Double-ended filling conveying line

A conveying line and filling technology, applied in the field of double-head filling conveying line, can solve the problems of workers' health impact, working environment pollution, slow filling process, etc., to improve filling efficiency, avoid environmental pollution, and improve assembly. The effect of precision and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

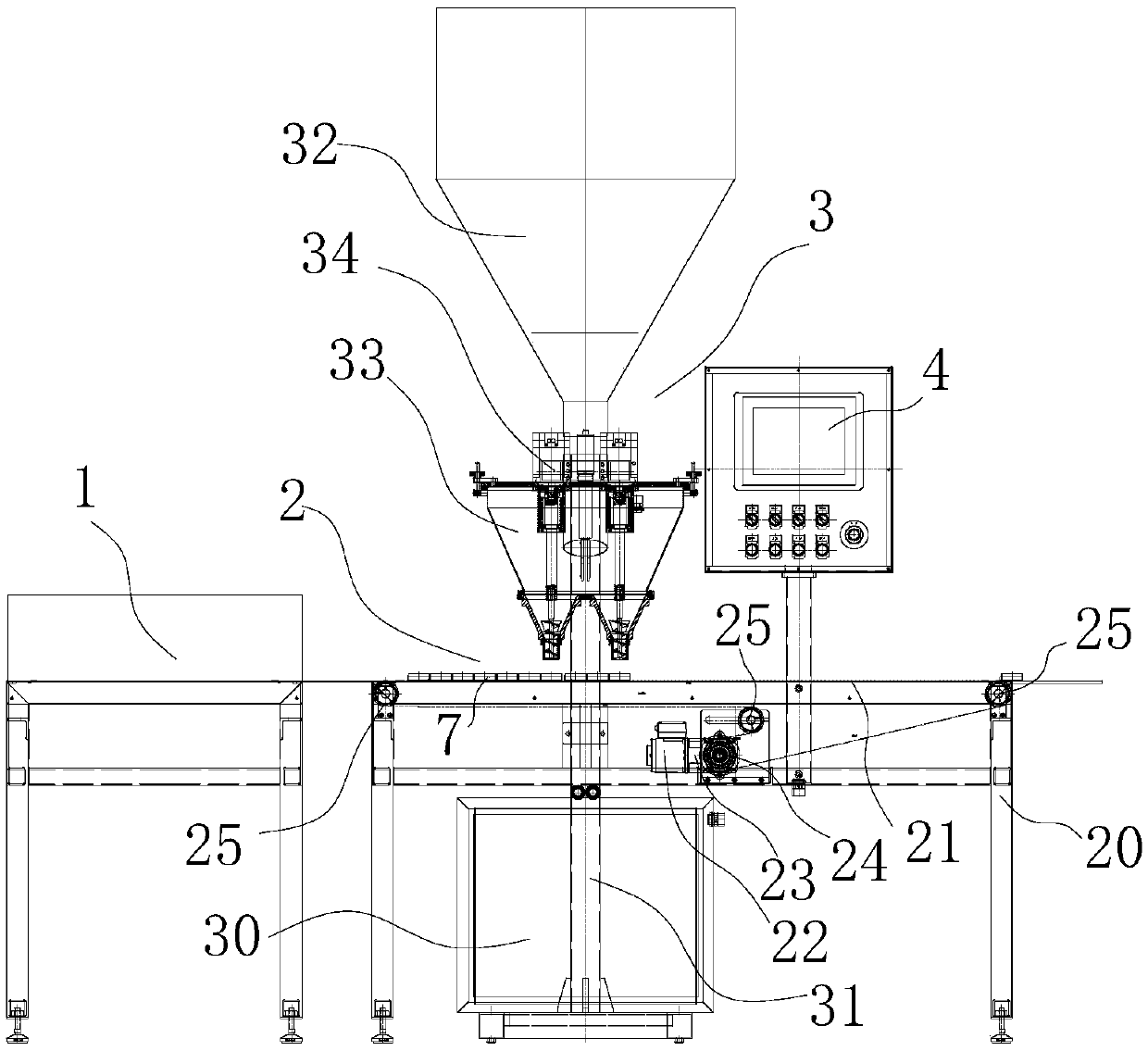

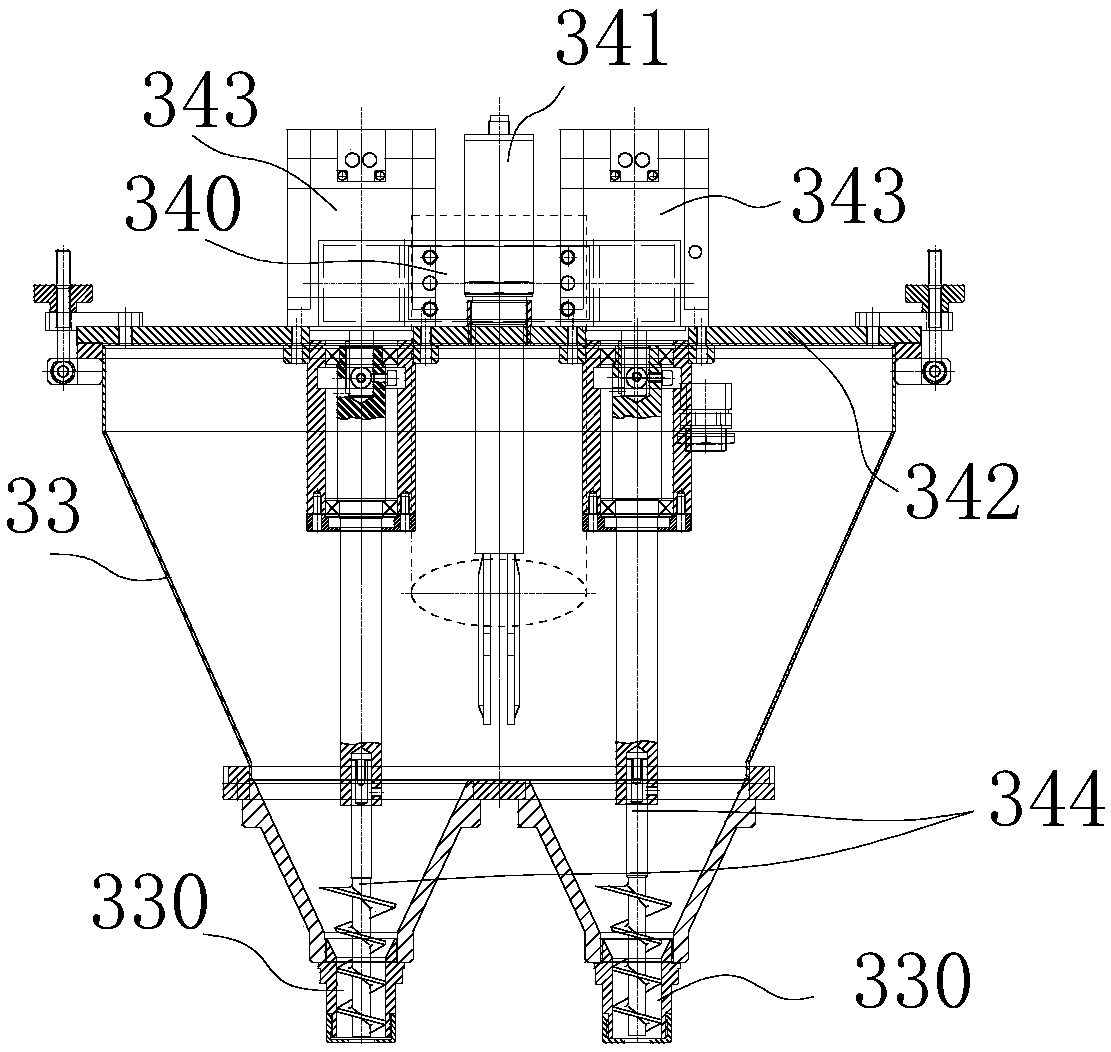

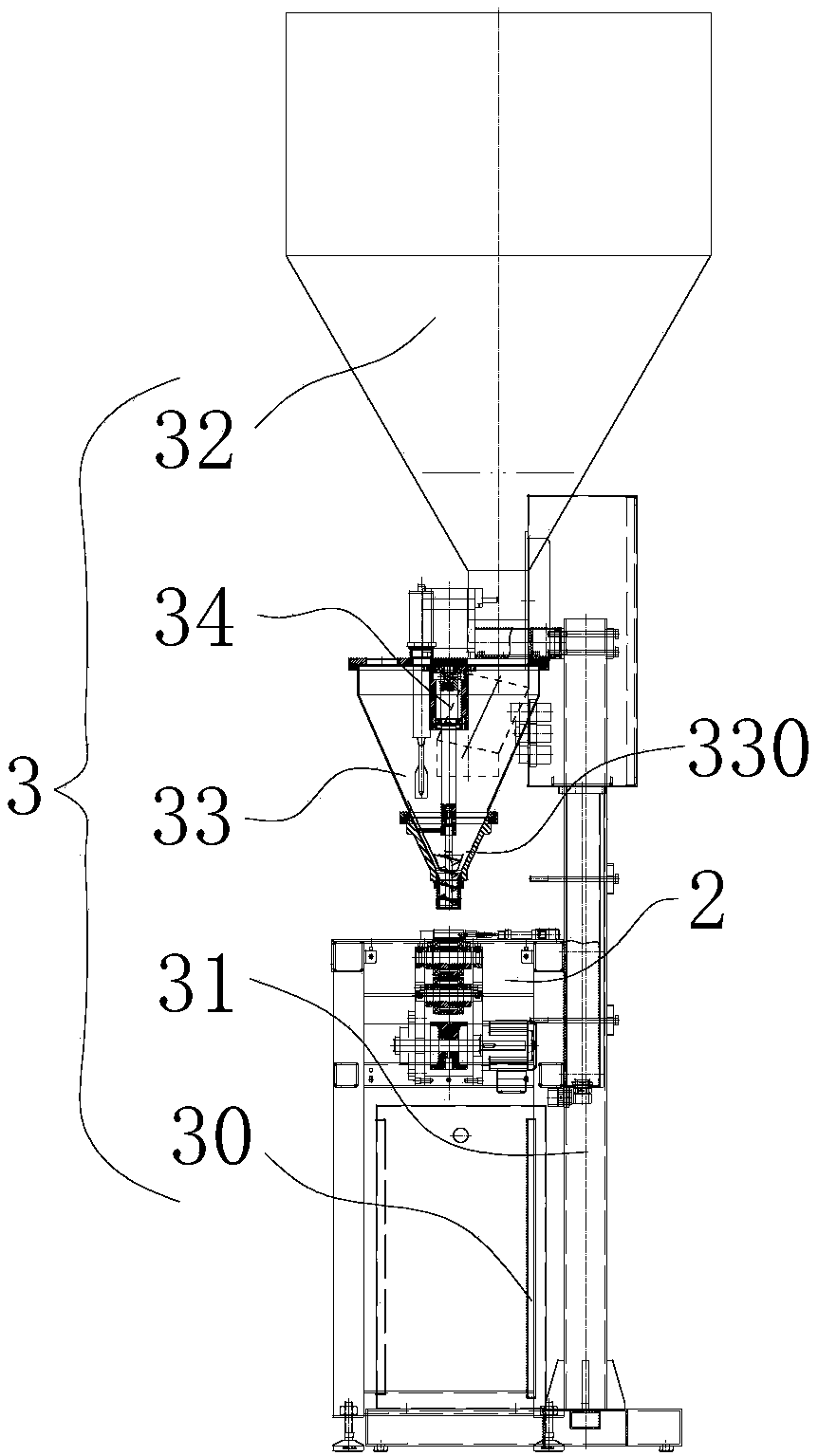

[0026] Double head filling conveyor line, such as Figure 1 to Figure 5 As shown, it is applied to the production and packaging of granules, powders, semi-fluid substances or liquid substances, including a filling container finishing machine 1, a conveying mechanism 2, a set of filling machines 3 and a display control panel 4, the conveying The mechanism 2 is used for the input of the cavity to be filled before filling and the output of the cavity after filling; The cavity is automatically pushed to the conveyor belt of the conveying mechanism 2 in an orderly manner; the group of filling machines 3 is set on the upper side of the conveyor belt of the conveying mechanism 2, and each time one or two cavities to be filled on the conveyor belt The display control panel 4 is installed on one side of the conveyer belt on the conveying mechanism 2; the control system of the display control panel 4 is connected with the filling container finishing machine 1, the conveying mechanism 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com