Patents

Literature

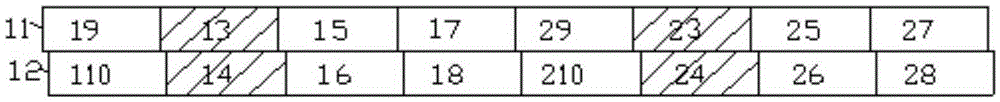

109results about How to "Avoid not being able to install" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

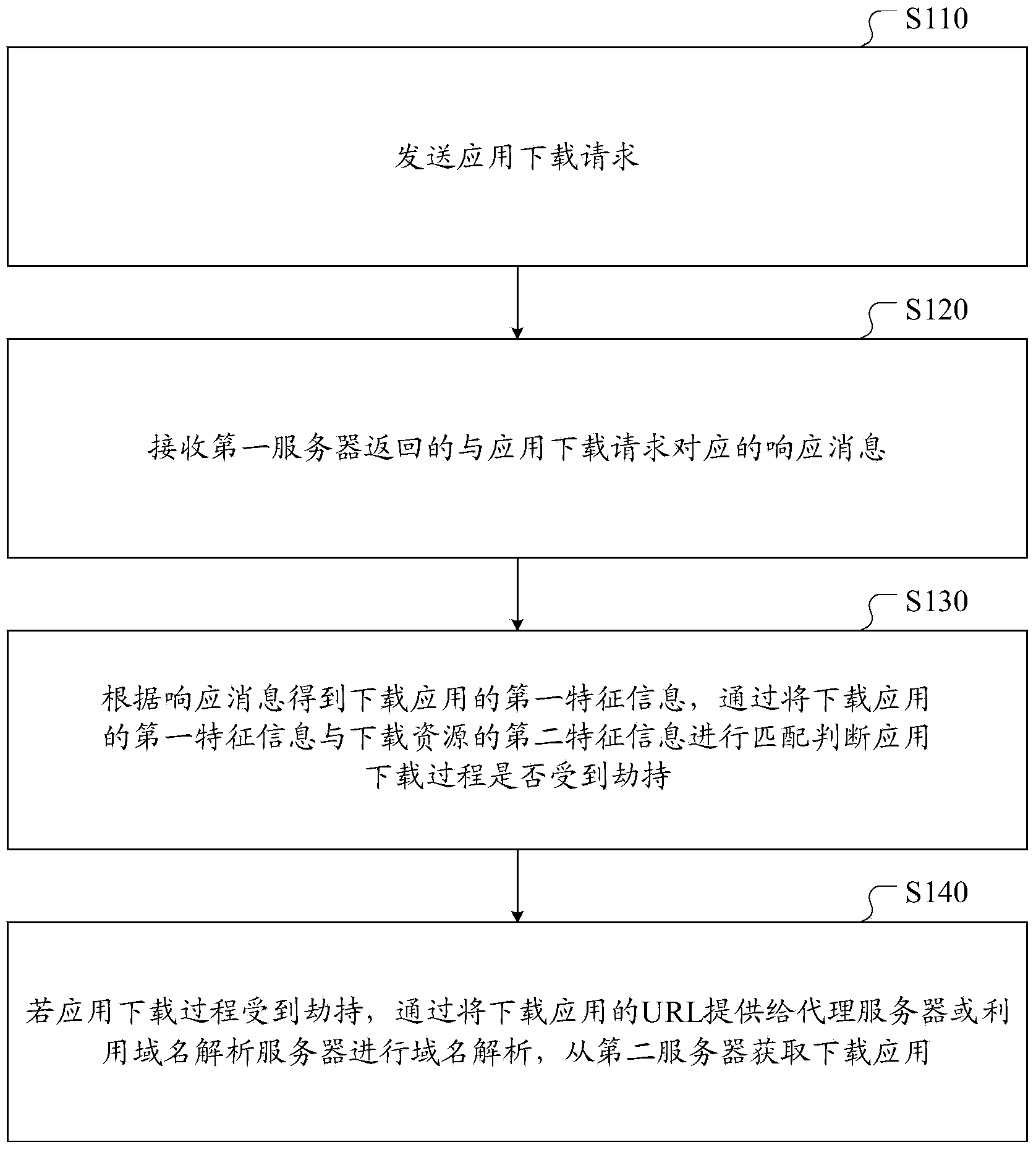

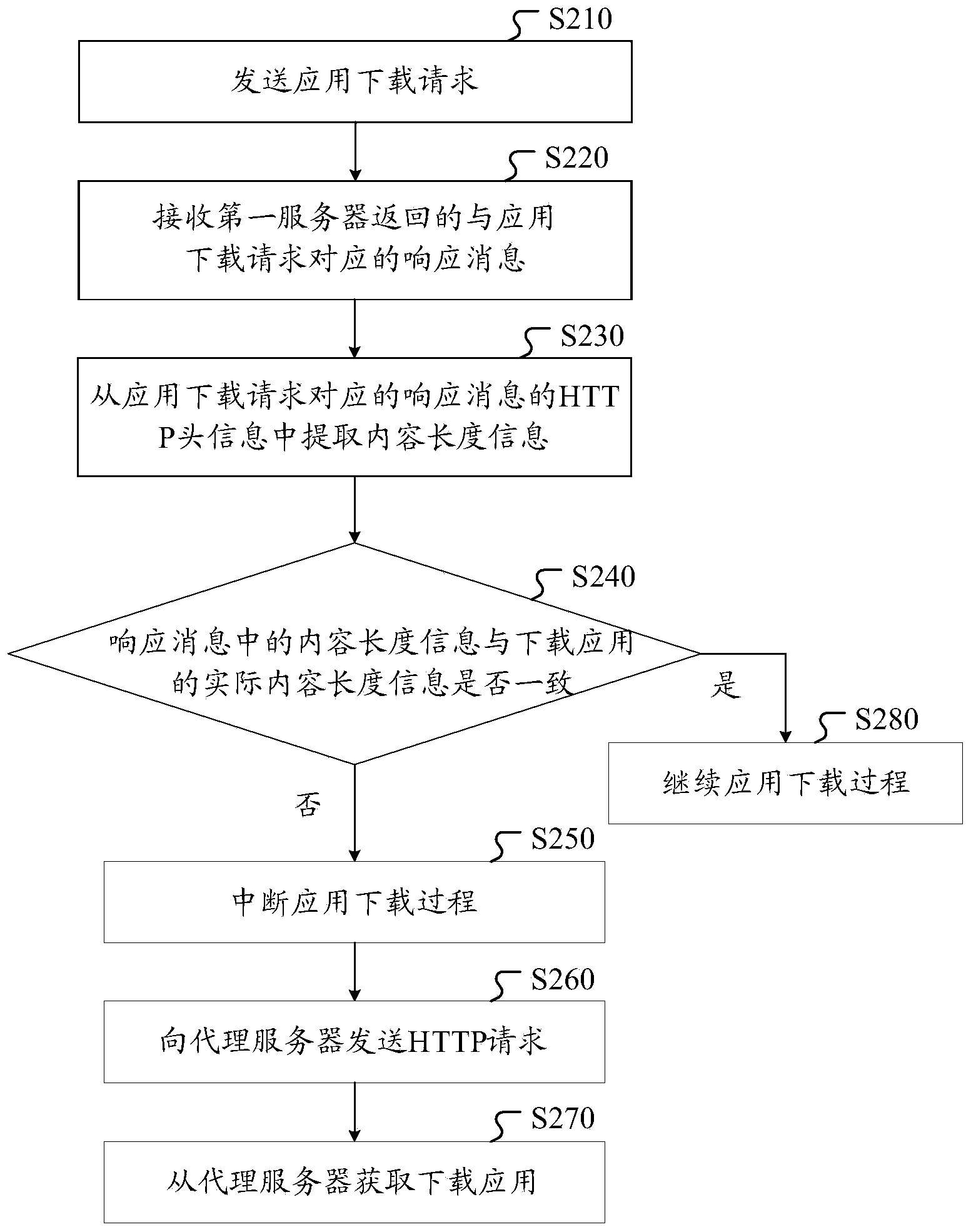

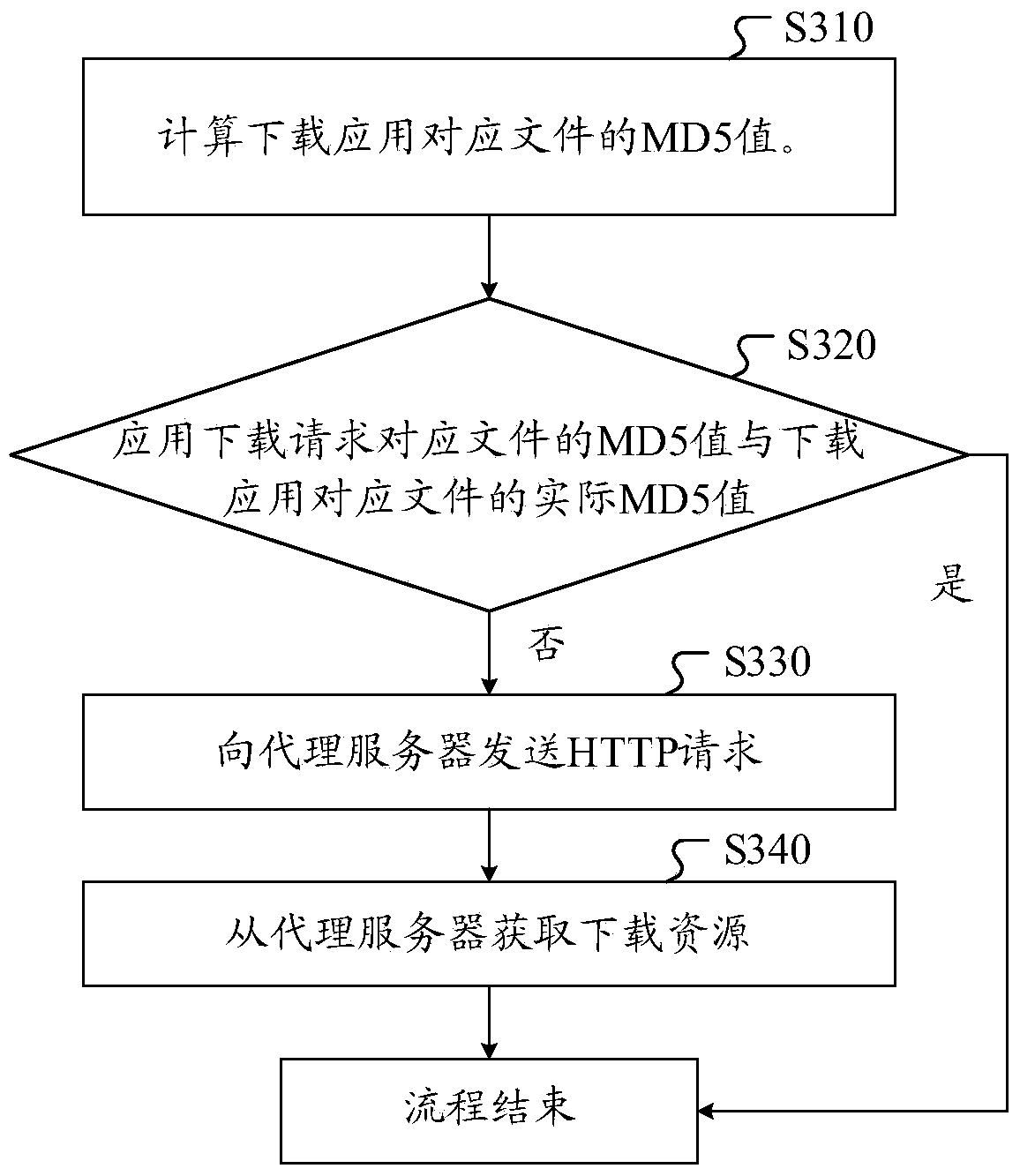

Method, device and system for preventing DNS hijack during application download

The invention discloses a method, device and system for preventing DNS hijack during application download. The method comprises the following steps: sending an application download request; receiving a response message returned by a first server and corresponding to the application download request; according to the response message, obtaining first feature information for downloading the application, matching the first feature information with second feature information for downloading the application and obtained from a second server providing the application in advance, and judging whether the application download process is hijacked; if yes, providing the URL for downloading the application for a proxy server or utilizing a DNS server to perform domain name resolution, and obtaining the download application from the second server. According to the method, the problems in the prior art that the application download and installation fail, a data package is replaced, the model change fails and the like caused by network hijack of an operator are solved, and the time, traffic and cost of a user are saved.

Owner:三六零数字安全科技集团有限公司

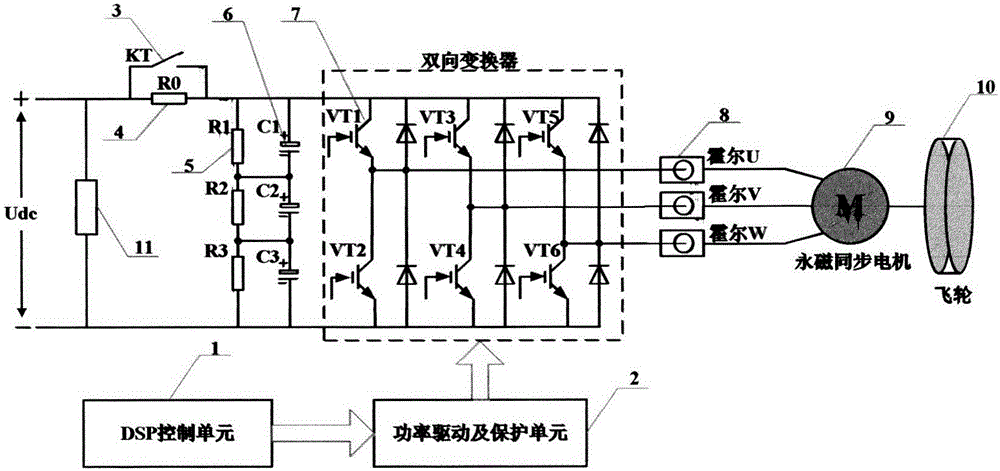

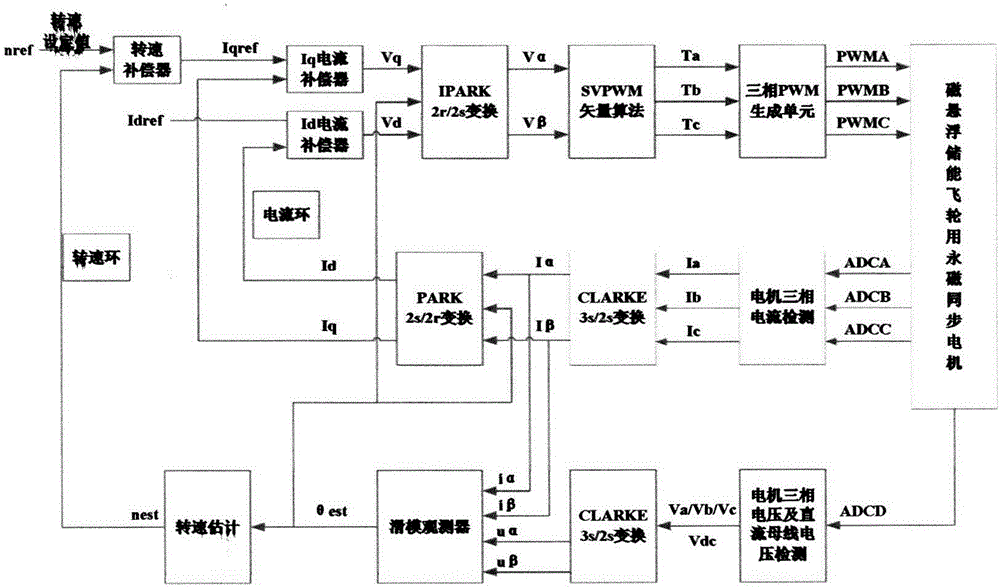

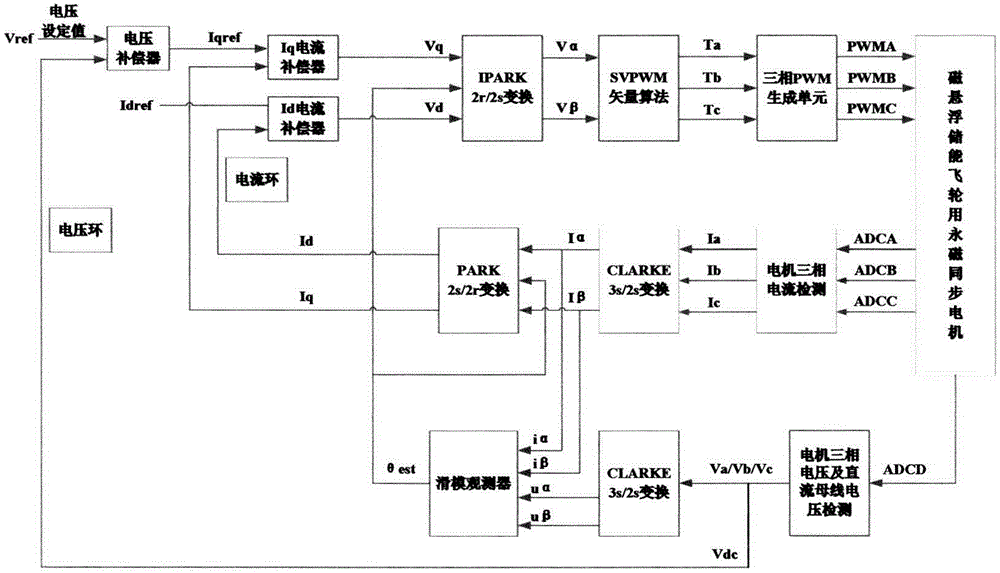

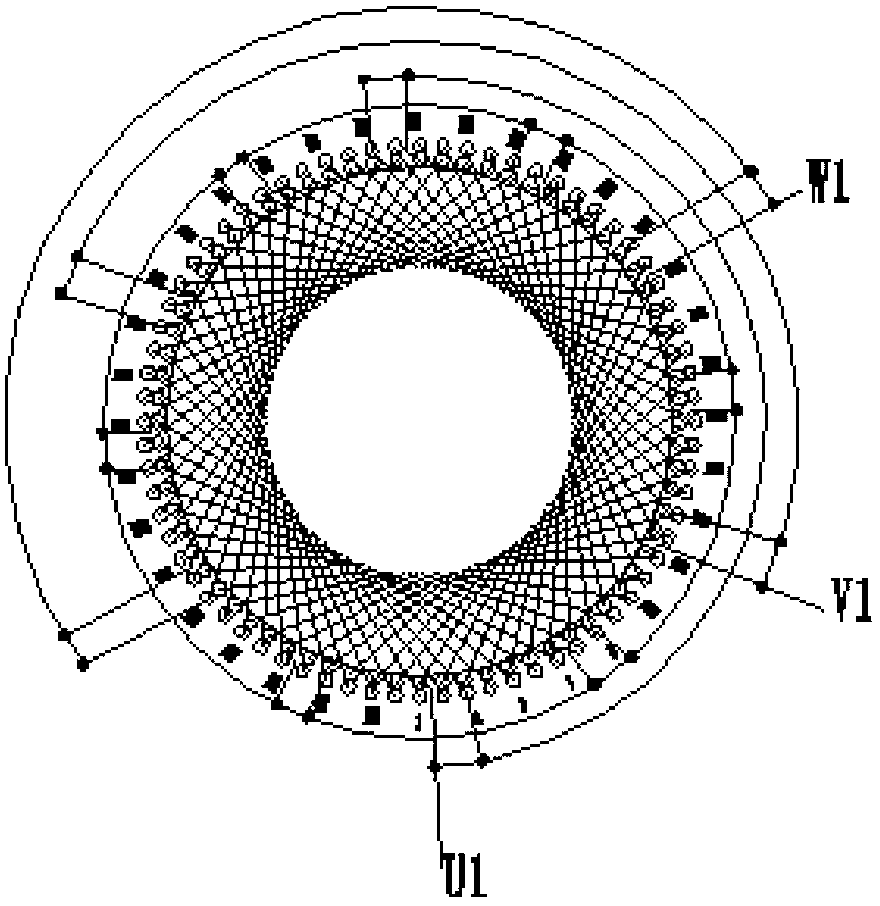

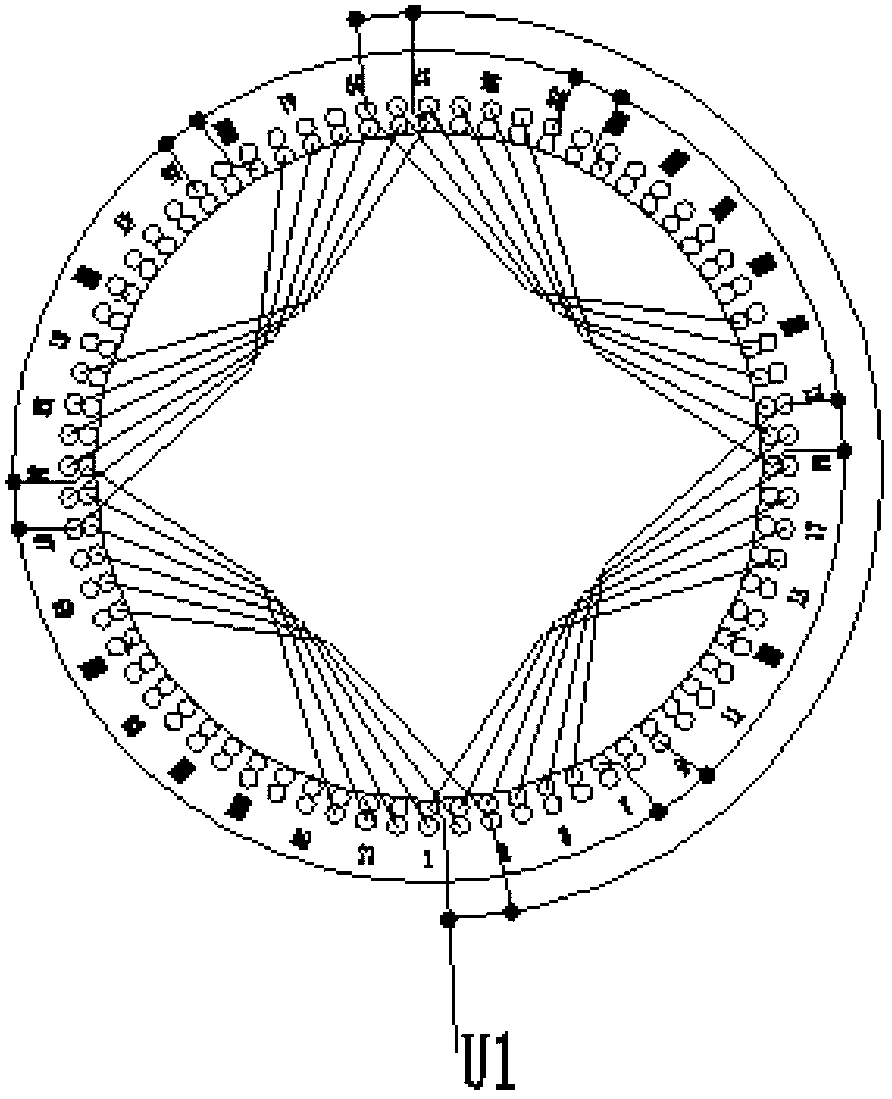

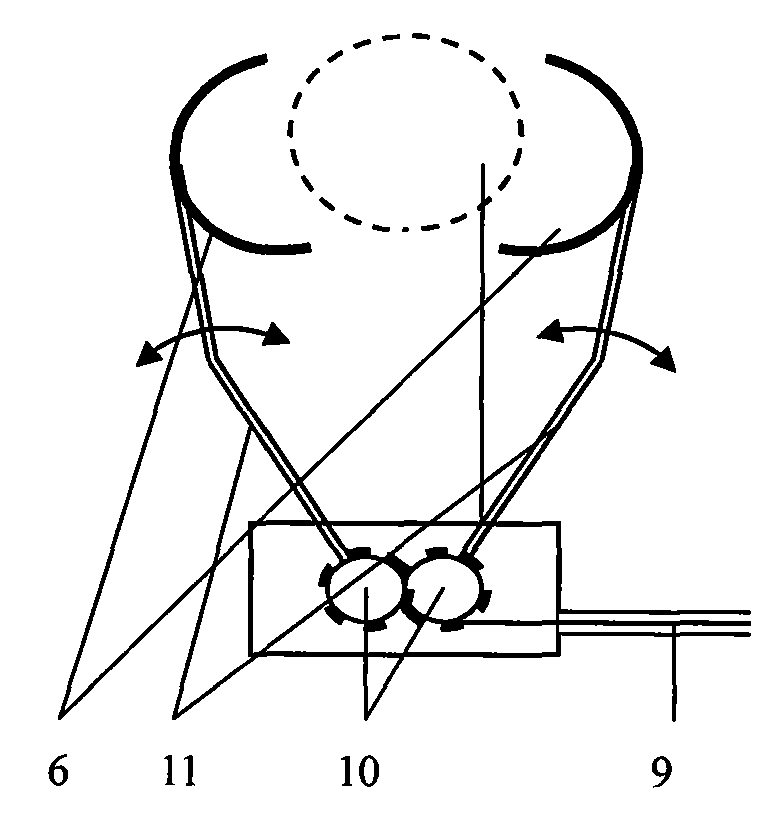

Magnetic suspension energy storage flywheel charging and discharging control method based on minimum power topology

InactiveCN106849139ASimple control structureSave resourcesAc network load balancingPower topologyPermanent magnet synchronous motor

The invention discloses a magnetic suspension energy storage flywheel charging and discharging control method based on minimum power topology, and is used for finishing the high-efficient magnetic suspension energy storage flywheel charging and discharging control to realize the energy conversion of electric energy-kinetic energy-electric energy. The power topology comprises a DSP (Digital Signal Processor) control unit, a power driving and protecting circuit, a bypass relay, a soft boot resistor, an equalizing resistor, a voltage stabilization capacitor, an IGBT (Insulated Gate Bipolar Translator) switching tube, a Hall current sensor, a permanent magnet synchronous motor, a flywheel and a direct-current load, wherein the IGBT switching tube is under a high-frequency inversion state when direct-current bus voltage Udc is higher than charging voltage, a permanent magnet synchronous motor drives the flywheel to be accelerated, and the flywheel is under a charging mode to finish the conversion of the electric energy to kinetic energy; when the direct-current bus voltage Udc is lower than discharging voltage, the IGBT switching tube is under a PWM (Pulse-Width Modulation) rectification state, the revolving speed of the flywheel is lowered, and the permanent magnet synchronous motor is under a discharging mode to finish the conversion of the kinetic energy to the electric energy. The magnetic suspension energy storage flywheel charging and discharging control method is used for the high-efficient magnetic suspension energy storage flywheel charging and discharging control.

