Bubble cap sealing-off technology with sealing cooling process and equipment of bubble cap sealing-off technology

A technology of blister and process, which is applied in the field of blister sealing and separation technology and its equipment, can solve the problems that affect the product qualification rate and the large discrete size of the sealing port, so as to achieve the effect of improving the qualification rate and ensuring cooling and hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

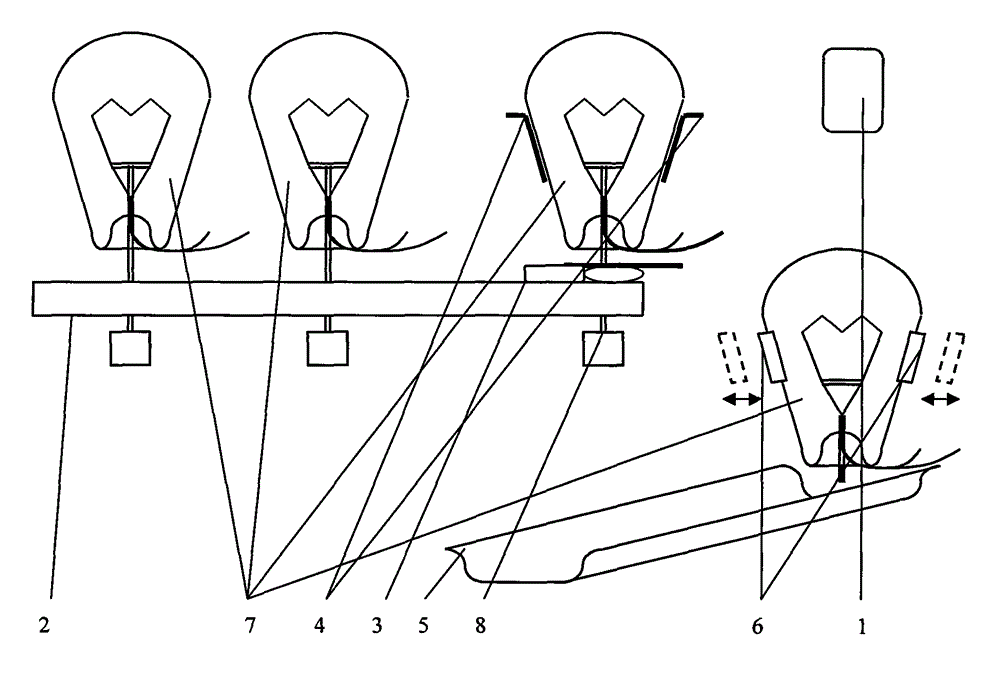

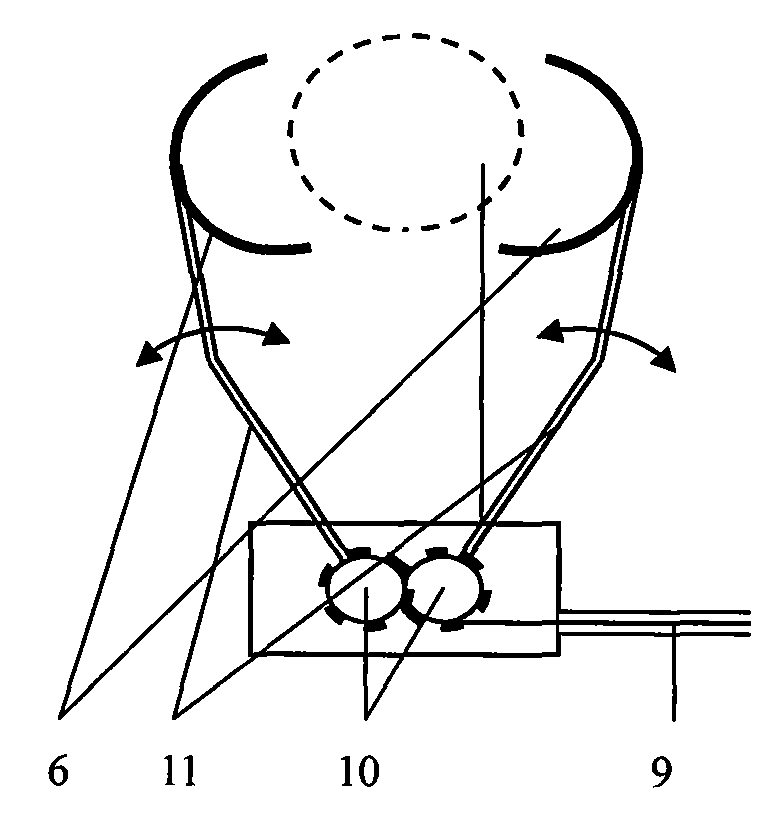

[0012] figure 1 and figure 2 An embodiment of the present invention is collectively given.

[0013] figure 1 and figure 2 In , a blister sealing and separating device with an intermediate fixture is manufactured, including a blister baking and sealing device, a workpiece picking manipulator assembly and a controller 1 . The blister baking and sealing equipment includes a multi-station rotary platform 2 and a movable sealing and separating fire head 3; the workpiece picking manipulator assembly includes an automatic blister fixture 4. An intermediate clamp is set between the movable sealing fire head 3 and the slideway 5, and the intermediate clamp comprises two cylindrical clamping valves 6; the inner surface of the cylindrical clamping valve 6 matches the shape of the bulb 7 neck; the cylindrical clamping The petals 6 have two states: the state where the two cylindrical clips 6 are combined and the two cylindrical clips 6 are separated; when the two cylindrical clips 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com