Method for assembling large-diameter tooth-shaped thread ring of high-pressure main steam valve of steam turbine

An assembly method and a threaded ring technology, which are applied in the field of steam turbines, can solve problems such as low assembly efficiency, damaged serrated threads, and thread roughening of valve casings, and achieve the effects of convenient operation, high installation efficiency, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

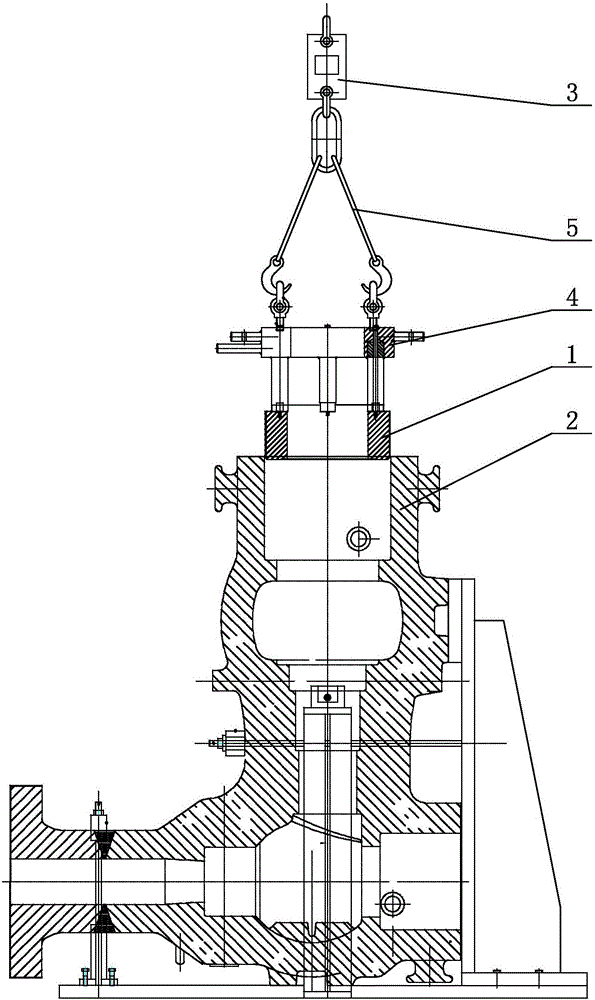

[0016] Specific implementation mode one: combine Figure 1 to Figure 4 To illustrate this embodiment, the specific steps of a method for assembling a large-diameter toothed threaded ring of a high-pressure main steam valve of a steam turbine described in this embodiment are as follows:

[0017] Step 1. Connect the 3M cyclone brush to the pneumatic tool to clean the threaded part of the threaded ring 1 and the valve housing 2;

[0018] Step 2. Fix the flange of the valve housing 2 upwards with a special fixture, adjust the flatness of the flange surface to no more than 0.2mm, connect the threaded ring 1 and the lifting tool 4 with bolts, and the lifting tool 4 passes the force measuring balance tool 5 is connected with the dynamometer 3, and the dynamometer 3 is connected with the crane;

[0019] Step 3: Mark the starting position of threaded ring 1 and valve casing 2, hoist the large-diameter serrated threaded ring 1 directly above the valve casing 2 by the crane and center i...

