Elastic positioning adjusting device for conical pulley

An elastic positioning and adjusting device technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the design requirements that cannot meet the miniaturization and lightness of welding trolleys and rails, and increase the design of welding trolleys and rails. Size, can not meet the steel pipe welding requirements and other issues, to achieve a wide range of position adjustment work anti-loose function, improve assembly accuracy and stability, and meet the effect of design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

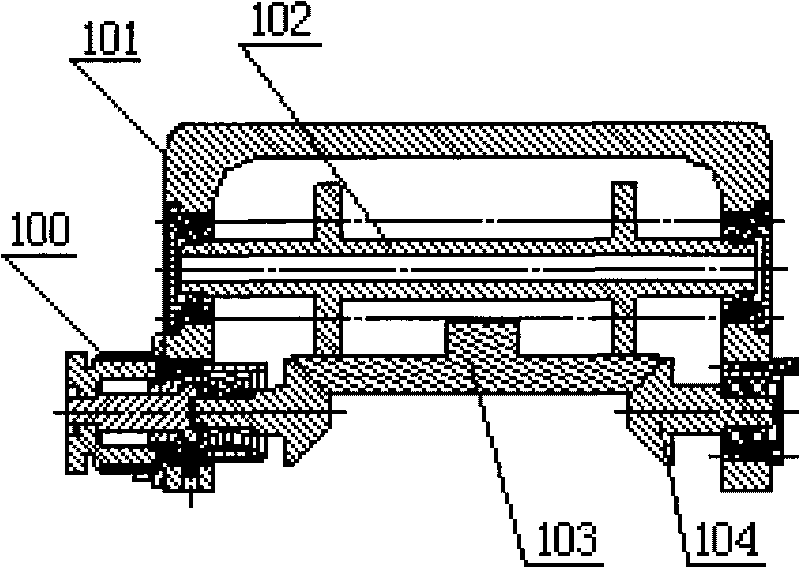

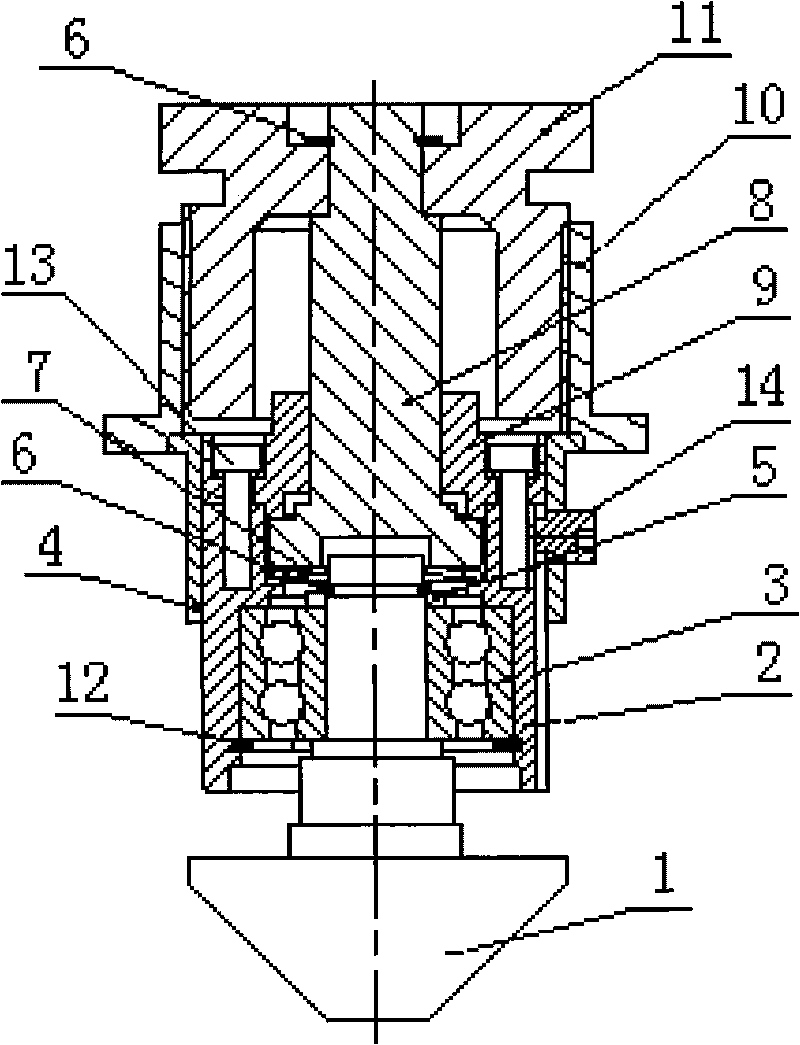

[0021] Taking a cone wheel elastic positioning adjustment device for an automatic welding trolley with a T-shaped joint of a jacket as an example, the present invention will be further described in detail.

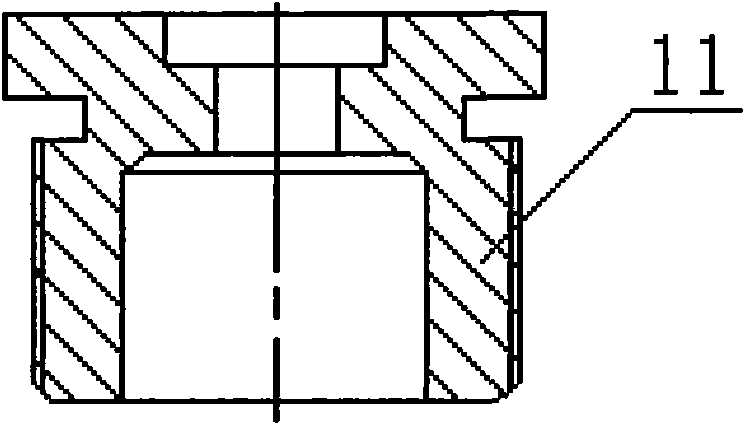

[0022] refer to figure 1 . The elastic positioning adjustment device of the cone wheel is mainly composed of the cone wheel shaft 1, the cone wheel shaft sleeve 2, the double row angular contact bearing 3, the copper sleeve 4, the bearing inner ring stop pad 5, the shaft circlip 6, the disc spring 7, and the floating shaft 8 , Bushing gland 9, adjusting mounting seat 10, adjusting hand wheel 11, circlip 12 for hole, fastening screw 13 and limit screw 14 are composed.

[0023] refer to Figure 9 . The cone shaft 1 is a stepped shaft whose lower end is a frustum, and the slope of the cone shaft 1 is 45 degrees. There is a retaining ring groove for the shaft at the upper end of the cone wheel shaft 1 . refer to figure 2 . A double-row angular contact bearing 3 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com