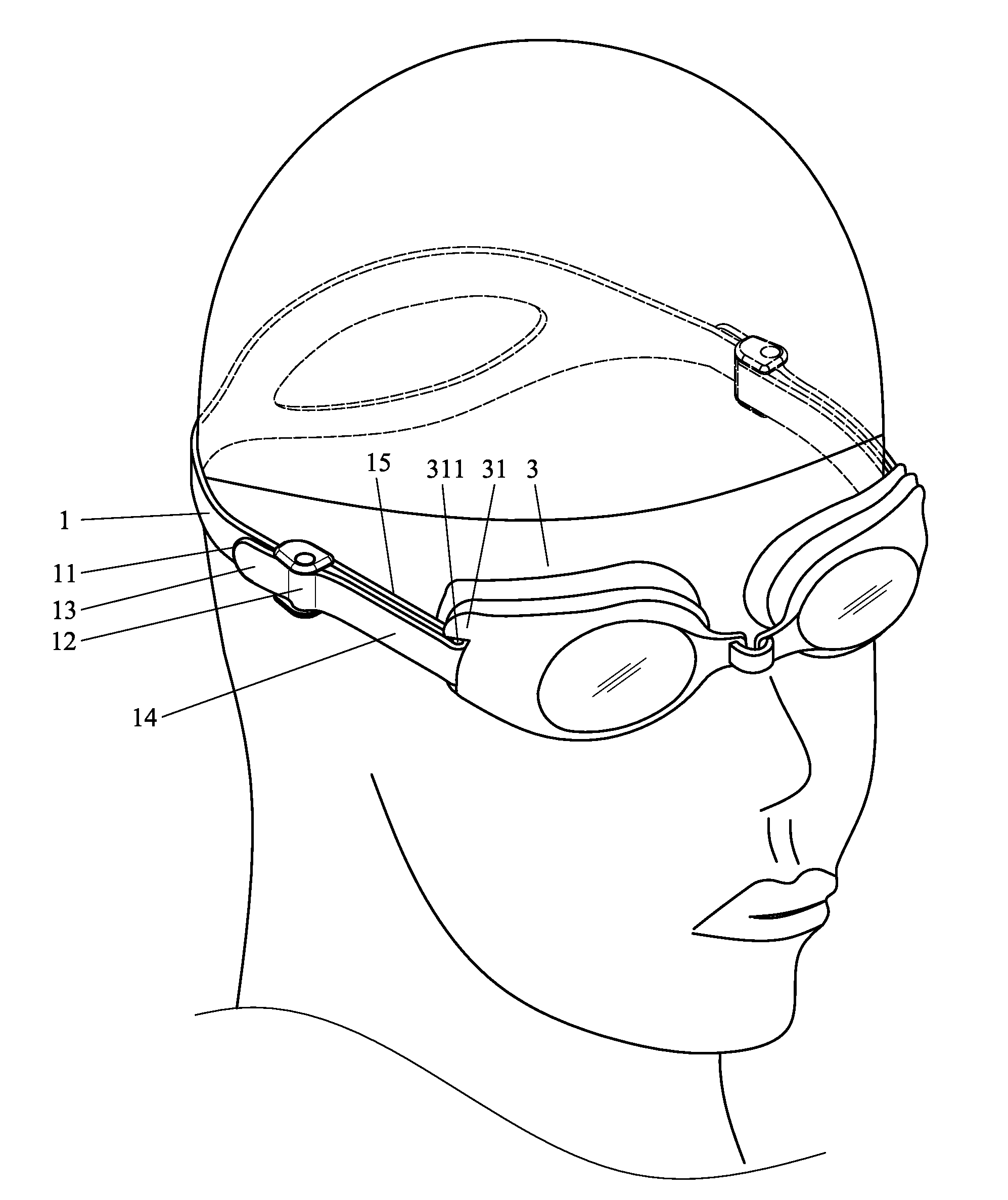

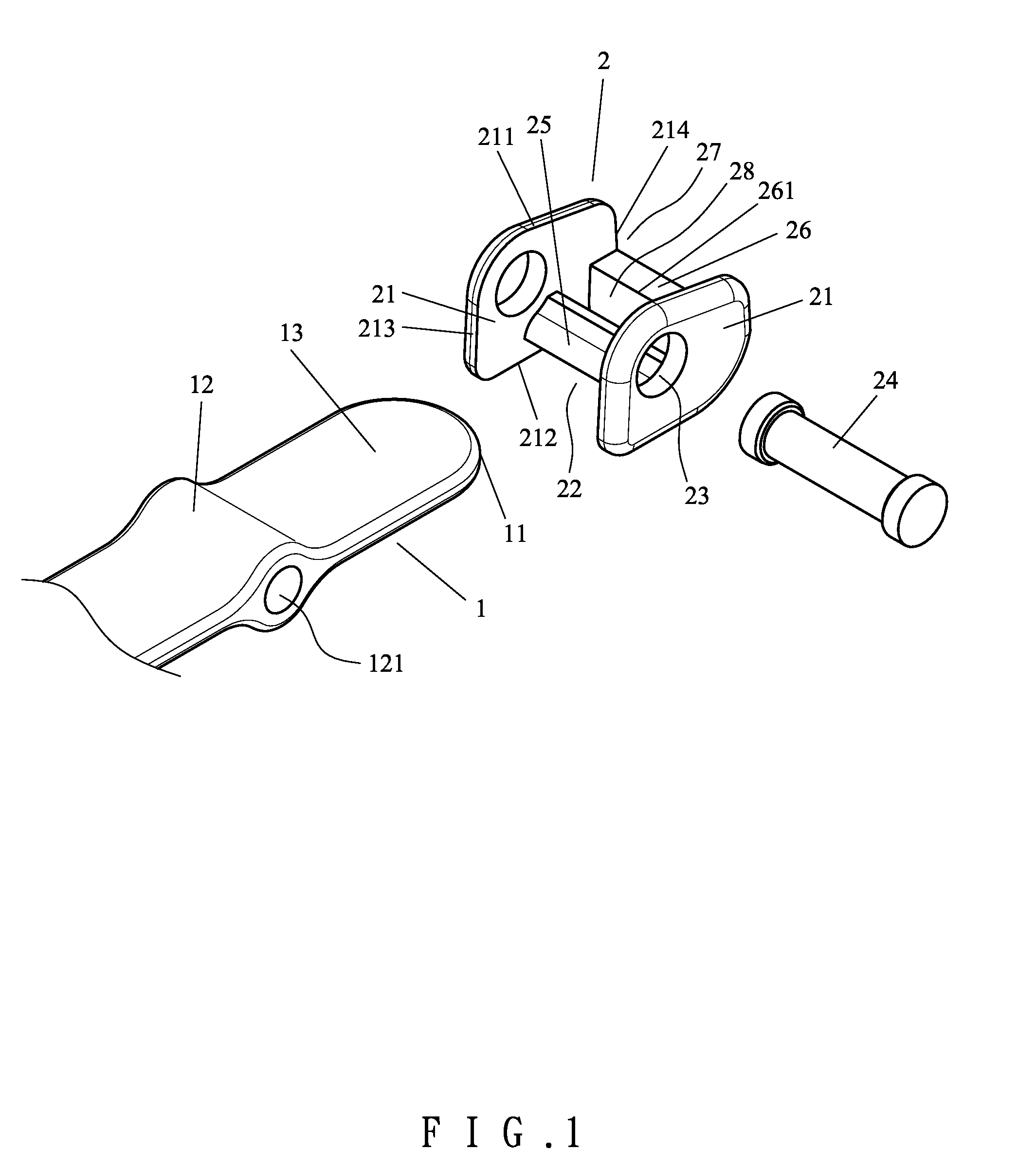

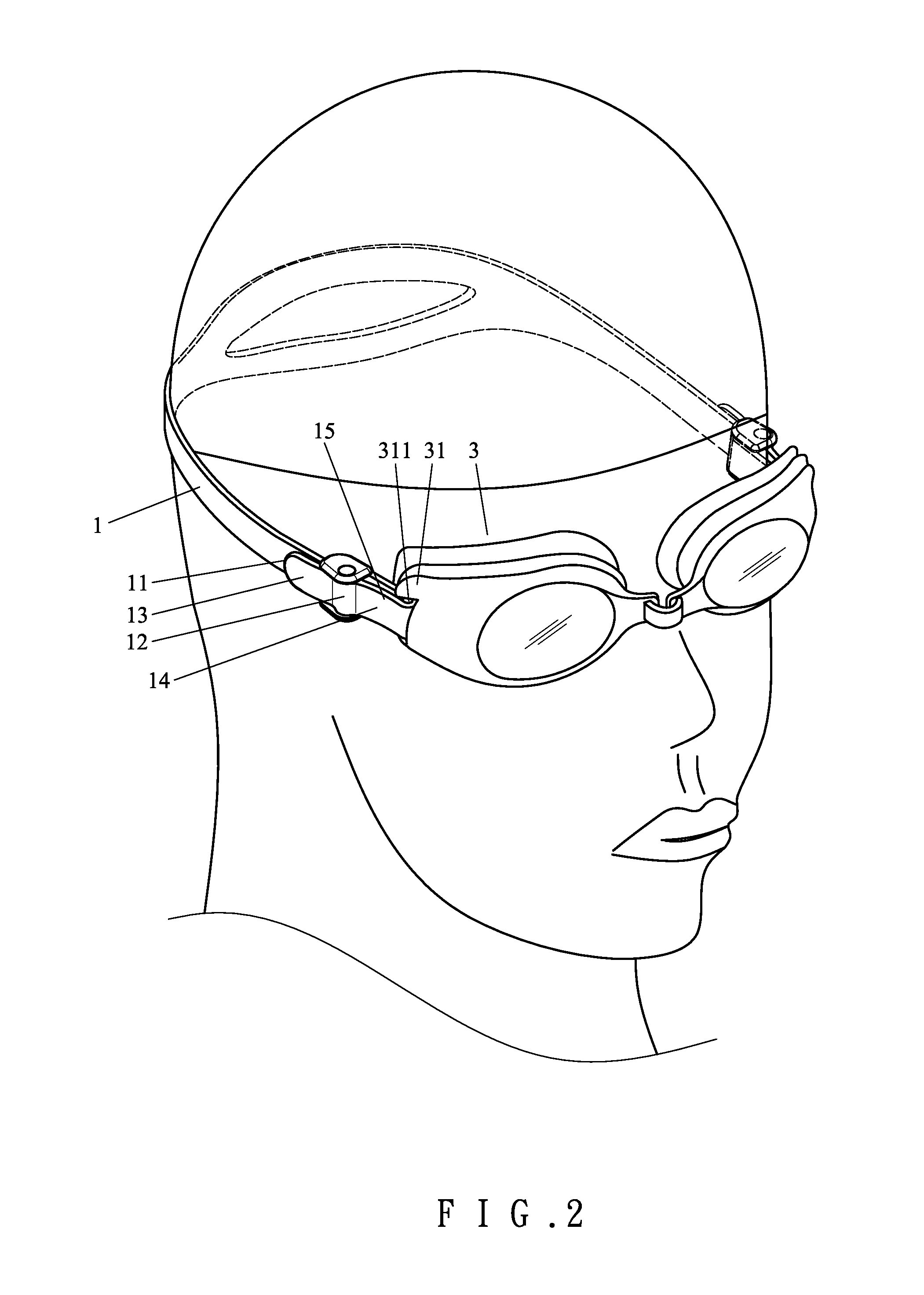

Head strap and buckle device for swimming/diving goggles

InactiveUS20160107035A1Improve assembly stabilitySpeed up tighteningGogglesSwim gogglesEngineeringSafety goggles

Swimming / diving goggles includes a main body with a head strap coupling portion. An attachment portion is formed on an end of a head strap. A buckle includes two sidewalls defining a space. An eccentric axle extends between upper front portions of the sidewalls and engages with the attachment portion. Front and rear posts extend between the sidewalls and define a passage. The end of the head strap extends through a rear opening of the buckle into the space, extends through the passage, and is wound around to form a bend. The head strap includes an inner section and an outer section having the attachment portion. The head strap and the buckle are jointly movable. A tightening force acting on the inner section makes the inner section form another bend in the passage. The inner section presses against the front post and the rear post to position the head strap.

