An adjustable inclined tube type hanging basket

An adjustable and tubular technology, applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of complex node connection, large space size of high tower body, etc., and achieve high reliability and convenience fastening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

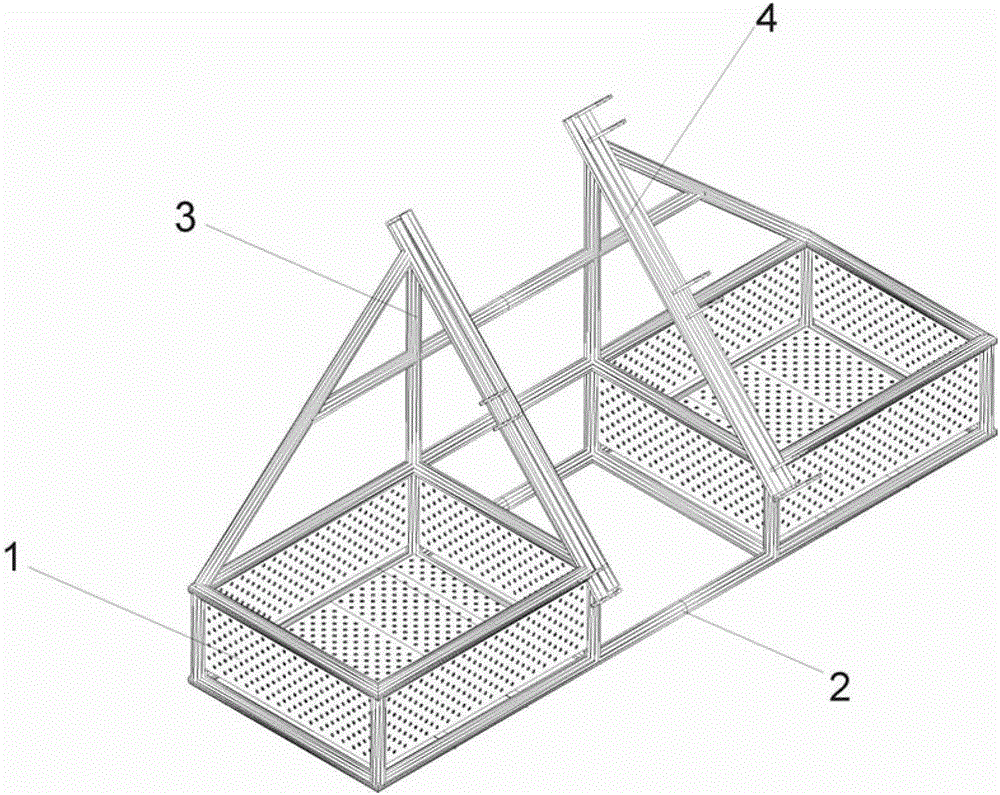

[0020] Such as figure 1 As shown, an adjustable inclined tube hanging basket described in this embodiment includes two standing platforms 1 fixed to each other horizontally through a plurality of cross bars 2, and one side of the two standing platforms 1 is fixed to each other. Longitudinal guide rods 3, the other sides of the two station platforms 1 are respectively fixed with a diagonal rod 4, the free ends of the diagonal rods 4 are connected with the free ends of the guide rods 3, and the two diagonal rods 4 are Multiple cable tie tightening devices are provided. The guide rod 3 is arranged on a corner of the station platform 1 , and the inclined rod 4 is arranged on an adjacent corner of the station platform 1 .

