Self-locking type lifting hook

A self-locking, hook technology, applied in the field of hooks, can solve problems such as troublesome, spring failure, etc., to achieve the effect of convenient use, improve work efficiency, and reduce the steps of manual unhooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

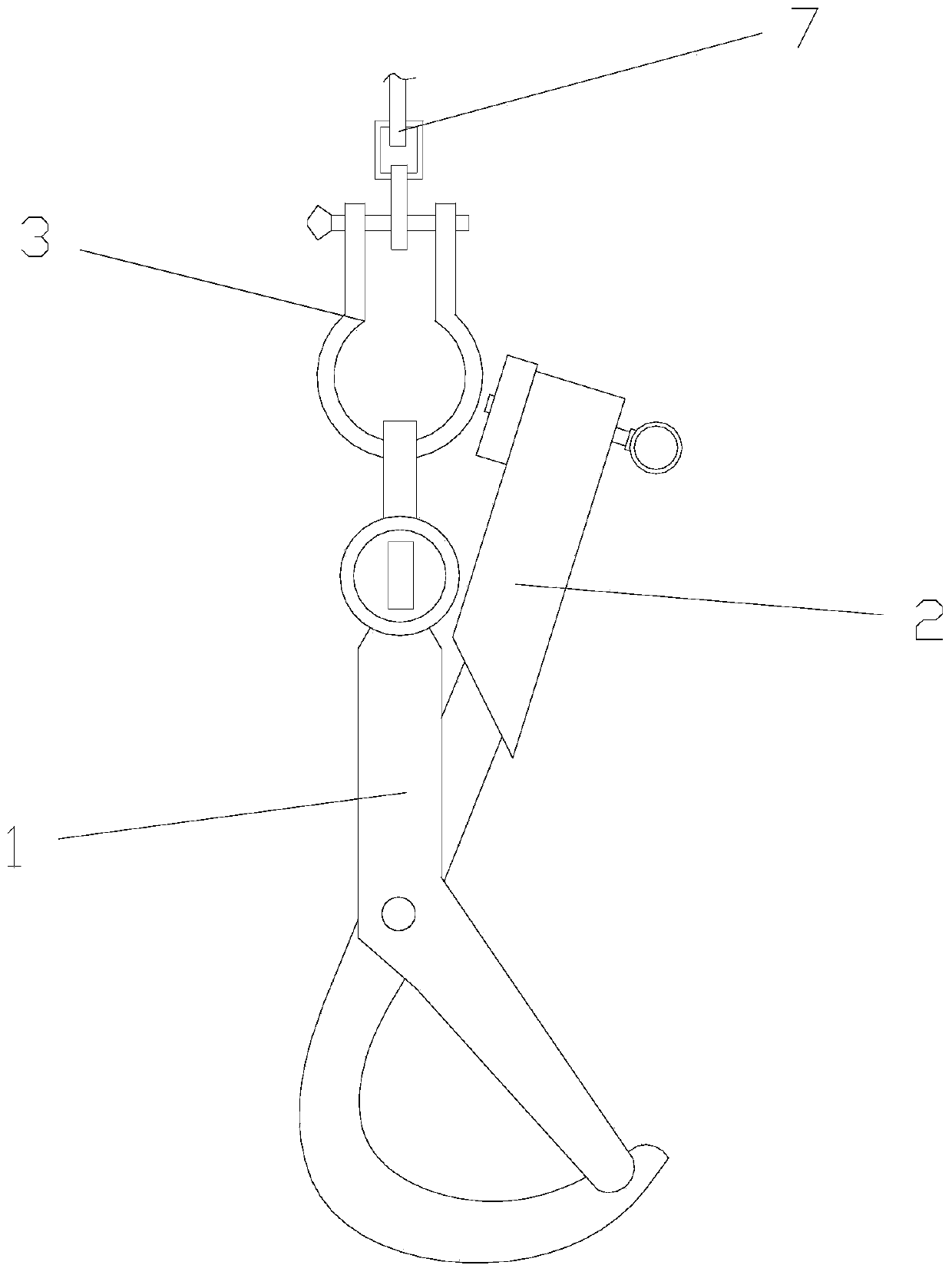

[0023] see Figure 1 to Figure 3 , In a preferred embodiment of the present invention, a self-locking hook includes a fixed hook seat 1 and a movable hook body 2 .