Owner:CHOU TERRY

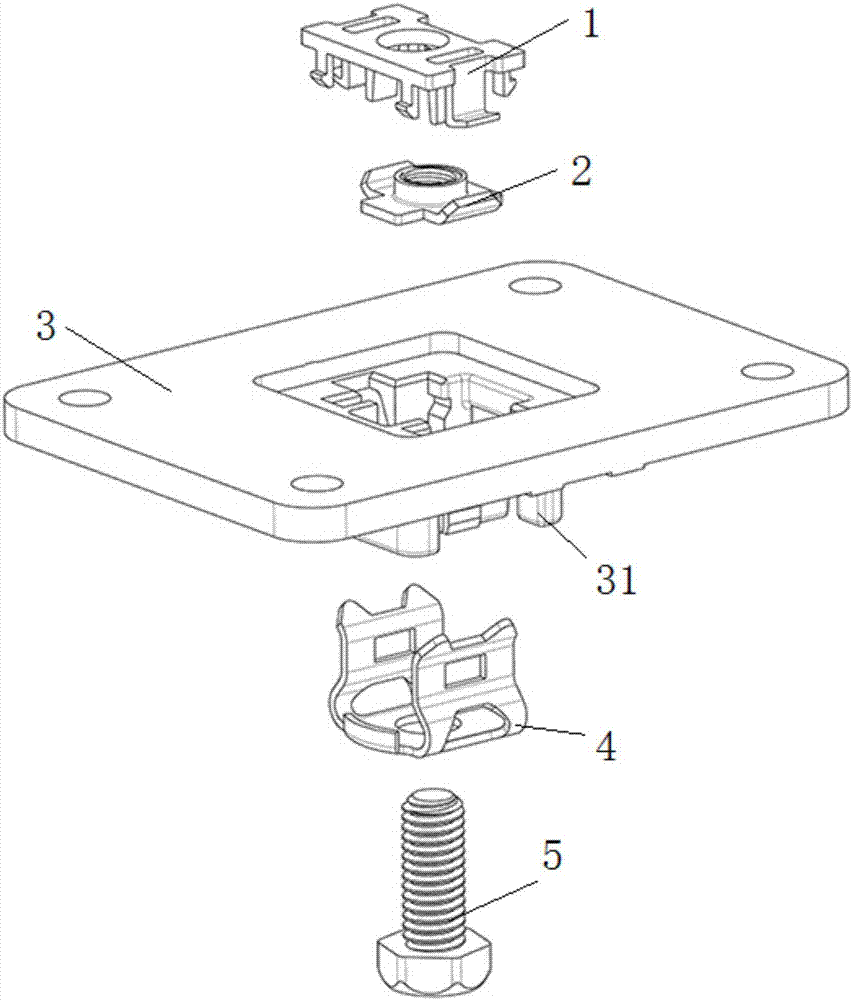

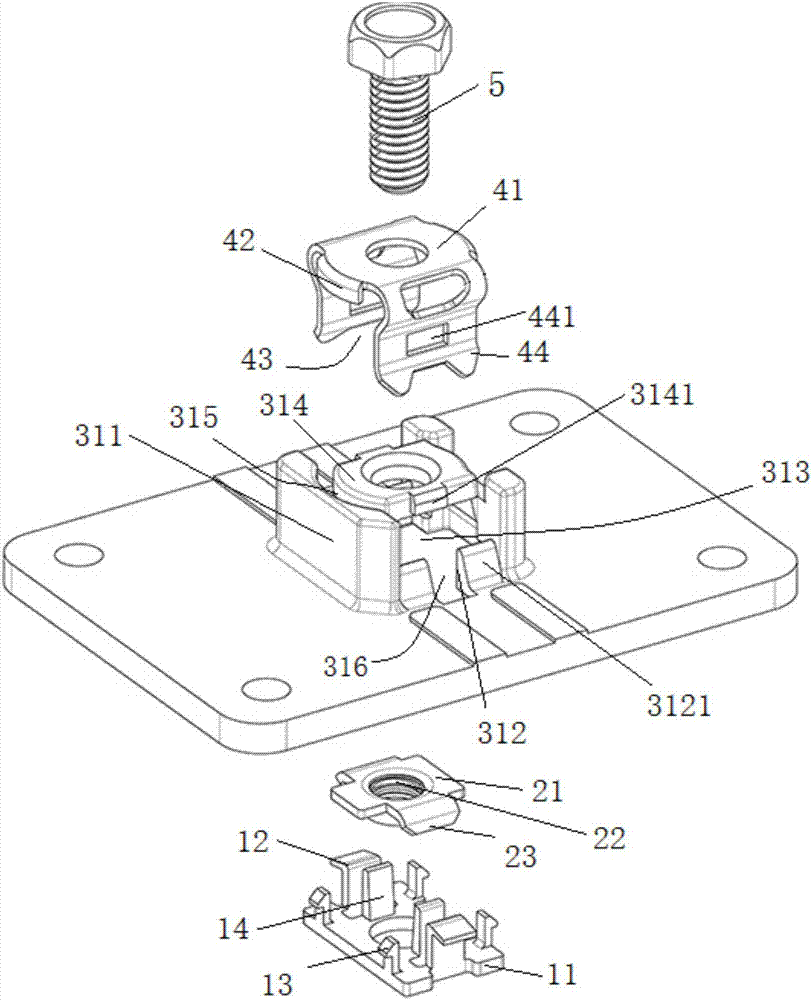

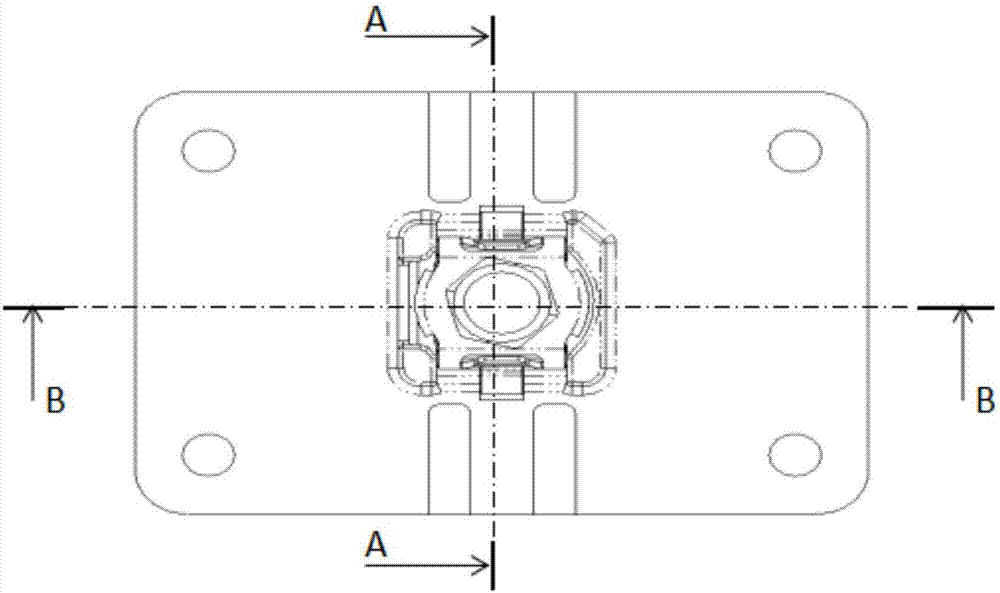

Installation fastening structure of vehicle overhead antenna

ActiveCN107196036AImprove installation efficiencyEasy to operateInternal combustion piston enginesAntenna supports/mountingsStructural engineeringMetal sheet

The invention relates to an installation fastening structure of a vehicle overhead antenna. The installation fastening structure is used for installing the antenna in an installation hole of a vehicle metal sheet, and comprises a snap joint, a threaded support gasket, an antenna base, a catch, and a bolt, wherein the initially assembled installation fastening structure is inserted along the installation hole of the vehicle metal sheet, the bolt is turned to drive the threaded support gasket to downward move; when a pushing part of the threaded support gasket pushes support legs at two sides of the catch to outwardly extend till to get rid of the limitation of a connecting end surface, the catch upwardly moves until the catch completely fits the connecting end surface and the support legs completely contact with the vehicle metal shell; therefore, the whole assembling is finished. The technical scheme disclosed by the invention solves the technical problems that the installation operation of the vehicle overhead antenna is complicated and hard to install and fix, and the occurrence rate of the bad assembling of a nut and the antenna component is increased.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

Elastic positioning adjusting device for conical pulley

ActiveCN101691000ARealize a wide range of position adjustment functionMeet the design sizeWelding/cutting auxillary devicesAuxillary welding devicesMiniaturizationEngineering

The invention discloses an elastic positioning adjusting device for a conical pulley, which is applied to the technical field of automatic welding. The elastic positioning adjusting device is characterized by consisting of a conical pulley shaft, a conical pulley shaft sleeve, a double row angular contact bearing, a copper bush, a bearing cone cushion, an elastic retainer ring for shafts, a disc spring, a movable shaft, a shaft sleeve gland, an adjusting mounting base, a regulating hand wheel, an elastic retainer ring for holes, fastening screws and limit screws. The elastic positioning adjusting device has the advantage that: the elastic positioning adjusting device realizes that the conical pulley can reliably and stably rotate, has functions of accurate elastic positioning and wide-range position adjustment, has looseness-proof function, has compact and even structure, meets the design requirements for miniaturization and portability of a welding carriage and a track, and improves the positioning precision and walking reliability of the steel pipe automatic welding carriage.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

