Decorative moulding sawing machine

A technology of decorative lines and sawing machines, applied in sawing components, sawing equipment, circular saws, etc., can solve problems such as increased production costs, waste of production raw materials, waste decorative lines, etc., to improve work efficiency and reduce labor intensity , The effect of high sawing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The terms "first", "second", etc. used herein do not specifically refer to a sequence or order, nor are they used to limit the present application, but are only used to distinguish components or operations described with the same technical terms. .

[0063] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

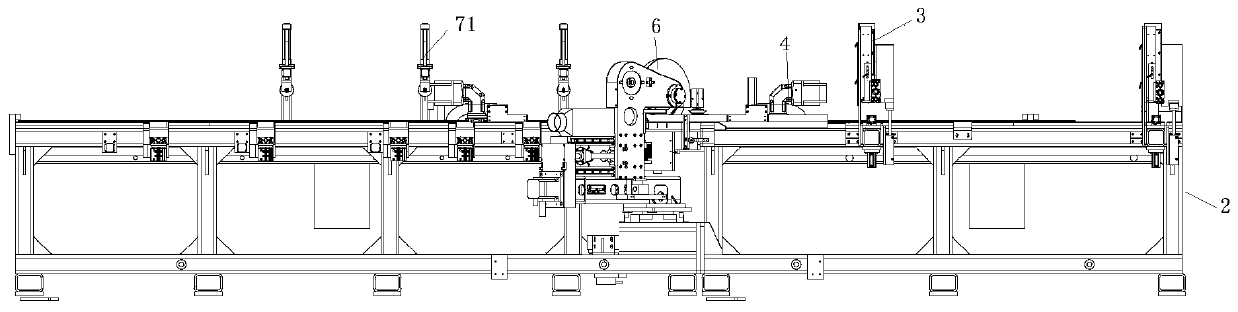

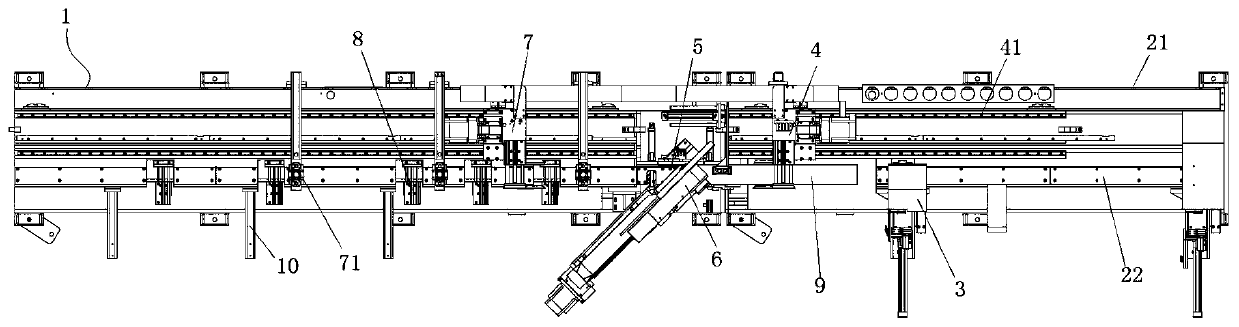

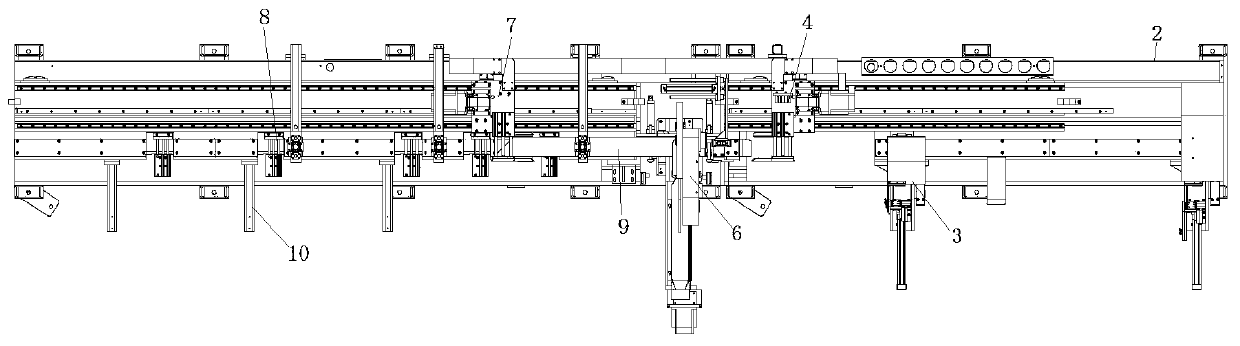

[0064] In an embodiment of the present invention, please refer to figure 1, which shows a front structural schematic diagram of a decorative line sawing machine 1 according to an embodiment of the present invention. The decorative line sawing machine 1 can saw any workpiece suitable for sawing in the present invention, including but not limited to structures such as decorative lines 9 and planks. The cutting machine 1 comprises a frame 2, a front clamping device 4, a sawing table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com