Patents

Literature

32results about How to "Meet the rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

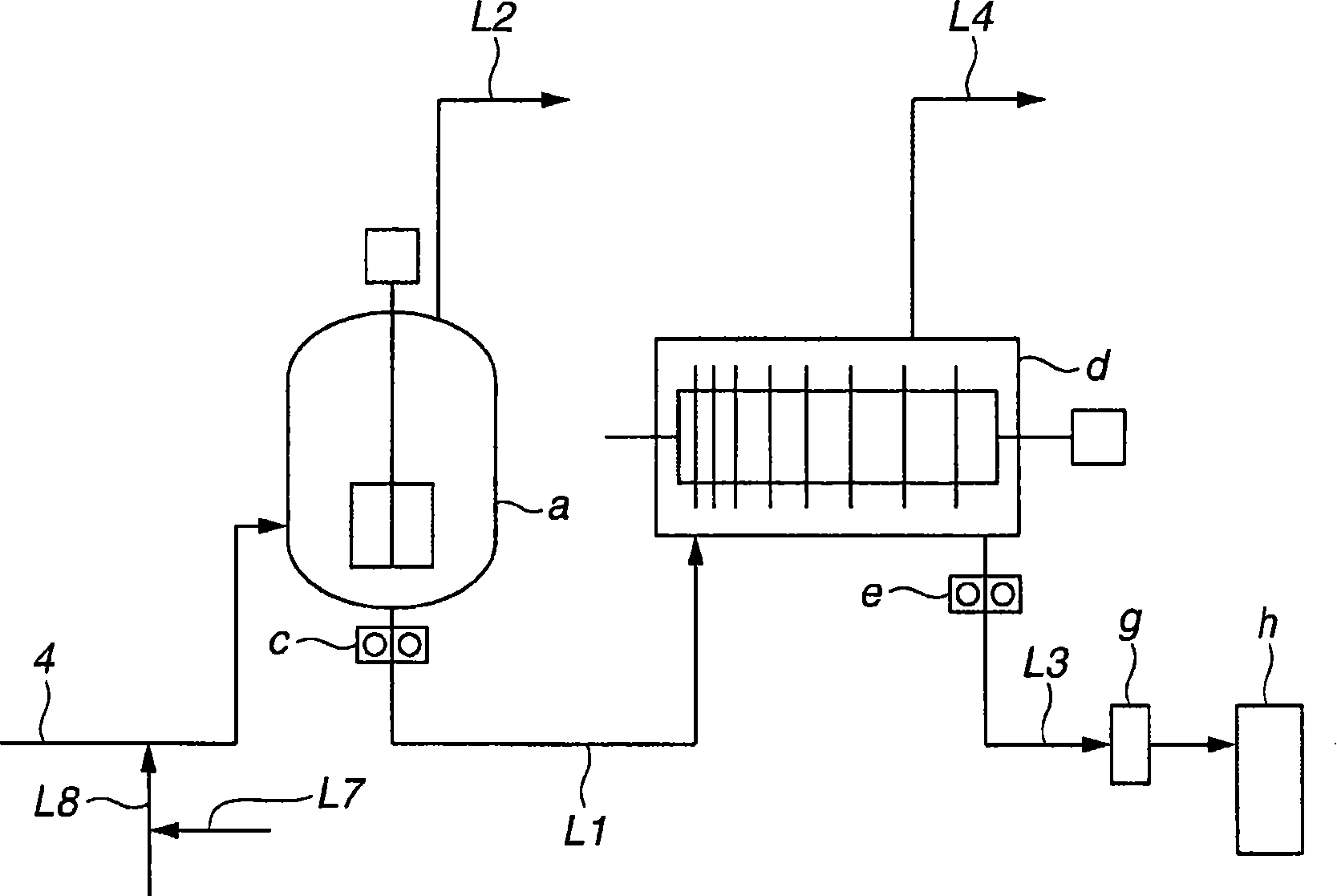

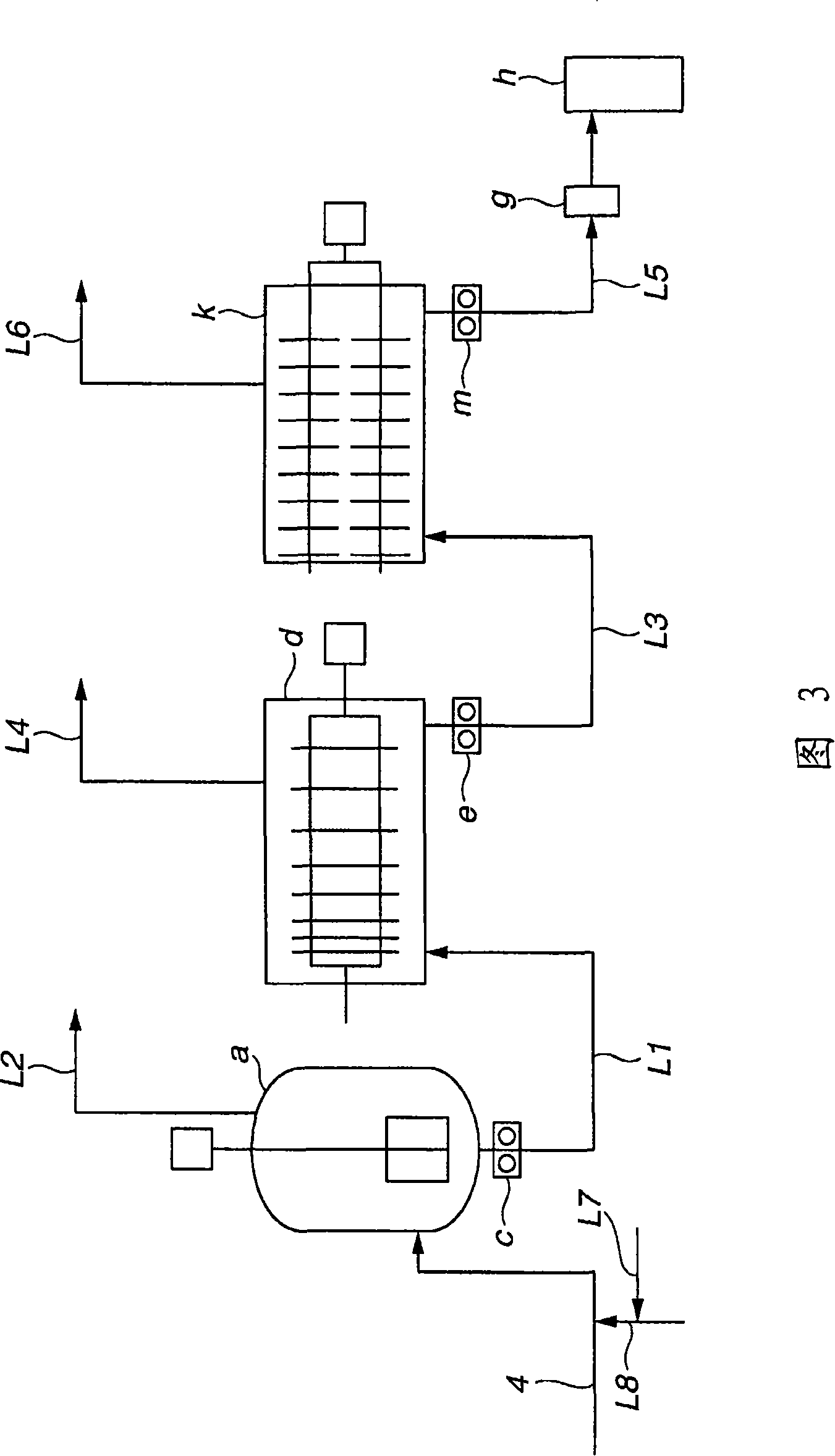

Method for preparing high-rigidity chlorinated polyethylene

The invention discloses a method for preparing high-rigidity chlorinated polyethylene by using a hydrochloric acid phase process, which comprises the following steps: adding high-density polyethylene, dispersing agent and anti-adhesion agent in hydrochloric acid solution in a stirring state to prepare suspension; feeding in chlorine into the suspension in two stages for implementing chlorination reaction, with the reaction temperature being from 30 to 140 DEG C, the reaction time being from 3-5 hours and the feed-in amount of the chlorine being 0.5-1.2 times as large as the weight of the high-density polyethylene; afterwards, separating, washing, dehydrating and drying the chlorinated products to result in the high-rigidity chlorinated polyethylene product with 20-35wt% of the chlorine content, DSC which is not more than 5J / g, 60-80 of Shore hardness and more than 2.0MPa of 100% modulus at definite elongation. The high-rigidity chlorinated polyethylene prepared according to the method can take the place of high-price MBS to serve as an anti-impact modifier of hard PVC articles and meet the demands of materials about rigidness and toughness.