Owner:BEIJING HONGHUI INT ENERGY TECH DEV CO LTD

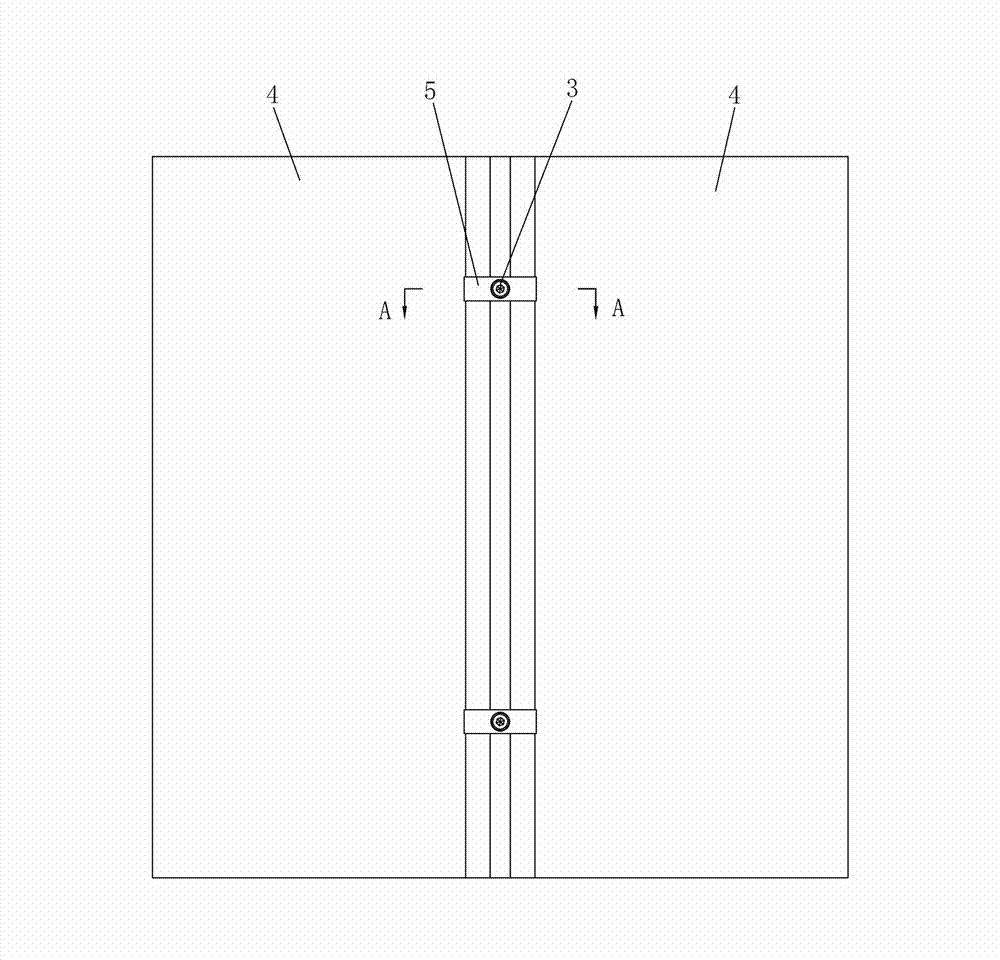

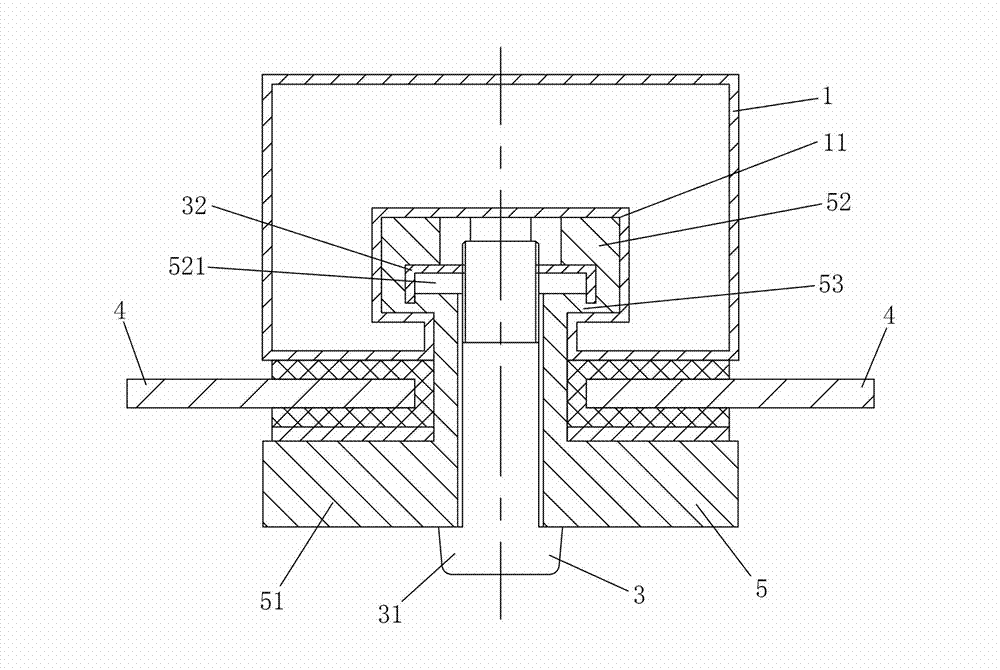

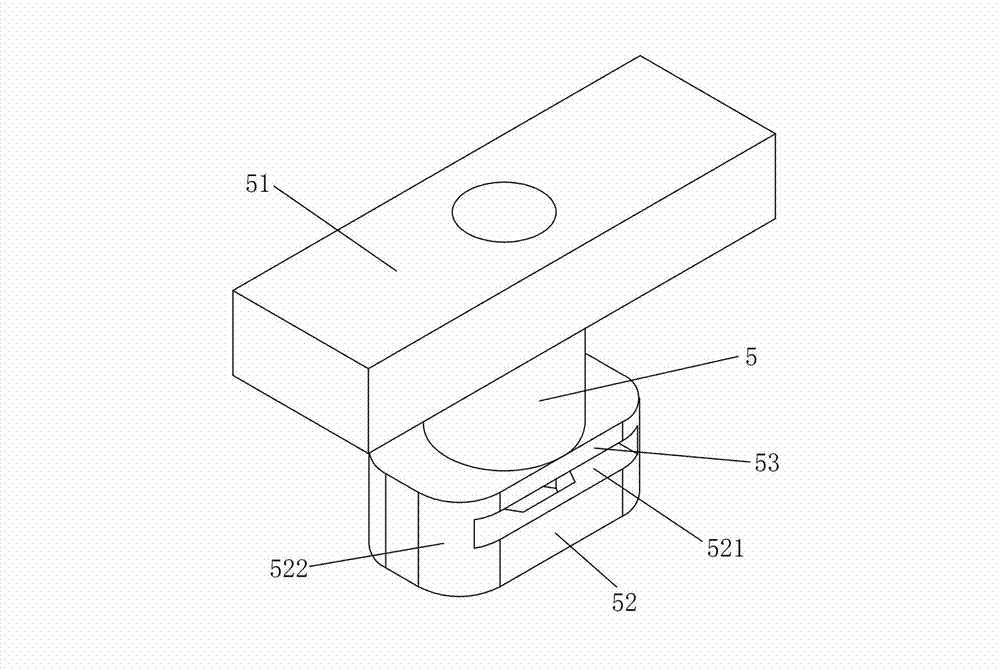

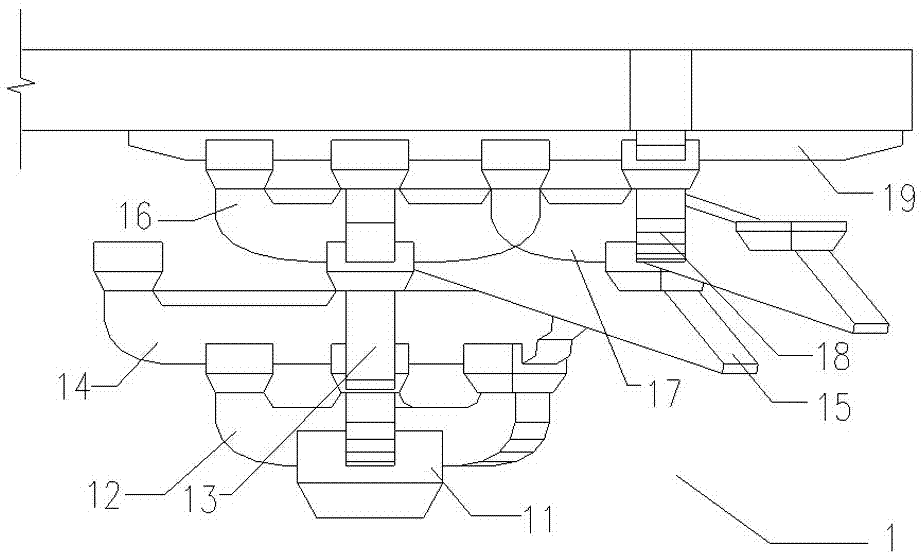

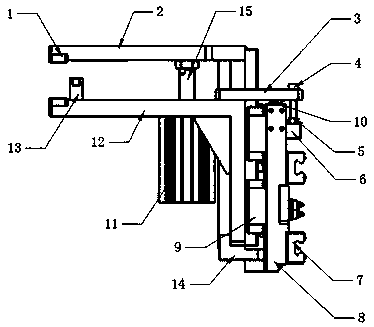

Connecting component for mounting curtain wallboard

ActiveCN102900182AAvoid the disadvantages of long-term operationImprove convenienceWallsKeelEngineering

The invention discloses a connecting component for mounting a curtain wallboard. The connecting component comprises a keel, a fastener and a limiting element, wherein the limiting element comprises a pressing limiting part and a keel connecting part; the keel connecting part is detachably connected with the keel; a pre-tightening mounting slot for the curtain wallboard is formed between the pressing limiting part and the keel; the fastener is connected between the pressing limiting part and the keel connecting part; and when the fastener is used for fastening, the pressing limiting part is deformed so as to press the curtain wallboard. The connecting component for mounting the curtain wallboard has the advantages of simple and compact structure, convenience in operation, high mounting efficiency, capability of increasing mounting safety, excellent heat-insulating property, and the like.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

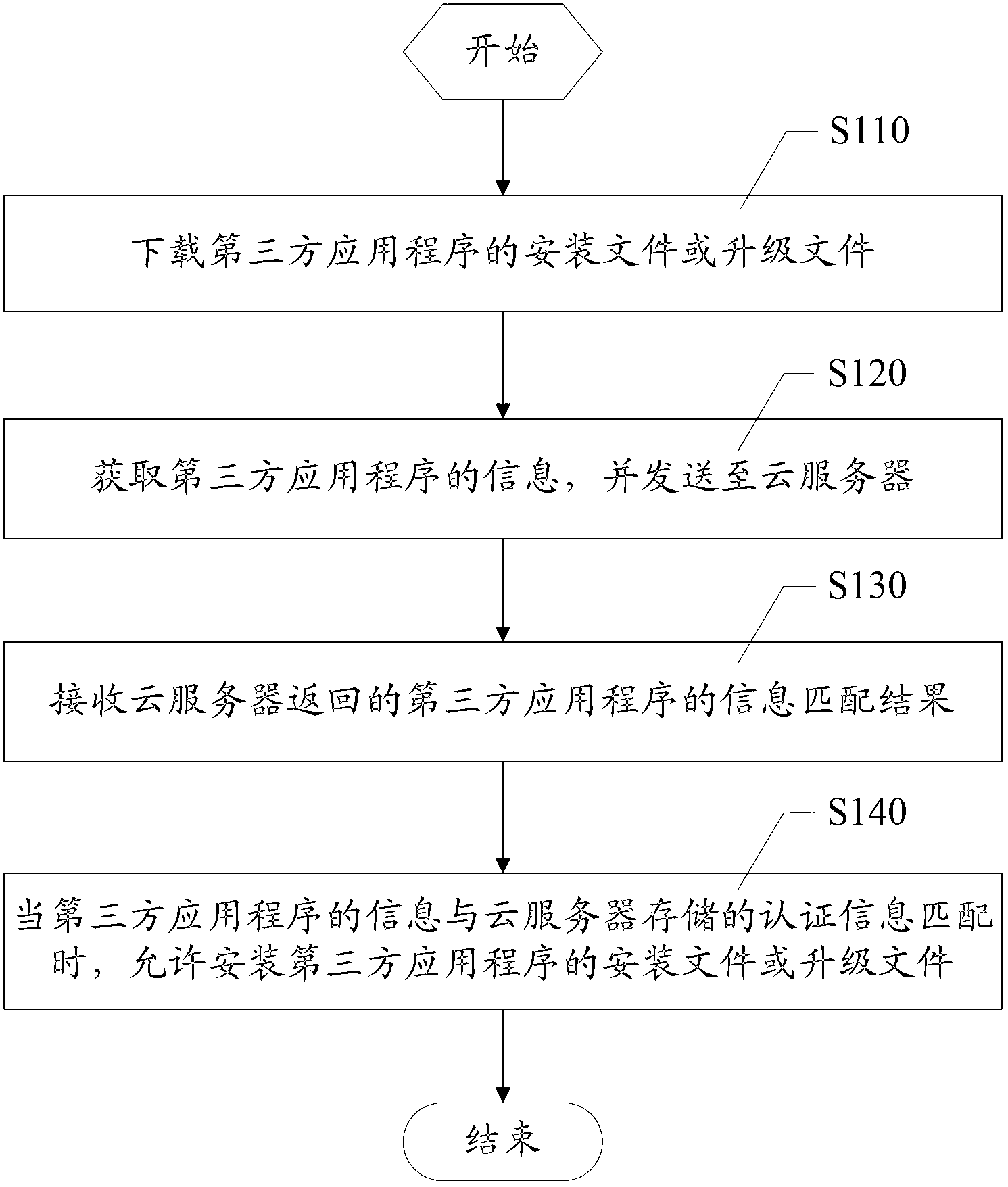

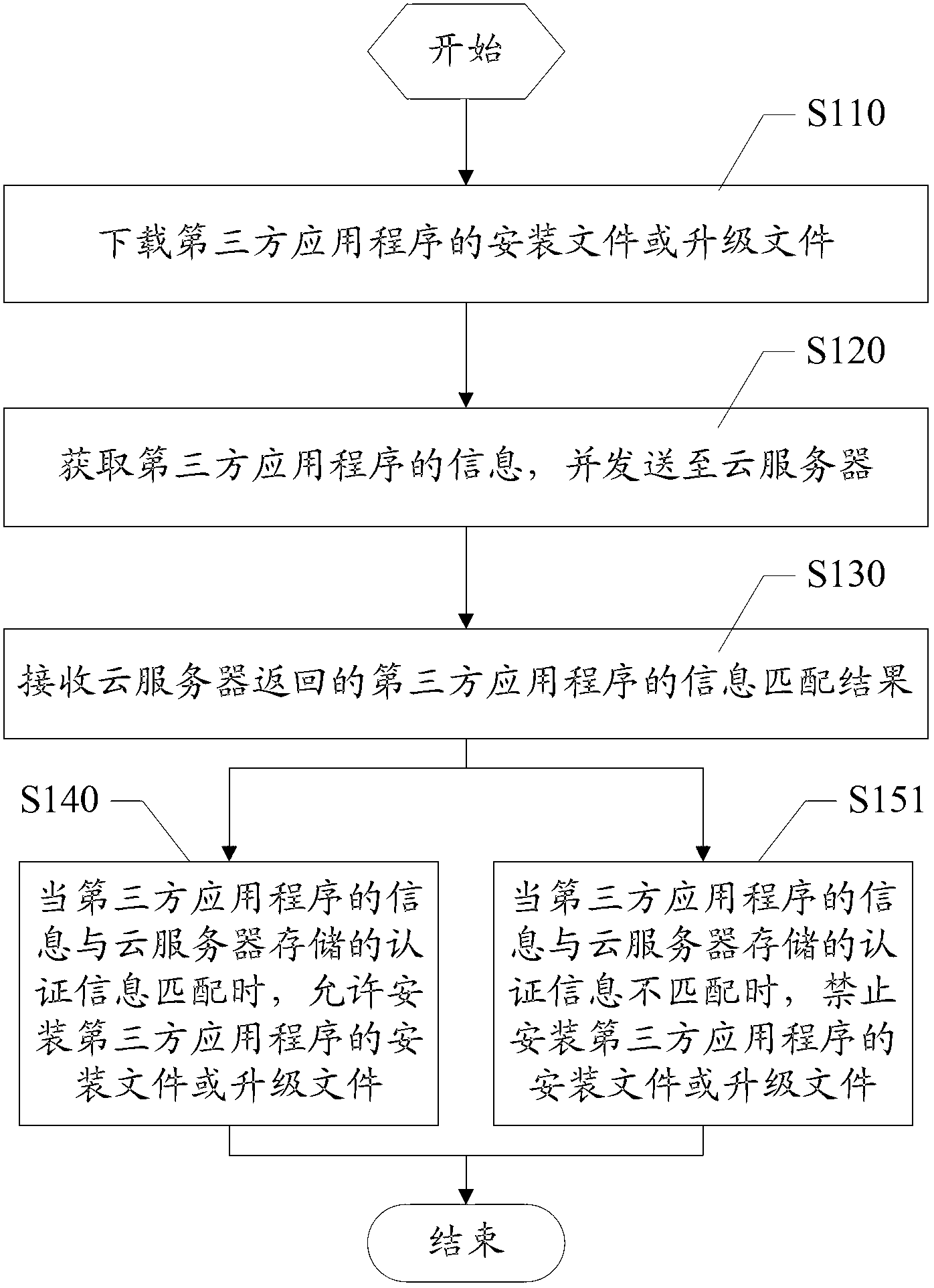

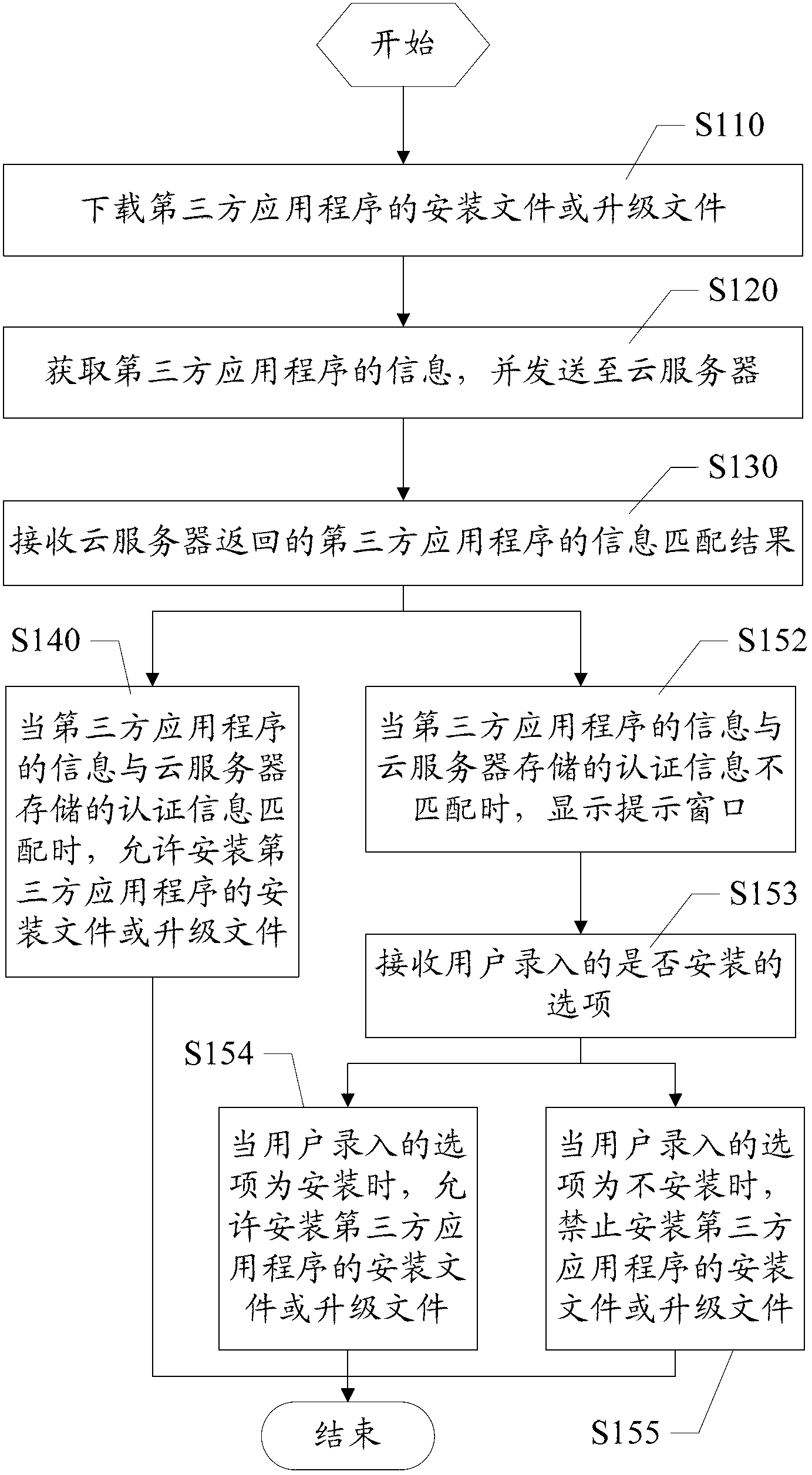

Method for certifying third-party application program, mobile terminal and cloud server

InactiveCN103179124AAvoid not being able to installImprove securityTransmissionThird partyComputer terminal

The invention discloses a method for certifying a third-party application program, a mobile terminal and a cloud server. The method for certifying the third-party application program via the mobile terminal comprises the following steps of: downloading an installation file or an upgrade file of the third-party application program; acquiring information of the third-party application program and sending the information to the cloud server; receiving an information matching result of the third-party application program retuned from the cloud server; and allowing to install the installation file or the upgrade file of the third-party application program when the information of the third-party application program is matched with certification information stored in the cloud server. The method can be used for avoiding the incapability of normally installing a safe application program or the installation of unsafe application program information by mistake caused by untimely upgrading of the certification information of the third-party application program, effectively improving the security of the mobile terminal and avoiding the affect on the normal use of the mobile terminal.

Owner:DONGGUAN YULONG COMM TECH +1

Automobile radiator detection device

ActiveCN110031202AEasy to disassembleEasy to detectMachine part testingOptically investigating flaws/contaminationEngineeringHeat spreader

The invention discloses an automobile radiator detection device, and belongs to the field of automobile component detection. The automobile radiator detection device comprises an upper bracket and a lower bracket, a heating detection mechanism, a hole site detection mechanism and a multifunctional detection mechanism are arranged at the top of the upper bracket, a climbing mechanism and an overturning mechanism are arranged at the top of the lower bracket, the overturning mechanism comprises two overturning components, the multifunctional detection mechanism comprises a mounting bar, a material moving plate and a material moving component, two extending plates are arranged on a right end of the material moving plate, a connecting shaft is arranged on each extending plate, and a rotating bar is sleeved on each connecting shaft. The automobile radiator detection device disclosed by the invention can detect the smoothness of the two sides of radiators with different sizes via the multifunctional detection mechanism, and meanwhile can also detect the presence or absence of welding leakage points on radiator core bodies, can detect the heating range of the automobile radiators through the heating detection mechanism, and can also eject the automobile radiators through the climbing mechanism, so that workers can conveniently dismount the automobile radiators.