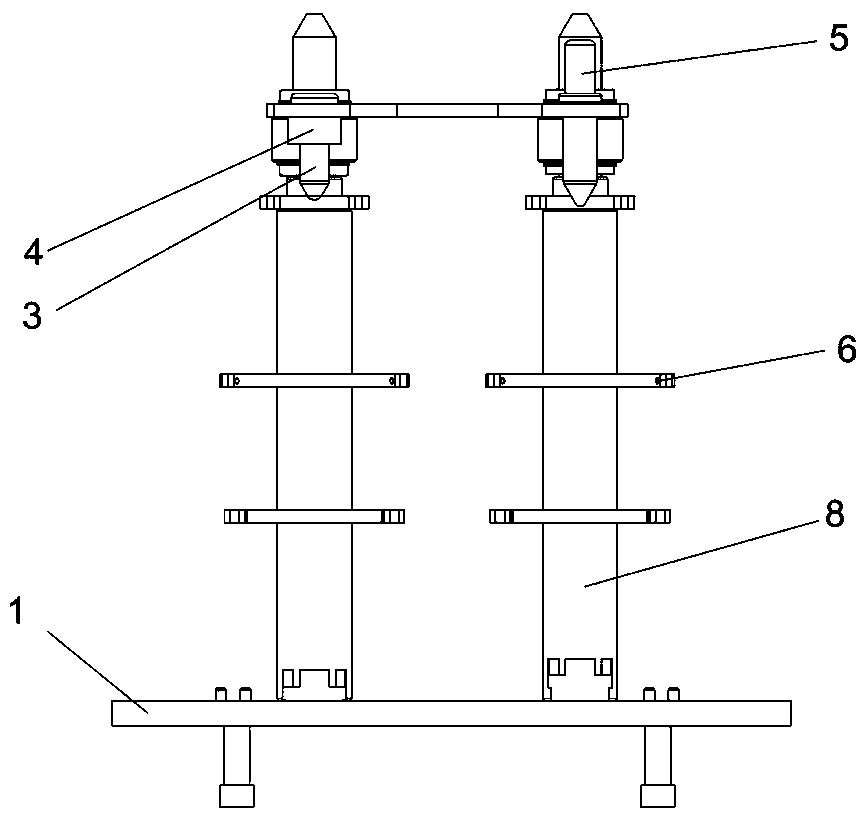

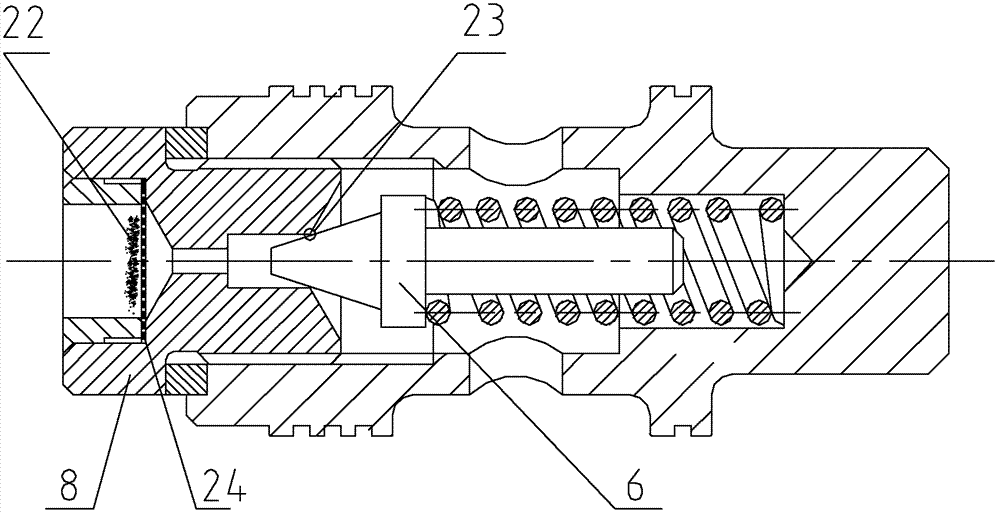

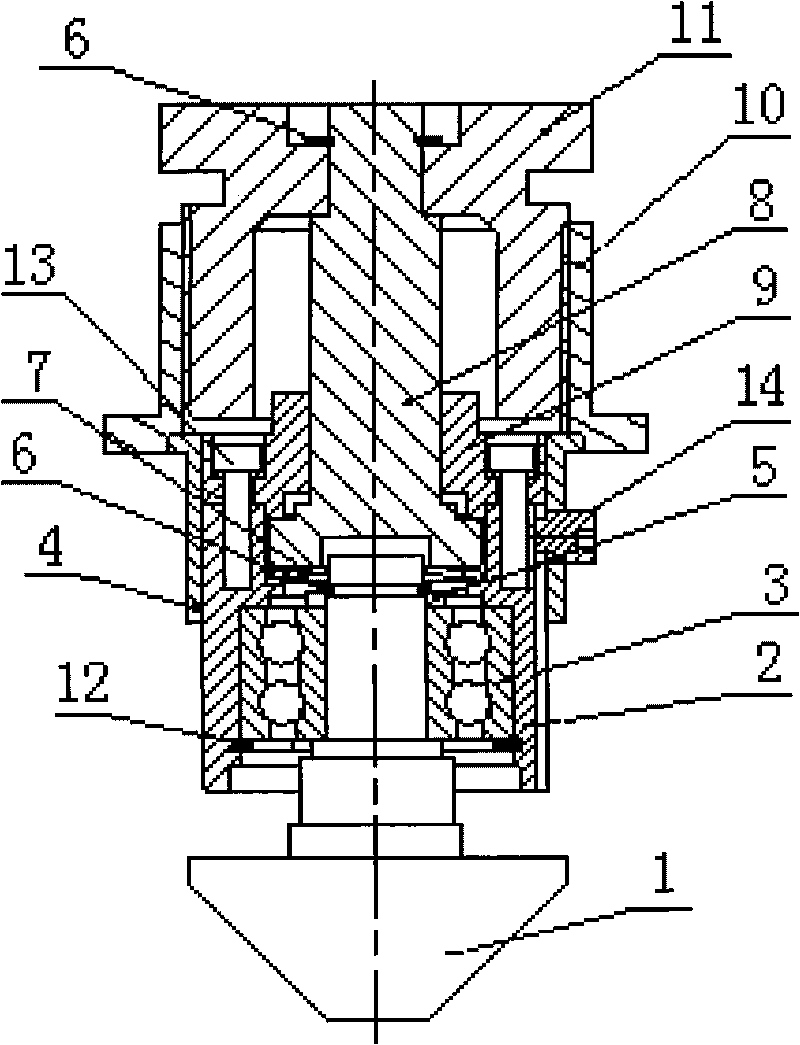

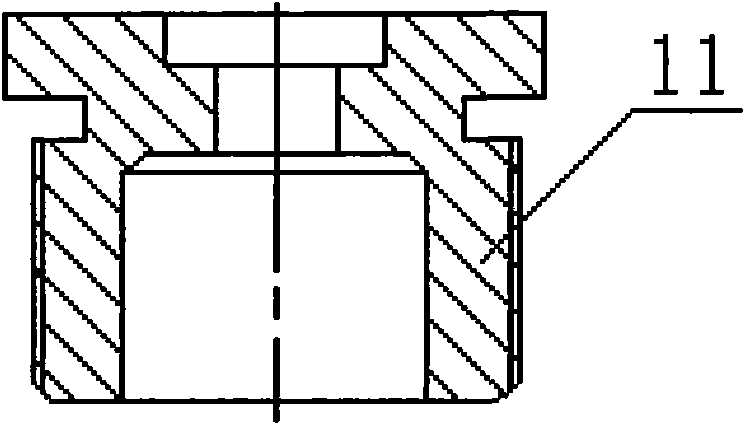

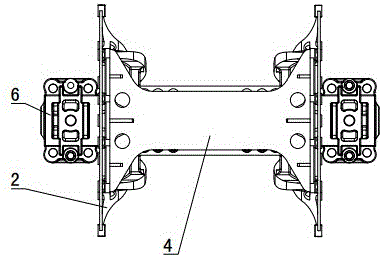

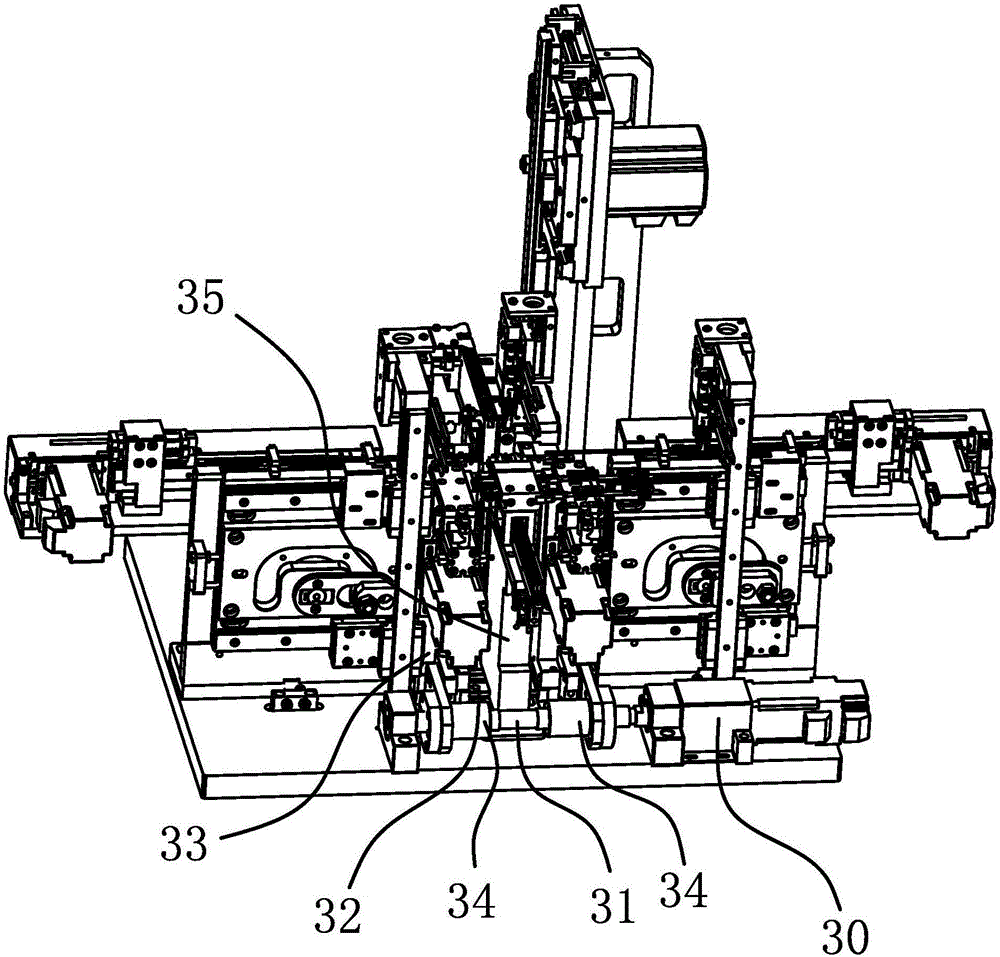

Automatic assembly device for starter one-way device

The invention adopts an automatic assembly device for a starter one-way device. The automatic assembly device comprises a positioning pressing mechanism, a pressing mechanism, a semicircular pad discharging mechanism, a semicircular pad assembling manipulator, a full-circular pad discharging mechanism, a cover discharging mechanism and a movement rotating mechanism; the positioning mechanism is used for positioning an assembly plate to which the one-way device is fixed; a semicircular pad at the discharge end of the semicircular pad discharging mechanism is moved to the semicircular pad assembling manipulator through a movement mechanism; the semicircular pad assembling manipulator adsorbs the semicircle pad to the one-way device so as to embed the semicircular pad outside the one-way device; a full-circular pad at the discharge end of the full-circular pad discharging mechanism and a cover at the discharge end of the cover discharging mechanism are moved to the movement rotating mechanism through a gripping assembly for pre-assembling; the pre-assembled full-circular pad and the cover are moved to the pressing mechanism through the rotating mechanism to be adsorbed by the pressingmechanism; the pre-assembled parts adsorbed by the pressing mechanism are moved to the position above the one-way device with the semicircular pad; and the pre-assembled parts are arranged on the one-way device in a sleeving mode and pressed with the semicircular pad. Automatic processing is achieved, and the precision is higher.

Owner:湖北神电汽车电机有限公司

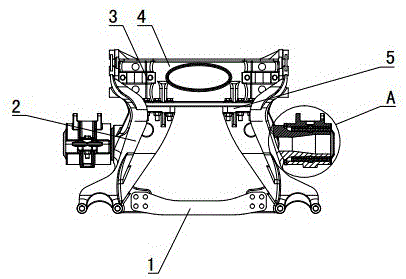

Ultra-lightweight balanced suspension

ActiveCN105751850AReduce stressImprove protectionLeaf springsInterconnection systemsVehicle frameModularity

