Vacuum arc-extinguishing chamber assembling calibration clamp

A vacuum interrupter and fixture technology, applied in electrical components, electrical switches, circuits, etc., can solve the problem of inability to guarantee the coaxiality of the vacuum interrupter, and achieve the effect of increasing the coaxiality and solving the coaxiality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

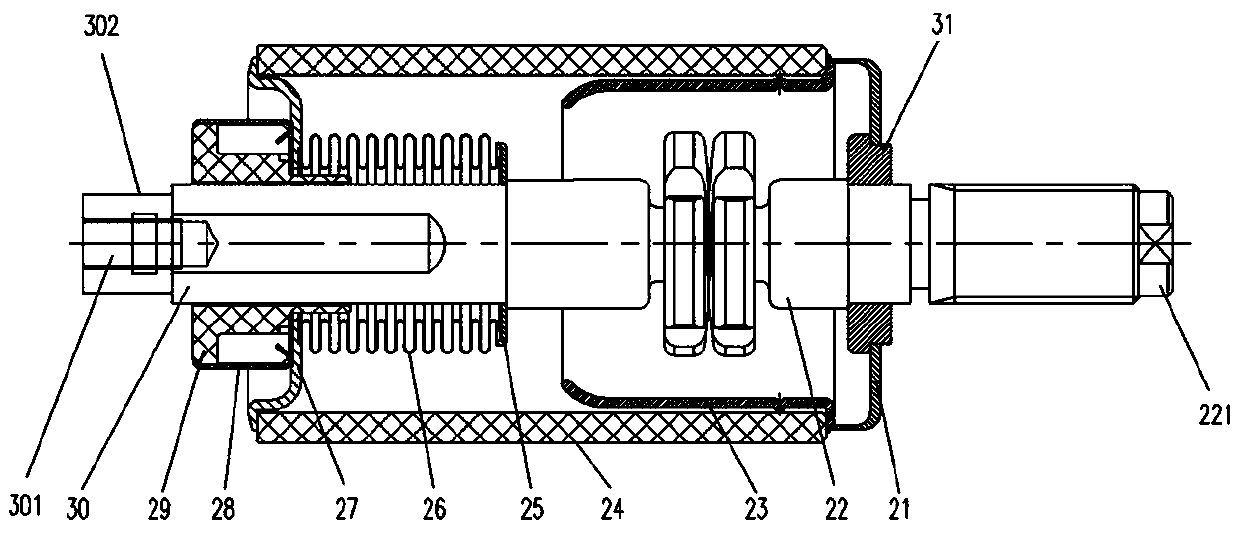

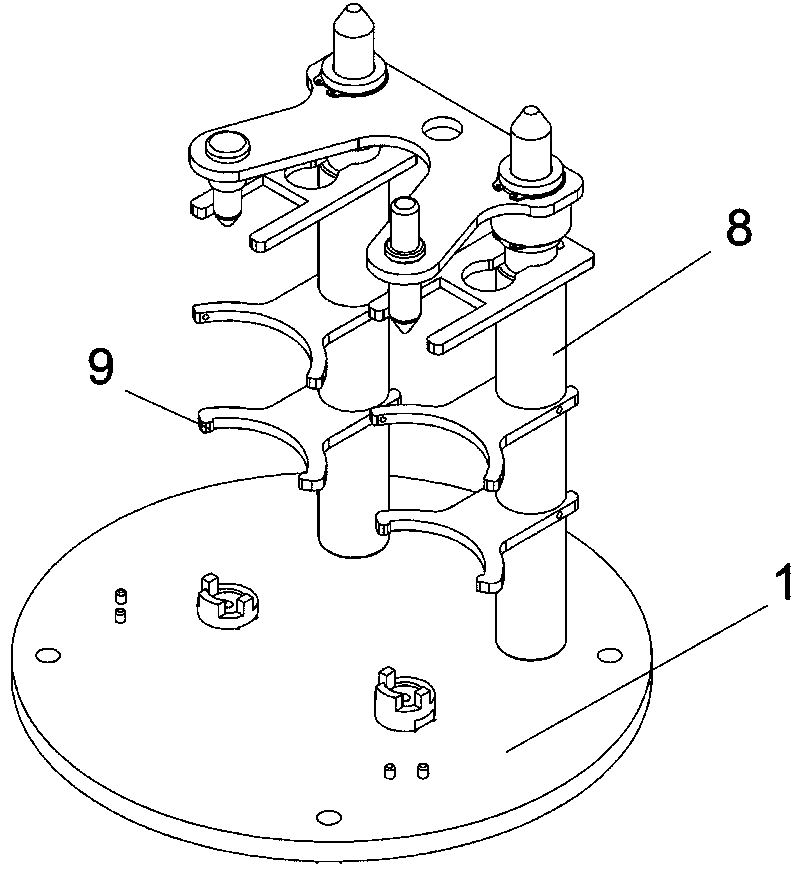

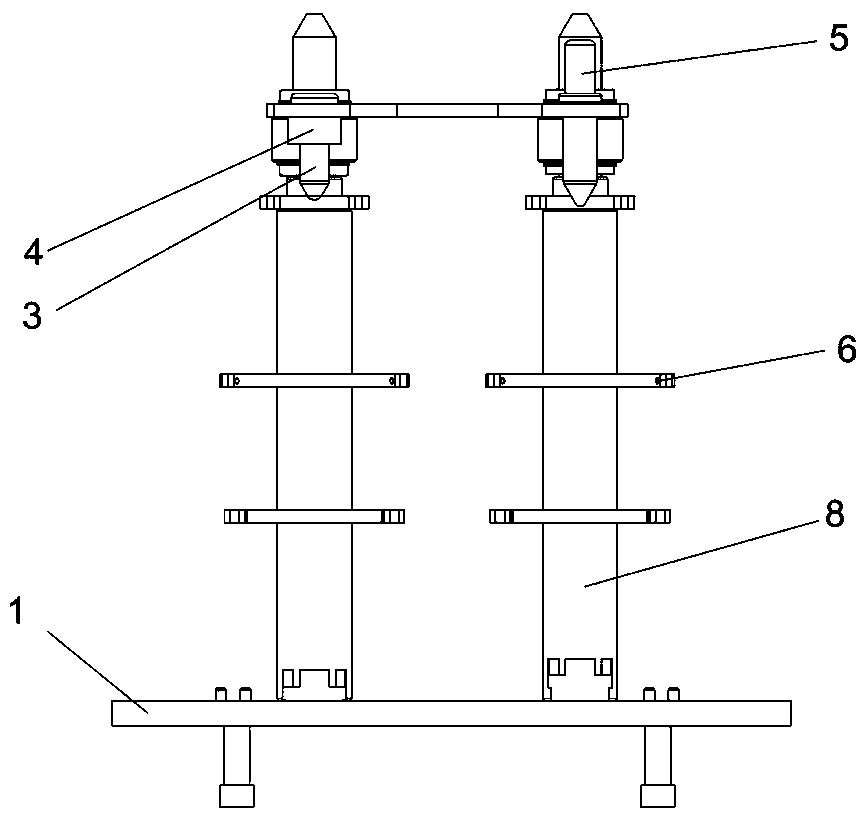

[0061] Specific embodiment 2 of the vacuum interrupter assembly calibration jig of the present invention, the vacuum interrupter assembly calibration jig includes a calibration unit for calibrating a single vacuum interrupter, and the calibration unit includes a moving end coaxially arranged in the up and down direction The positioning pin and the static tube core positioning structure, the moving end positioning pin is used for coaxial positioning and plugging with the threaded hole of the moving tube core, the static tube core positioning structure is used for coaxial positioning and assembly with the static tube core, and the static tube A centralizing structure for centralizing the vacuum interrupter is provided above the core positioning structure. During the assembly of the vacuum interrupter, the positioning structure of the static tube core is coaxially positioned and installed with the static tube core, the positioning pin of the moving end is coaxially inserted into t...

specific Embodiment 9

[0068] The specific embodiment 9 of the vacuum interrupter assembly and calibration jig of the present invention, as a further optimization of the specific embodiment 8 of the vacuum interrupter assembly and calibration jig of the present invention, defines the width direction of the cover positioning body in this embodiment for Corresponding to the circumferential direction of the static cover plate, the static cover plate positioning body includes a static cover plate positioning body body and at least two static cover plate positioning body bodies protruding at intervals along the width direction of the static cover plate positioning body. The cover plate pressing protrusion is used for pressing and supporting the static cover plate along the radial direction of the static cover plate. The cover plate positioning body has a simple structure and is convenient for installation and positioning operations. In other embodiments, the positioning body of the static cover may be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com