Owner:安徽建勋科技有限公司

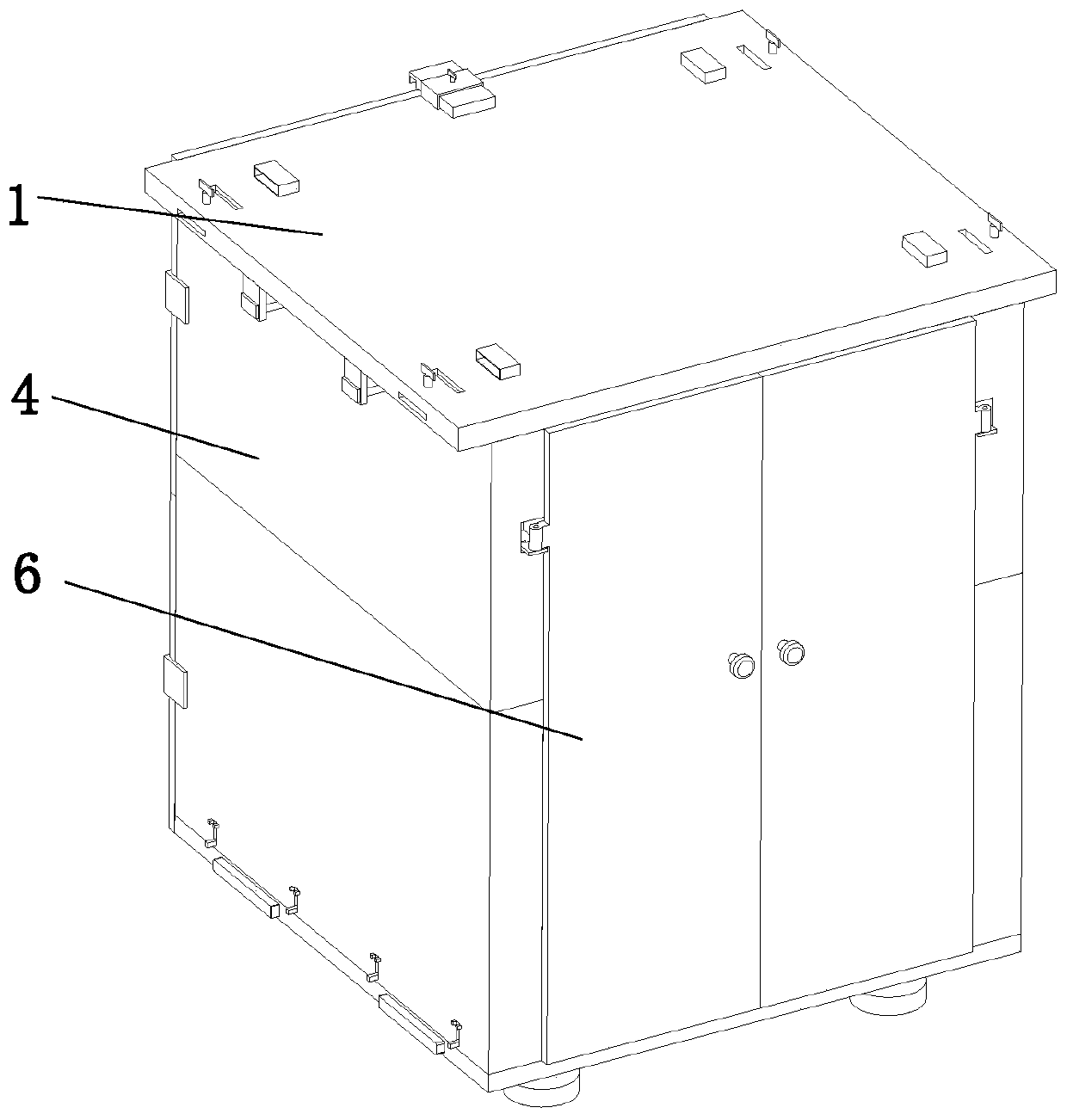

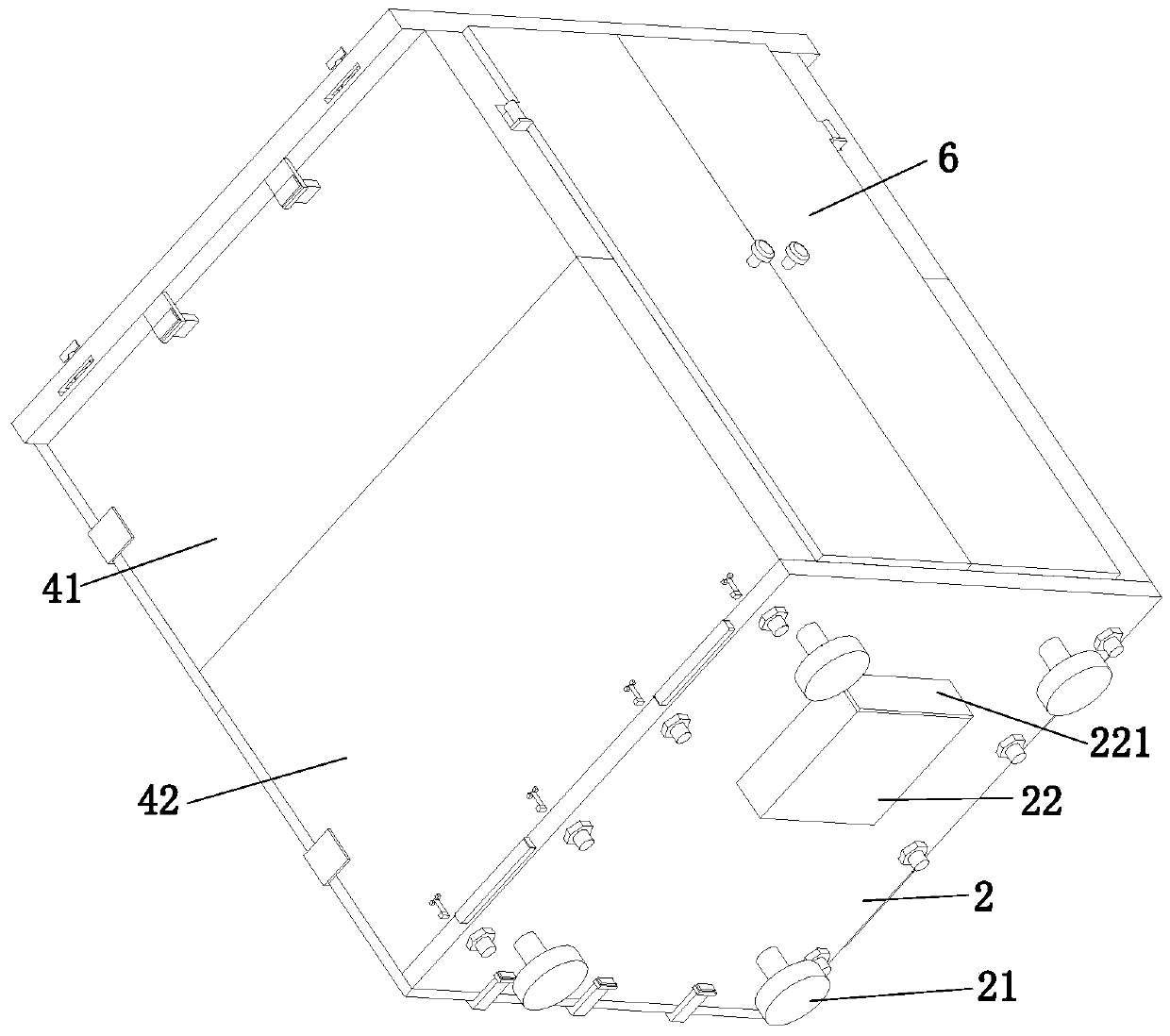

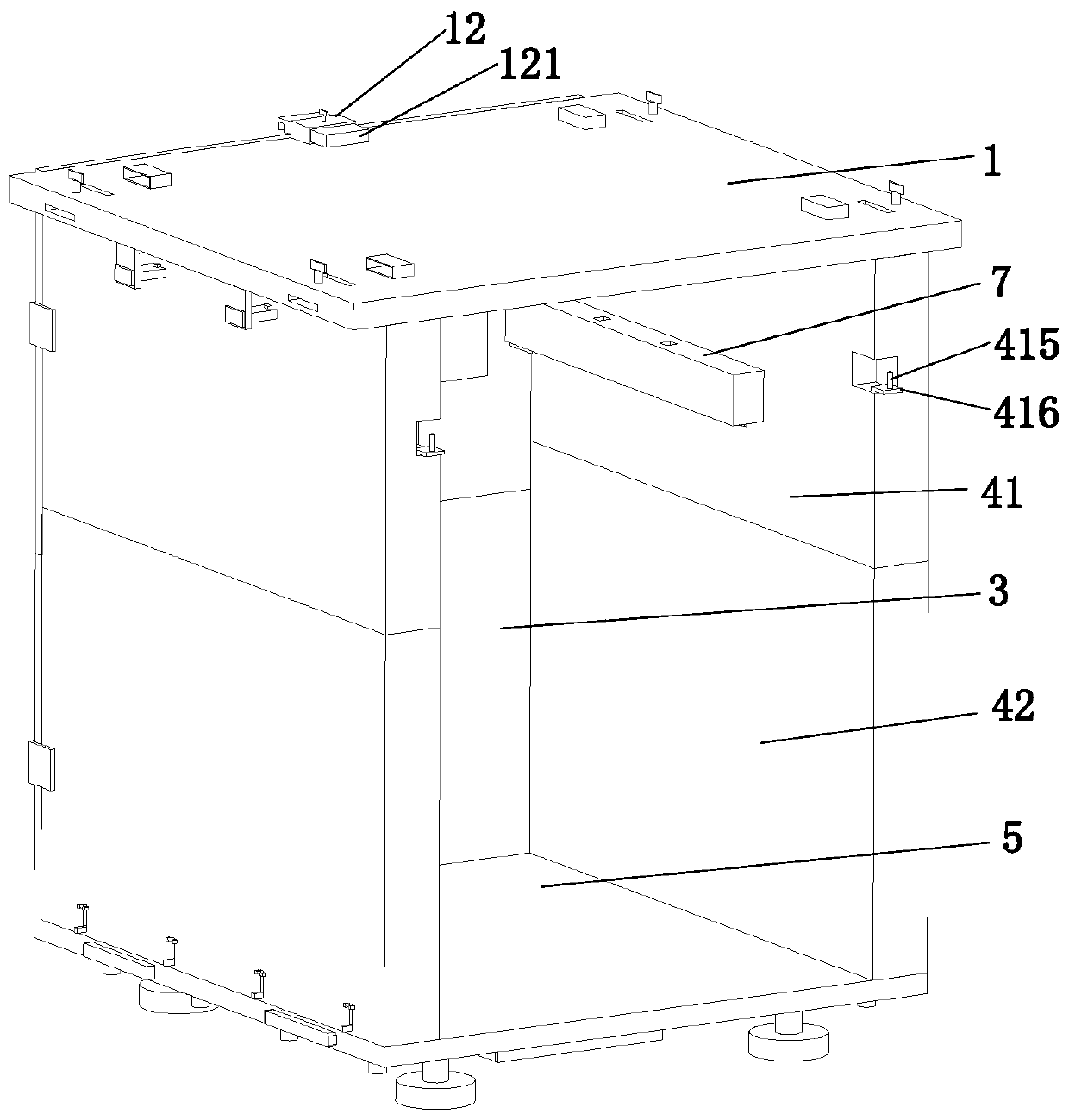

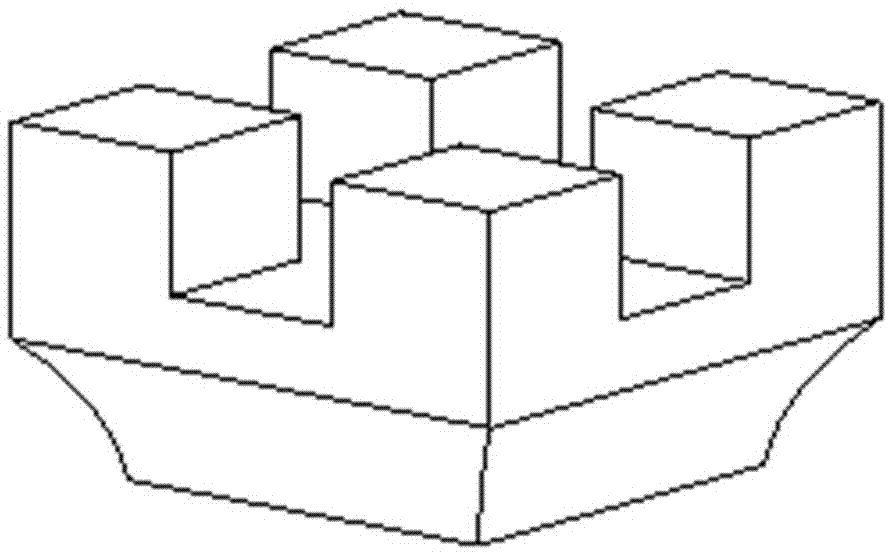

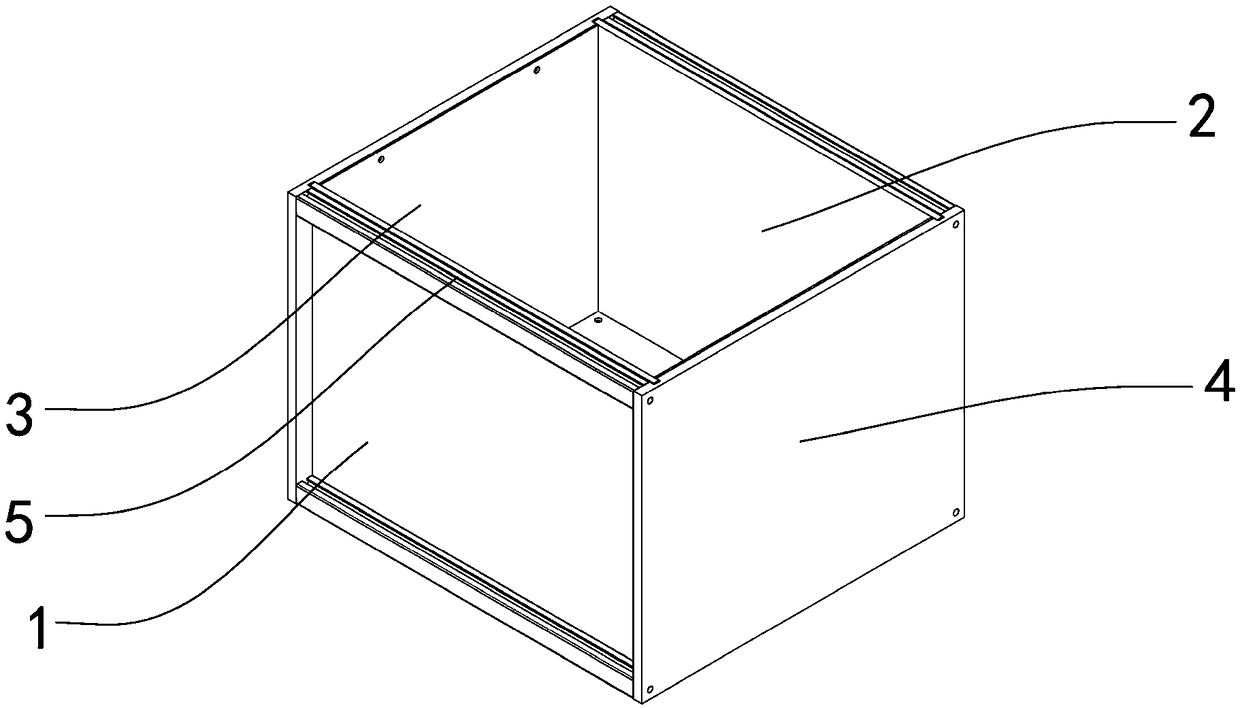

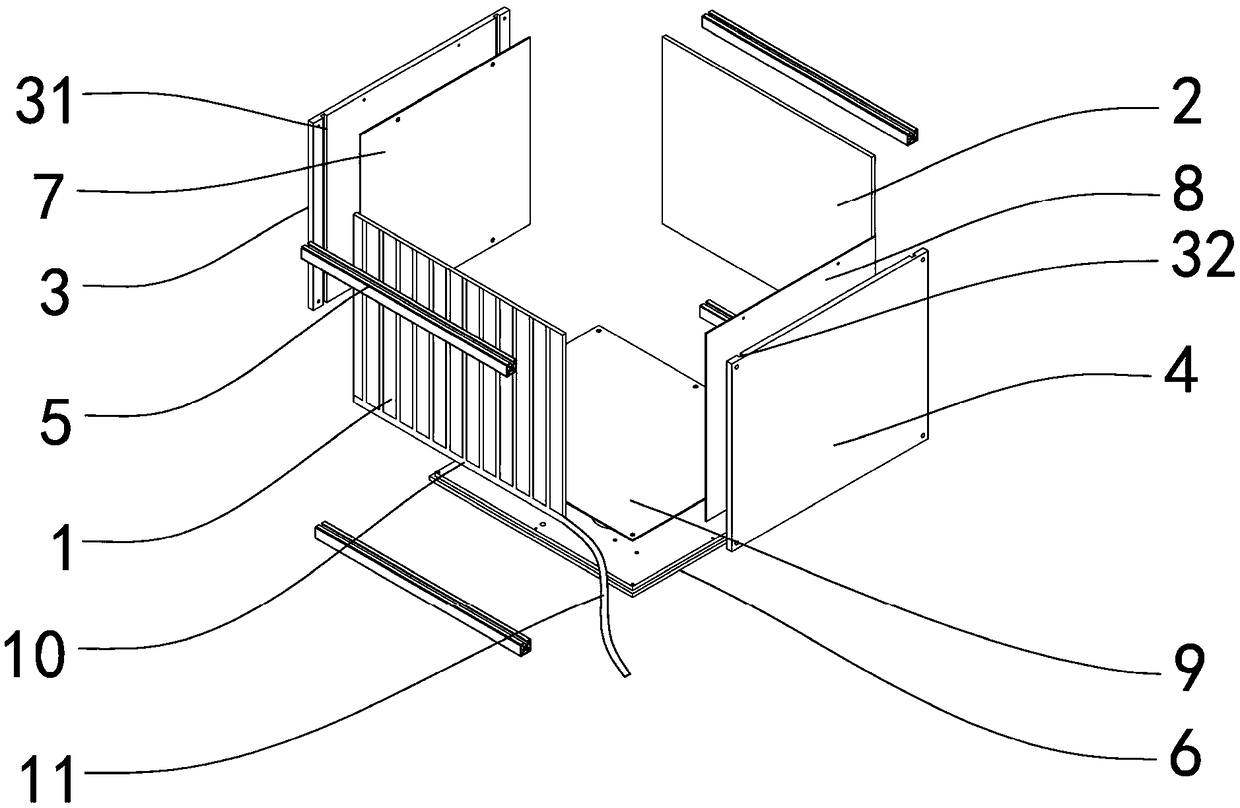

Combined high-voltage cabinet

ActiveCN110829210ASave spaceEasy to shipSubstation/switching arrangement casingsLap jointMechanical engineering

The invention discloses a combined high-voltage cabinet, and belongs to the technical field of high-voltage cabinets. The high-voltage cabinet comprises a top plate, a bottom plate, a back plate and two side plates, the tops of the two side plates are both matched with the top plate in an inserted mode, the bottoms of the two side plates are both matched with the bottom plate in an inserted mode,the bottom of the back plate is matched with the bottom plate in a lap joint mode, one side of the back plate is attached to the two side plates, the top plate, the bottom plate, the back plate and the two side plates form a containing cavity, two cabinet doors for sealing the containing cavity are arranged at the front end of the containing cavity, one cabinet door is hinged to one side plate, the other cabinet door is hinged to the other side plate, and a placing piece is arranged between the two side plates and matched with the two side plates in a lap joint mode. When a first baffle or other parts are damaged in the conveying process, the combined high-voltage cabinet can be mounted and spliced in time by disassembling and replacing the first baffle with a new first baffle, and the back plate, the top plate and the two side plates are stacked on the bottom plate in sequence in the conveying process, so that the space can be reduced, and transportation is facilitated.

Owner:正电电力集团有限公司

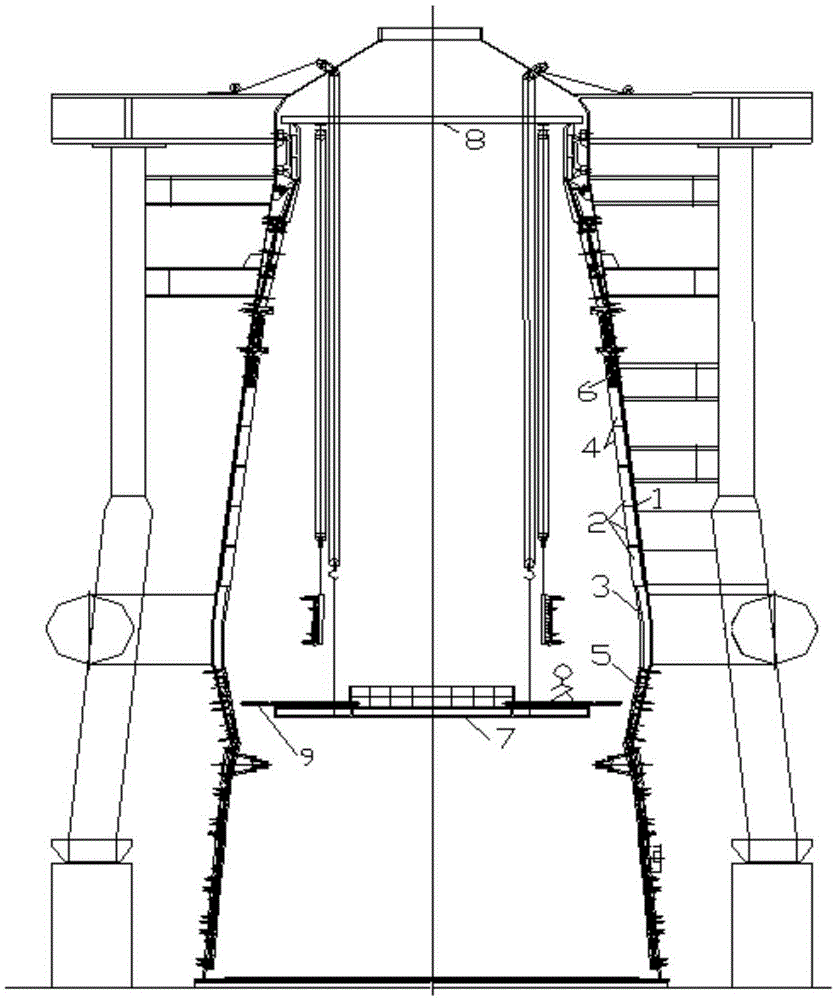

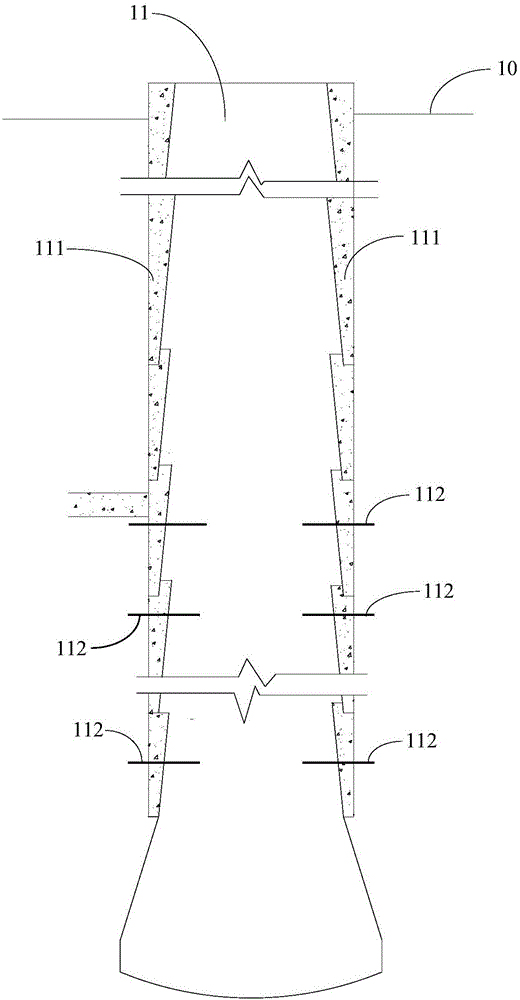

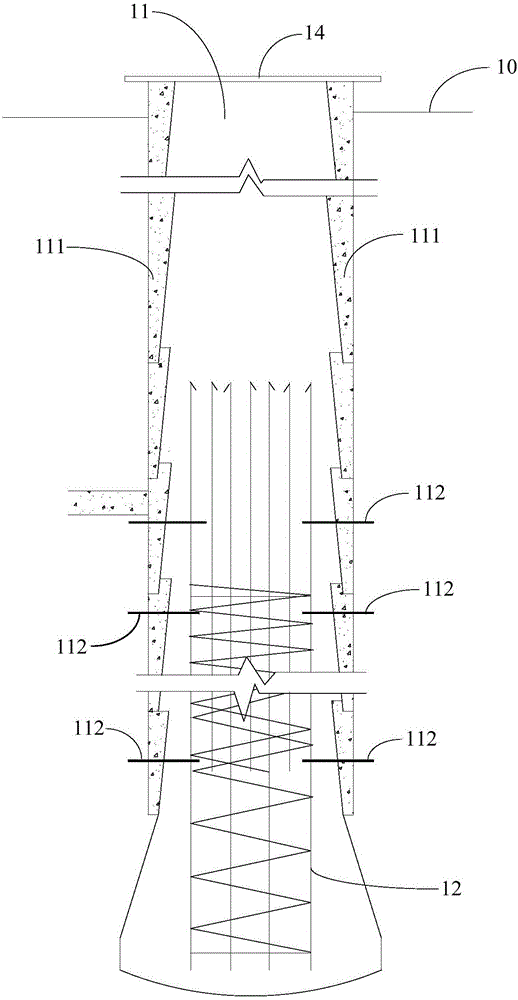

Cross construction method of replacing furnace shells and cooling walls of blast furnaces

ActiveCN105200173AConvenient in placeFast replacementBlast furnace componentsBlast furnace detailsAnnular beamWater pipe

The invention discloses a cross construction method of replacing furnace shells and cooling walls of blast furnaces and belongs to the technical field of construction of the blast furnaces. The cross construction method comprises the following steps: A, dividing each ring of furnace shell to be replaced into equal blocks, then dismounting and replacing the ring of furnace shell; B, determining a furnace shell replacing and constructing sequence; C, descending charging level, damping down, fetching water and cooling the furnaces; D, dismounting straight blasting pipes and medium-small sleeves, scrabbling the furnaces, simultaneously dismounting cooling water pipes of cooling walls of the furnace shells to be replaced and welding inverted-L-shaped plates on the furnace shells; E, assembling movable hoisting disks and hoisting annular beams in the furnaces; F, dismounting the cooling walls, instantly beginning to replace the furnace shells which are divided into blocks in the step B in the upper rings, the lower rings and the opposite perforated positions at the same time, and welding the furnace shells at the exterior; and G, firstly welding the inner welding seams in the furnace shells and finally welding the outer welding seams of the furnace shells which are divided into blocks for the finally-mounted furnace shells which are divided into blocks. According to the method, the sequence of replacing the overall furnace shells which are divided into blocks can be optimized, the sequence of replacing the furnace shells and the cooling walls can also be optimized, the cross construction of the furnace shells and the cooling walls can be implemented to the greatest extent; the main line construction period is shortened.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

