Power steering pump

A technology of power steering pump and pump body, which is applied to rotary piston pumps, pumps, pump components, etc., can solve the problems of reduced stability and service life of steering system, increased cost of processing procedures, and shortened service life of steering system, etc. Improve assembly stability and service life, reduce heat generation and pressure loss, and reduce the effect of flow pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

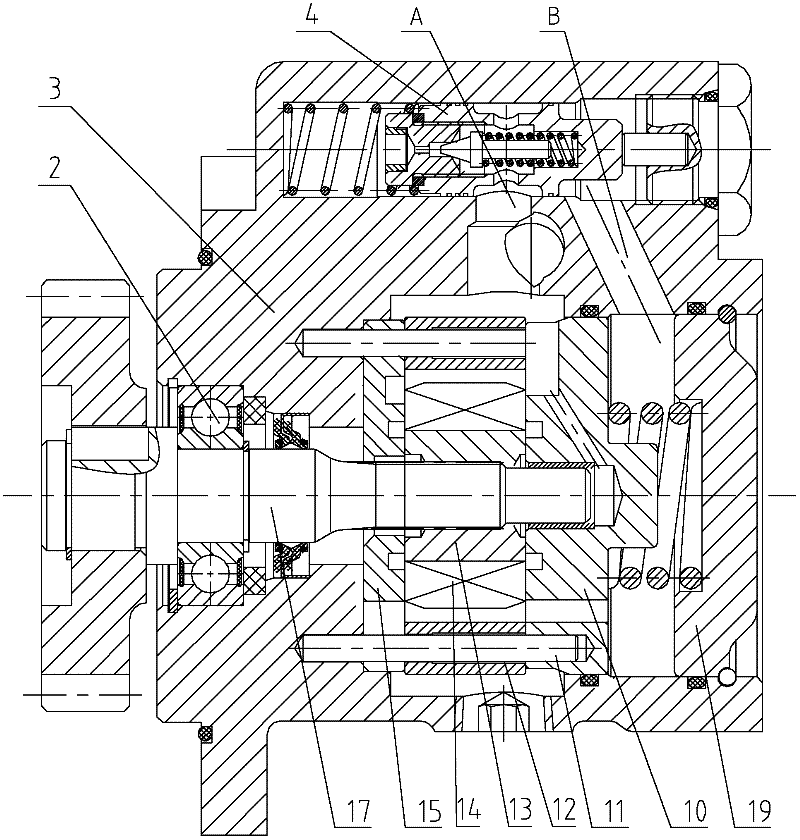

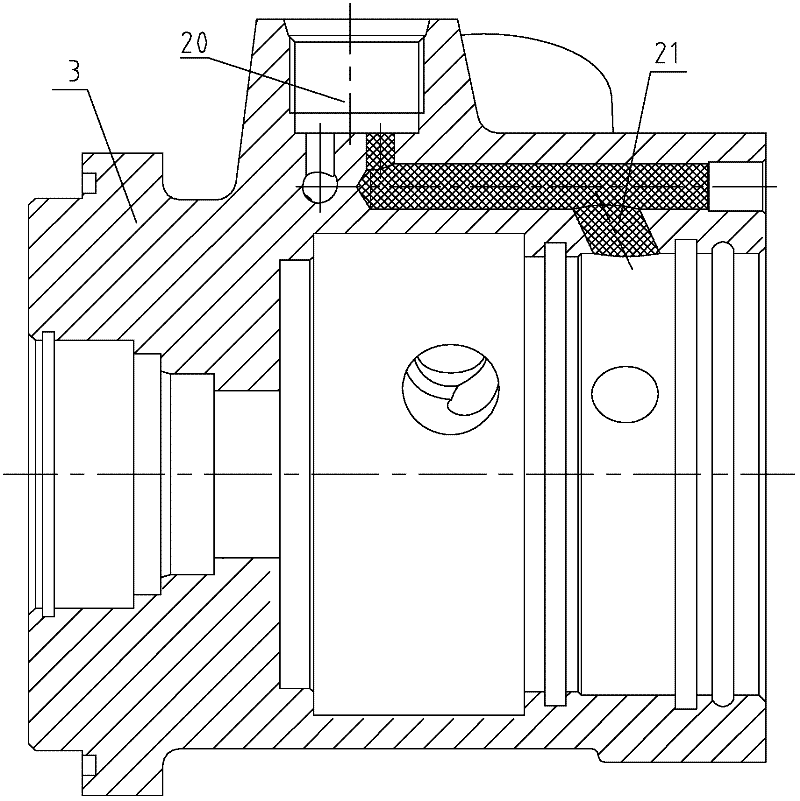

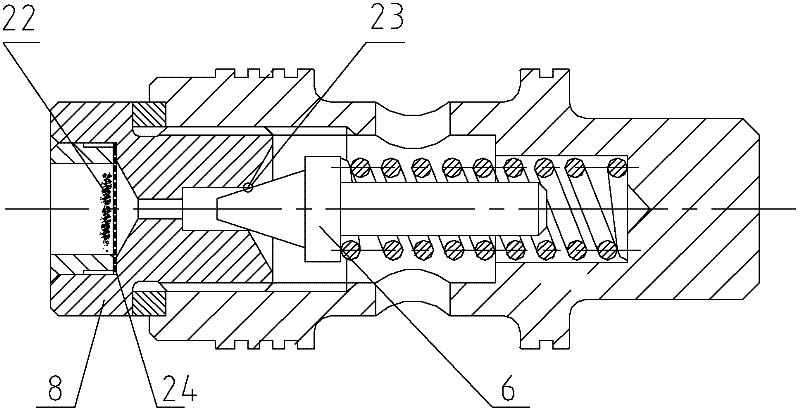

[0030] Such as Figure 5 As shown, the high-pressure cooling power steering pump in the front cavity includes a pump body 3, and the pump body 3 is provided with an inner cavity. The inner cavity of the pump body is sequentially provided with a rear oil distribution plate 10, a stator 12, a rotor 13, and blades. 14. Locating pin 11, front oil distribution plate 15, compression spring 16, a pump shaft 17 connects the rear oil distribution plate 10, stator 12, rotor 13, vanes 14 and front oil distribution plate 15 in series and installs it into the pump body 3 In the inner cavity, the front end of the pump shaft 17 protrudes from the front end of the pump body 3 and the drive gear 1 is installed. The rear end of the pump shaft 17 is supported on the rear oil distribution plate 10. The pump body 3 is provided with a valve hole on the outer circumference side of the pump body cavity, the valve hole communicates with the oil outlet front chamber A, and a flow safety control valve i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com