Owner:WEIFANG YAXING GRP CO LTD +1

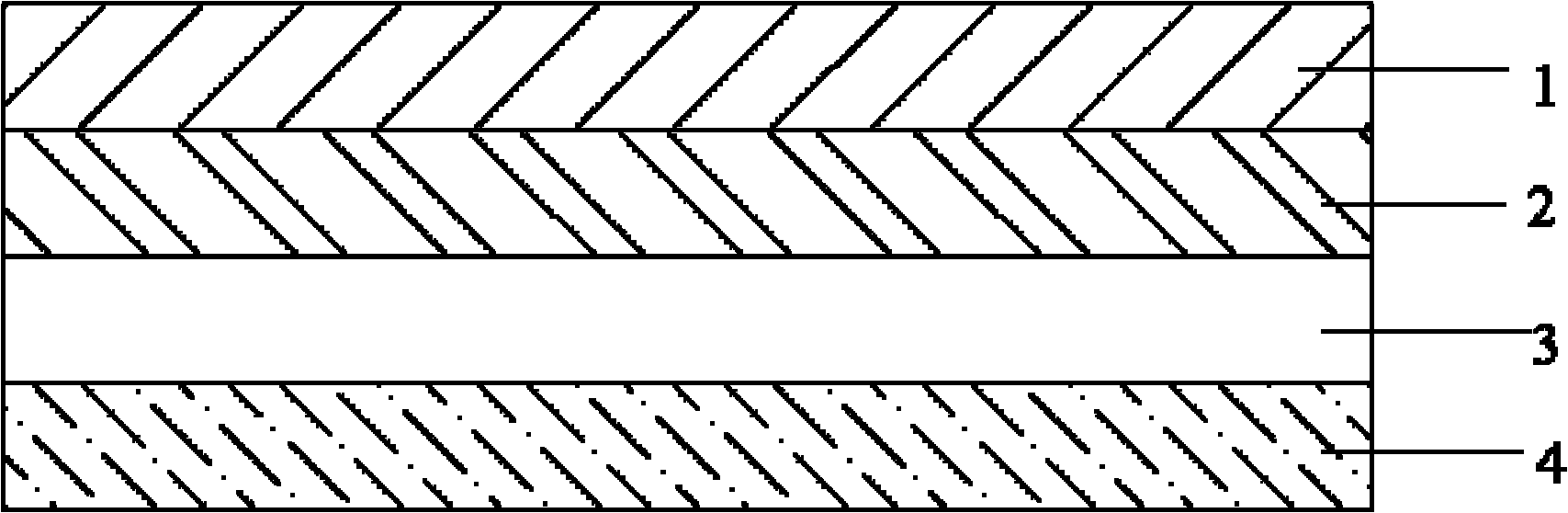

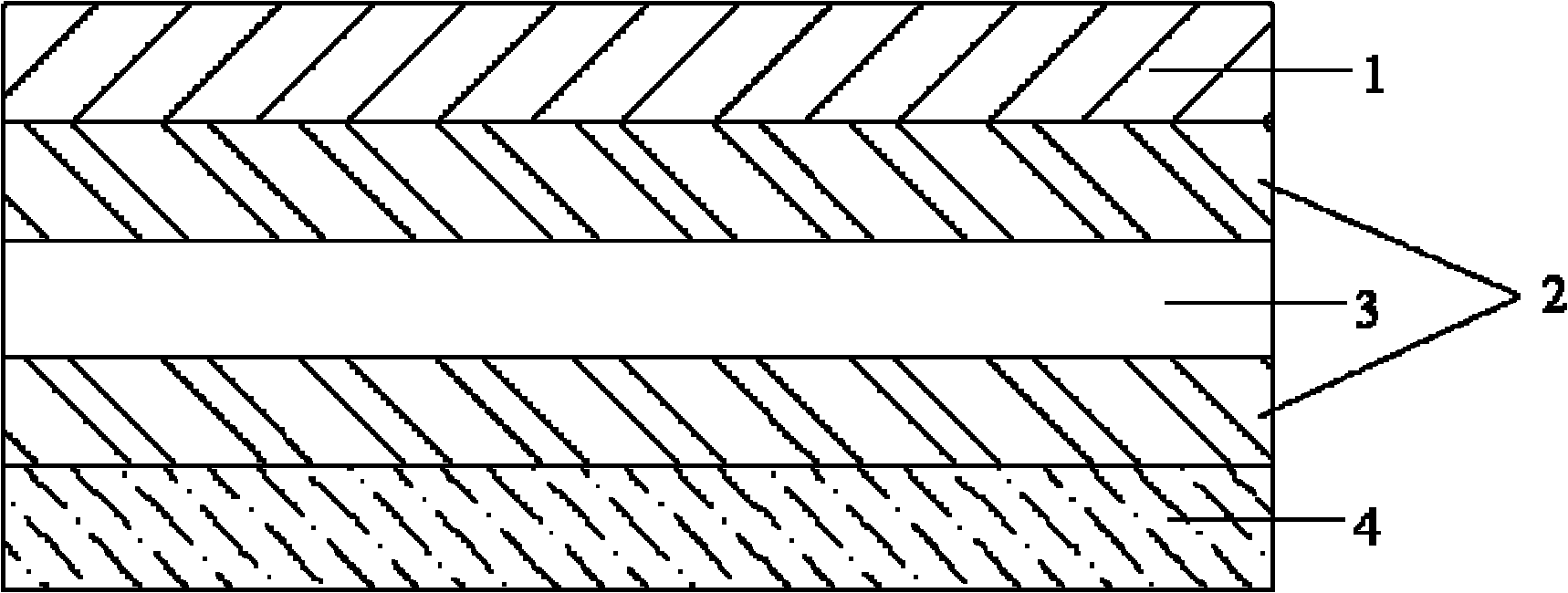

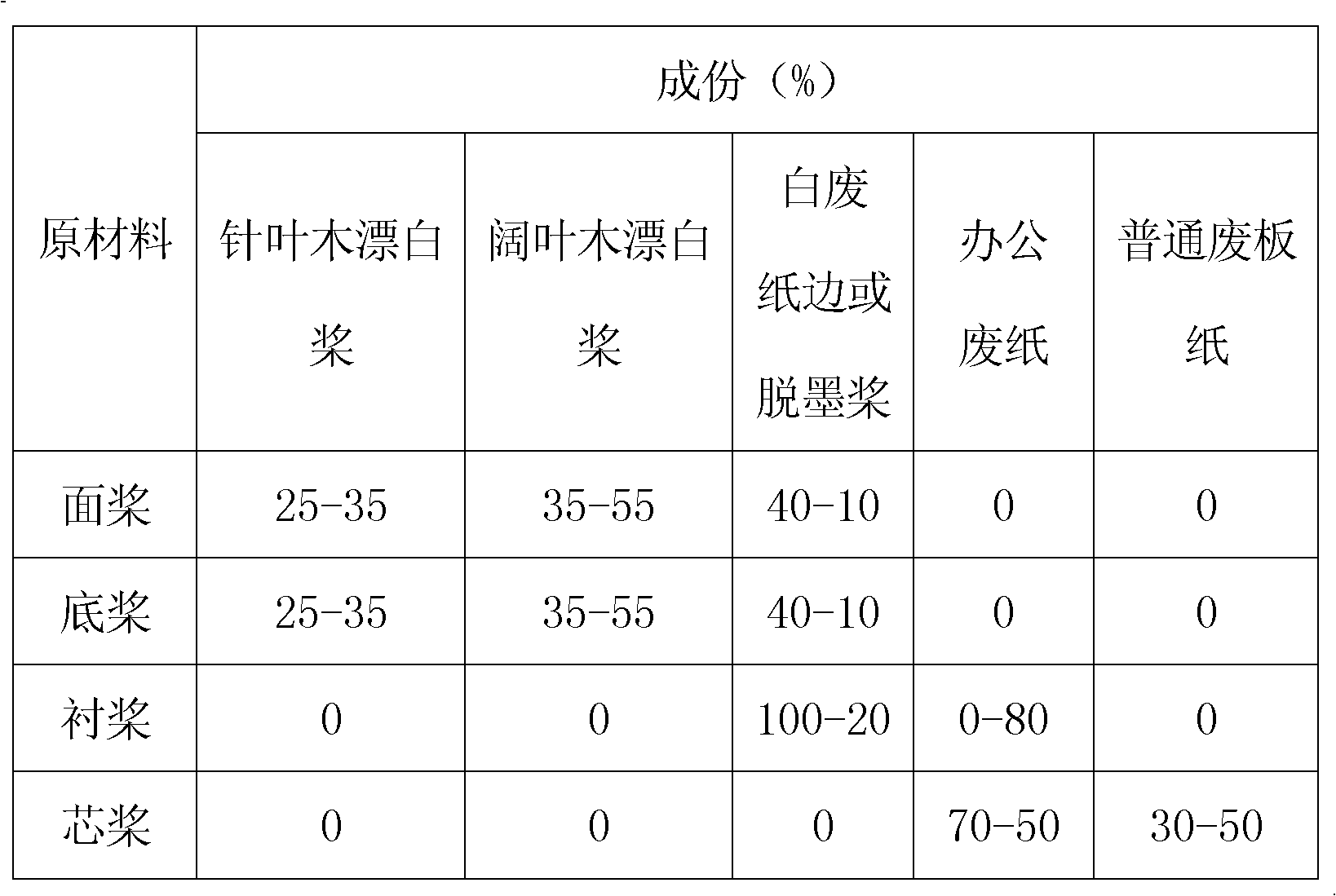

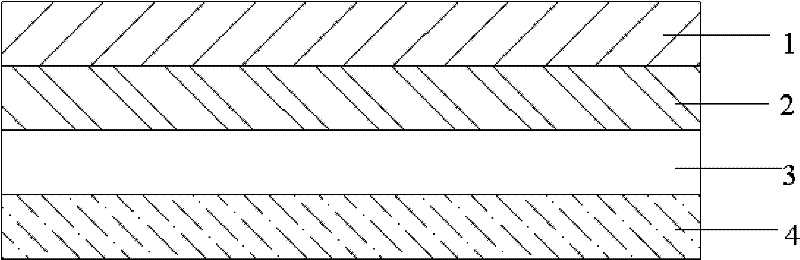

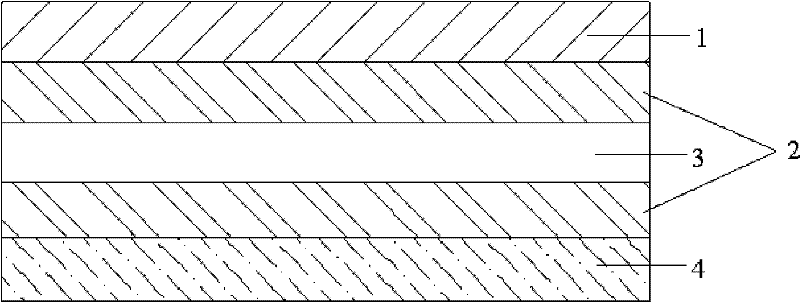

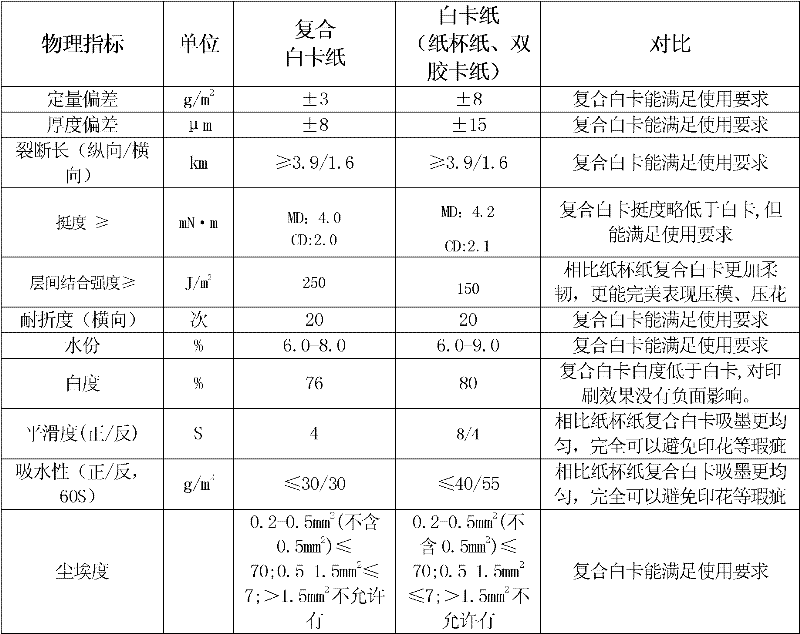

Double-sided composite card paper and preparation method thereof

InactiveCN101818466AFeel thickCrisp paperSpecial paperWaste product additionEconomic benefitsEngineering

The invention provides double-sided composite card paper and a preparation method thereof. A lining pulp layer is covered on one side of a core pulp layer, a bottom pulp layer is covered on the other side of the core pulp layer and a surface pulp layer is covered on the lining pulp layer; or lining pulp layers are covered on two sides of a core pulp layer, a surface pulp layer is covered on the lining pulp layer on one side, and a bottom pulp layer is covered on the lining pulp layer on the other side. Common waste paper pulp (office waste paper, common waste paper boards and the like) is used for replacing wood pulp to serve as core pulp, and waste paper de-inking pulp and waste white paper edge pulp are used for replacing wood pulp to serve as lining pulp so as to save the cost; each layer is specifically quantified; and the obtained double-sided composite card paper has heavy handfeel and crisp paper surface, press molding and embossing processes required for processing and molding have better implementing effects, the expressed levels are richer, the dependency of the product on operating workers is furthest reduced, and effective expansion of the capacity and increment of the economic benefit are furthest realized.