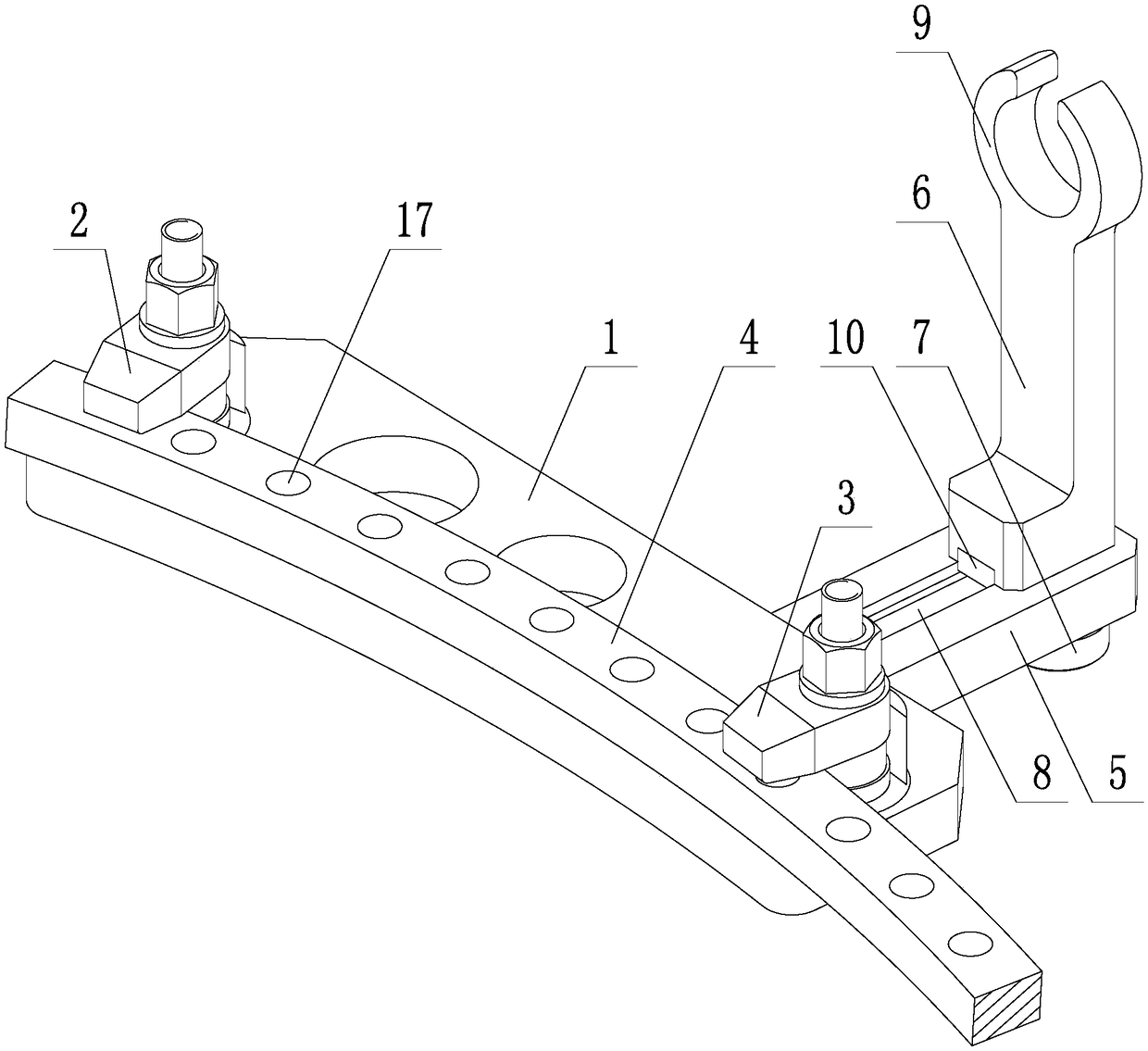

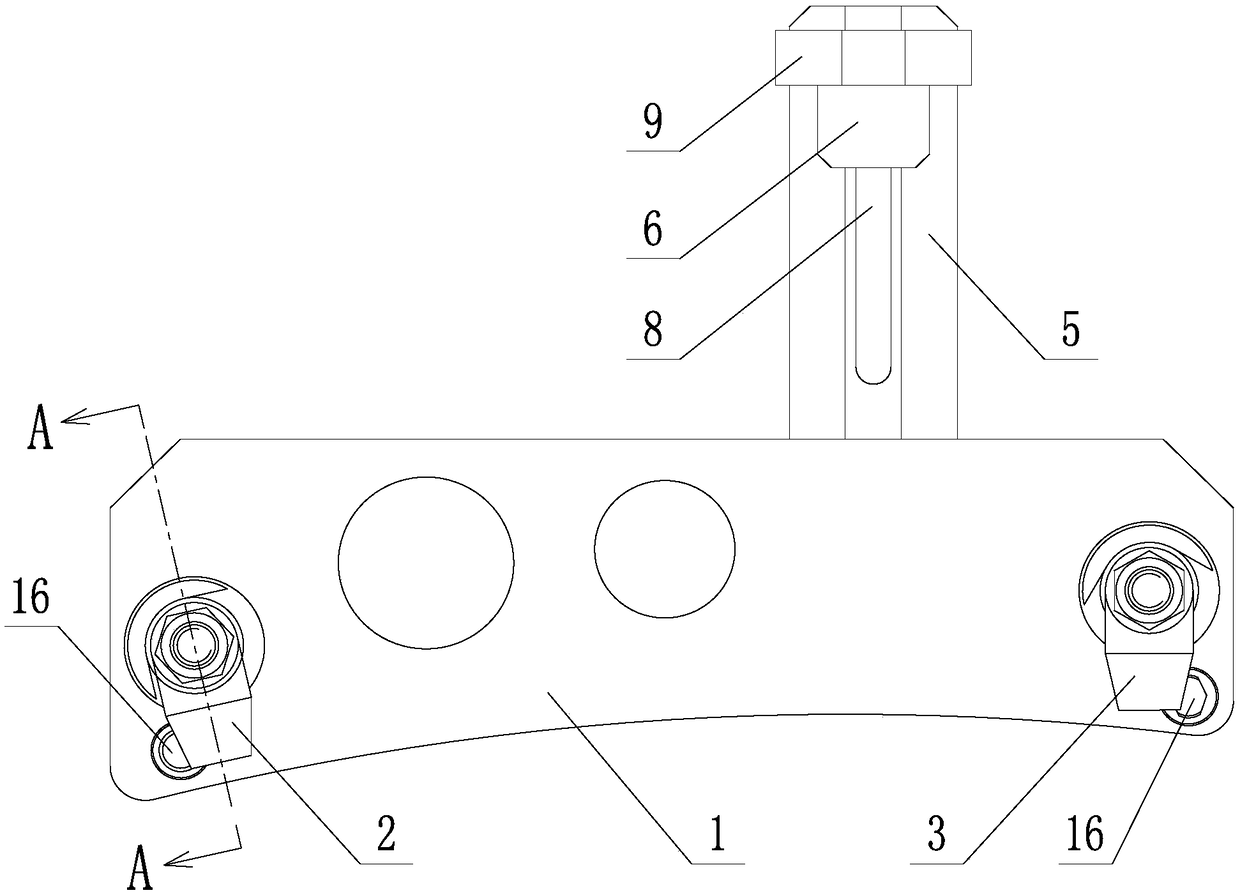

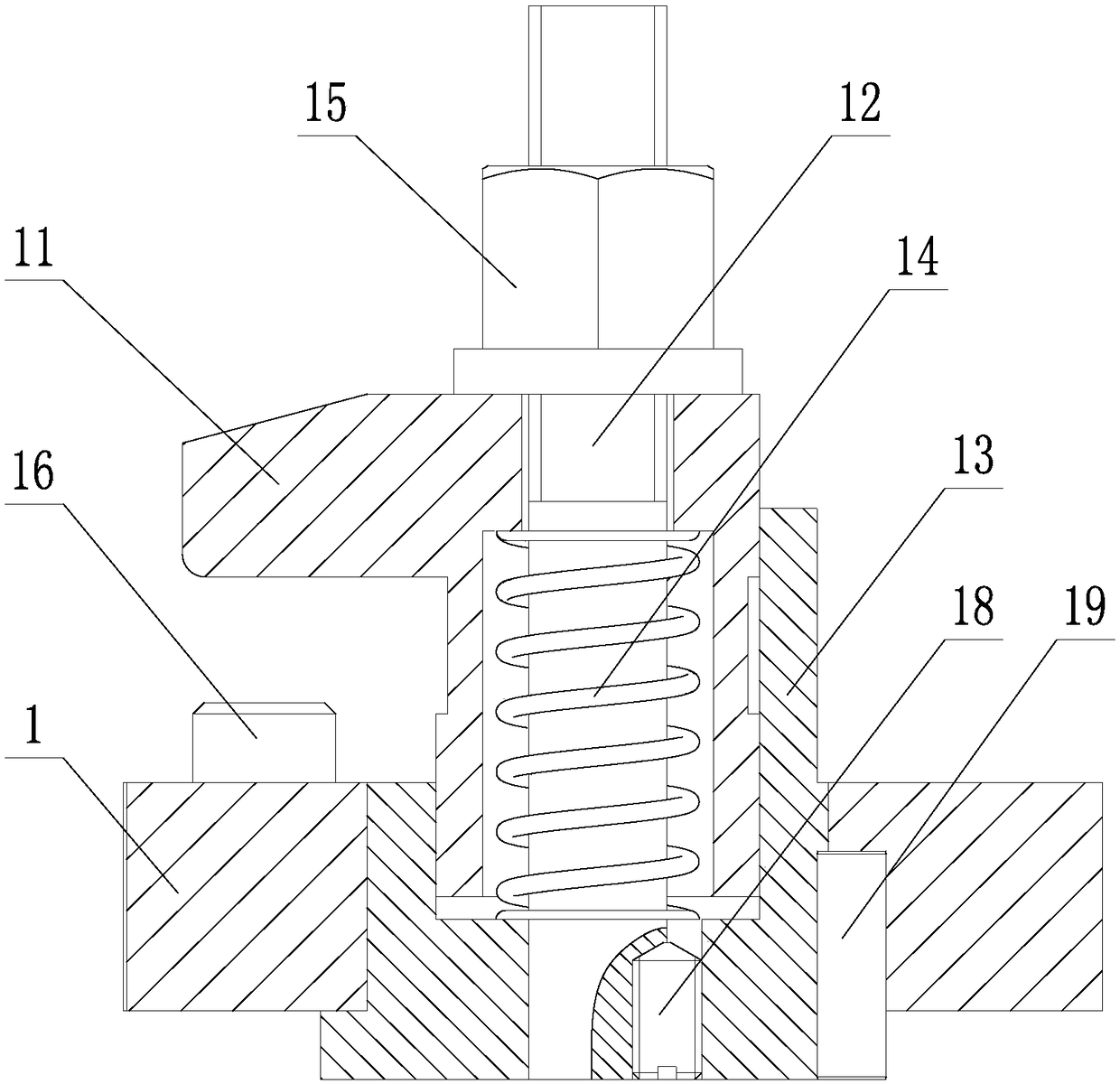

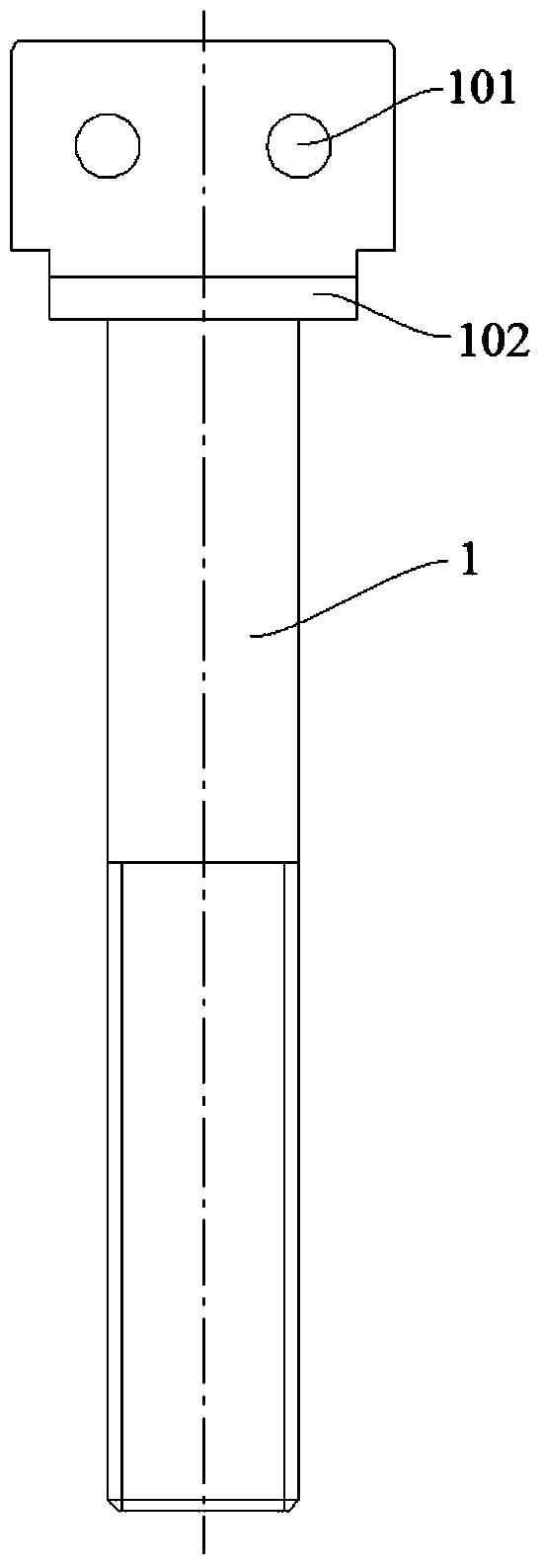

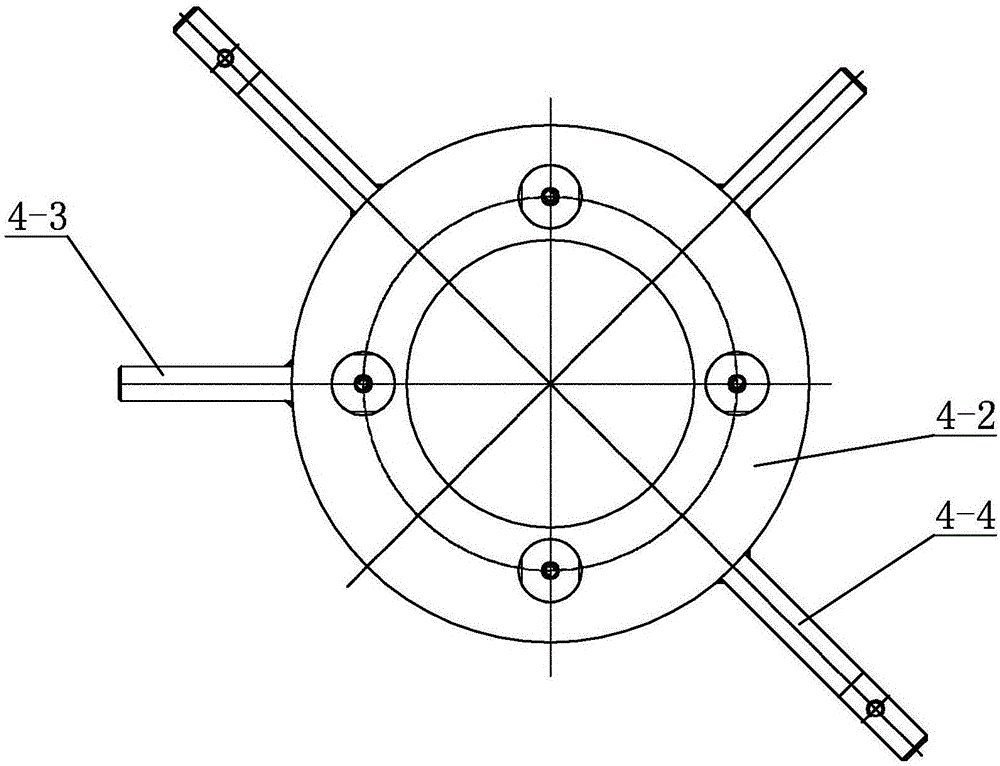

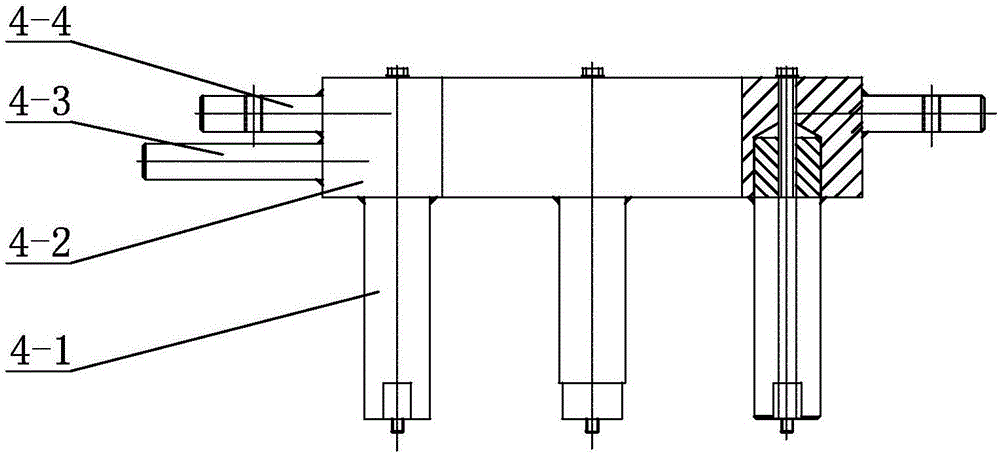

Jet nozzle fast installing tool and using method

ActiveCN109366413AThe installation position is accurateAvoid not being able to installMetal-working hand toolsGas compressorEngineering

The invention discloses a jet nozzle fast installing tool and a using method. The tool comprises a base plate, a positioning and pressing assembly and a bypass duct case bush hole simulation assembly;the positioning and pressing assembly is installed on the base plate, the base plate is positioned and fixed on the mounting edge of a gas compressor case through the positioning and pressing assembly; the bypass duct case bush hole simulation assembly comprises a guide plate, a simulation block and a guide limiting bolt, the guide plate is fixedly connected to the base plate, the simulation block can slide along the guide plate, a simulation bush hole is formed in the top end of the simulation block; the positioning and pressing assembly comprises a pressing plate, a stud, a bush, a spring,a nut and a positioning pin, the stud is fixedly arranged on the base plate through the bush, the nut, the pressing plate and the spring are sequentially arranged on the stud in a sleeving mode, the positioning pin is fixed on the base plate and is in insertion fit with a mounting hole of the mounting edge of the gas compressor case. The method comprises the following steps that firstly, the mounting edge of the gas compressor case is clamped between the pressing plate and the base plate so as to complete tool fixing, then the position of the simulation block is adjusted, meanwhile, the position of a jet nozzle is adjusted until the jet nozzle can accurately penetrate through the simulation bush hole.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

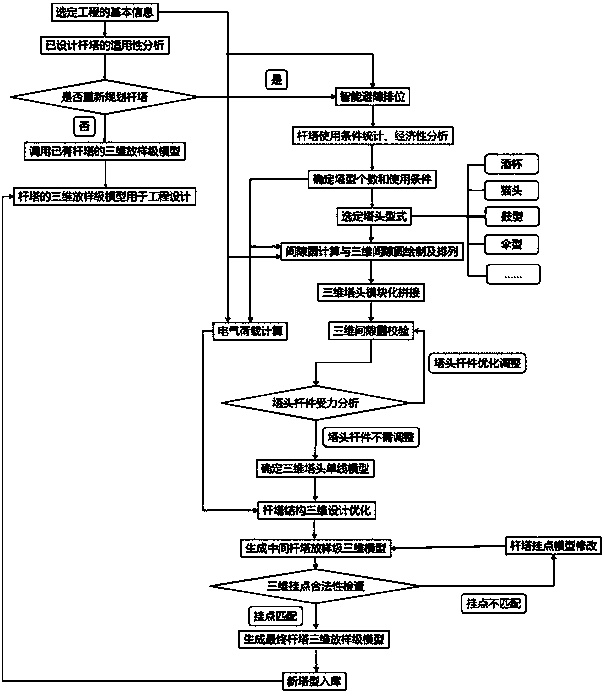

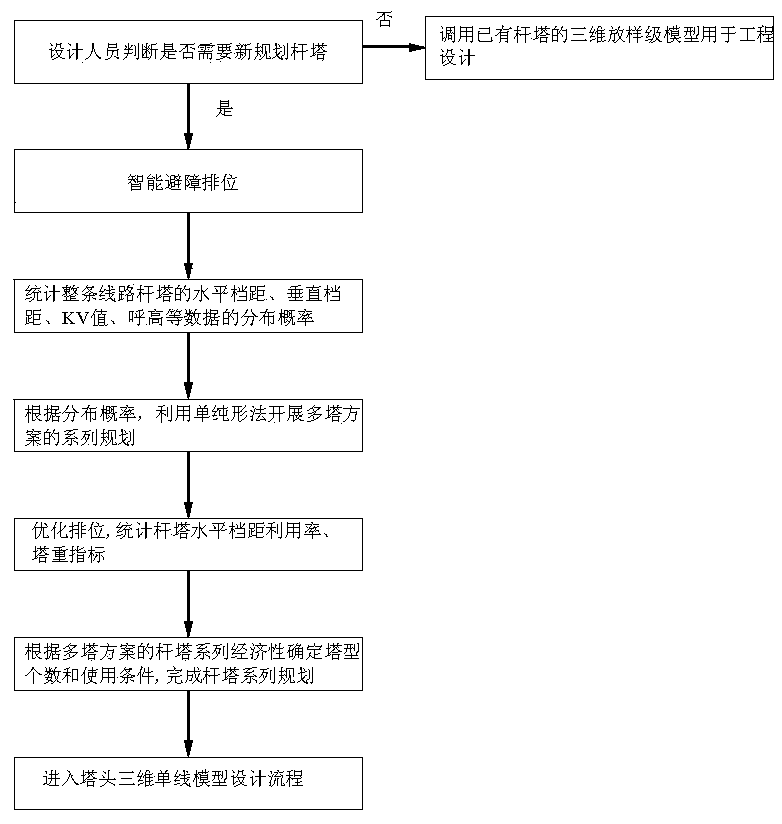

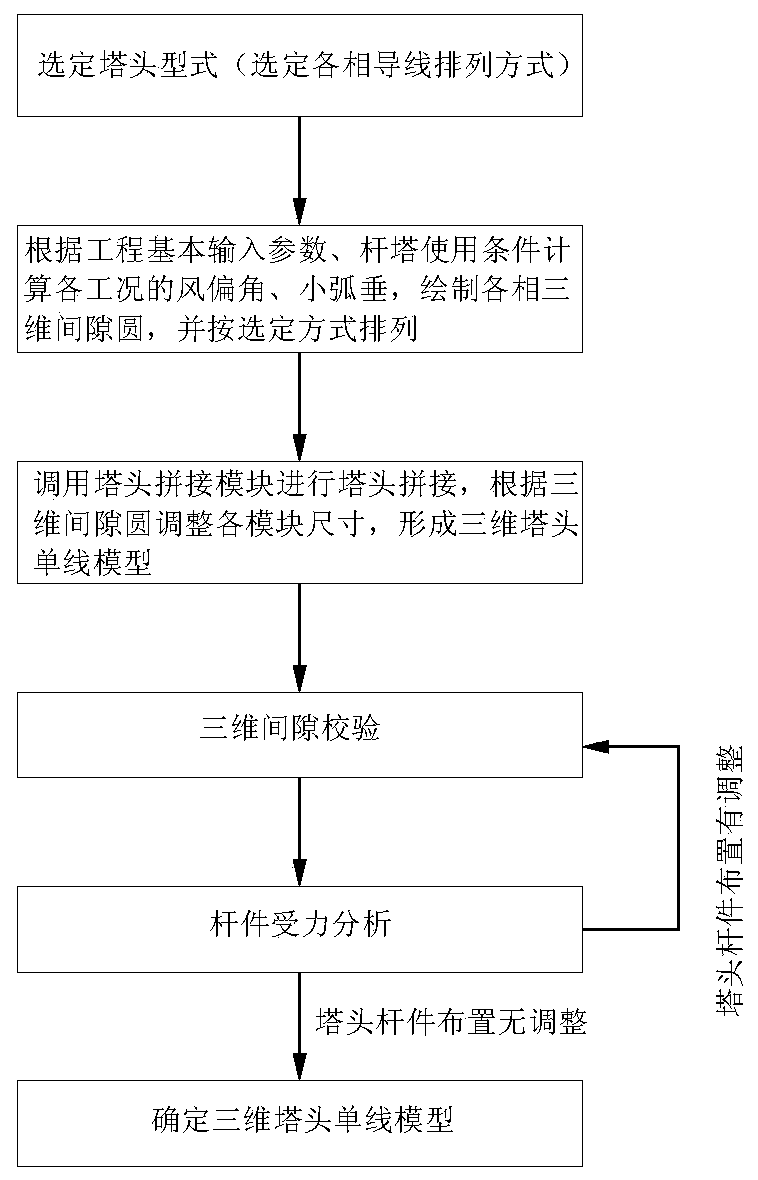

Power transmission line tower three-dimensional collaborative planning design method and system

InactiveCN110046405ARaise the level of digitizationAvoid duplication of effortDesign optimisation/simulationSpecial data processing applicationsEngineeringTower

The invention discloses a power transmission line tower three-dimensional collaborative planning design method and system, and the method comprises the following steps: obtaining the engineering basicinformation of tower design, wherein the engineering basic information comprising engineering topographic data and tower basic parameters; planning a tower series according to the engineering basic information to obtain tower use conditions of different tower types in the tower series; designing tower head three-dimensional single-line models of different tower types in the tower series; according to the tower basic parameters, the tower use conditions and the three-dimensional single-line model, calculating the electrical load of each working condition; performing three-dimensional design optimization on the tower structure to obtain a three-dimensional model of the tower; and performing three-dimensional hanging point verification on the three-dimensional model of the tower, and finishing the three-dimensional design of the tower if the verification is qualified. The tower planning and designing links are integrally completed in the three-dimensional design system, repeated work ofworkers in all the links can be avoided, information loss and errors in the connection process of all the links are completely eradicated, and the digitization level of tower design is improved.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

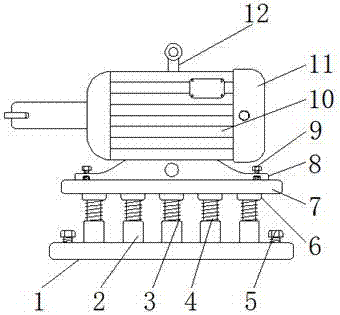

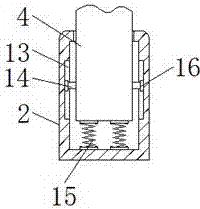

Damping motor

InactiveCN107231059AExtended service lifeFast installationSupports/enclosures/casingsMotor vibrationArchitectural engineering

Owner:王秋林

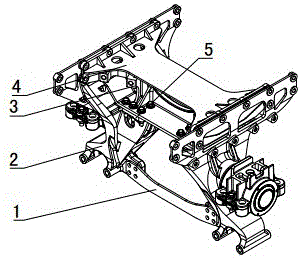

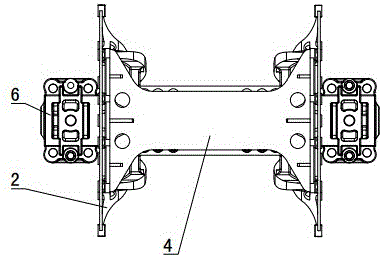

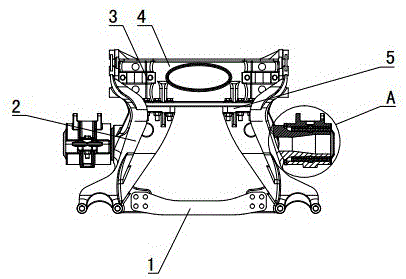

Ultra-lightweight balanced suspension

ActiveCN105751850AReduce stressImprove protectionLeaf springsInterconnection systemsVehicle frameModularity