Owner:山东安博机械科技股份有限公司

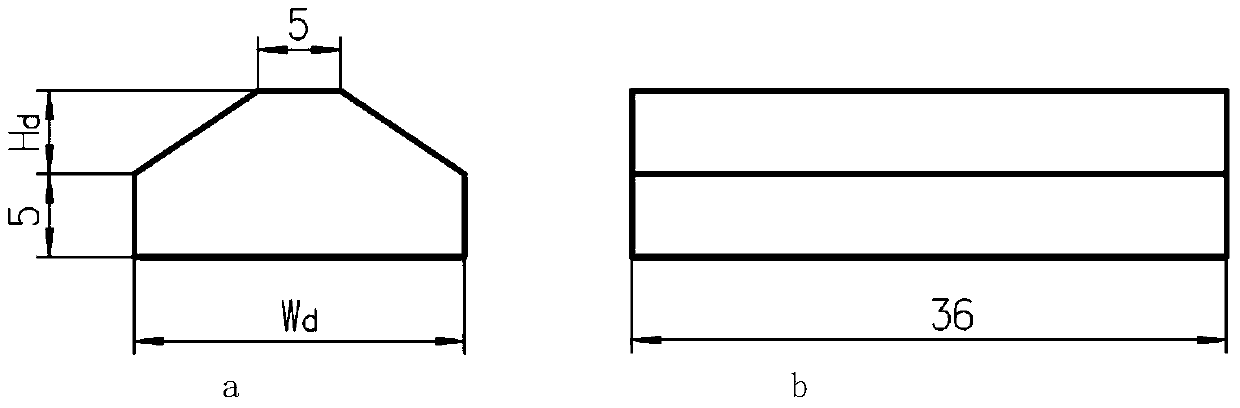

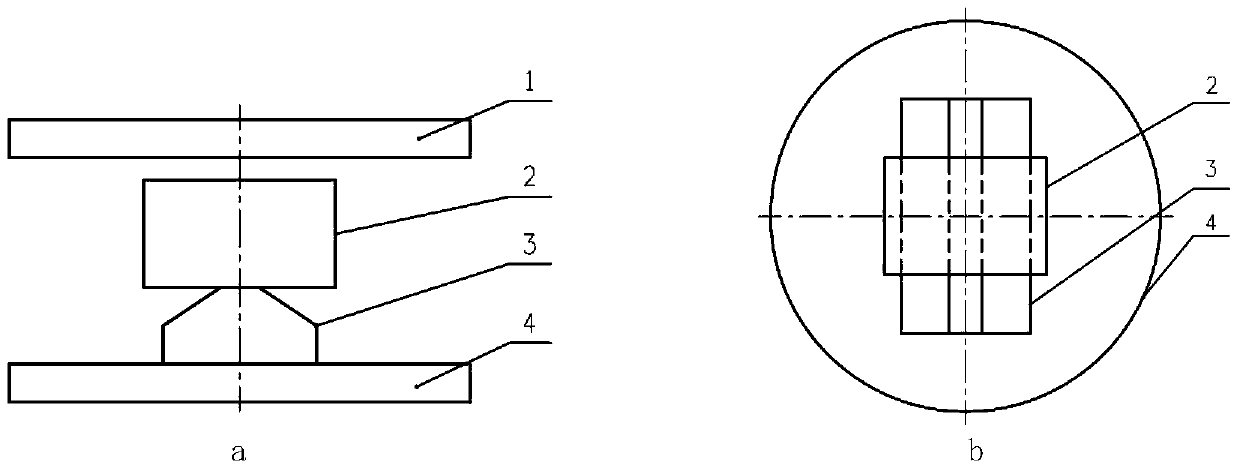

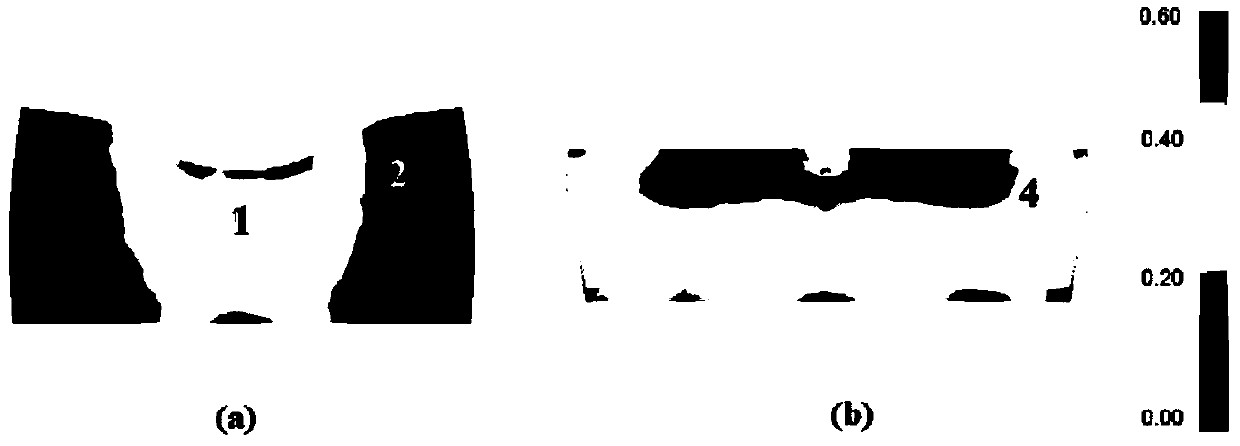

Experimental method for isothermal local loading formation of titanium alloy

The invention discloses an experimental method for isothermal local loading formation of a titanium alloy. By adopting a terrace die to increase the stability of a die and a blank which are matched, the problem that a test sample and an arc-shaped die are easy to deviate to be unstabilized in the assembling process is solved, and the experimental success rate is remarkably increased. Inhomogeneous deformation of a local loading formation transition region is realized by way of loading in steps by using the terrace die and not using the terrace die. Die processing and experimental operation are simple, convenient and feasible and well reflect the deformation characteristic of the transitional region in local loading formation. According to the experimental method disclosed by the invention, the deformation gradient of the blank is more uniform, easy to control and convenient for subsequent tissue observation of a special deformation region compared with that of an arc-shaped die, and thus a good experimental foundation is provided for quantitative research which discloses microstructure development mechanism and rule in the transitional region in isothermal local loading formation of the titanium alloy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

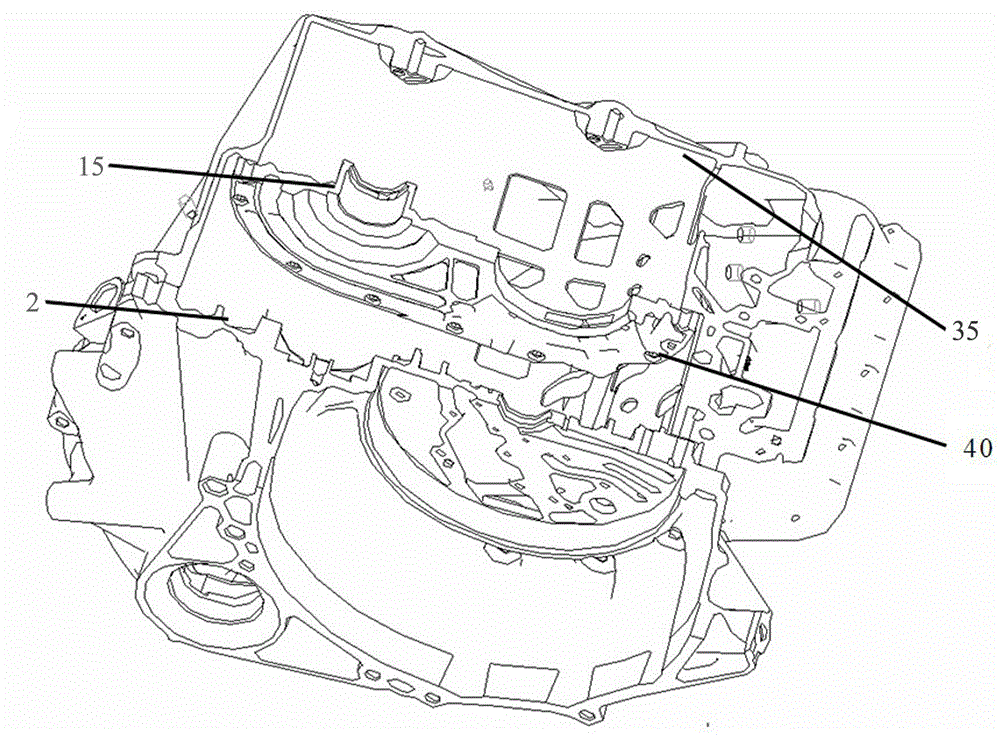

Automatic gearbox and assembling method thereof

ActiveCN104455340AImprove assembly efficiencyImprove the assembly methodGearboxesGearing detailsGear driveAgricultural engineering

The invention relates to an automatic gearbox and an assembling method thereof. The automatic gearbox comprises a main shell and a torque converter shell, and a middle partition plate is arranged between the main shell and the torque converter shell. The entire gearbox is divided into a main shell assembly, a torque converter shell assembly and a middle partition plate assembly. The three assemblies can be assembled at the same time, so that the assembling efficiency is greatly improved, and batch production on an assembling line can be facilitated. A gear drive assembly is fixed in the middle partition plate, then the middle partition plate is fixed on the main shell, the middle partition plate achieves the transition supporting function of a connecting link, and the assembling stability of the gear drive assembly is greatly improved. Adjusting gaskets are additionally arranged at a uniaxial shaft system, a two-axis shaft system and a three-axis shaft system, and the assembling precision is improved; the gearbox with the structure is convenient to maintain.