Owner:CHANGSHA TIANTIAN PAPER

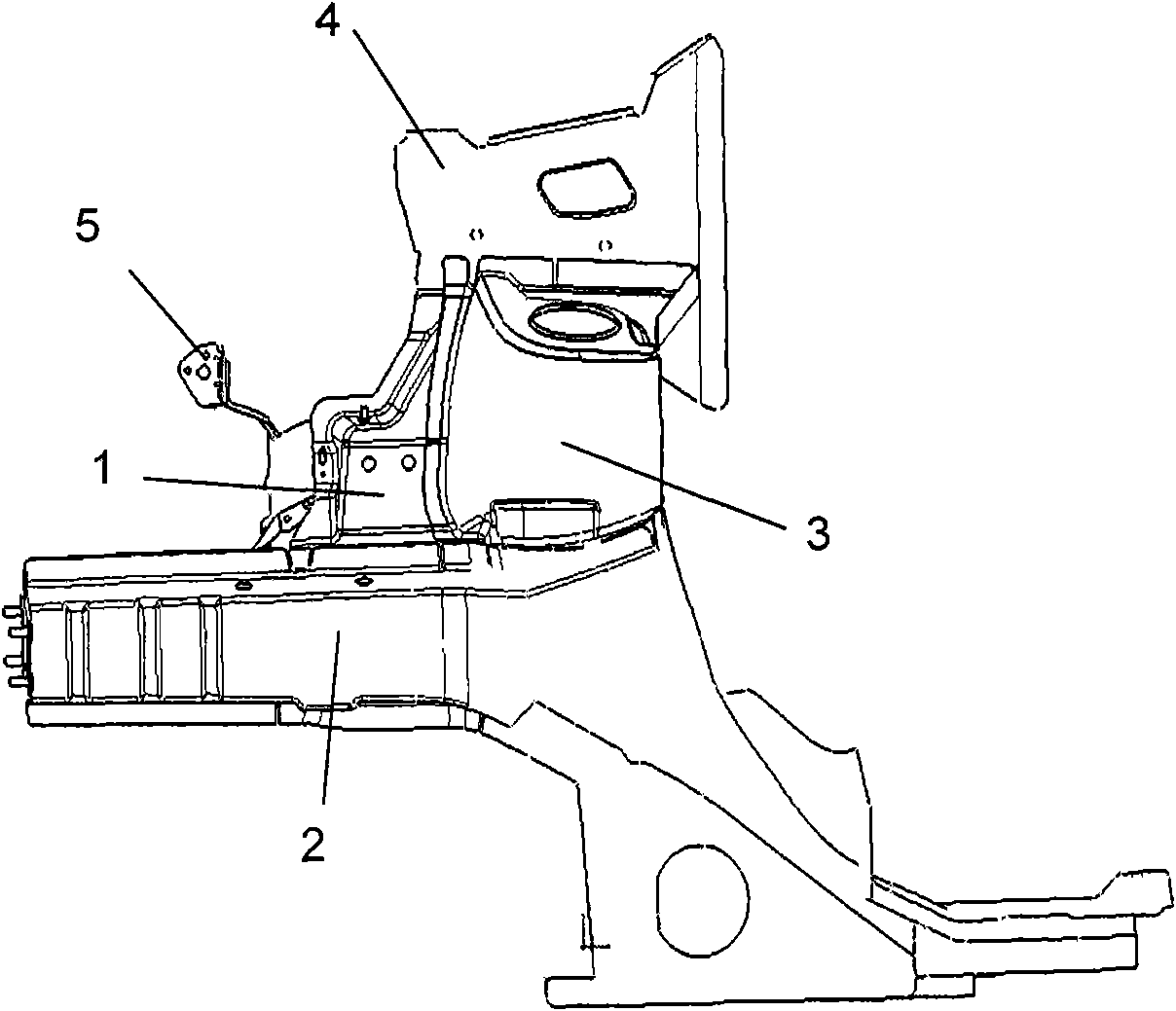

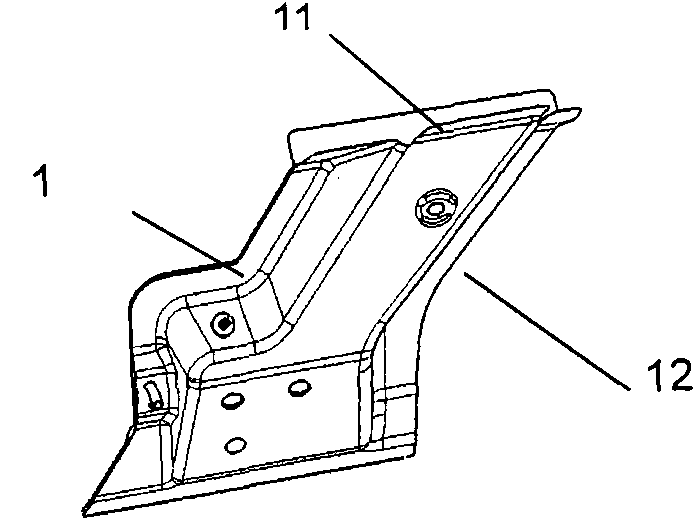

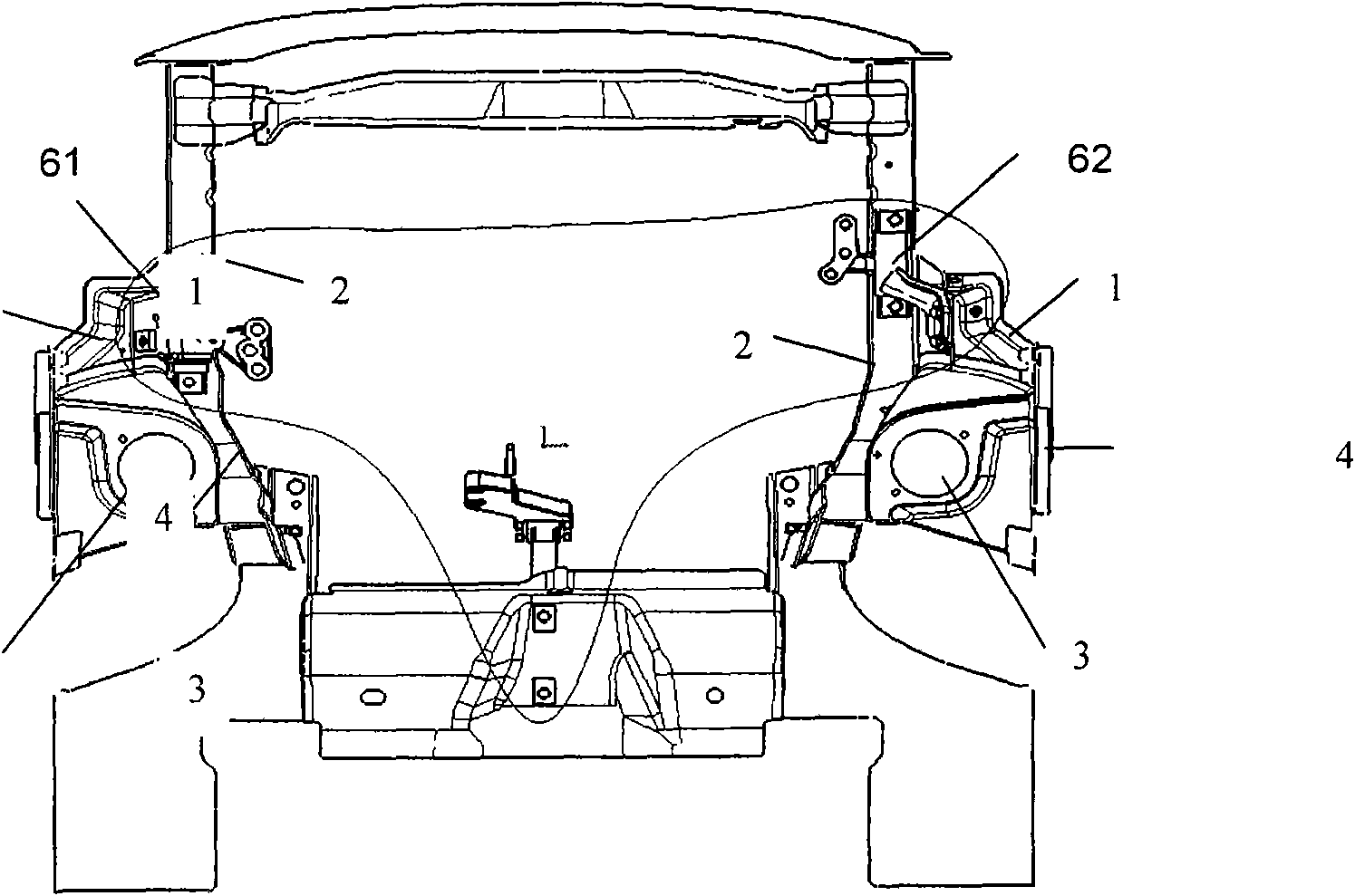

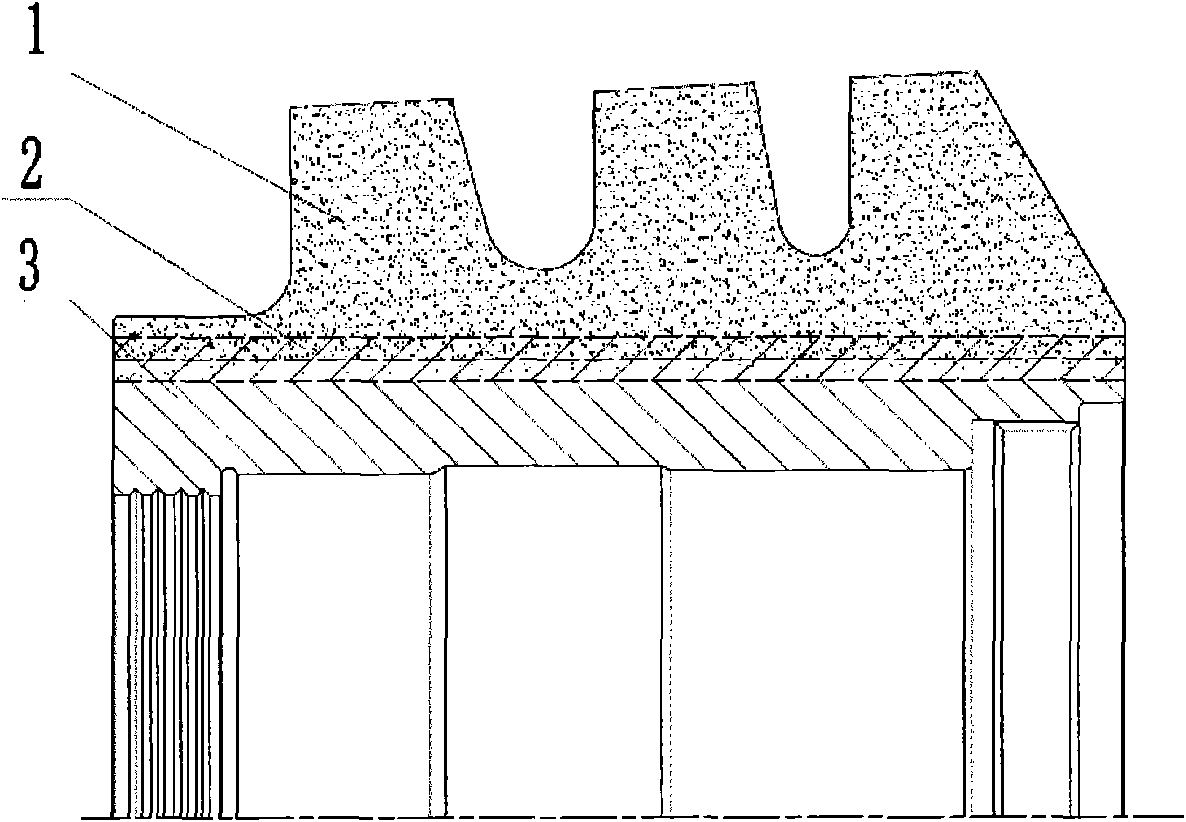

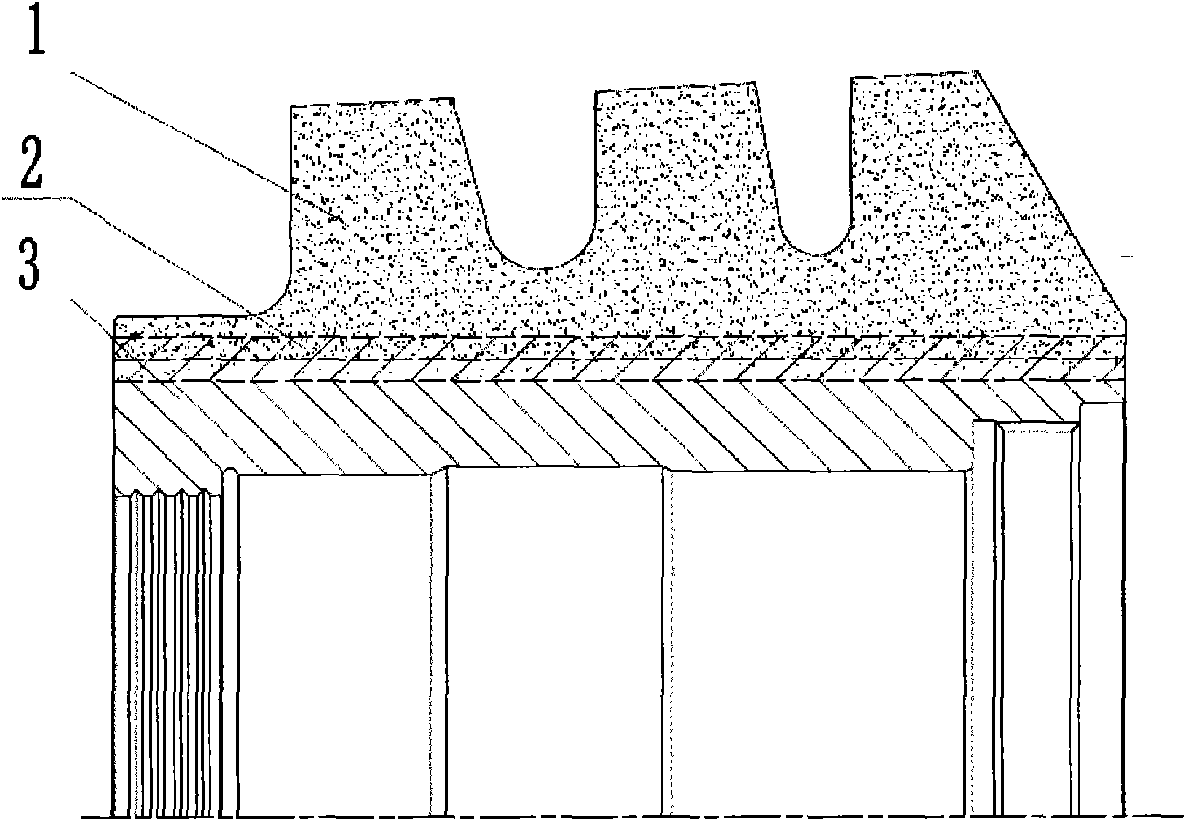

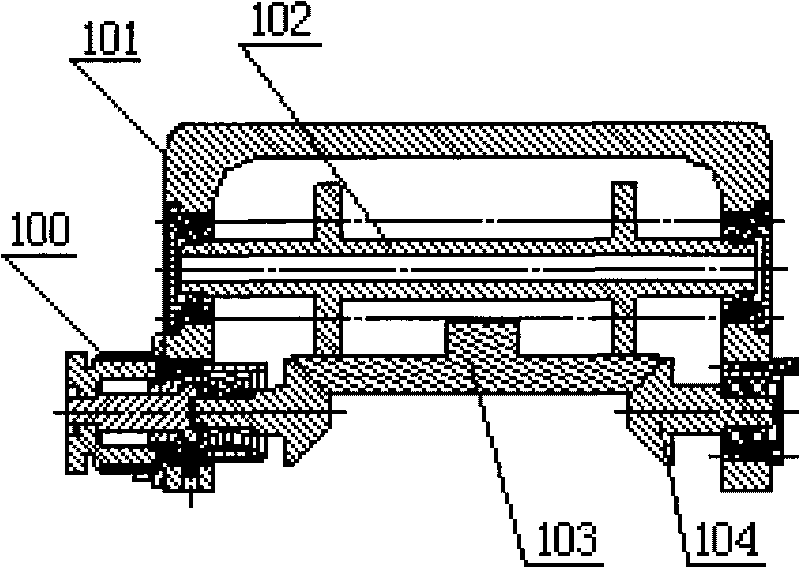