Owner:山东安博机械科技股份有限公司

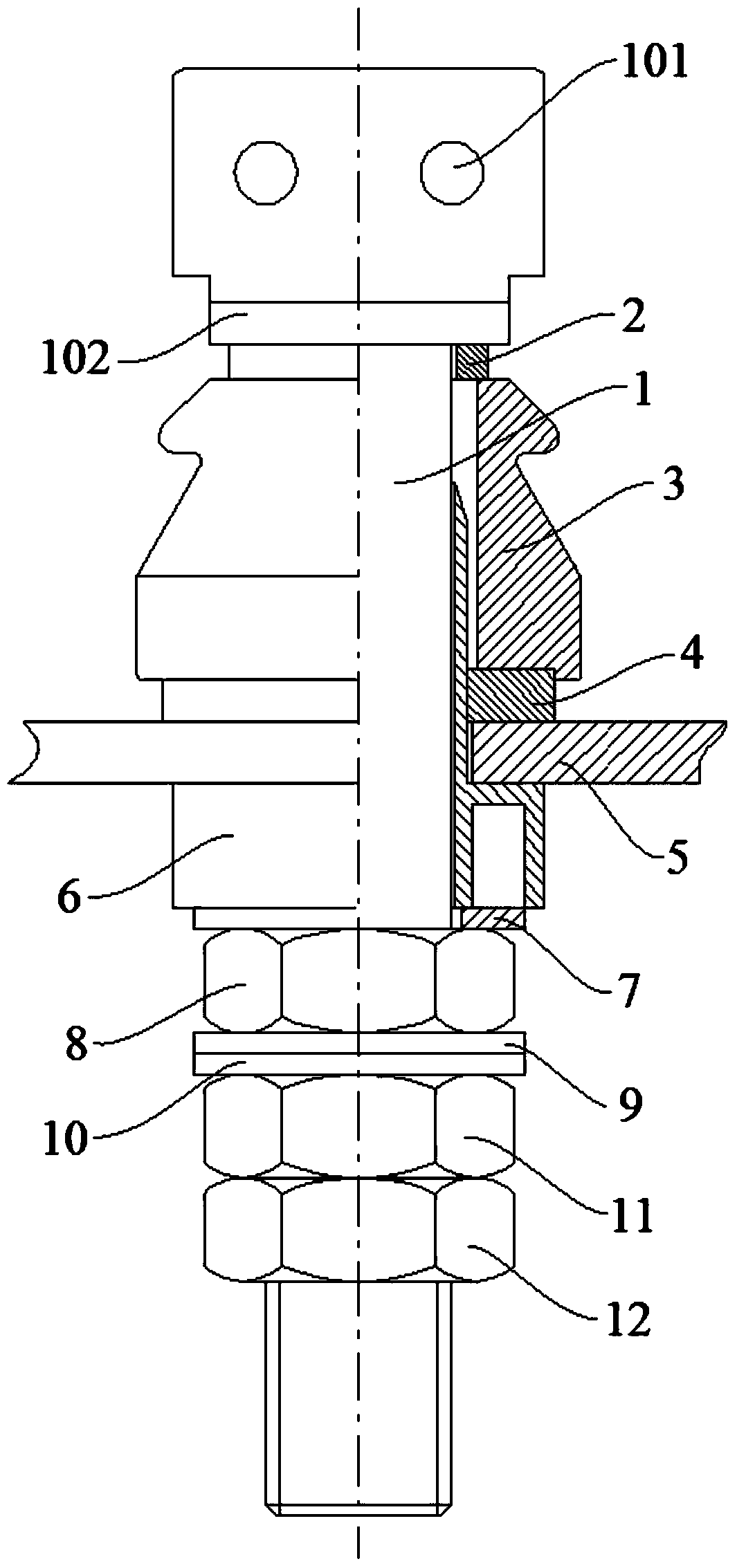

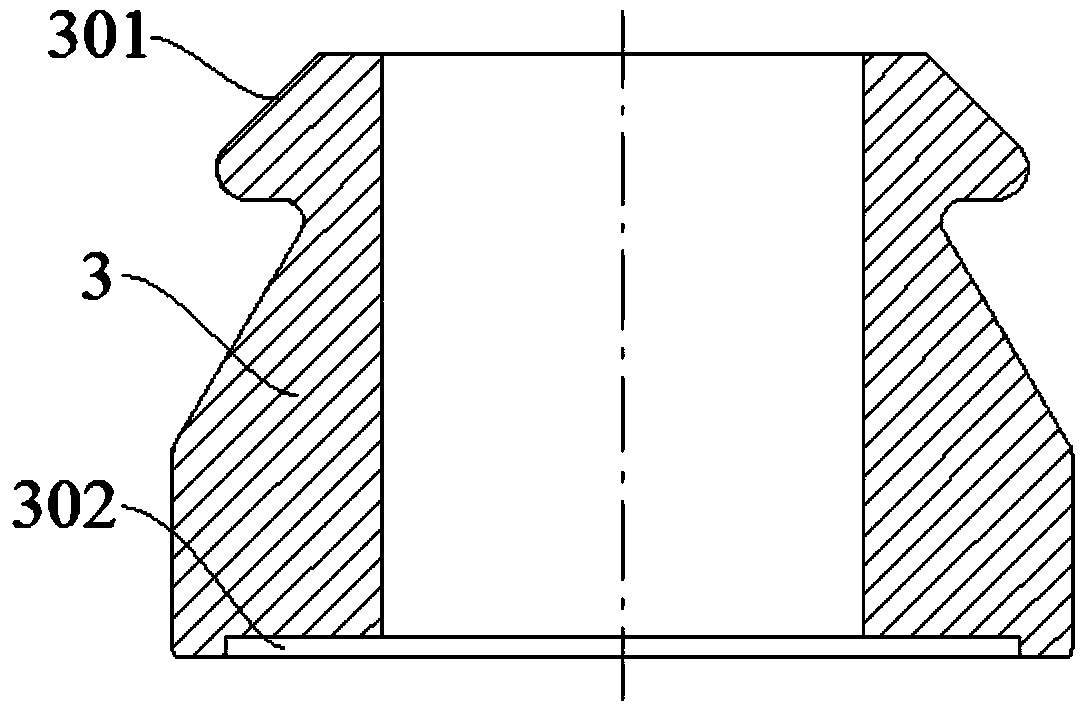

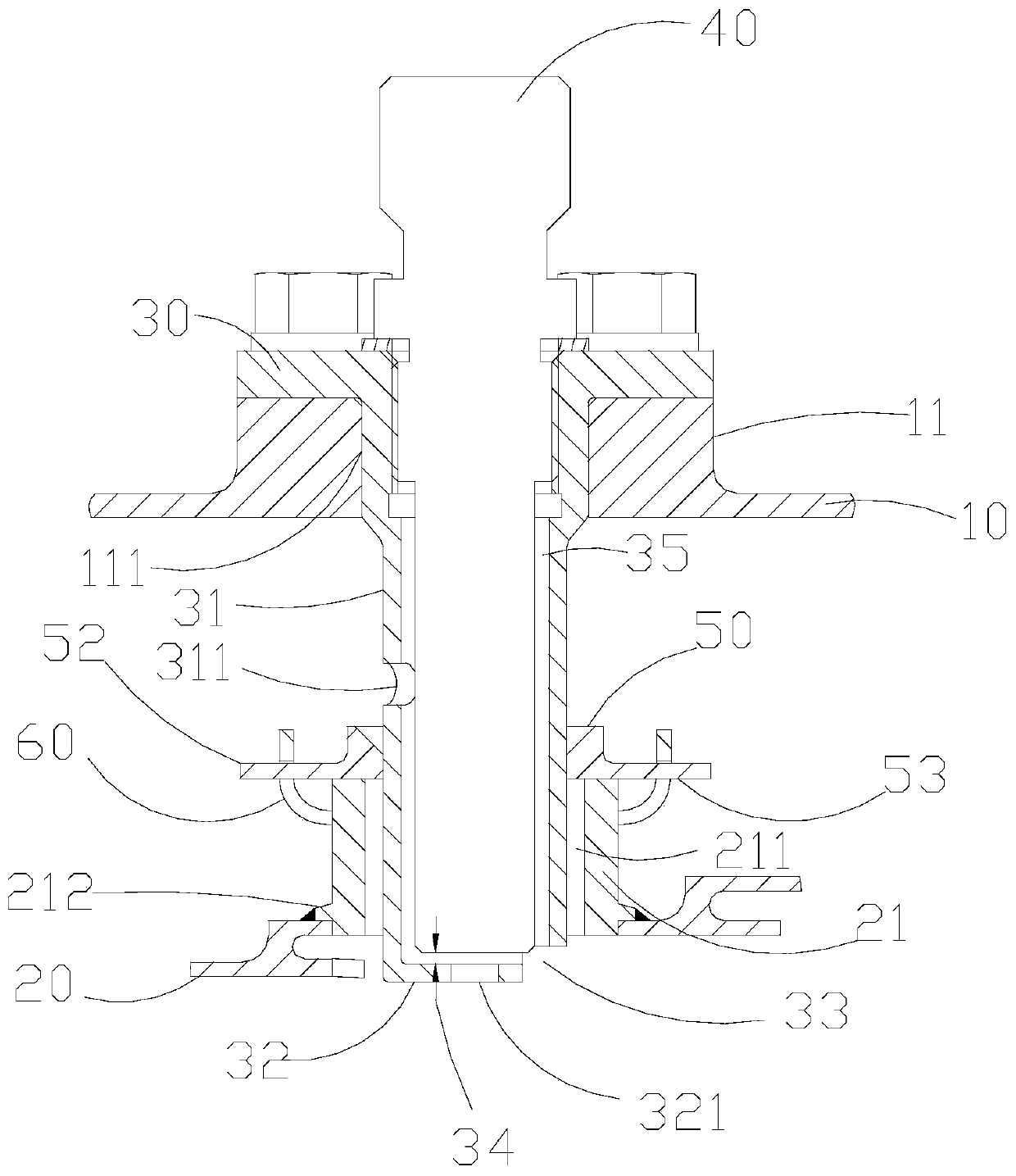

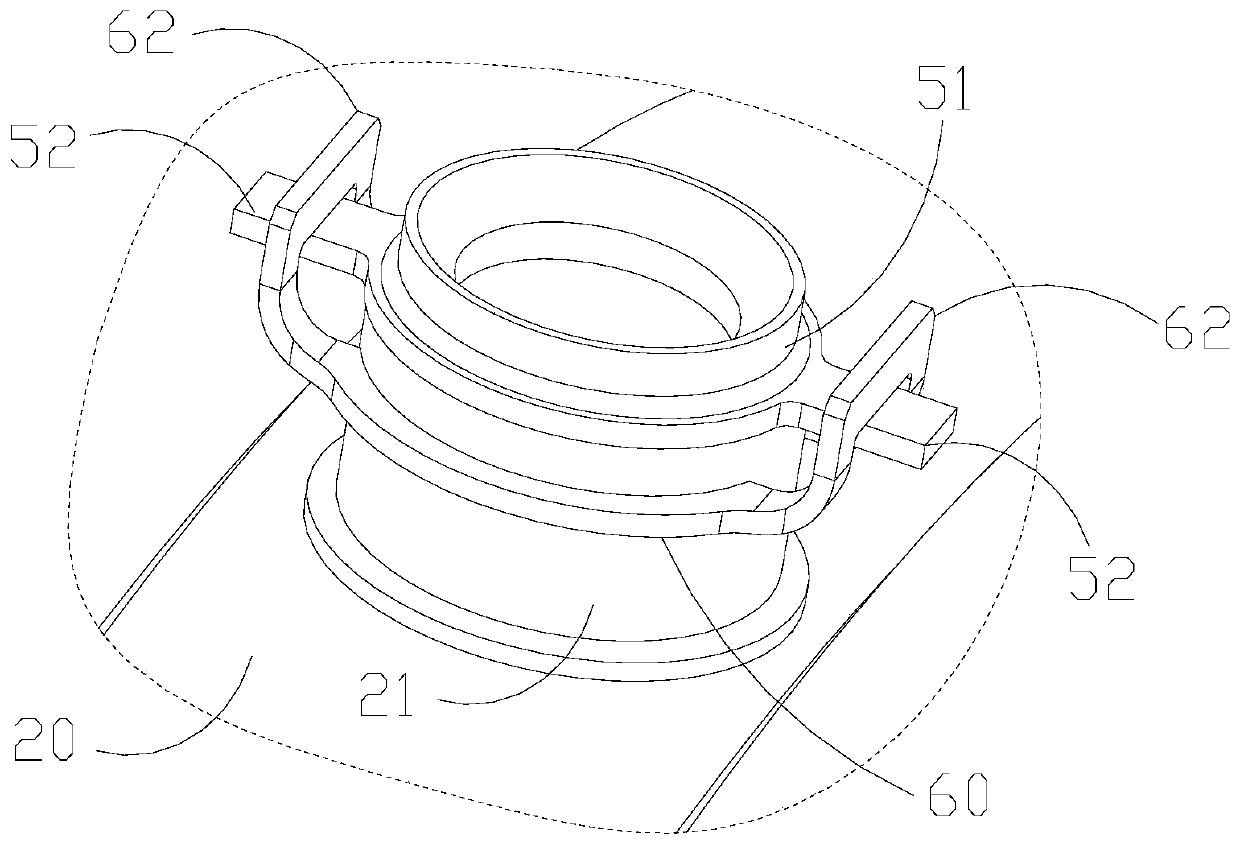

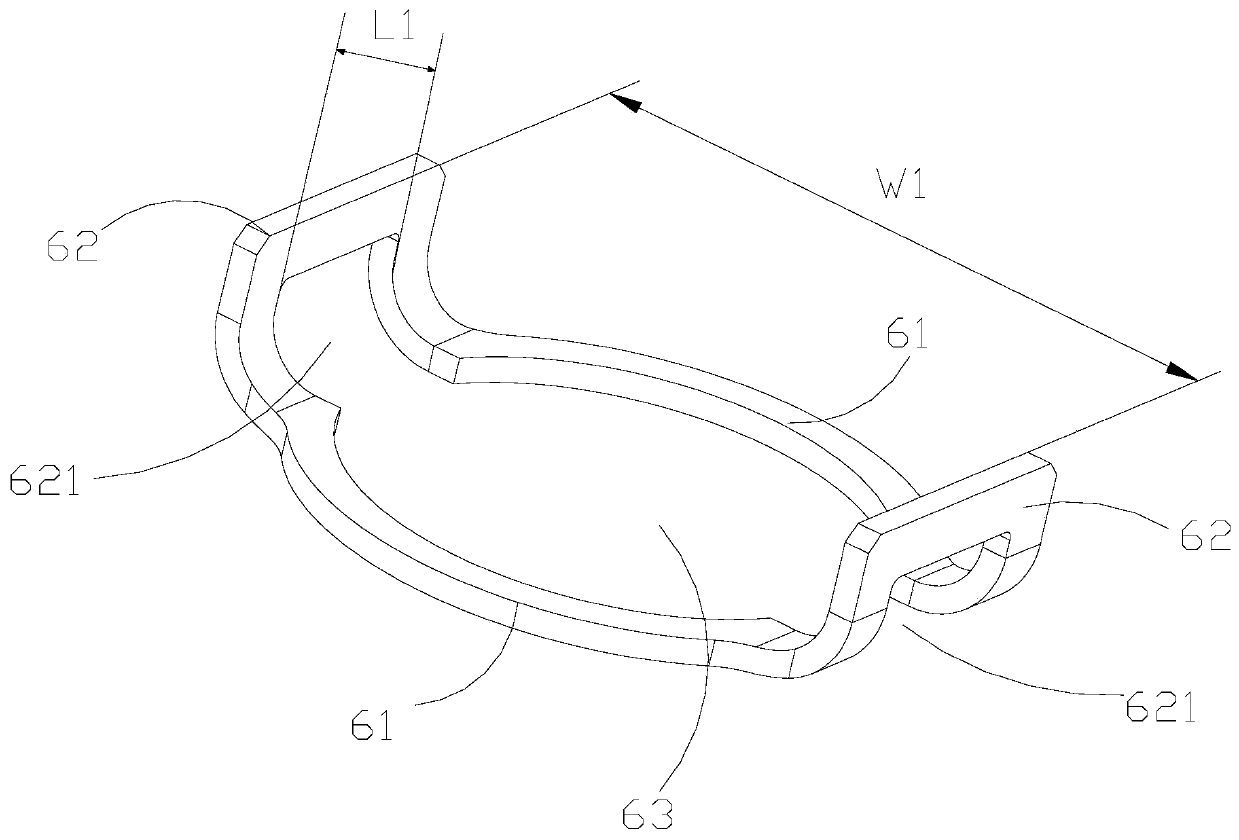

Combined low-voltage bushing of transformer

ActiveCN103456474AAvoid not being able to installSimple structureTransformers/inductances coils/windings/connectionsLow voltageFuel tank

The invention discloses a combined low-voltage bushing of a transformer, and belongs to the field of transformer bushings. The combined low-voltage busing of the transformer comprises a conductive rod, a porcelain bushing, a first sealing ring, a second sealing ring, a base and a first nut. A circular truncated cone and a connector lug are integrally formed at one end of the conductive rod. The connector lug is positioned above the circular truncated cone, and the first sealing ring, the porcelain bushing, the second sealing ring and the base are sequentially sleeved below the circular truncated cone. The other end of the conductive rod is provided with an external thread. The first nut is matched with the external thread to compress the base. Production cost of the low-voltage busing of the transformer is reduced, assembly technique is simplified, studs are not required to be welded on a transformer tank wall, incapability of mounting due to inaccurate welding positions is avoided, and good sealing effect is achieved.

Owner:江苏金诺电气科技有限公司

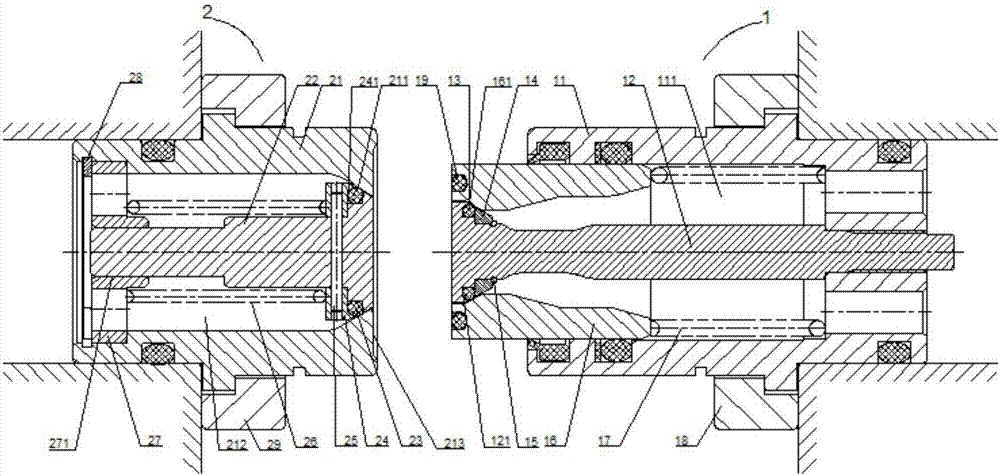

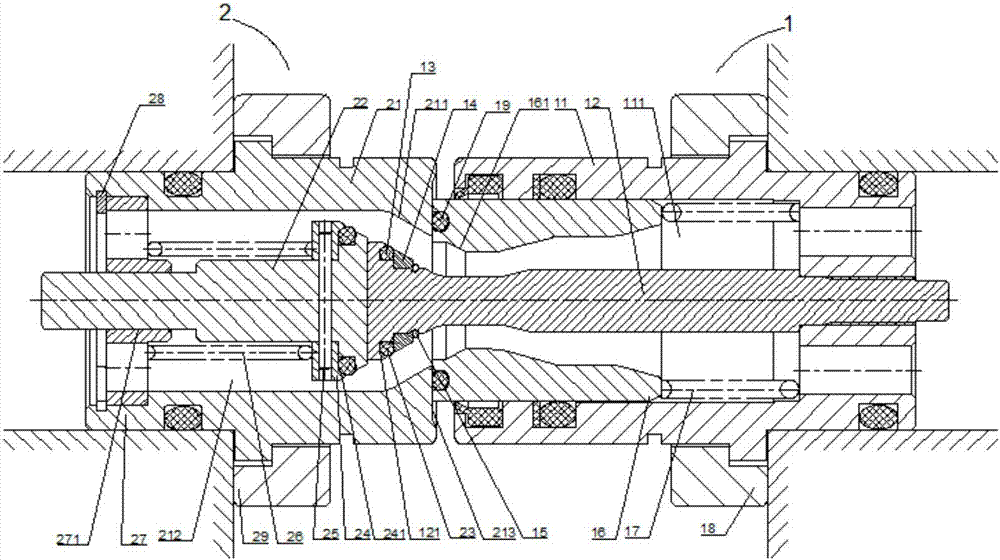

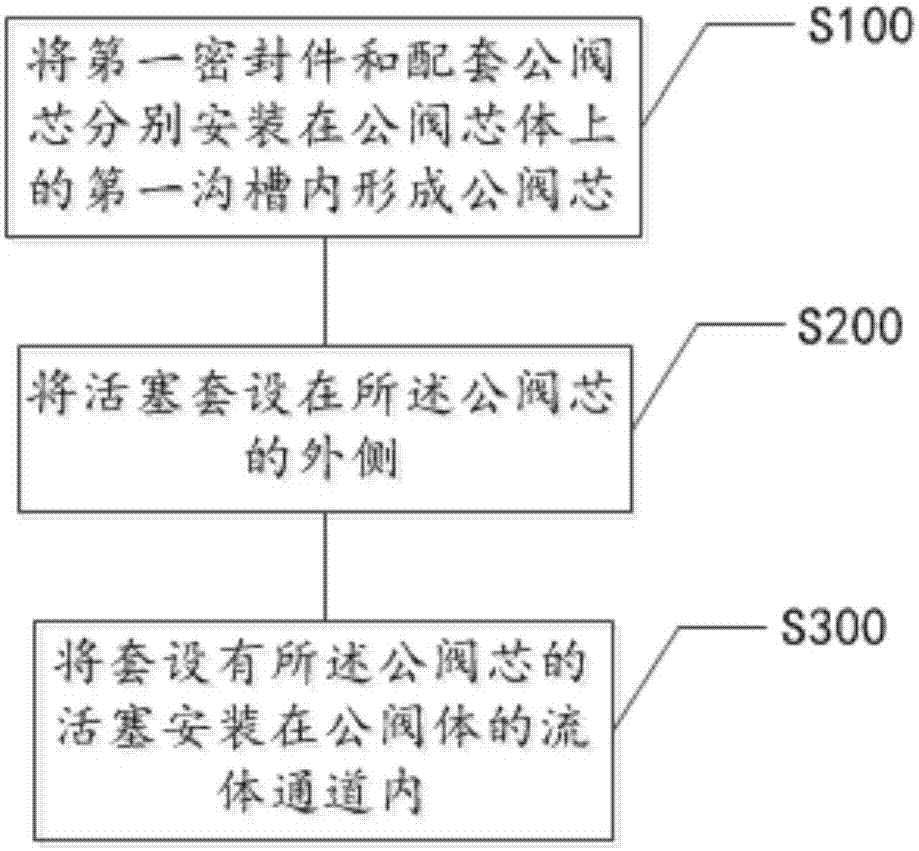

Split butt joint and male joint and female joint thereof

The invention discloses a split butt joint and a male joint and a female joint thereof. The male joint comprises a male valve body, a piston and a male valve core body, wherein a first fluid channel is formed in the male valve body in the axial direction; the piston is arranged in the first fluid channel of the male valve body in a sliding manner; the male valve core body sleeves the piston; and a first groove used for accommodating a first sealing element and a matched male valve core is formed in the position, in contact with the piston, of the male valve core body. The male joint is convenient to process, high in finished product rate, convenient to assemble, good in sealing performance, long in service life, high in practicability and wide in application range and has good market prospects.