Owner:SHENGRUI TRANSMISSION

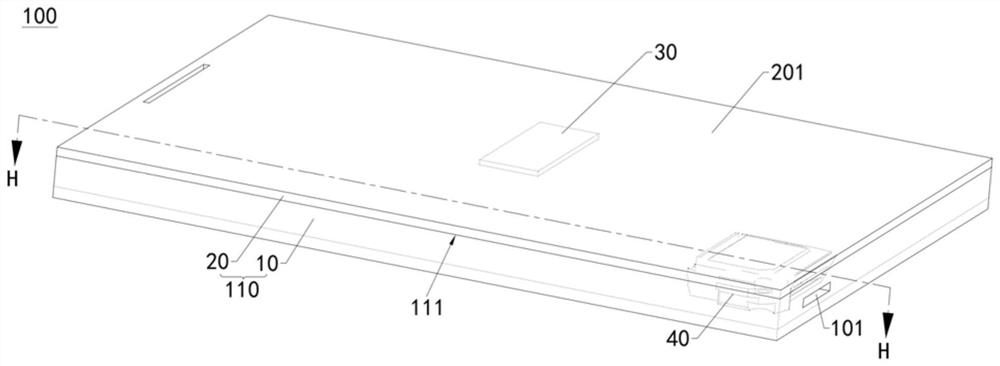

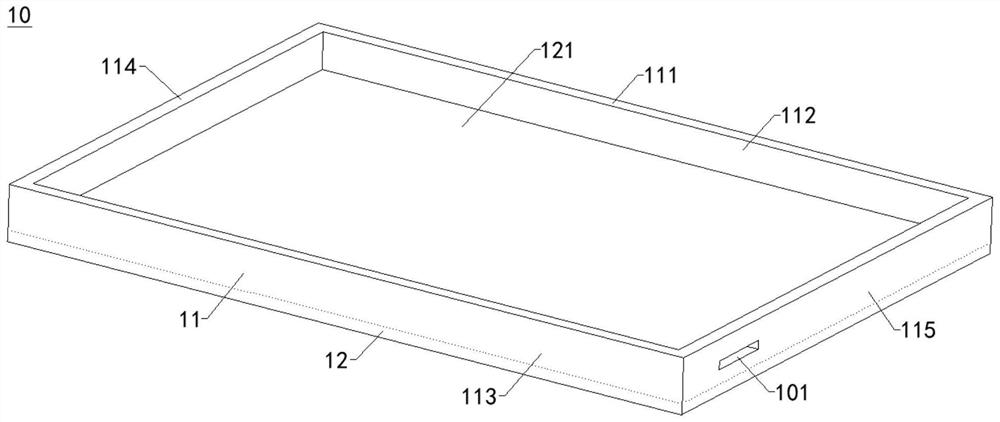

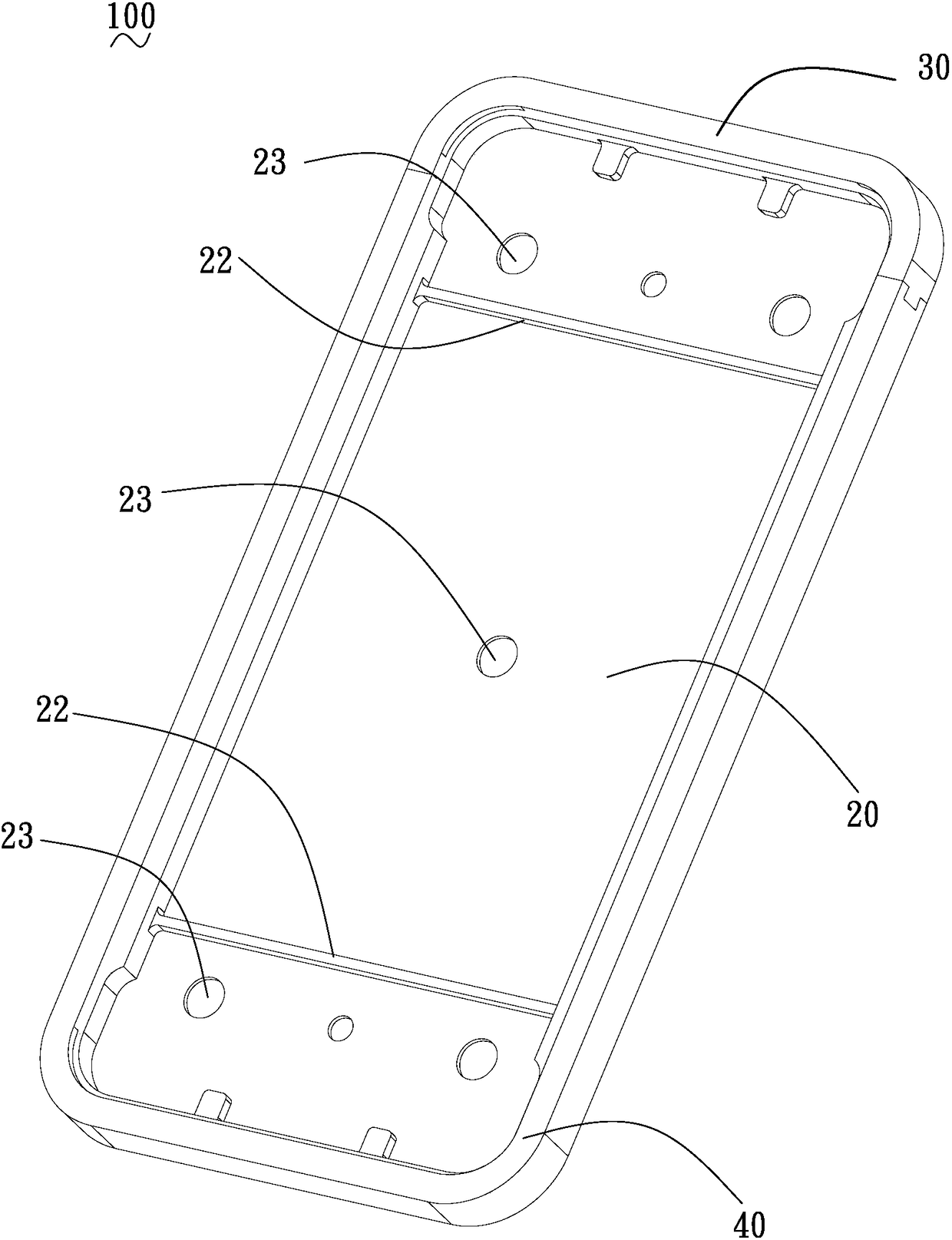

Metal middle frame and processing method of metal middle frame

ActiveCN108337335AReduce manufacturing costIncrease productivityCasings/cabinets/drawers detailsTelephone set constructionsEngineeringMetal

The invention relates to a metal middle frame and a processing method of the metal middle frame. The metal middle frame comprises a middle plate, and a first member and a second member, which are installed on the peripheral edge of the middle plate. A clamping edge is convexly arranged on the peripheral edge of the middle plate, a first neck adapted to the clamping edge is arranged on an inner wall of the first member, a projection is convexly arranged on the end part of the first member, a second neck adapted to the clamping edge is arranged on the inner wall of the second member, and a groove adapted to the projection is formed in the end part of the second member. The first member and the second member are in preset fit so that the clamping edge is riveted in the first next and the second neck, and the projection is riveted in the groove. In the metal middle frame, as the middle plate is well clamped with the first member and the second member through the clamping edge, the first neck and the second neck, a greater large shearing force and drawing force can be withstood, the opening phenomenon of the second member can be avoided, and the assembly stability is good. No welding process is used, so that the process is relatively simple, the production cost is reduced, and the production efficiency is improved.

Owner:GUANGDONG EVERWIN PRECISION TECH

Multifunctional pipeline gas self-closing valve and self-closing method thereof

ActiveCN113483130AImplement the shutdown functionRealize mechanical control functionOperating means/releasing devices for valvesEqualizing valvesRemote controlMagnetic valve

The invention provides a multifunctional pipeline gas self-closing valve and a self-closing method thereof. A first valve rod and a second valve rod are arranged in an in-valve working space of a valve body, one end of the first valve rod is connected with a magnet in an automatic valve, the other end of the first valve rod is connected with the second valve rod, and a magnetic disc is assembled at the bottom end of an attraction rod and connected with the magnet at the upper end of the first valve rod in an attraction manner; and the upper end of the attraction rod in an electromagnetic head drives the first valve rod to move downwards in the valve body through the electromagnetic effect, and the second valve rod is driven to move horizontally in the valve body through the guiding effect of a pin hole of the first valve rod on a pin of the second valve rod. The mechanical control function of the gas self-closing valve and the electric appliance control function of a gas electromagnetic valve are combined, when the gas supply pressure of a pipeline is under-pressure, over-pressure and over-flow, a machine is automatically closed, a gas source is cut off, meanwhile, the remote control cut-off function is achieved, the gas source is remotely controlled and emergently cut off in linkage with a gas alarm, manual opening is achieved, multiple functions are achieved, and gas use safety is guaranteed.