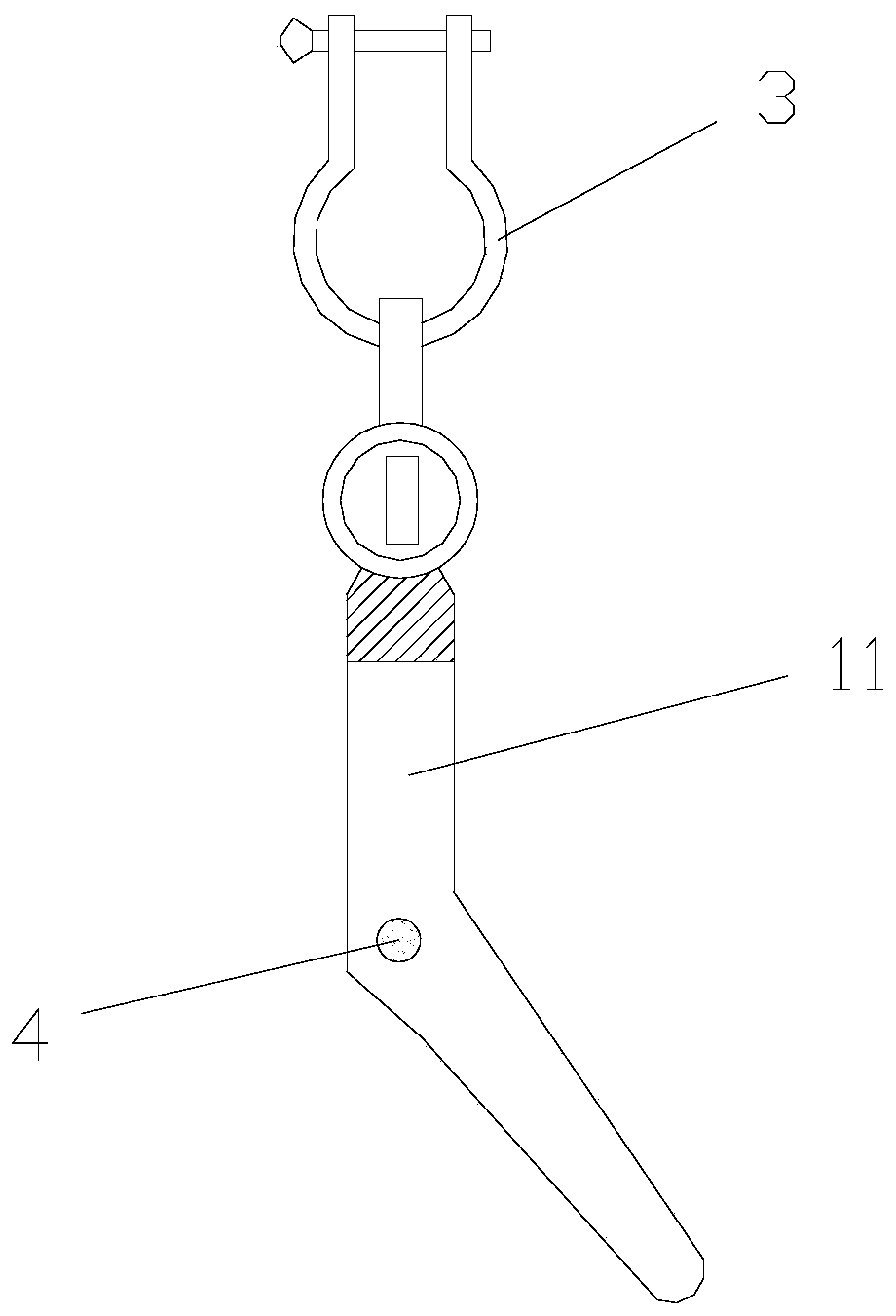

[0024] The top of the fixed hook seat 1 is provided with a connecting part 3 for connecting the external rope 7, the connecting part 3 is a ring structure, and the external rope 7 is one of a rope, a belt, and a chain, so as to connect with the external crane through the connecting part 3. connect.