Owner:SHANGHAI SONCO QUICK CHANGE SYST

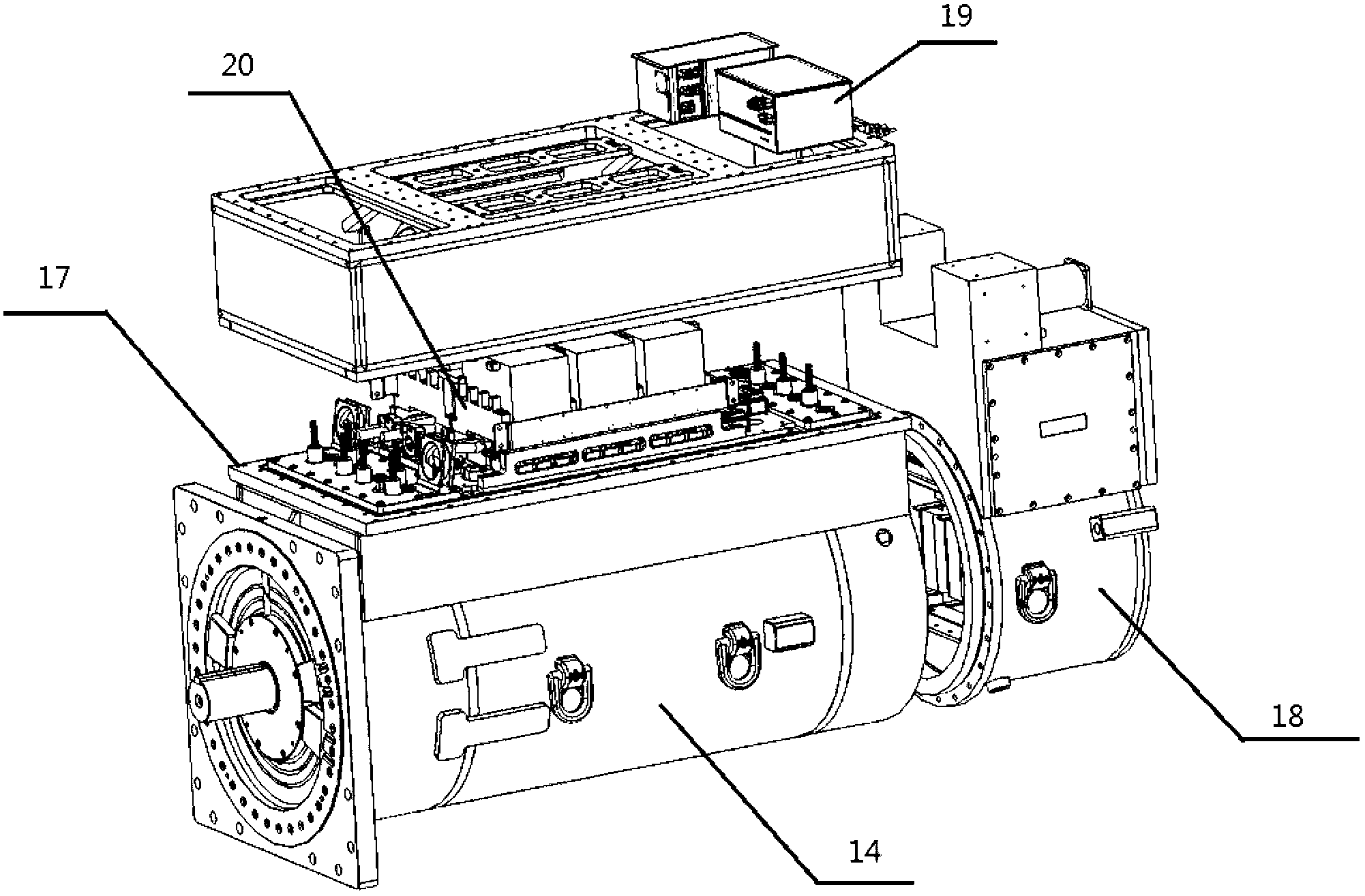

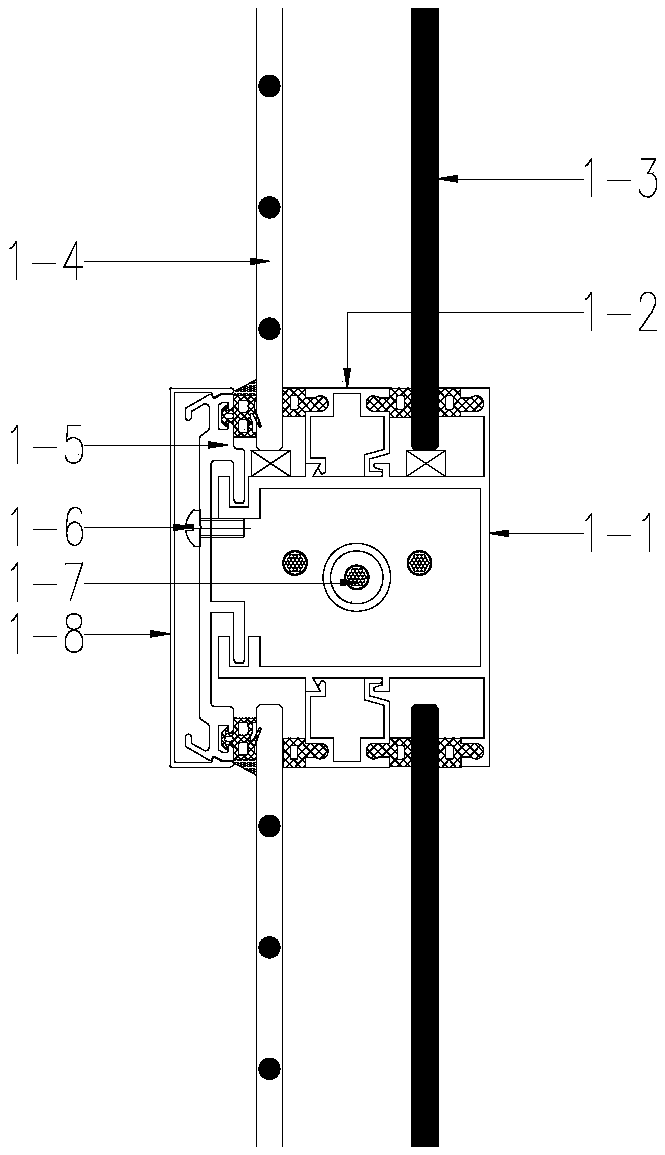

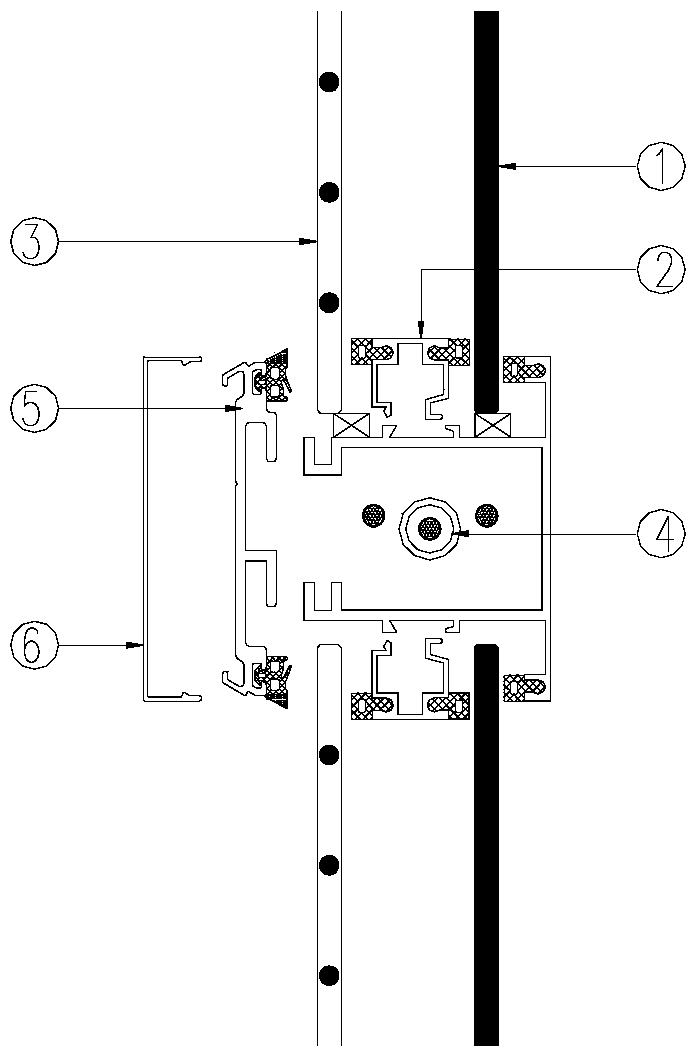

Explosion suppression and intrinsically safe type frequency conversion and speed regulation integral machine with 3300V for mine

ActiveCN103219834AReduce volumeImprove cooling effectStructural associationCooling/ventilation/heating modificationsElectricityFrequency changer

The invention discloses an explosion suppression and intrinsically safe type frequency conversion and speed regulation integral machine with 3300V for a mine. The frequency conversion and speed regulation integral machine comprises an electric motor and a frequency converter, wherein the frequency converter is arranged in the upper part of the electric motor, a motive force power supply cavity is arranged on the rear end of the electric motor, a control module which is electrically connected with the frequency converter is arranged on a casing of the frequency converter, a frequency-converted power and energy storage module is arranged inside the frequency converter, and the electric motor is a multi-winding electric motor. The frequency-converted power and energy storage module of the explosion suppression and intrinsically safe type frequency conversion and speed regulation integral machine with 3300V for the mine is distributed in a layered shape from bottom to top, and thus the overall size of the frequency converter is reduced. A multi-circuit independent coil group is adopted for the multi-winding electric motor, each independent coil group can be independently matched with a power supply with the same circuit number, thus the requirement of simultaneous input of multiple power supplies is met, the problem of outputting by the electric motor which is used for matching with the multiple power supplies of the frequency converter is solved, and the matching of the electric motor and multiple output of the frequency converter is realized. The multiple output is adopted for the frequency converter topology structure of the frequency converter, so that the output voltage of each circuit is relatively decreased, and the requirement of a withstand voltage of a power appliance is further lowered.

Owner:QINGDAO CCS ELECTRIC CORP

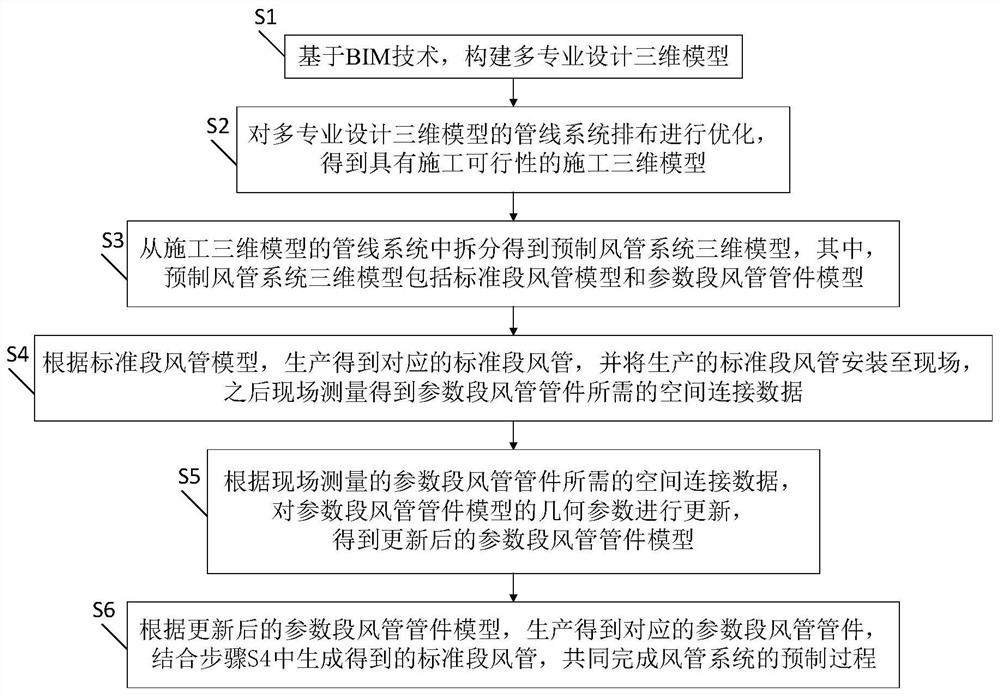

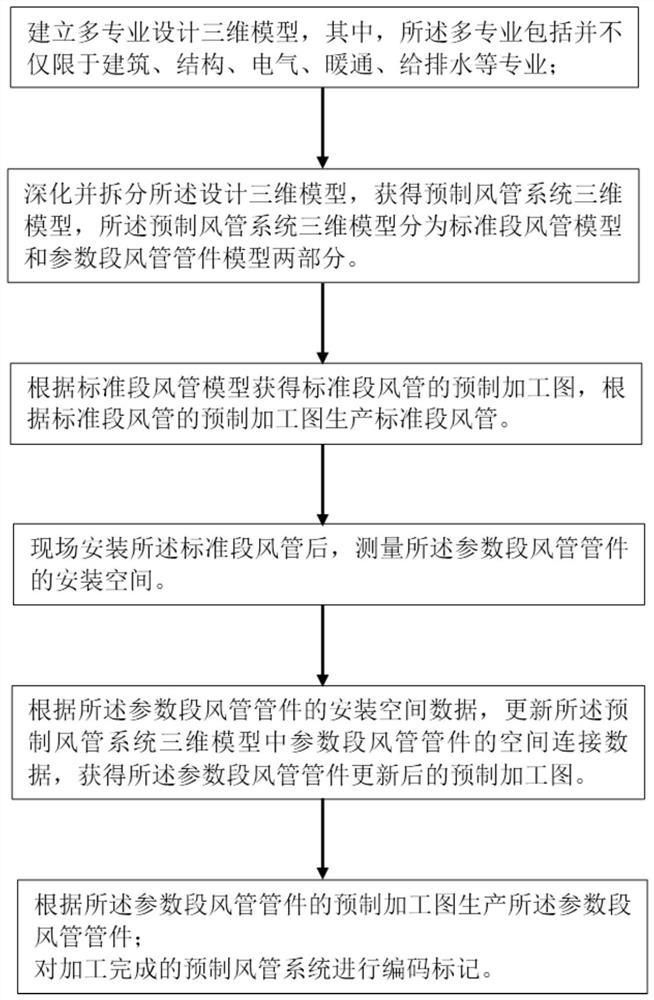

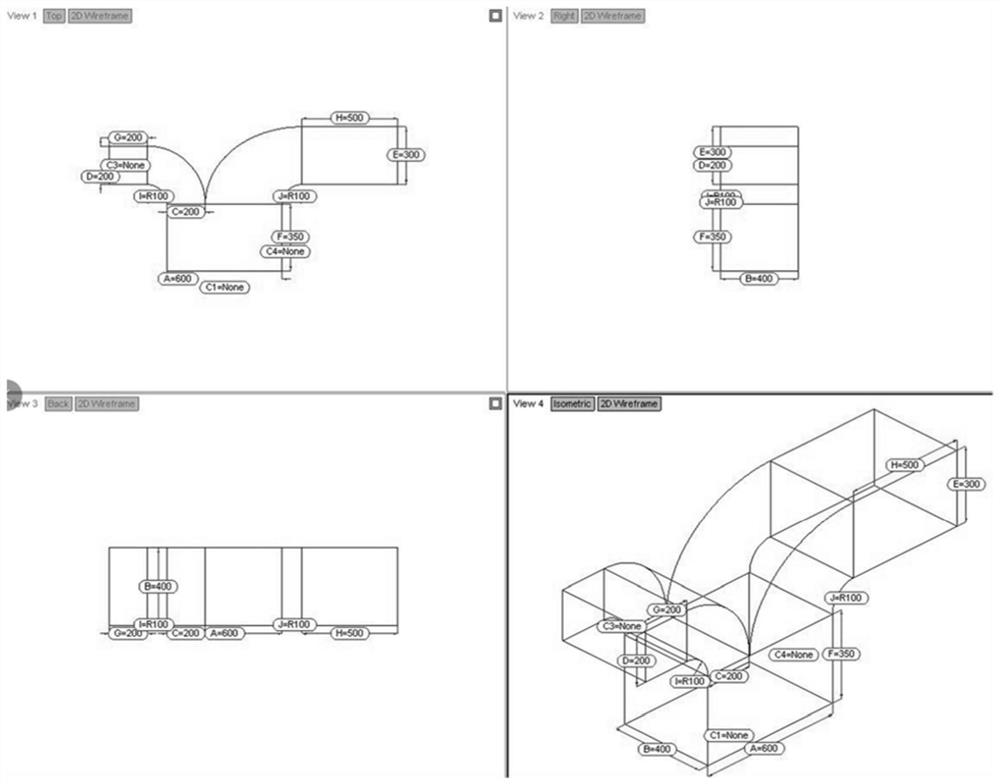

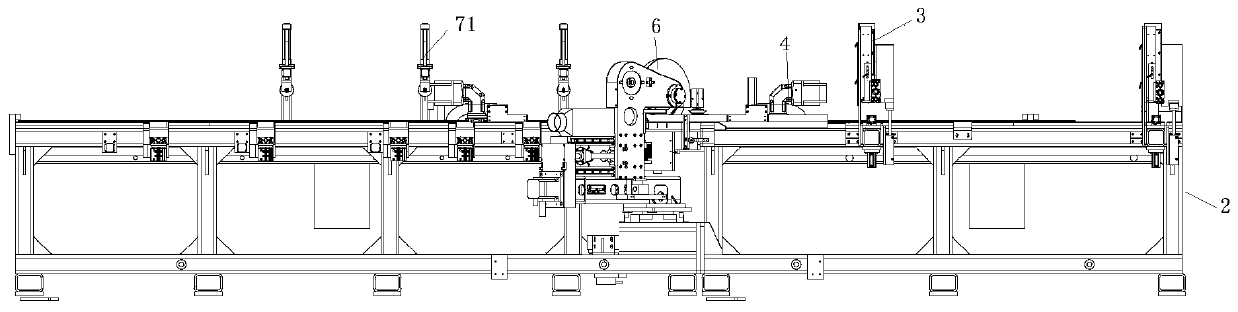

BIM-based air duct system prefabricating method

PendingCN112464424AAvoid not being able to installImprove accuracyGeometric CADDesign optimisation/simulationPipe fittingEngineering

The invention relates to a BIM-based air duct system prefabricating method, which comprises the following steps of constructing a multi-specialty design three-dimensional model based on a BIM technology; optimizing pipeline system arrangement of the multi-specialty design three-dimensional model to obtain a construction three-dimensional model; splitting from a pipeline system of the constructionthree-dimensional model to obtain a standard section air pipe model and a parameter section air pipe fitting model; according to the standard section air pipe model, a corresponding standard section air pipe is obtained through production, the standard section air pipe is installed on site, then space connection data needed by the parameter section air pipe fitting are obtained through on-site measurement, and therefore geometrical parameters of the parameter section air pipe fitting model are updated, and according to the updated parameter section air pipe fitting model, the parameter sectionair pipe fitting is obtained. Corresponding parameter section air pipe fittings are obtained through production. Compared with the prior art, the parameter section air pipe fitting matched with the on-site installation distance can be accurately machined. Therefore, the problem that a prefabricated air pipe system cannot be installed due to on-site operation and other construction errors is solved.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

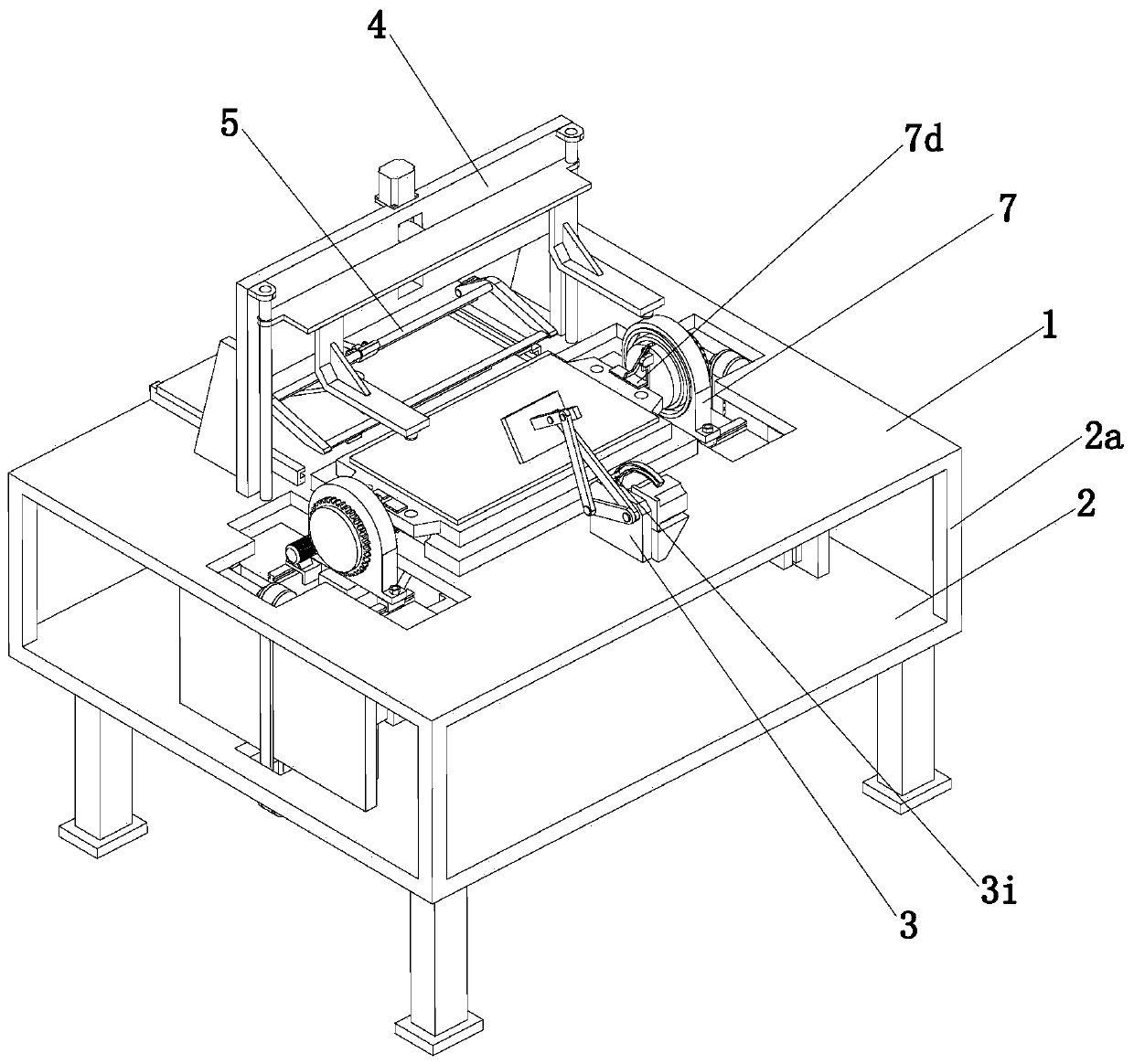

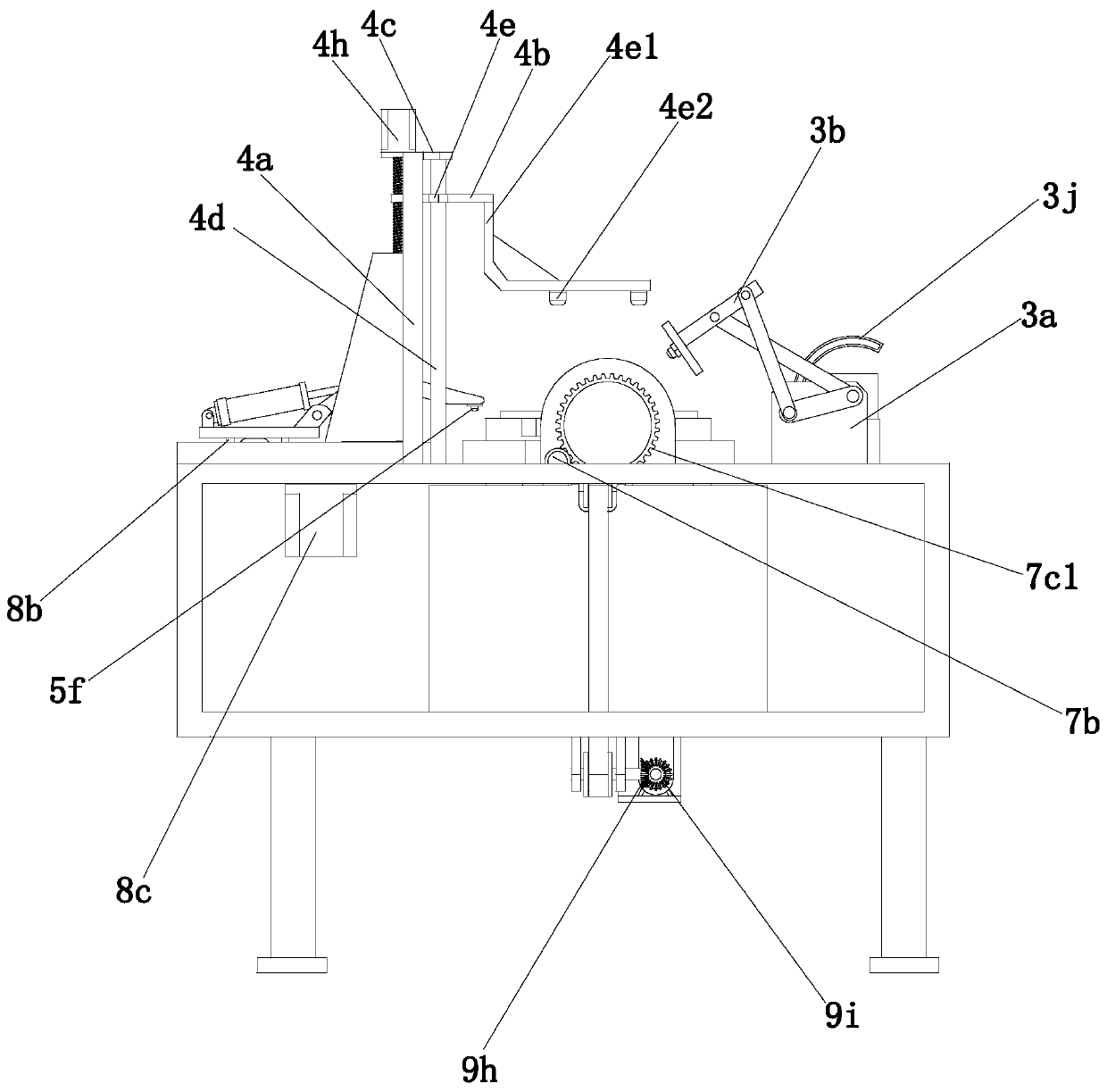

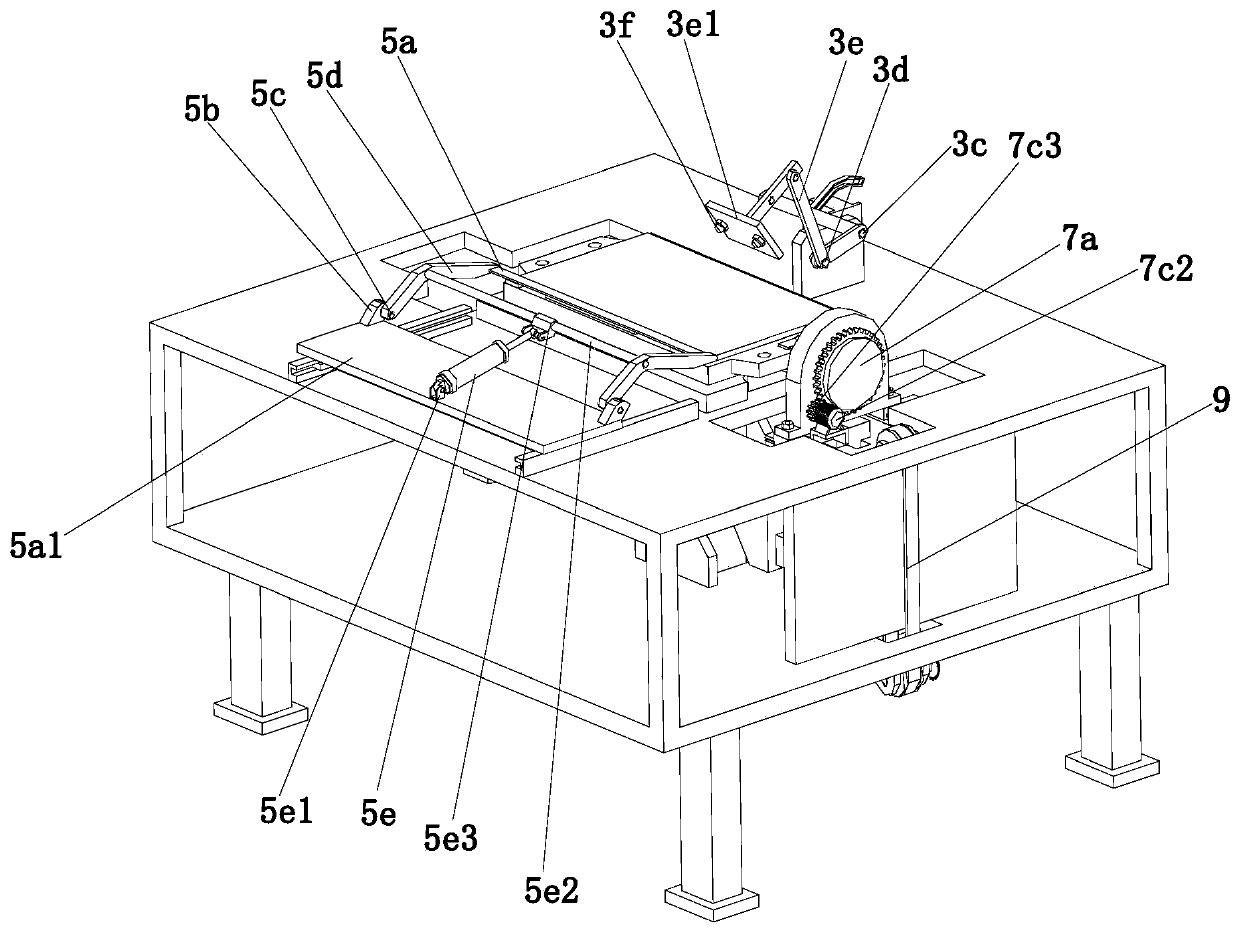

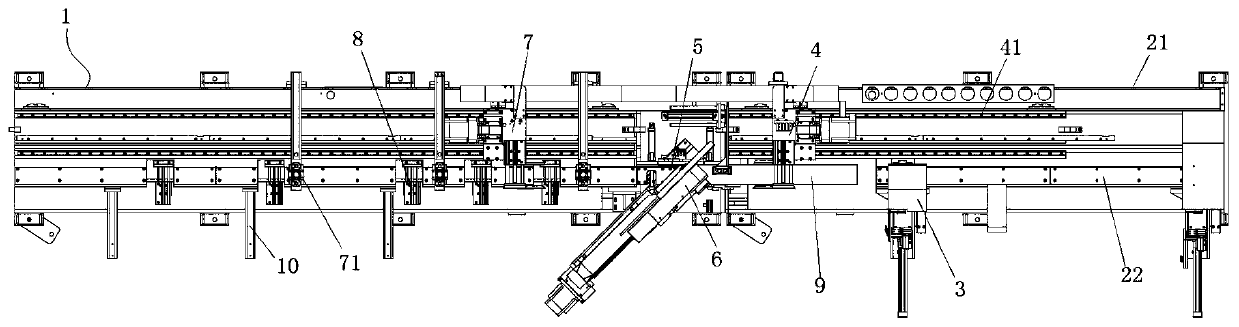

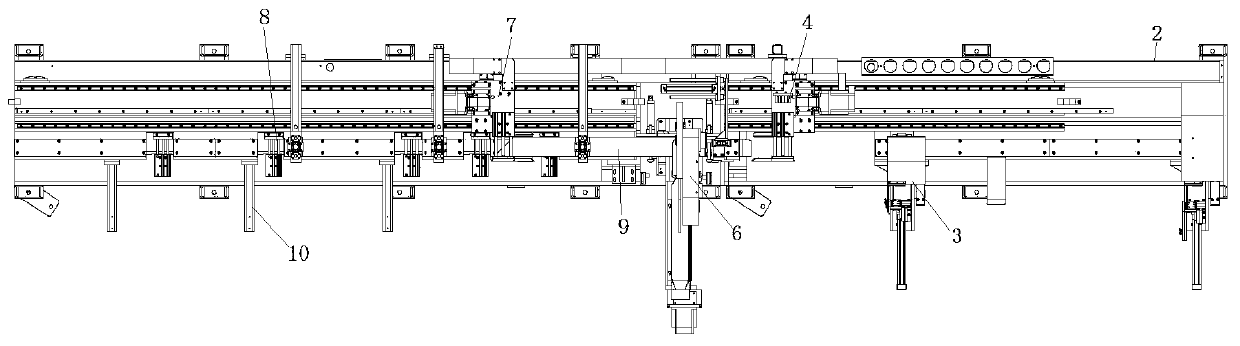

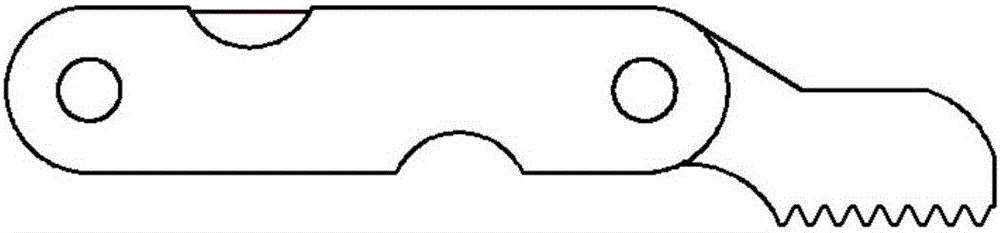

Decorative moulding sawing machine

PendingCN110014483AReduce labor intensityImprove work efficiencyFeeding devicesGripping devicesMechanical engineeringEngineering

The invention relates to a decorative moulding sawing machine. The decorative moulding sawing machine comprises a rack, a sawing workbench assembly, a rotatable sawing assembly and a rear clamping device. The rack is provided with a table board. The sawing workbench assembly and a front clamping device are connected to be arranged on the rack, and the sawing workbench assembly is used for clampingand locating decorative mouldings. The rotatable sawing assembly is arranged on the rack in a manner of corresponding to the sawing workbench assembly and is used for sawing the decorative mouldings.The rear clamping device is connected with the sawing workbench assembly to be arranged on the rack and is used for locating and conveying the decorative mouldings. When the front clamping device conveys the decorative mouldings onto the sawing workbench assembly, the decorative mouldings are clamped and located by the sawing workbench assembly, and one ends of the decorative mouldings are sawn by the rotatable sawing assembly. When the rear clamping device locates the decorative mouldings, the decorative mouldings are clamped and located by the sawing workbench assembly. According to the decorative moulding sawing machine, manual operation is replaced, the labor intensity of workers is reduced, and the work efficiency is improved through cooperation of the front clamping device and the rear clamping device.

