Slab seal dummy ingot method for preventing break-out of steel

A slab and breakout technology, which is applied in the field of slab sealing and starting ingots to prevent breakout at the start, can solve problems such as breakout and uneven distribution of cold iron, achieve good capping effect, avoid adhesion, and have remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

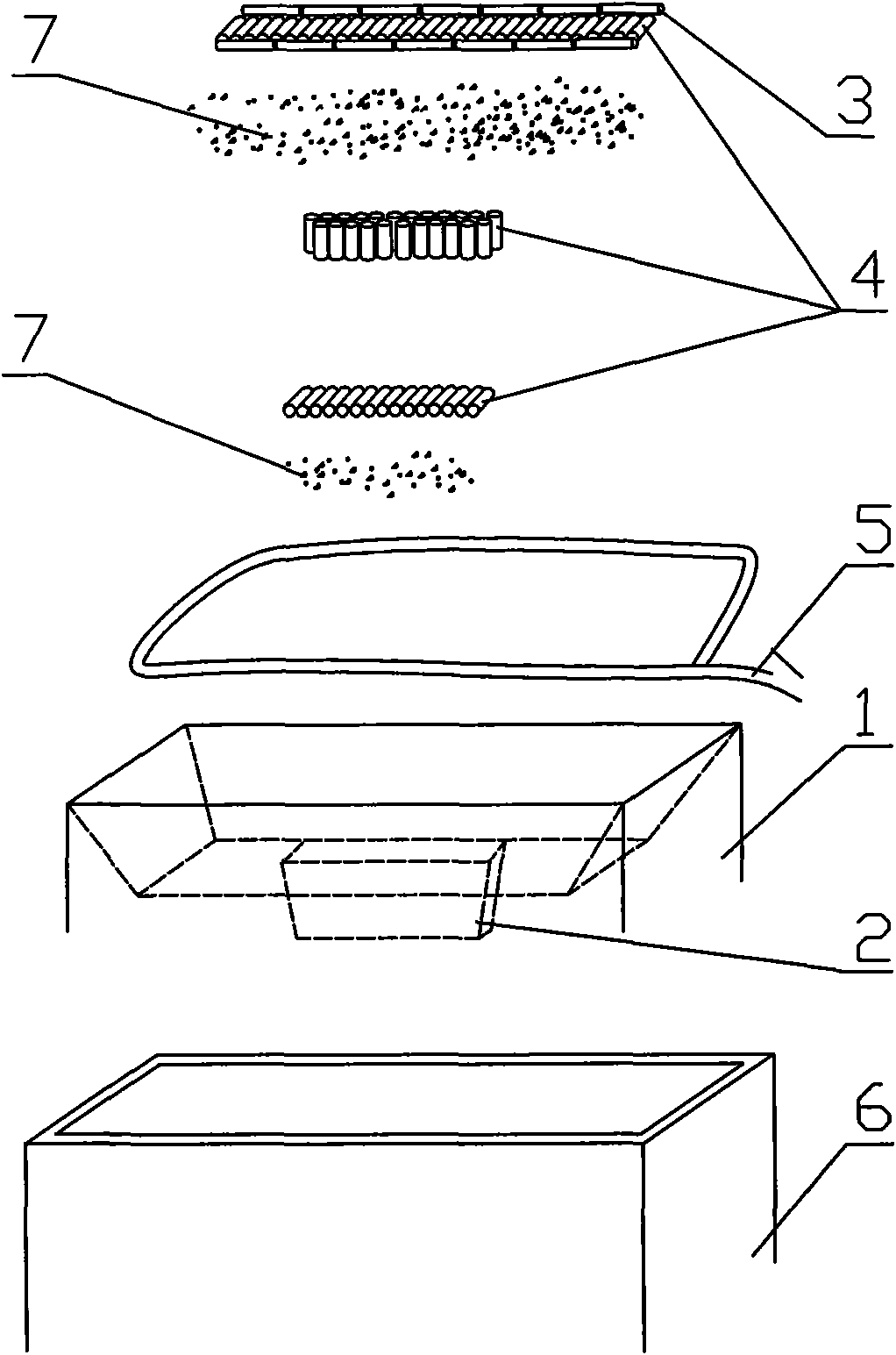

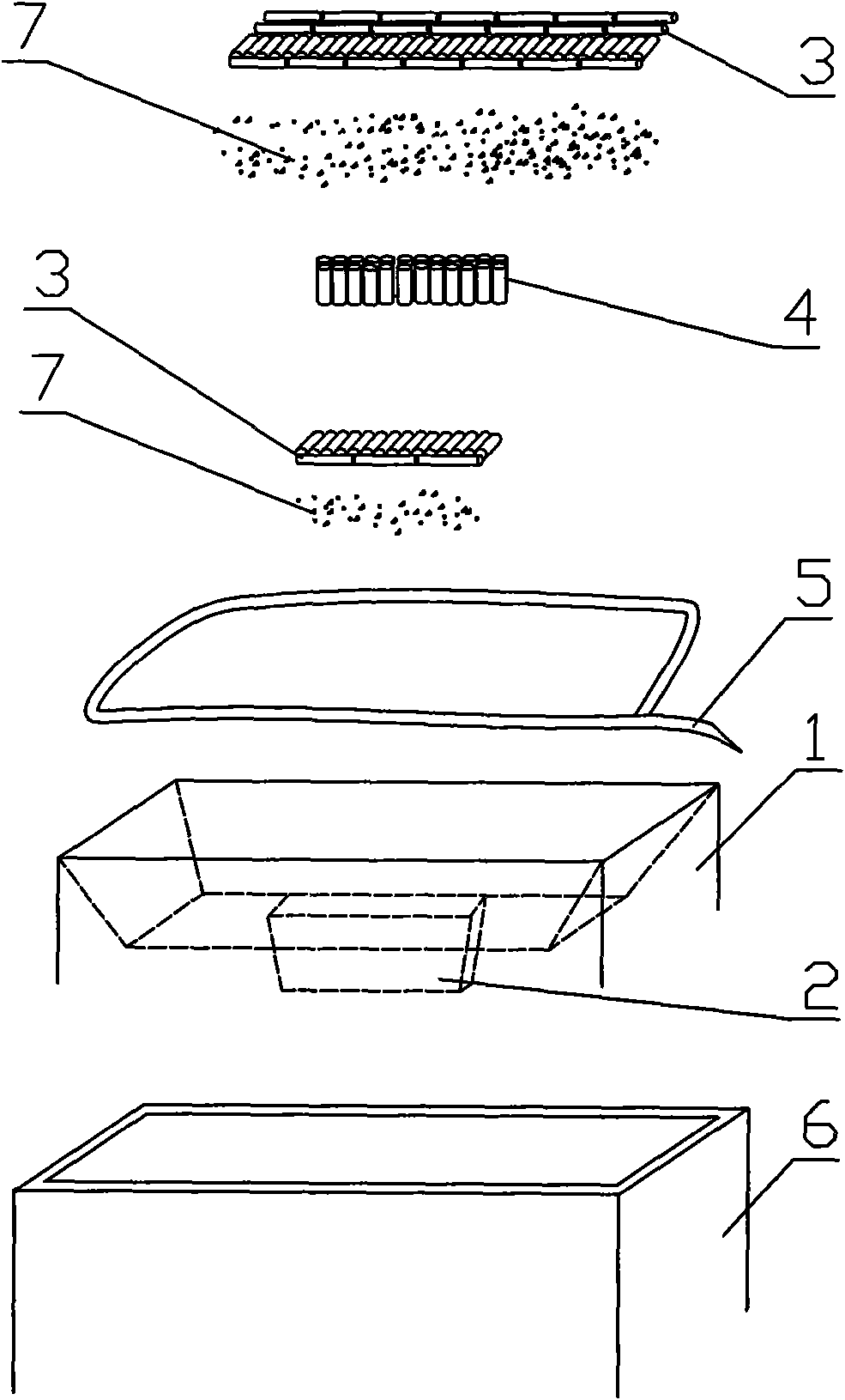

