Protecting method for metal component screwed hole in hot-dip galvanizing antiseptic treatment t

A technology for metal parts and anti-corrosion treatment, which is applied in hot-dip plating process, metal material coating process, coating and other directions to improve labor efficiency and ensure quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for protecting threaded holes of metal parts in hot-dip galvanizing anticorrosion treatment, which mainly includes the following steps:

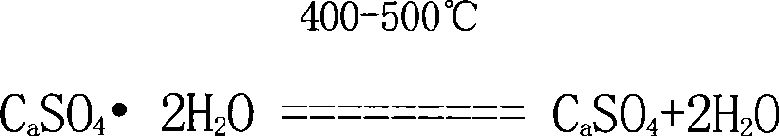

[0027] The first step is to prepare the paste glue, pour three parts of gypsum powder into the container, according to the volume ratio

[0028] Gypsum powder: water = 3-4: 1

[0029] Pour in a portion of water and stir evenly. The stirring time is 100 seconds. Shake the container left and right, and then shake it at an angle of more than 30 degrees from the horizontal until the gypsum powder and water are fully blended to form a paste;

[0030] The second step is to fill the paste with an iron plate into the cylindrical threaded hole to be protected of the metal part, squeeze it tightly after filling, and scrape off the remaining paste with an iron plate;

[0031] The third step is to perform hot-dip galvanizing anti-corrosion treatment on the above-mentioned metal parts filled with paste;

[0032] The fourth step is to ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com