Owner:NANTONG YUETONG CNC EQUIP CO LTD

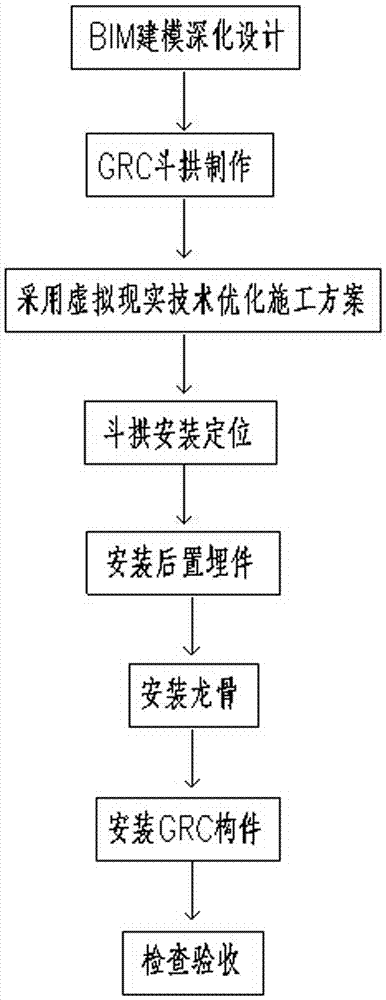

Tang-dynasty ancient architecture imitated bucket arch installing and constructing method

ActiveCN107227852AEnable intuitive analysisSpeed up the installation processGeometric CADAdditive manufacturing apparatusKeelEngineering

The invention discloses a tang-dynasty ancient architecture imitated bucket arch installing and constructing method. A bucket arch is a GRC bucket arch. The constructing method of the bucket arch comprises the following steps that 1, BIM modeling and design deepening are performed; 2, the bucket arch is manufactured; 3, a virtual reality technology is adopted to optimize a construction scheme; 4, the bucket arch is installed and positioned; 5, embedded parts are arranged after installation; 6, keels are installed; 7, GRC members are installed; 8, checking and inspection are performed. The construction difficulty of a bucket arch installing project is effectively reduced, the bucket arch installing progress is accelerated, and the construction quality of bucket arch installing is effectively guaranteed.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU +1

Protecting method for metal component screwed hole in hot-dip galvanizing antiseptic treatment t

ActiveCN101440467AQuality assuranceAvoid not being able to installHot-dipping/immersion processesIron panelZinc

The invention provides a method for protecting a screwed hole of a metal part in galvanizing antiseptic treatment. The method comprises: a first step of mastic preparation, pouring gypsum powder into a container, filling water into the container according to a volume ratio of the gypsum powder to the water of 3-4:1 to be sufficiently and evenly stirred; a second step, filling the mastic into screwed hole to be protected of the metal part by an iron panel, and extruding the mastic tightly after filling; a third step, carrying out the galvanizing antiseptic treatment on the metal part filled with the mastic; and a fourth step: taking out the mastic, and cleaning the screwed hole. The protecting method does not increase the thickness of a galvanizing coat of the screwed hole of the metal part in the process of carrying out the galvanizing antiseptic treatment on the surface of the metal part, thereby avoiding the problem that a processed screwed hole can not be assembled because of increased thickness of the galvanizing coat and other problems, and ensuring the preprocessed screw quality after the metal part is galvanized. The method is simple and feasible, and can greatly improve labor efficiency.

Owner:青岛中车四方轨道车辆有限公司

BIM-based mountain building electromechanical pipeline construction method

PendingCN110990918AImprove the degree of layout beautificationImprove construction qualityGeometric CADData processing applicationsPipe fittingConstruction engineering

The invention particularly relates to a mountain building electromechanical pipeline construction method based on the BIM technology. The method is characterized by comprising the following steps: establishing an original BIM model; holding a conference to gather specific requirements of all parties; performing model pipeline adjustment on the basis of an original three-dimensional model by referring to design specifications according to the requirements of all parties to obtain a primary-edition BIM model of pipe comprehensive optimization; collecting opinions of all parties on the managementand integration optimization model again, and modifying the model until a final optimization BIM model is obtained; exporting a two-dimensional CAD drawing according to the BIM model of final management optimization; exporting the use amount of each pipeline according to the finally optimized BIM model, and handing over the use amount of each pipeline to a construction team for prefabricating andprocessing the pipelines; enabling a field construction team to perform reservation and pre-burying according to the optimized CAD drawing; and installing pipe fittings such as valves, spray heads, shutters and air ports by referring to the original design. The internal use space of a mountain building is improved to the greatest extent, the pipeline arrangement beautification degree is improved,and the electromechanical construction quality of the mountain building is improved.

Owner:SHANGHAI BAOYE GRP CORP

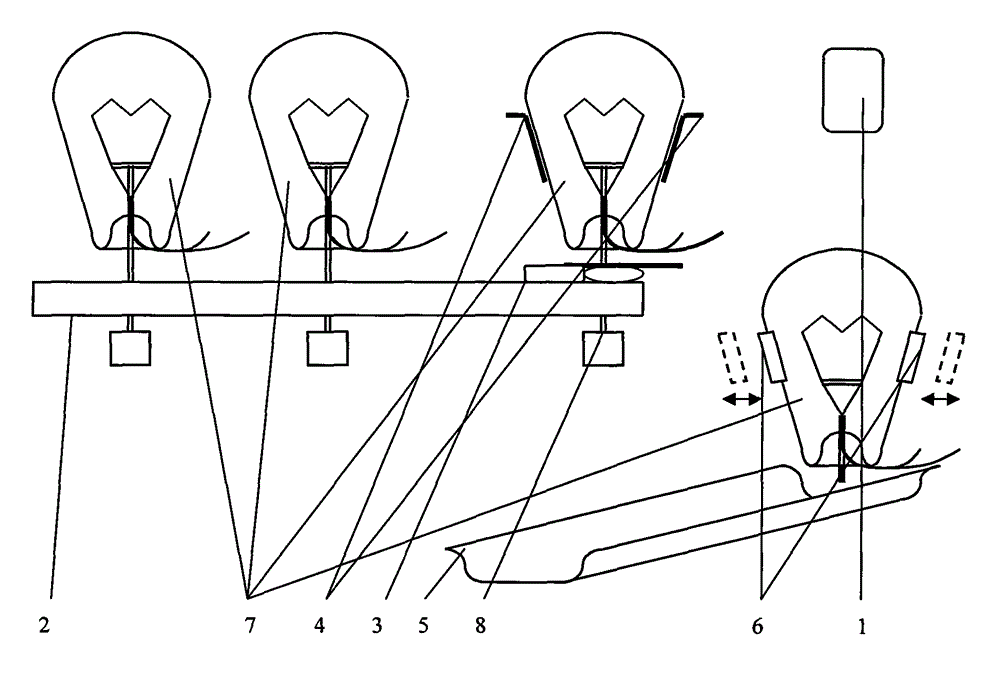

Bubble cap sealing-off technology with sealing cooling process and equipment of bubble cap sealing-off technology

InactiveCN105003842AEnsure cool hardeningAvoid not being able to installPoint-like light sourceProtective devices for lightingSeparated stateEngineering

The invention discloses a bubble cap sealing-off technology with the sealing cooling process. The sealing end cooling process is added after an exhaust pipe is sealed off. The sealing end cooling process comprises the steps that an automatic middle clamp is adopted for clamping a sealed bubble cap for 0.6-3 seconds, and then the bubble cap is placed down to fall into a sliding way to execute the latter process. Equipment special for bubble cap sealing off is manufactured according to the bubble cap sealing-off technology and comprises bubble cap baking sealing-off equipment, a workpiece taking mechanical hand assembly and a controller. The equipment is characterized in that the middle clamp is arranged between a movable sealing-off flame head and the sliding way, and the middle clamp comprises two cylindrical clamp pieces; the two cylindrical clamp pieces can be just supported by a bubble cap when in the folded state; and the two cylindrical clamp pieces can just enable the bubble cap to fall into the sliding way when being in the separated state. According to the bubble cap sealing-off technology and the equipment of the bubble cap sealing-off technology, the sealed bubble cap can be clamped for 0.6-3 seconds through the automatic middle clamp, and cooling hardening of a sealing-in port of the exhaust pipe can be ensured; and the product yield is remarkably improved.

Owner:HAINING XINYU SOLAR ENERGY EQUIP

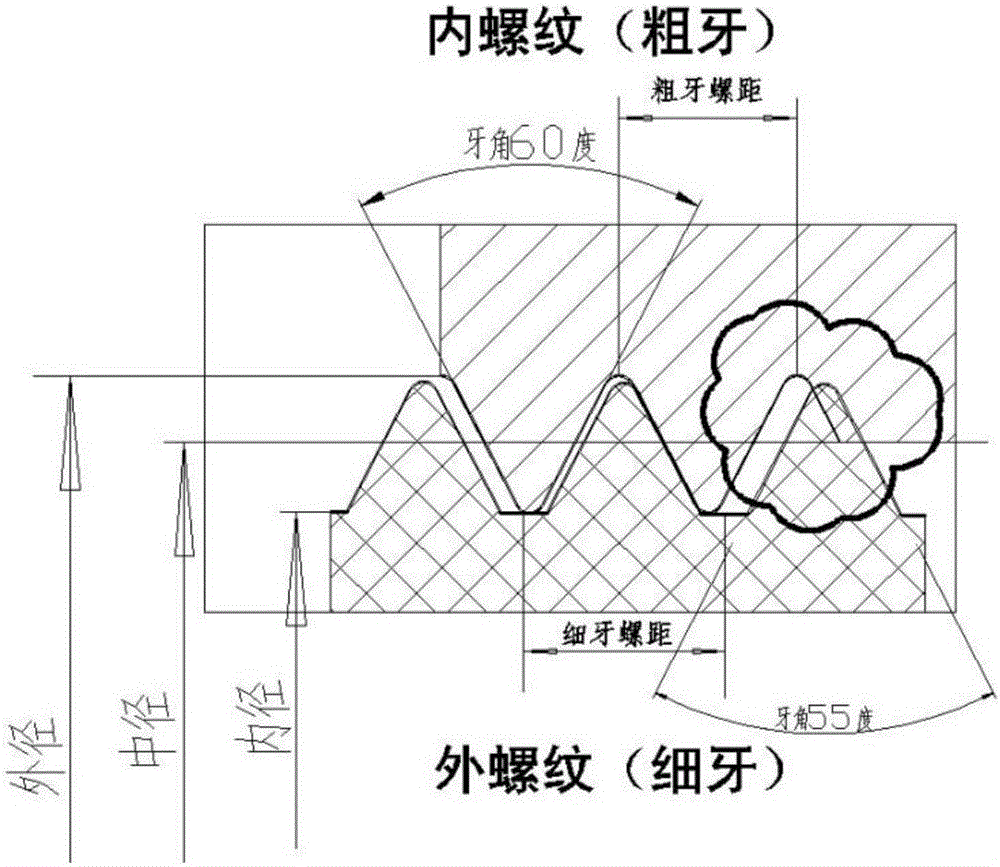

Internal thread sampling tool and sampling method

InactiveCN106017253ASmall sizeSize standardMechanical measuring arrangementsScrew threadComputer science

The invention discloses an inner thread sampling tool. The inner thread sampling tool includes a sampling ruler body and AB type curing adhesive grease which is bonded at one end of the sampling ruler body; the sampling ruler body is provided with scale marks; and the thread pitch, thread angle and effective thread length of an inner thread in a threaded hole of a flange are sampled through a resin embossing mode, so that the related dimensions and standards of the thread can be judged. The inner thread sampling tool of the invention is low in manufacturing and material cost. With the inner thread sampling tool of the invention adopted, a phenomenon that a fastener in the inner threaded hole of the flange cannot be installed or is installed in a non-in-place manner can be avoided.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

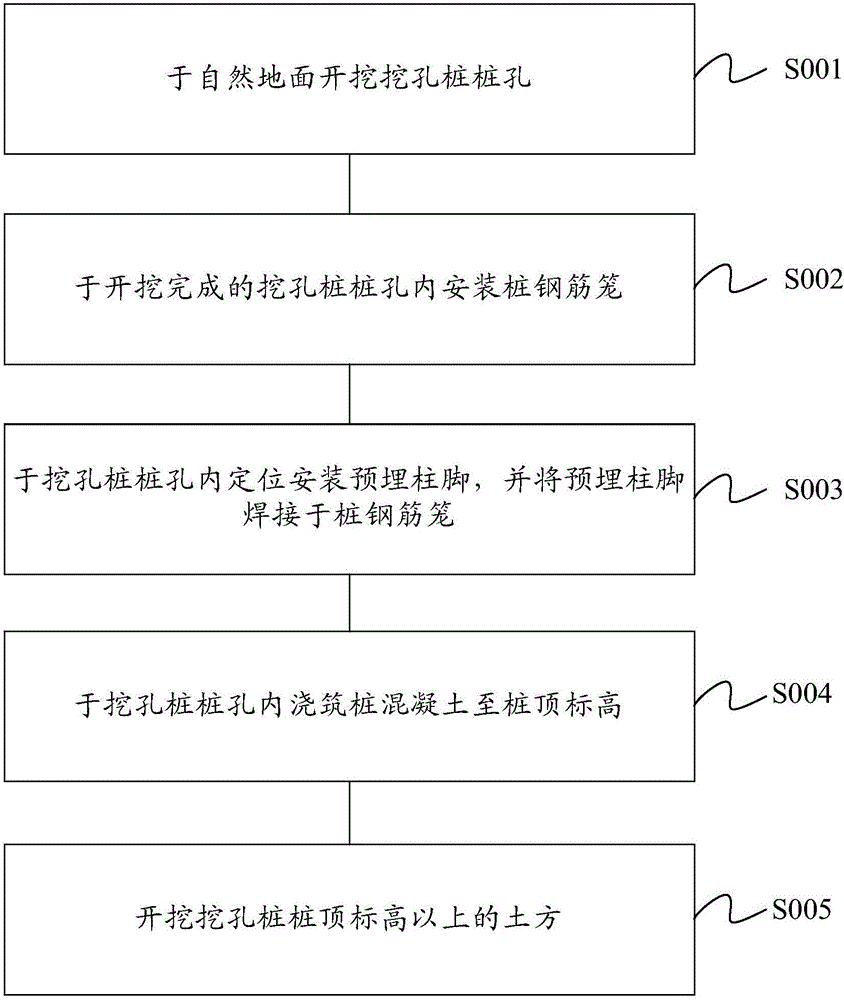

Construction method for digging pile with pile top elevation below natural ground

ActiveCN106087991AShorten the construction periodAvoid road repairsBulkheads/pilesRebarSteel columns

The invention discloses a construction method for a digging pile with the pile top elevation below the natural ground. The method comprises the steps that a digging pile hole is dug in the natural ground; a pile reinforcement cage is mounted in the dug digging pile hole; an embedment column leg is mounted in the digging pile hole in a positioned mode; pile concrete is poured into the digging pile hole till the pile top elevation; and earth above the pile top elevation of the digging pile is dug. Through the modes that construction of the digging pile is conducted at first instead of excavating the earth, and a construction person performs positioning mounting of the embedment column leg in the pile top before pouring of the pile concrete, on the one hand, the project period can be shortened, road maintenance is avoided, and cost is reduced; on the other hand, the mounting precision of the embedment column leg can be accurately mastered, and the embedment column leg is prevented from shifting in the pouring vibration process of the pile concrete, so that accurate positioning of a supporting steel column of an upper main building structure mounted based on the embedment column leg is ensured.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

3D printer leakproof working cylinder

ActiveCN109049691AAvoid deformationAvoid corrosionManufacturing enclosuresAdditive manufacturing with solidsEngineeringUltimate tensile strength

The invention provides a 3D printer leakproof working cylinder. The 3D printer leakproof working cylinder comprises a first cylinder wall, a second cylinder wall, a first side plate, a second side plate, positioning rods and a piston plate; a rectangular channel structure is jointly defined by the first cylinder wall, the second cylinder wall, the first side plate and the second side plate; the first cylinder wall and the second cylinder wall are cooperatively connected through grooves in the first side plate and the second side plate; the first side plate and the second side plate are fastened and connected through the positioning rods; the piston plate slides in the rectangular channel; and the first cylinder wall and the second cylinder wall are made of glass or resin. The problems that3D printer working cylinders are insufficient in strength, and sand is prone to leaking are solved, the 3D printer leakproof working cylinder is convenient to dismount, mount and maintain and has good application prospects, on the basis of superior performance than original metal cutting machining, the cost is greatly reduced, the corrosion resistance is significantly improved, the especially inapplication of a large-sized piston cylinder blocks, the flatness of a whole board cannot be ensured by metal cutting machining easily, and the 3D printer leakproof working cylinder can be widely popularized in similar application.

Owner:武汉阿尔法激光有限公司

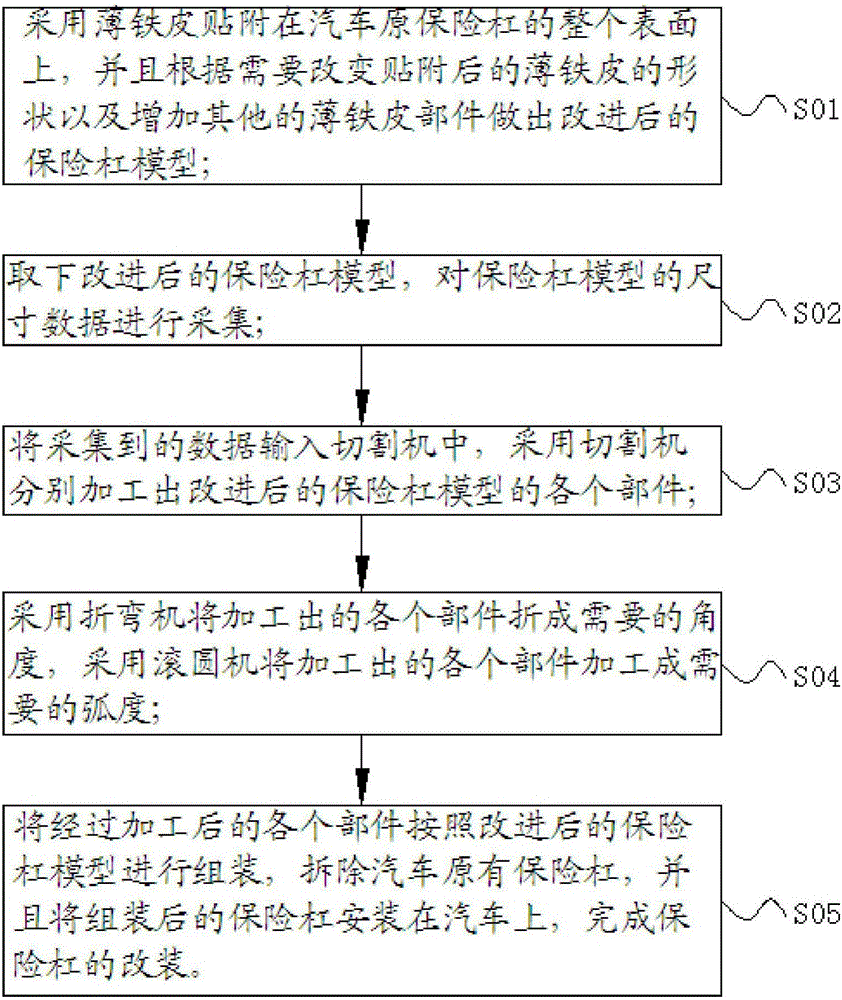

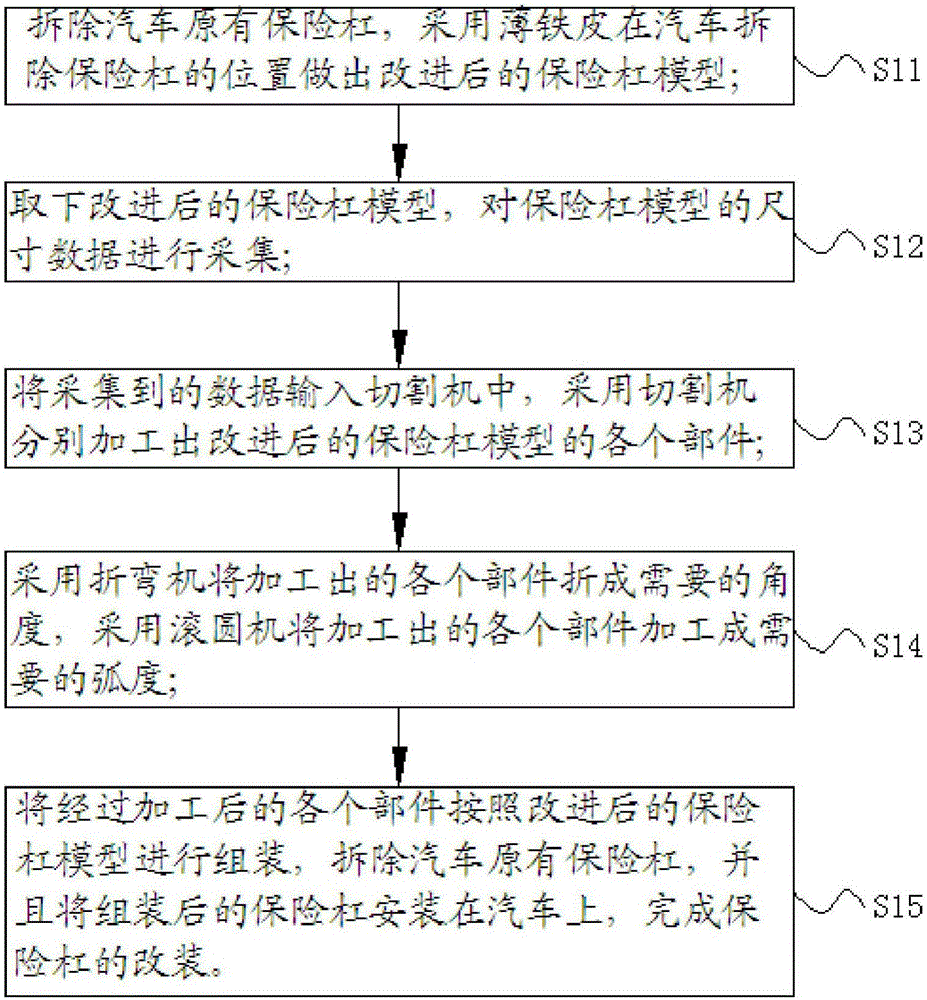

Modifying and manufacturing process of automobile bumper

The invention relates to a modifying and manufacturing process of an automobile bumper, which comprises the following steps of: 1, manufacturing an improved bumper model by sheet iron; 2, taking out the bumper model and acquiring the size data of the bumper model; 3, processing all parts of the improved bumper model respectively by a cutting machine; 4, bending the processed parts into the required angle and radian; and 5, assembling the processed parts according to the improved bumper model and mounting the assembled bumper on an automobile so as to finish modification of the bumper. The modifying and manufacturing process of the automobile bumper, provided by the invention, has the beneficial effects that the automobile bumper can be customized according to the actual requirements of automobile users; and manufacturing of the bumper is facilitated, so the manufacturing process is simple, complex manufacturing equipment is not needed, and the manufacturing cost is reduced.