specific Embodiment approach 2

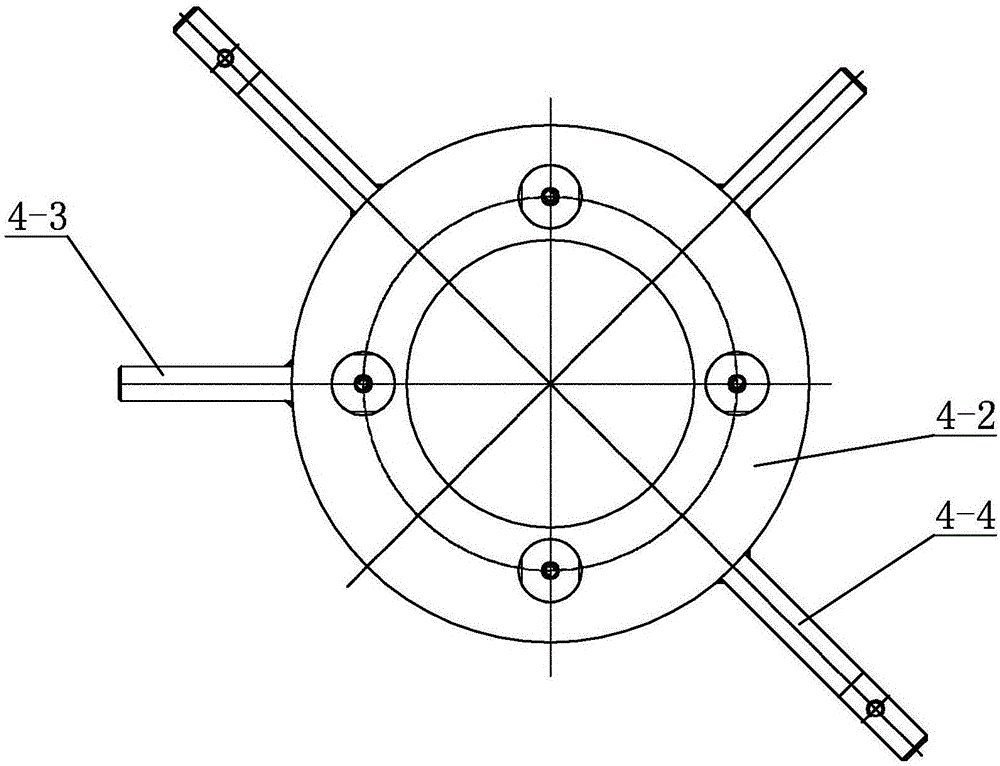

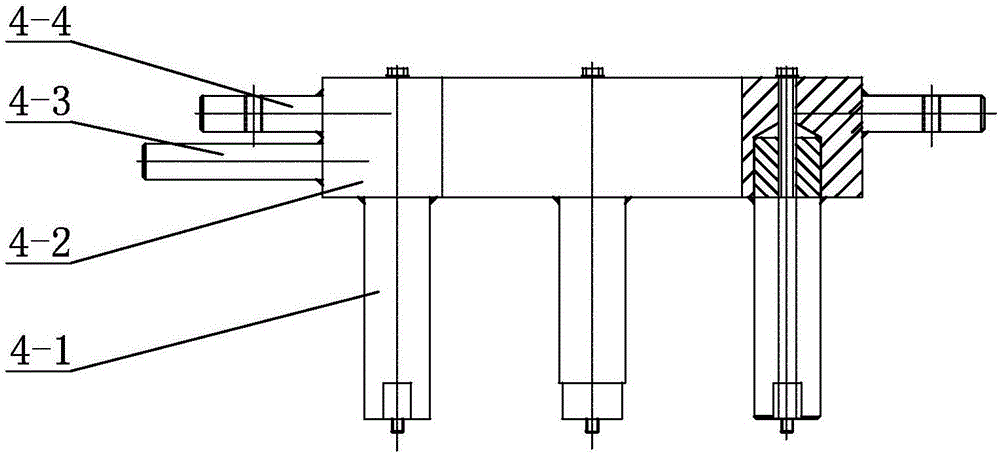

[0021] Specific implementation mode two: combination Figure 1 to Figure 4 Describe this embodiment, the hoisting tool 4 in step 2 of the assembly method of a large-diameter toothed threaded ring of a high-pressure main steam valve of a steam turbine described in this embodiment is composed of a plurality of claws 4-1, a ring 4-2, and a handle 4 -3 and a plurality of round steel 4-4, the lower surface of the ring 4-2 is provided with a plurality of claws 4-1, the handle 4-3 is arranged on the outer wall of the ring 4-2, and a plurality of round steel 4-4 is arranged on the outer wall of the ring 4-2, and the claw 4-1 is connected with the threaded ring 1.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination Figure 1 to Figure 4 Describe this embodiment, the force measuring balance tool 5 in step 2 of a large-diameter toothed thread ring assembly method for a high-pressure main steam valve of a steam turbine described in this embodiment is composed of a chain lock 5-1, two shackles 5-2 and Two lifting ring screws 5-3, the upper end of the chain lock 5-1 is connected with the dynamometer 3, the lower end of the chain lock 5-1 is connected with two shackles 5-2, and the two shackles 5-2 pass through two lifting rings The screw 5-3 is connected with the upper surface of the ring 4-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com