Embodiment 2

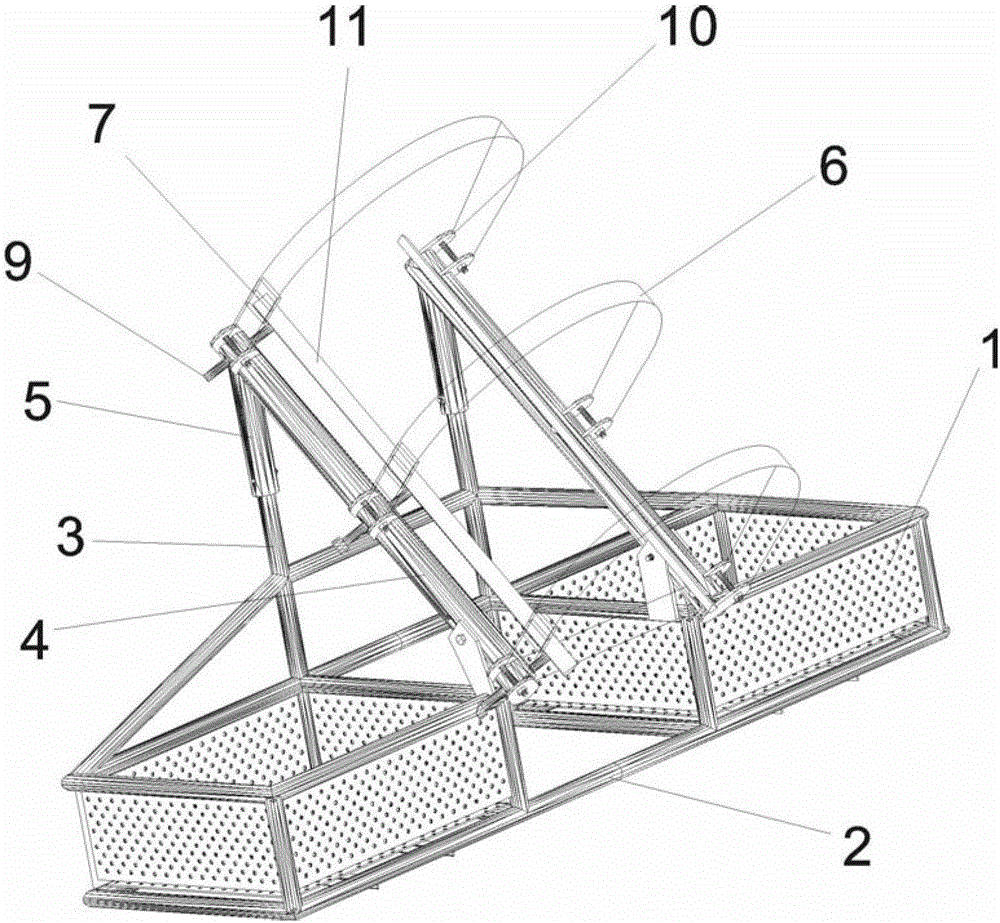

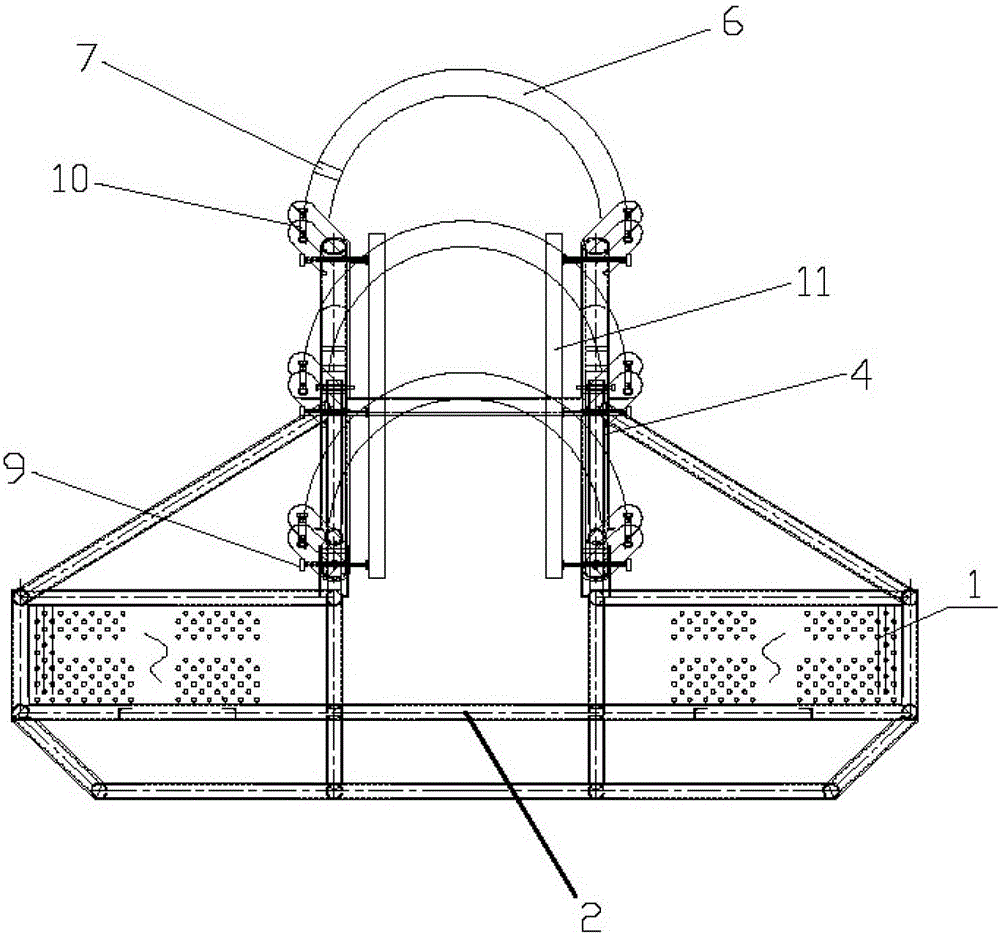

[0022] Such as Figure 2-Figure 5 As shown, the two oblique rods 4 of the present technical solution can be adjusted to connect with a push rod 11 respectively. The connecting end of the guide rod of the inclined rod 4 is affixed to a longitudinal conduit 5, and the conduit 5 is sleeved outside the guide rod 3, and the conduit 5 and the guide rod 3 are respectively provided with corresponding pin holes and passed through a The latch fixes the conduit 5 and the guide rod 3.

[0023] The cable tie tightening device includes a tightener 7 arranged on one oblique bar 4 and a cable tie 6 affixed to the other oblique bar 4, the free end of the cable tie 6 is connected to the corresponding tightener 7 connection, the cable tie 6 surrounds the outer ring of the inclined pipe 8 and is tightened by the tightener 7, so that the hanging basket is tightly fixed on the inclined pipe 8. The inclined rod 4 and the push rod 11 are connected through the adjusting screw 9, and the cable tie 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com