Owner:XIAN DONGXIN GASOLINEEUM EQUIP PLANT

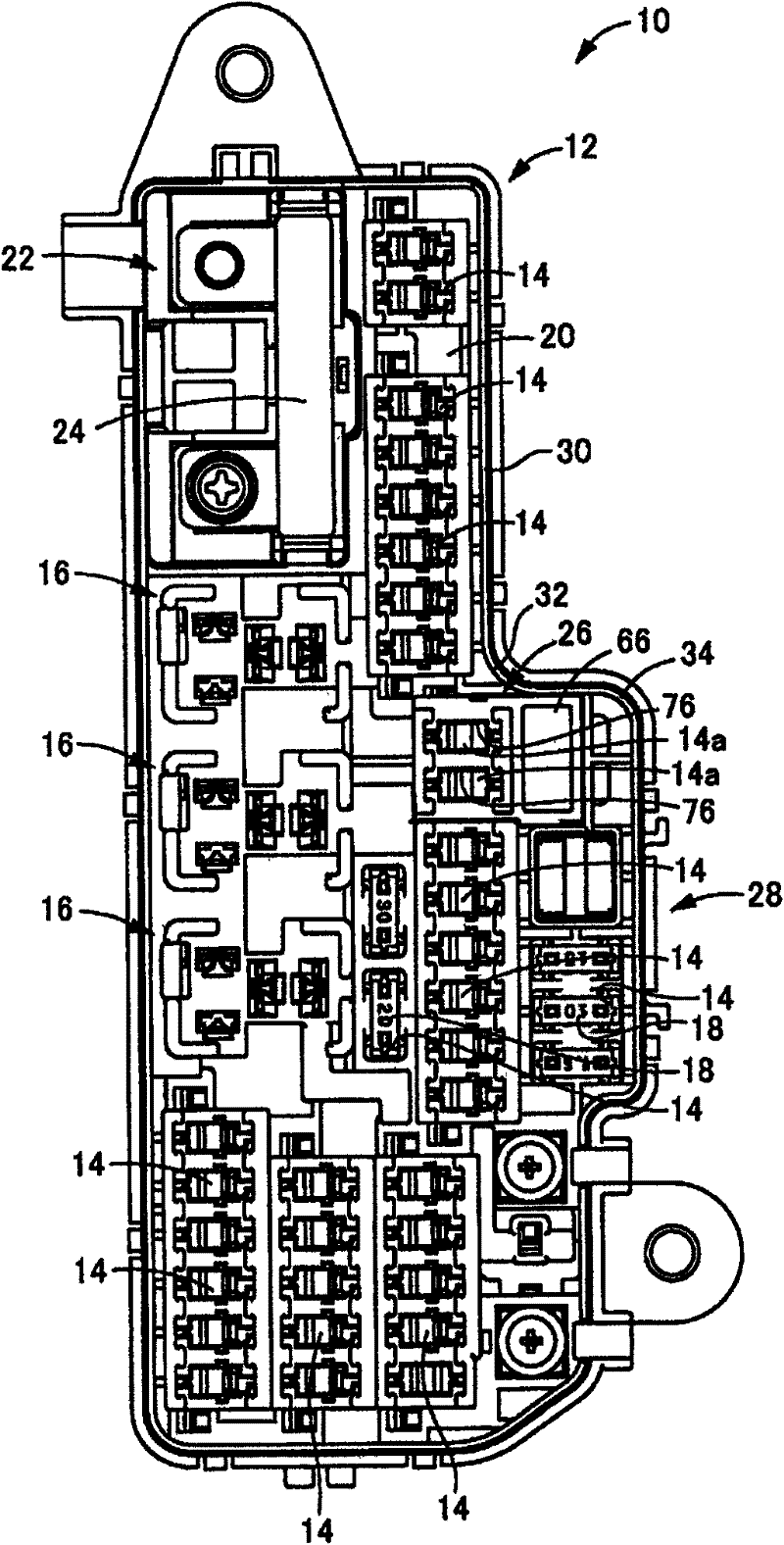

Electric junction box

InactiveCN102055152AImprove assembly stabilityGuaranteed StrengthElectric/fluid circuitMultiple connection subassembliesElectrical elementJunction box

Vertical bus bars are mounted on a first surface of a box main body. A connection terminal of the vertical bus bars projects inside a fitting peripheral wall of a connector fitting portion provided to a second surface of the box main body. A retainer is provided off of the electrical component connection portion, the retainer holding the vertical bus bars disengageably from the first surface.

Owner:SUMITOMO WIRING SYST LTD

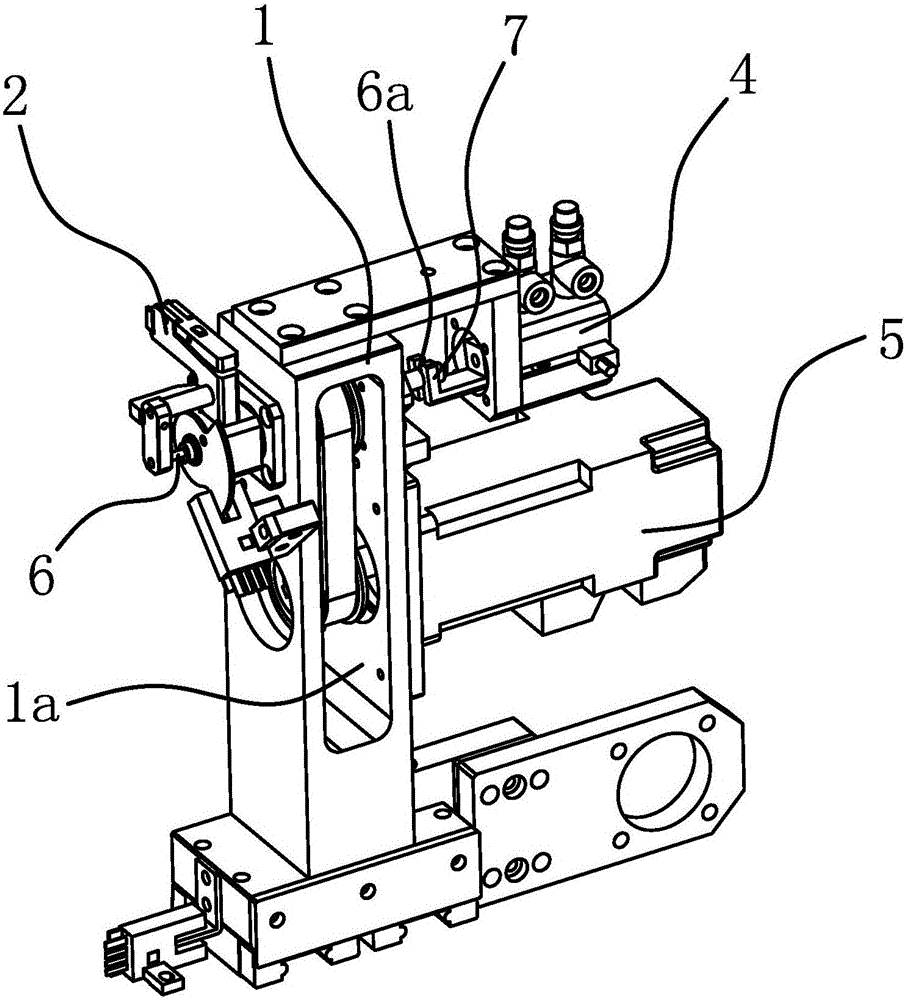

Automated assembling machine for solenoid coil

ActiveCN106392627AStable assembly workImprove assembly stabilityAssembly machinesEngineeringManipulator

The invention provides an automated assembling machine for a solenoid coil, belongs to the technical field of machinery and solves the problem of low automation degree in prior art. The automatic assembling machine for a solenoid coil comprises a support. The support has an assembling part for assembling the solenoid coil, the upper part of the assembling part has a manipulator for conveying the coil, clamping parts for conveying a magnetic core are arranged at left and right sides of the assembling part, the support is also provided with a storage groove for storing the magnetic core, and the two clamping parts can be connected through a synchronous driving mechanism which can drive the two clamping parts to act oppositely and synchronously. The automated assembling machine for a solenoid coil is high in automation degree.

Owner:TANAC AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com