Ultra-lightweight balanced suspension

A technology for balancing suspensions and balance shaft brackets, applied in suspensions, elastic suspensions, interconnection systems, etc., can solve problems such as difficult installation of V-shaped thrust rods, achieve small stress, reduce cumulative assembly errors, and reduce stress deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

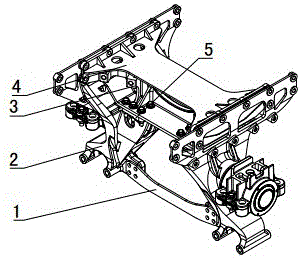

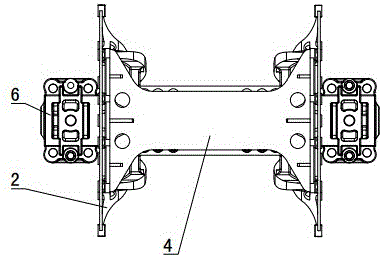

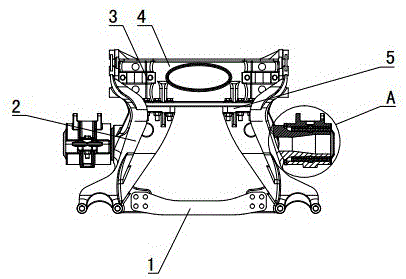

[0031] Figure 1~6 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~6 The present invention will be further described.

[0032] An ultra-lightweight balanced suspension, comprising a beam 4 connected as one, a balance shaft bracket 2 and a lower connecting plate 1, the two ends of the beam 4 are respectively fixedly connected to the upper parts of the two balance shaft brackets 2, and the two ends of the lower connecting plate 1 They are respectively connected to the bottom ends of the two balance shaft supports 2 , the crossbeam 4 is provided with V-shaped thrust rod mounts 3 symmetrically front and back, and the outer sides of the two balance shaft supports 2 are provided with leaf spring mounts. The ultra-lightweight balance suspension is internally connected between the vehicle frames, so that the ultra-lightweight balance suspension realizes a modular assembly process, and a crossbeam 4 is arranged between the two balance s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com