Owner:黄世咸

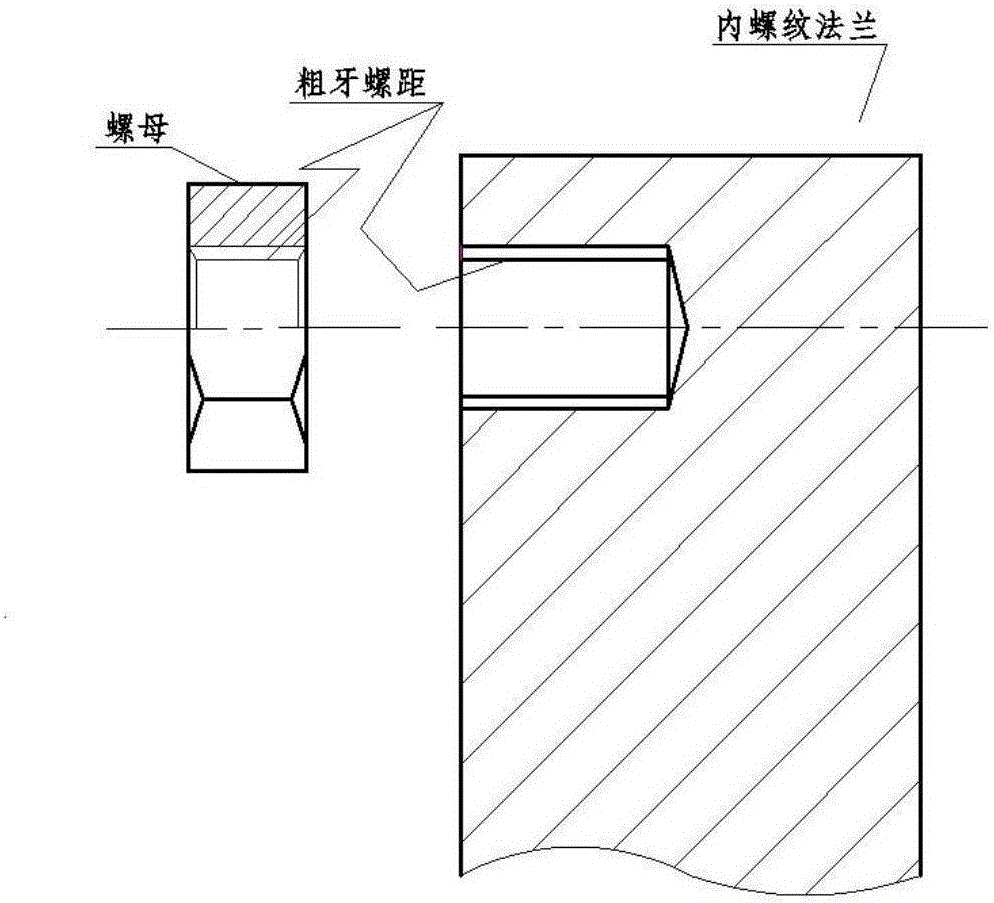

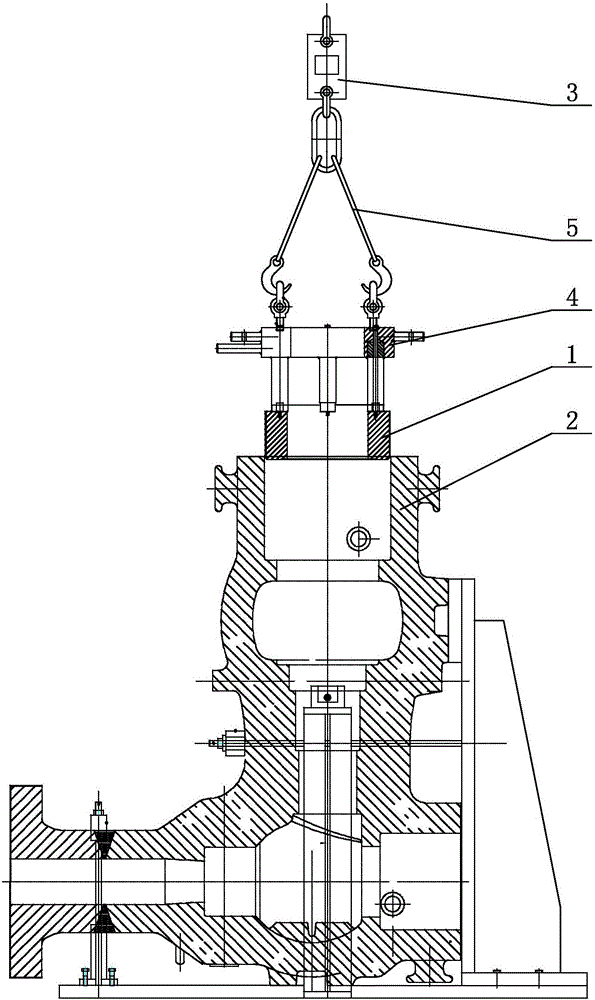

Method for assembling large-diameter tooth-shaped thread ring of high-pressure main steam valve of steam turbine

InactiveCN107520602AHanging stableControl installation speedMetal working apparatusCycloneDynamometer

The invention discloses a method for assembling a large-diameter tooth-shaped thread ring of a high-pressure main steam valve of a steam turbine, and relates to an assembling method of tooth-shaped thread rings. The method aims to solve the problems that the assembling gap between the thread ring of the steam turbine and a valve casing of the steam turbine is small so that the thread ring and the valve casing cannot be installed in the installation process, or threads of the valve casing are prone to galling in the assembling process and then the buttress threads are damaged, and the assembling efficiency is not high. The method comprises the following specific steps that 1, a 3M cyclone brush is connected to a pneumatic tool to clean threads of the thread ring and the threads of the valve casing; 2, a flange of the valve casing faces upwards and is clamped stably through a special clamp; 3, starting positions of the threads of the thread ring and the valve casing are marked, the large-diameter buttress thread ring is lifted to the position right above the valve casing and is centered through a crane, torque values, displayed on a dynamometer, of the thread ring and a lifting tool are recorded, and the thread ring is slowly dropped to the position 100mm away from the horizontal position of the threads; and 4, the thread ring is screwed into the valve casing from the starting positions. The invention belongs to the field of steam turbines.

Owner:HARBIN TURBINE

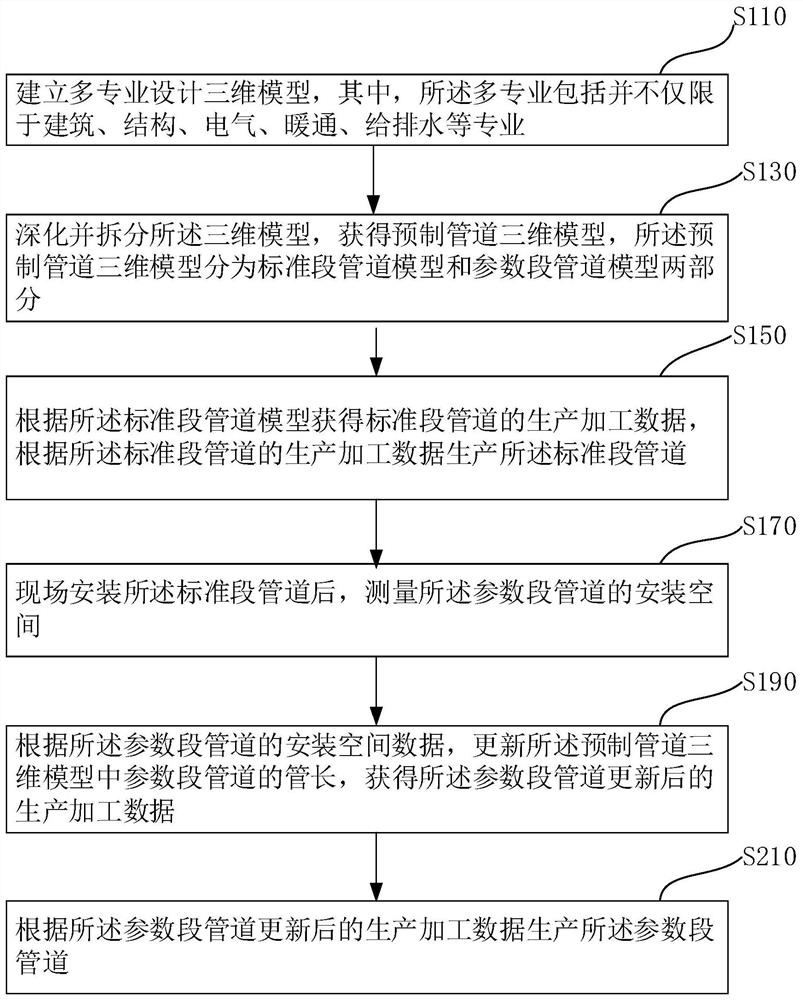

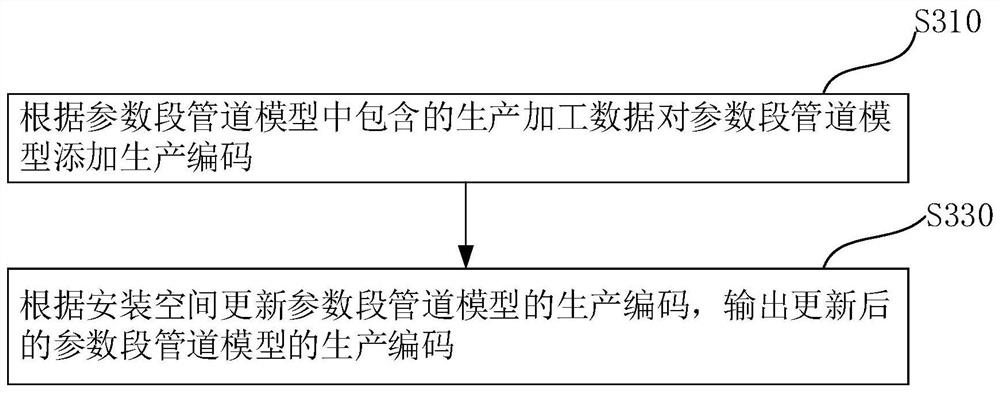

Pipeline prefabricating method based on BIM

PendingCN111666625AReduce labor costsEnsure safetyGeometric CADDesign optimisation/simulationDimensional modelingReliability engineering

The invention provides a pipeline prefabricating method. The pipeline prefabricating method comprises the steps that three-dimensional modeling is conducted; after deepening, the prefabricated pipeline three-dimensional model is split into a standard section pipeline model and a parameter section pipeline model; according to the production and processing data of the standard-section pipeline model, a standard-section pipeline is produced, field installation is completed, and the installation space of the parameter-section pipeline is measured; and final production and processing data of the parameter section pipeline is obtained according to the updated design length of the parameter section pipeline and other production and processing data of the parameter section pipeline model. Due to the fact that the design length of the parameter section pipeline is obtained according to the installation distance, the parameter section prefabricated pipeline which is very matched with the installation distance can be accurately machined, and the problem that the prefabricated pipeline cannot be installed due to field operation and other construction errors is solved.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Engine combustion chamber

ActiveCN111502861AExtended service lifeAvoid not being able to installContinuous combustion chamberRocket engine plantsAutomotive engineeringCombustion chamber

The invention provides an engine combustion chamber. The engine combustion chamber comprises a casing, a flame tube, a sleeve, an ignition plug and a bushing, the casing is provided with a first mounting seat, and the first mounting seat is provided with a first middle hole; the flame tube is provided with a second mounting seat, and the second mounting seat is provided with a second middle hole;the sleeve is mounted on the first mounting seat and extends from the first middle hole to the second middle hole; at least part of the ignition plug is arranged in the sleeve and is fixedly connectedwith the sleeve; and the bushing sleeves the periphery of the sleeve and is movably connected to the second mounting seat.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

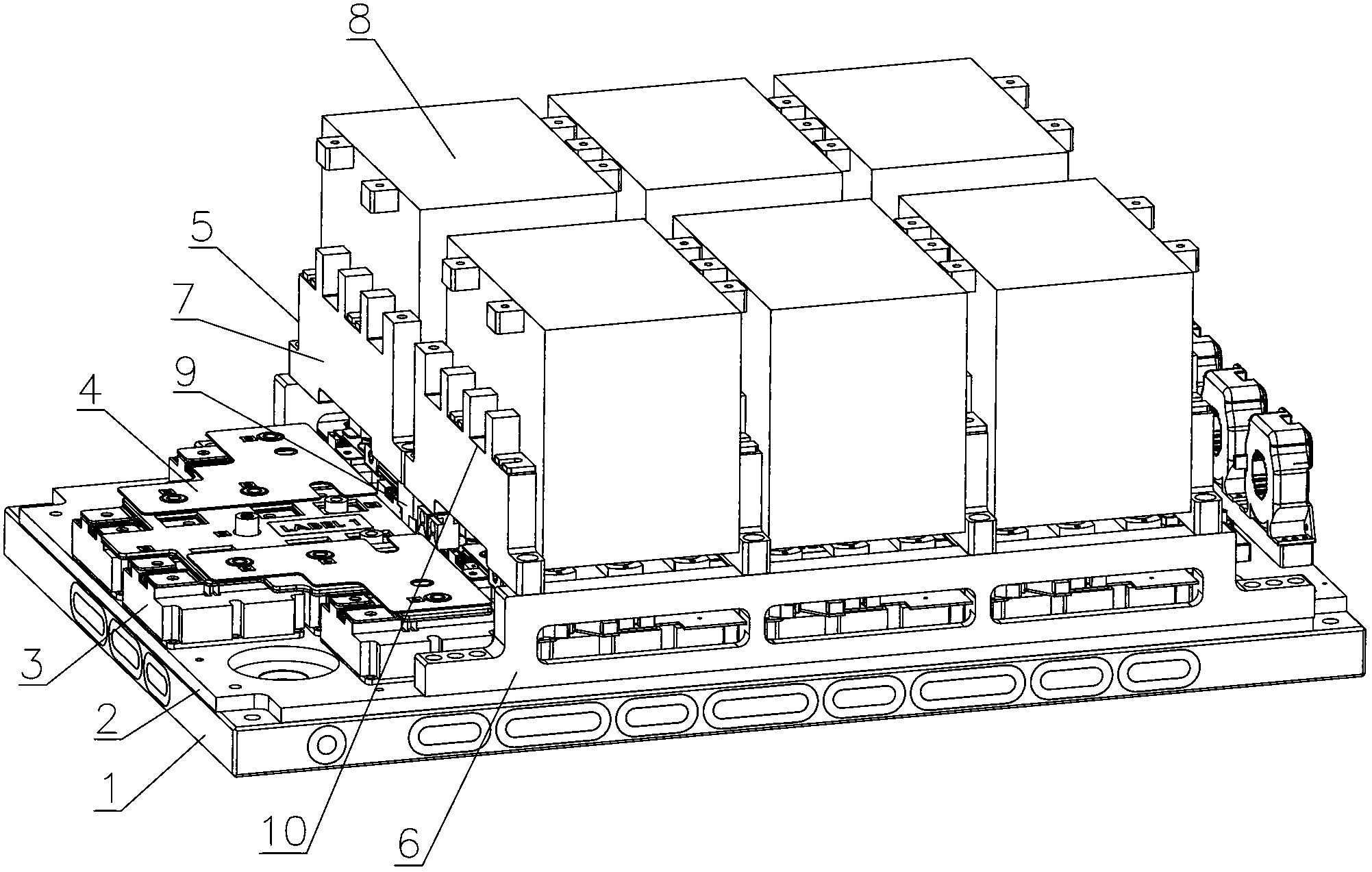

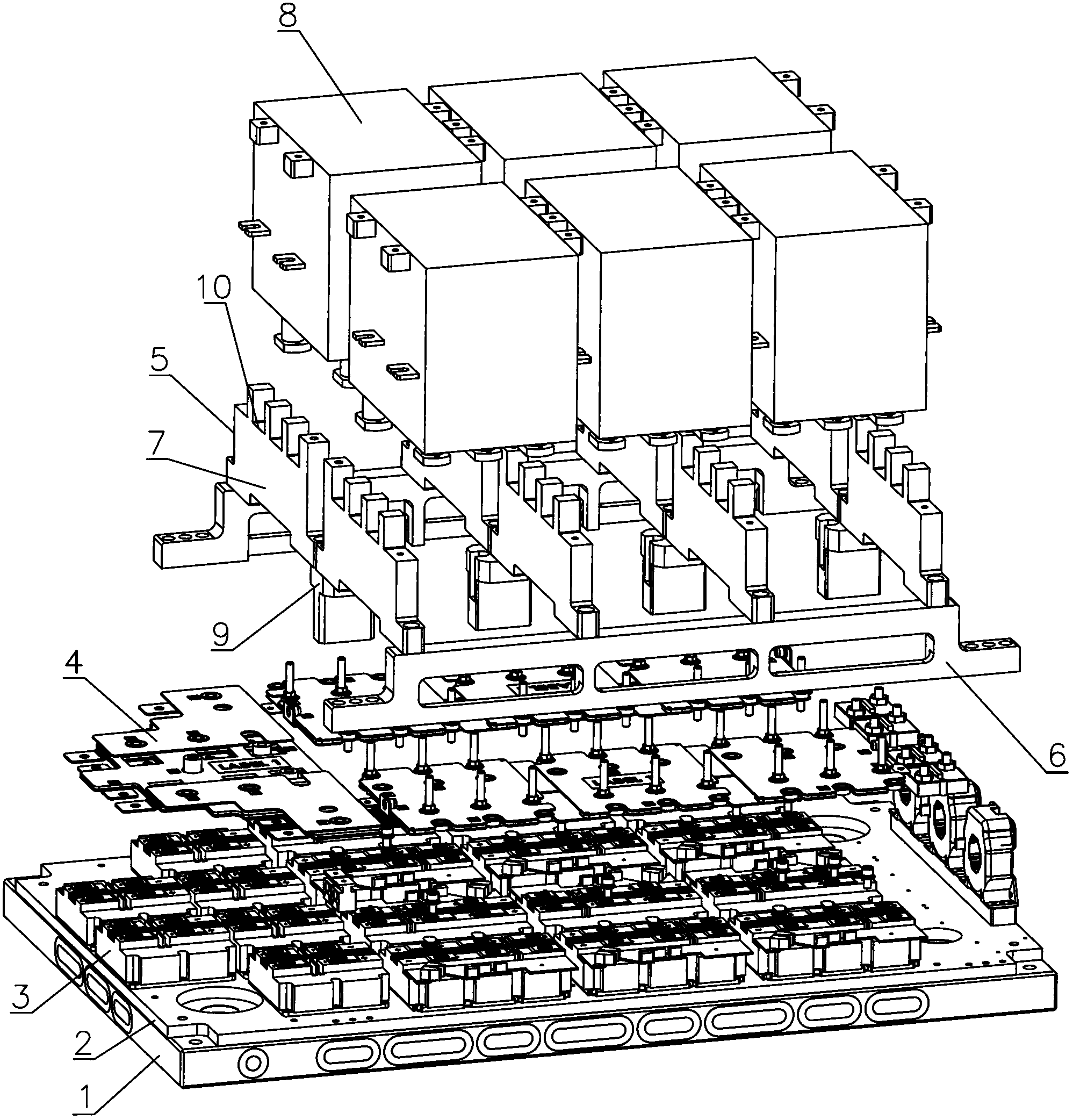

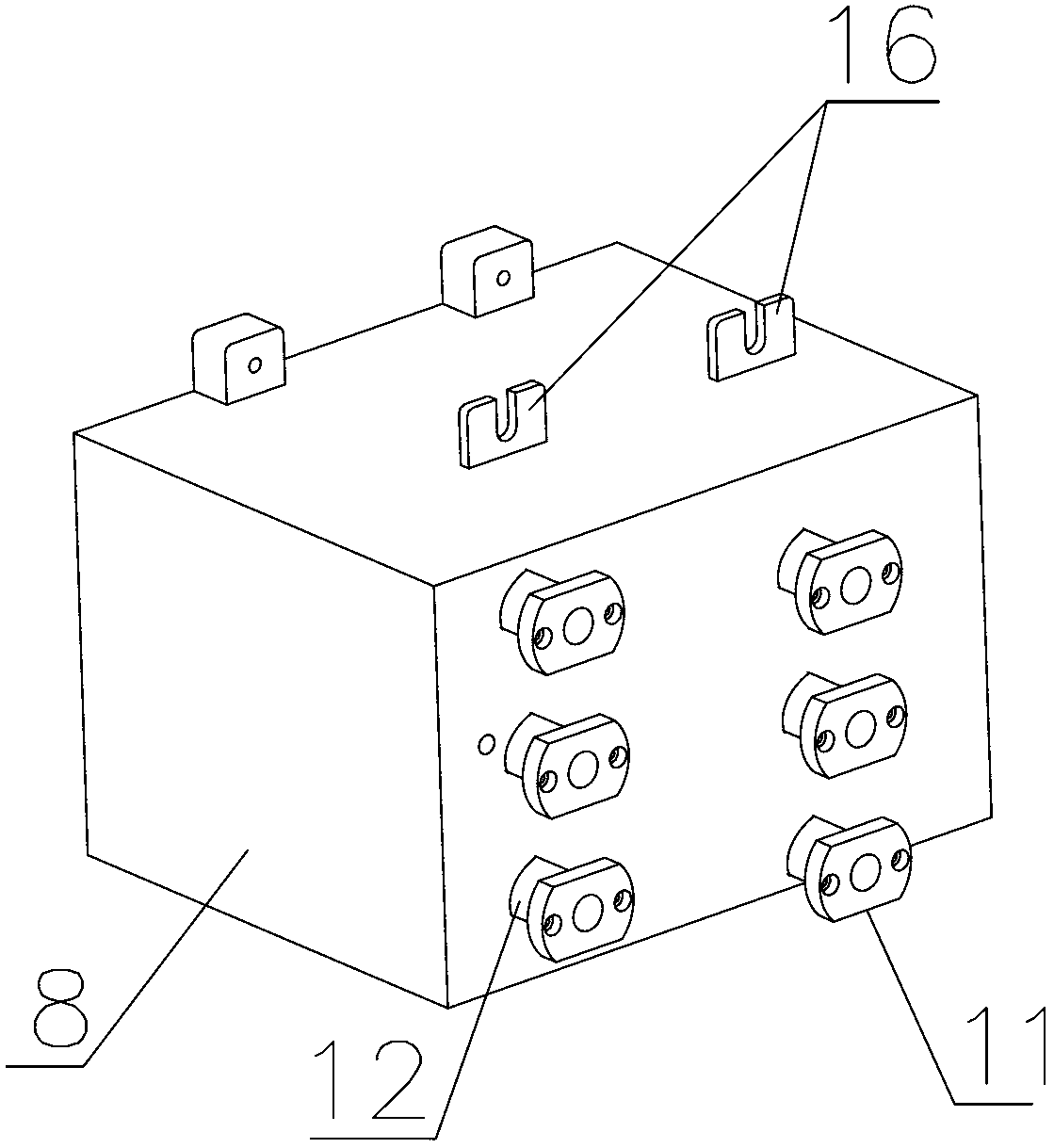

Power and energy storage structure of mine anti-explosion frequency control all-in-one machine

ActiveCN103187855AReduce volumeImprove cooling effectCooling/ventilation/heating modificationsPower conversion systemsElectricityBusbar

The invention relates to a power and energy storage structure of a mine anti-explosion frequency control all-in-one machine. The power and energy storage structure of the mine anti-explosion frequency control all-in-one machine comprises a water cooling plate, a water channel is arranged inside the water cooling plate, a copper plate is arranged on the water cooling plate, multiple power devices are arranged on the copper plate, a laminated busbar electrically connected with one power device is arranged on each power device, an insulation support is also arranged on the water cooling plate, the insulation support comprises two support frames which are arranged at the front side and the rear side of the water cooling plate in parallel, multiple separating and fixing plates are arranged in parallel between the two support frames, a plug-in type power capacitor is respectively arranged between every two separating and fixing plates, and the bottom of the plug-in type power capacitor is connected with the power devices. The power and energy storage structure of the mine anti-explosion frequency control all-in-one machine reduces the whole volume of a frequency converter; and plug-in type power capacitors can be directly plugged on a connecting pole and do not need to be connected by cables, so that the whole volume of equipment is reduced; and the plug-in type power capacitor is convenient to dismount, so that dismounting time is saved, working efficiency is improved, a connection inductance is small, no absorption capacitor is required to be arranged on each power device, and mounting error probability is greatly reduced.

Owner:QINGDAO CCS ELECTRIC CORP

Photovoltaic LED module

PendingCN109192087AGuaranteed power generationEasy to installBatteries circuit arrangementsElectric powerLight spotKeel

A photovoltaic LED assembly includes a main keel, a PV Module, an LED module, and a cable; two sets of upper and lower notches are respectively arranged on the end faces of the two sides of the main keel, the LED assembly is fixed on both sides of the main keel through a first notch, the photovoltaic module is fixed on both sides of the main keel through a second notch, the cable is introduced into the main keel frame through a wiring hole in the center of the main keel, The LED assembly and the photovoltaic assembly are respectively connected, the LED assembly and the photovoltaic assembly are distributed on both sides of the main keel in a spaced and non-contact manner, and a slider with adjustable size is arranged between the LED assembly and the photovoltaic assembly. The module realizes the purpose of easy heat dissipation and avoiding the generation of light spots. At the same time, the installation and disassembly of the components are more convenient.

Owner:BEIJING HANERGY PV TECH CO LTD

Six-face drilling adjustable clamp mechanism

PendingCN109290610ARealize the clamping effectAchieve positioningWork holdersPositioning apparatusEngineeringMechanical engineering

The invention discloses a plate machining device, and particularly relates to a six-face drilling adjustable clamp mechanism. The six-face drilling adjustable clamp mechanism is provided, a pluralityof vertical sliding blocks and a plurality of horizontal sliding blocks are arranged on the inner side and the outer side of a clamp base correspondingly, an adjusting block is further arranged on theclamp base at the upper ends of the horizontal sliding blocks, and a limiting block is arranged on one side of the bottom end of the clamp base; the limiting block is connected with a lower clampingplate, an upper clamping plate is arranged in the vertical sliding blocks, one side of the lower clamping plate is connected with a height adjusting plate, the lower clamping plate is fixedly providedwith an air cylinder, and the air cylinder is fixedly connected with the upper clamping plate through an air cylinder rod; and a positioning column is arranged on one side of the lower clamping plate, clamping heads are fixedly installed at the positions, corresponding to the lower clamping plate and the upper clamping plate, of one end of the positioning column, the height adjusting plate is connected with the clamp base through an adjusting screw and an adjusting nut on the adjusting block. The mechanism has the beneficial effects that material loss of the plate machining enterprise is reduced, and great convenience is brought to the daily work of people.

Owner:济南缔明数控科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com