Cross construction method of replacing furnace shells and cooling walls of blast furnaces

A blast furnace shell and cross-construction technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as long construction time, achieve the effect of compressing the construction period, shortening the main line construction period, and realizing cross-construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In order to improve the efficiency of blast furnace maintenance and improve the production efficiency of the enterprise, a steel factory proposes a cross-construction method of blast furnace shell replacement and stave replacement. The steps are as follows:

[0038] A. Divide each ring of furnace shell to be replaced; because the height of each stave is fixed, and the height of each ring of staves is also fixed, then, for different blast furnaces, the height of each ring of staves is different. The height of the circle furnace shell is the same as that of each circle of staves. Each circle of furnace shell is divided into 8, 10 or 12 pieces. If the furnace shell is divided into more pieces, it will be necessary to replace multiple pieces of furnace shell, which will delay the construction period of the main line. , if the furnace shell is divided into fewer pieces, when replacing each piece of furnace shell, it will affect the overall structural strength of the blast fur...

Embodiment 2

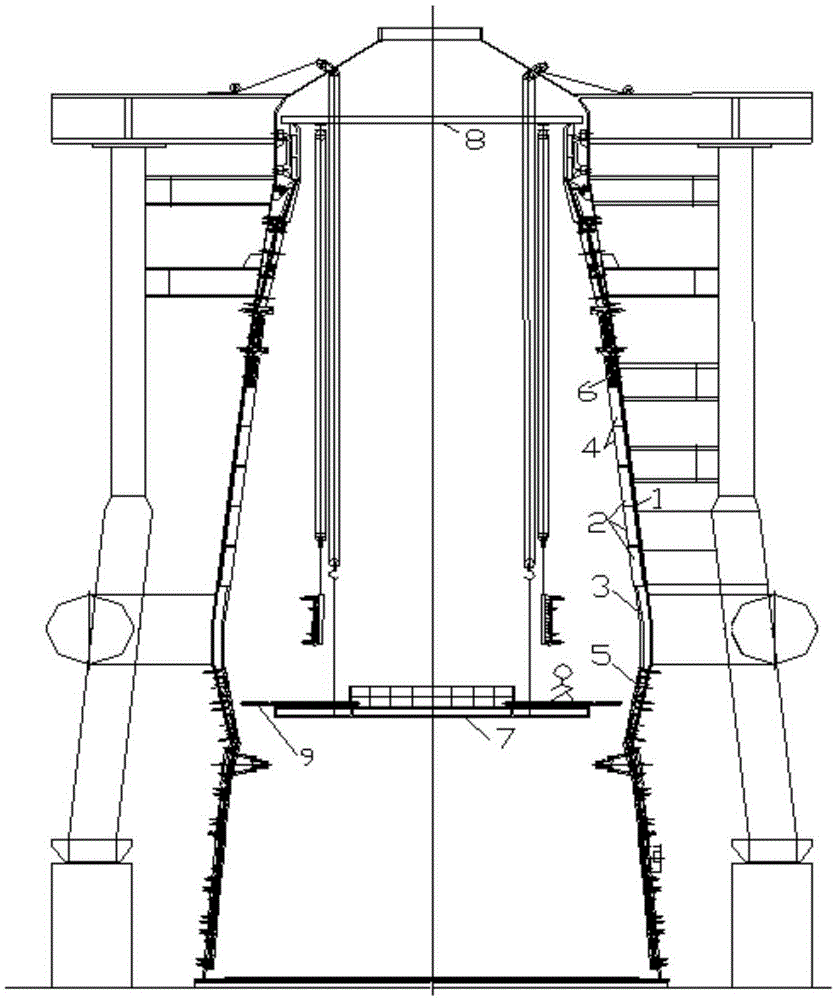

[0051] Such as figure 1 , the furnace shell 1 is the furnace shell to be replaced, the stave 1 2 is the stave to be replaced at the position of the furnace shell, the stave 2 3 and the stave 3 4 are the staves to be replaced, the stave 4 5 and the stave 5 6 For non-replaceable staves.

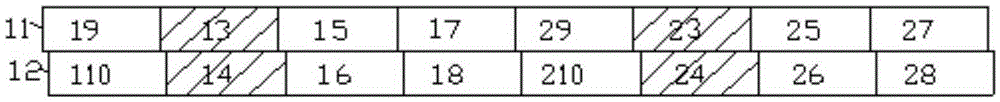

[0052] Such as figure 2 , the furnace shell 1 is divided into an upper ring furnace shell 11 and a lower ring furnace shell 12, both of which are divided into 8 pieces, and the upper ring furnace shell 11 is correspondingly divided into an upper block furnace shell 19, an upper block furnace shell Two 13, upper block furnace shell three 15, upper block furnace shell four 17, upper block furnace shell five 29, upper block furnace shell six 23, upper block furnace shell seven 25, upper block furnace shell eight 27 ;

[0053] The lower ring furnace shell 12 is correspondingly divided into lower block furnace shell one 110, lower block furnace shell two 14, lower block furnace shell three 16, l...

Embodiment 3

[0062] Overhaul of a certain number blast furnace of a steel company, replacing the 8th to 13th floor staves and the two rings of the furnace shell at the position of the 9th to 12th floor staves, the specific steps are:

[0063] 1. Shut off the wind, fetch water and cool the stove on the lowering surface;

[0064] 2. Straight blowing pipe, small and medium-sized sets are disassembled, and the griddle is dismantled, and the water pipe pad is dismantled and the 7-shaped board is welded at the same time;

[0065] 3. Assemble the movable hanging pan and hoisting ring beam in the furnace and put it in place;

[0066] 4. Remove staves from the 11th floor to the 8th floor;

[0067] 5. Lift the tray to the lower edge of the 12th floor stave, replace the 12th and 13th floor staves and replace the furnace shell at the 9th-11th floor stave;

[0068] 6. The 12th and 13th layers of stave mats are welded, and the furnace shell is continued to be replaced at the same time;

[0069] 7. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com