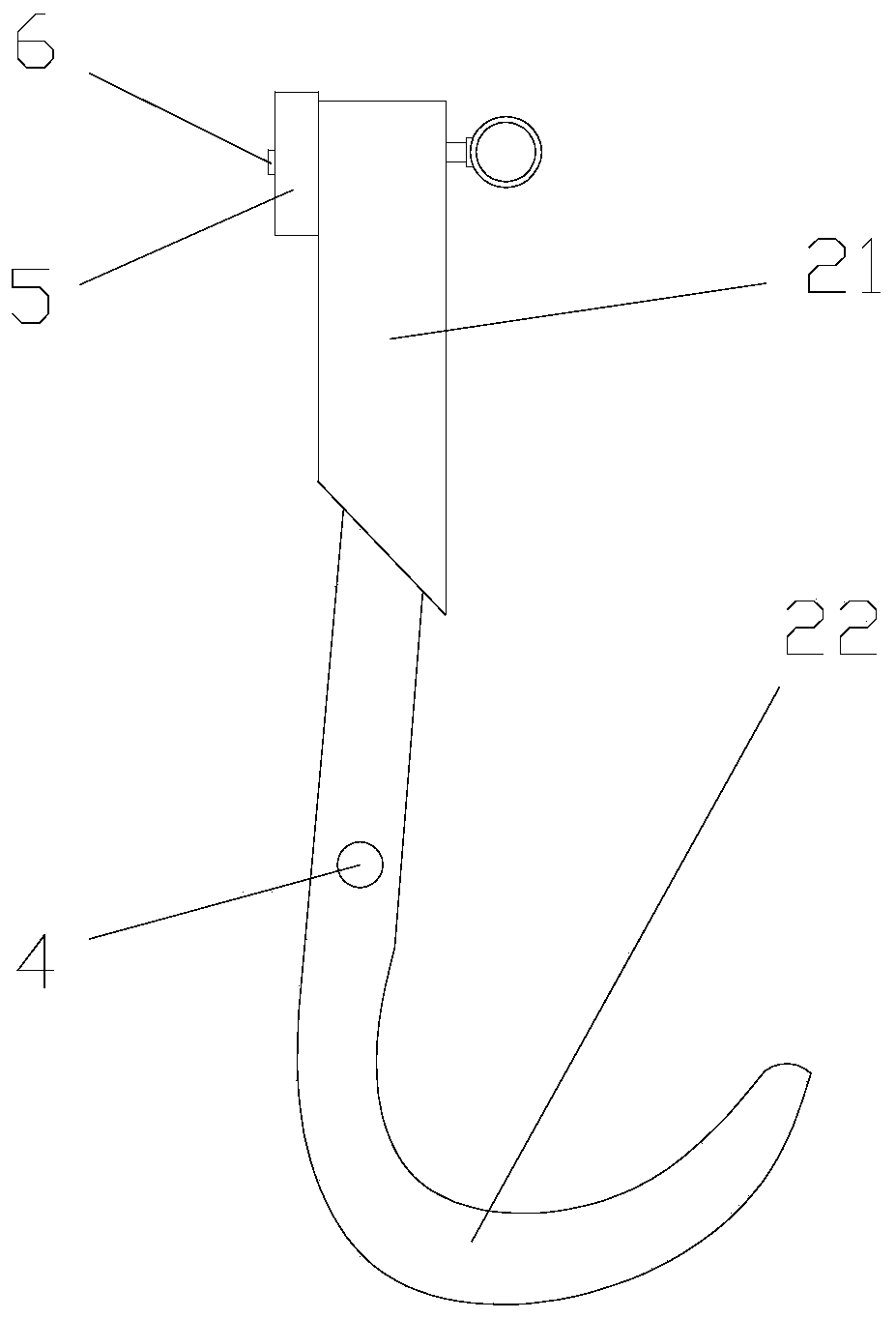

[0025] The lower part of the fixed hook seat 1 is provided with a through hole 11, and the movable hook body 2 is pierced with the through hole 11, and is connected with the fixed hook seat 1 through the rotating shaft 4 at the through hole 11, and the rotation axis is perpendicular to the described Fix the length direction of the hook seat 1. The movable hook body 2 is divided into a hook portion 22 and a rod portion 21 with the position of the rotating shaft 4 as a dividing point, and the rod portion 21 and the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com