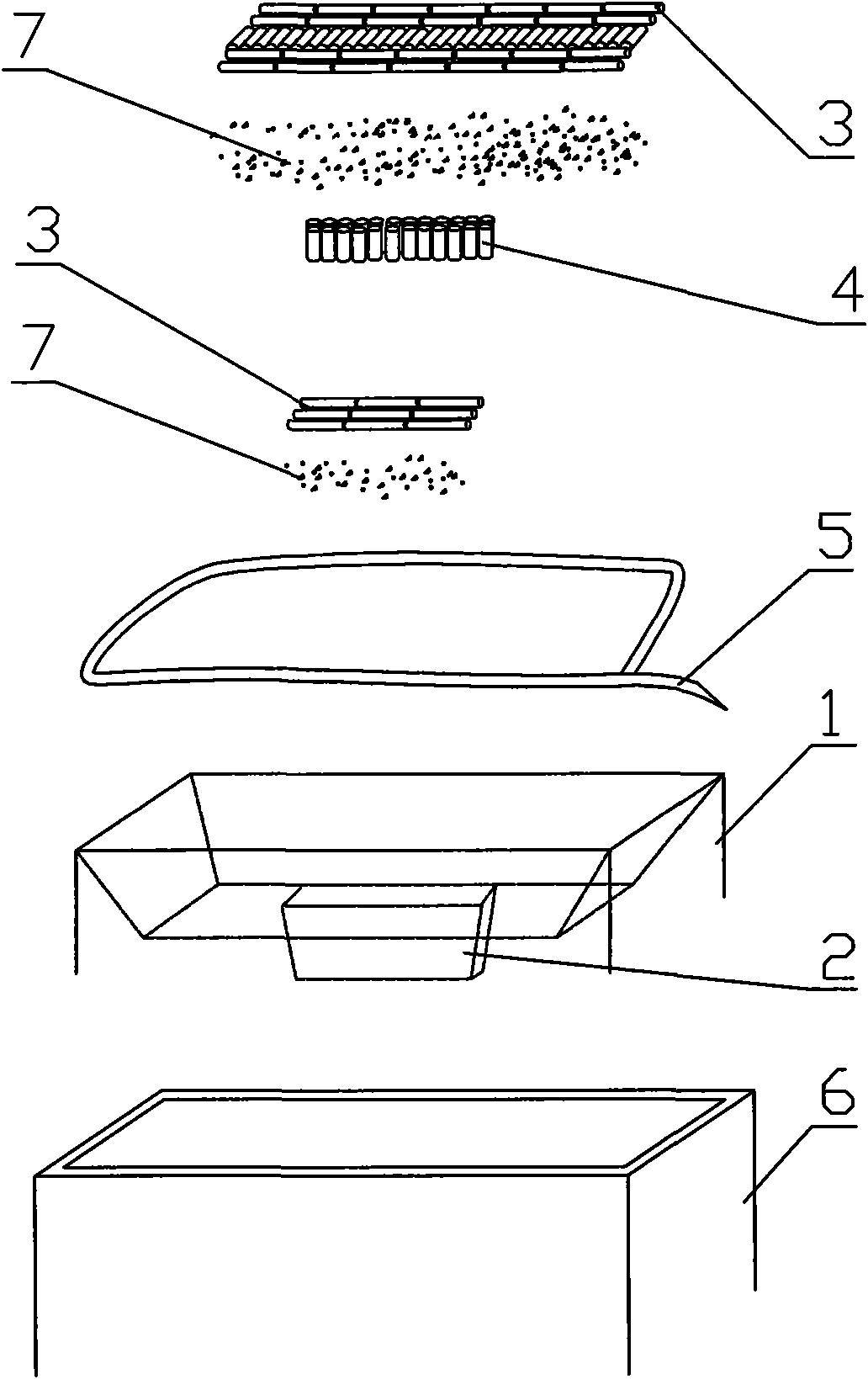

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] See figure 1 , a method for blocking the dummy head 1 with a slab that prevents start-up breakout when the casting blank is 200mm thick, the method may further comprise the steps:

[0019] 1) Use a paper rope 5 to block the gap between the dummy head 1 and the crystallizer 6;

[0020] 2) Evenly spread a layer of pins 7 on the bottom of the dovetail groove 2 of the dummy head 1 and the surface of the dummy head 1;

[0021] 3) Evenly spread a layer of short springs 4 on the bottom of the dovetail groove 2, and then place a layer of short springs 4 until the bottom of the dovetail groove 2 is filled;

[0022] 4) Arrange short springs 4 and long springs 3 on the surface of the dummy head regularly until the surface of the dummy head 1 is covered.

[0023] The material of the spring is made of Q235B steel to replace the cold iron block. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com