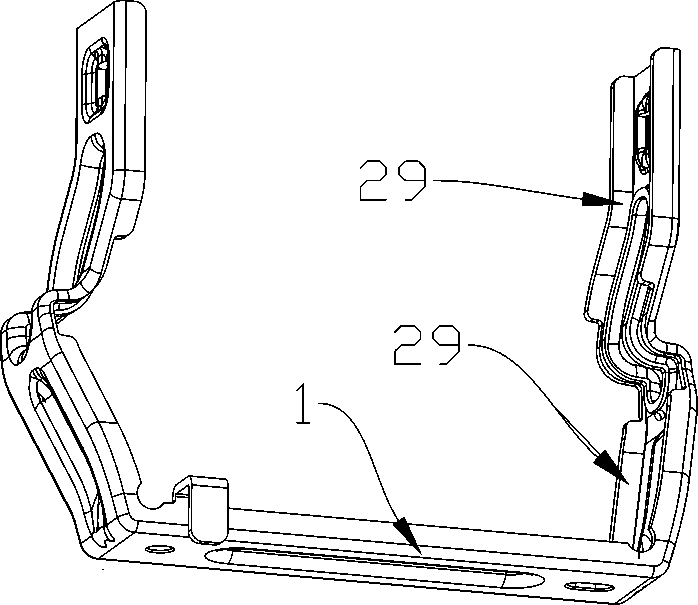

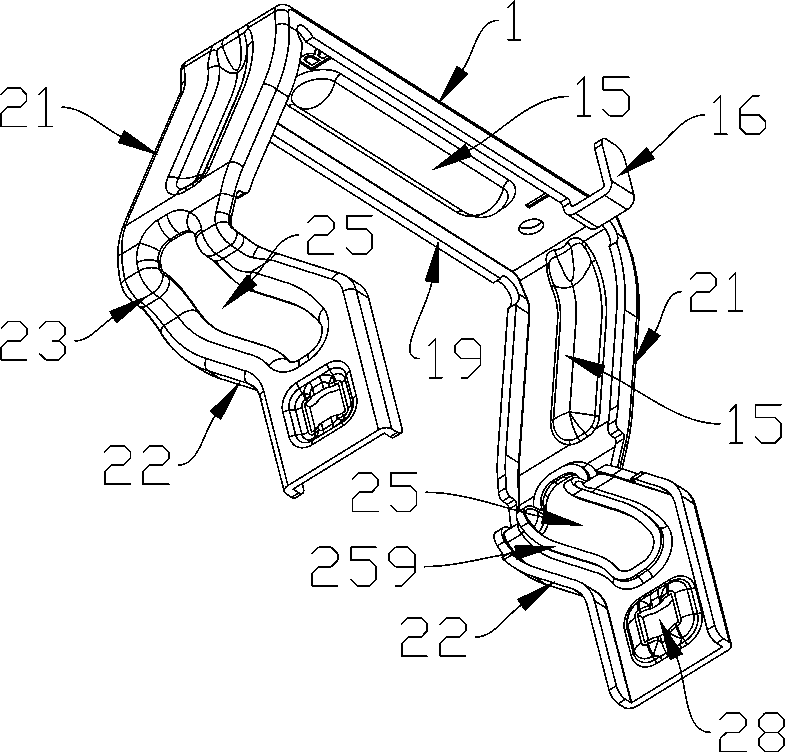

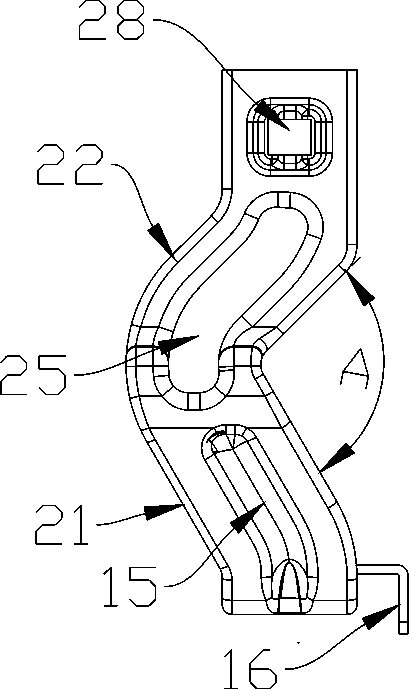

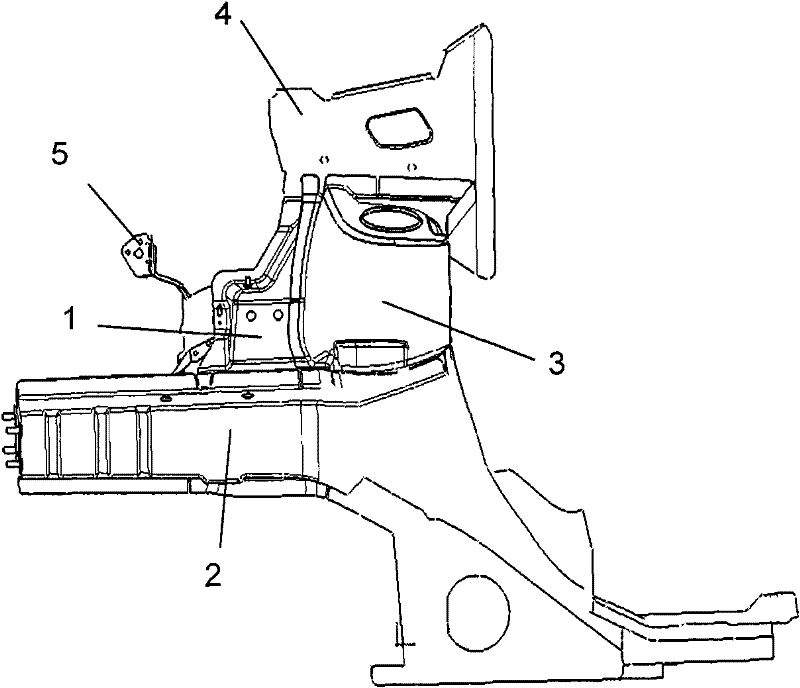

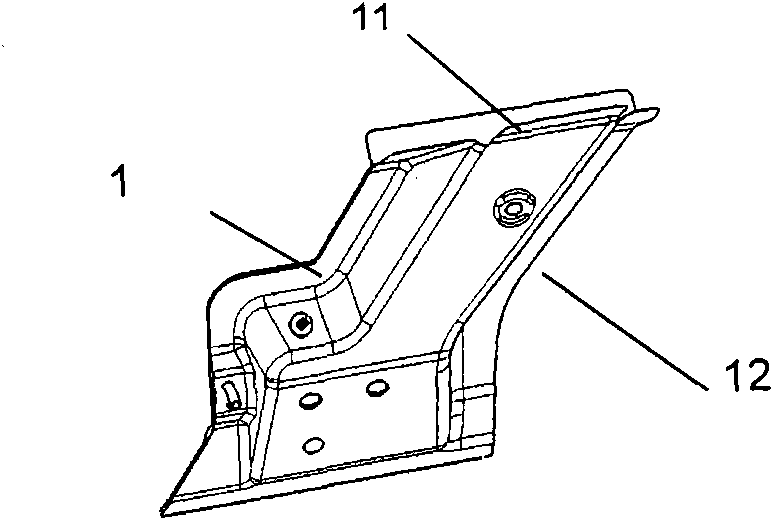

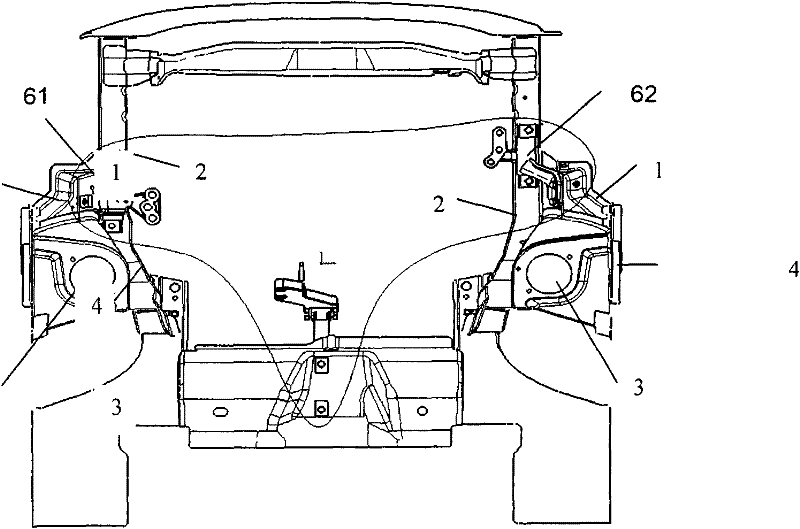

Front wheel cover side plate assembly for automobile

InactiveCN101863288AMeet the rigidityGuaranteed installation strengthSuperstructure subunitsMonocoque constructionsEngineeringFront edge

The invention discloses a front wheel cover side plate assembly for an automobile. The assembly comprises a front wheel cover side plate, a front longitudinal beam, a front shock absorber mounting plate, a connecting plate and a front fender mounting bracket which are arranged on the automobile body in a lateral symmetry way, wherein the front wheel cover side plate has a cavity structure with a top opening; the upper edge of the front longitudinal beam is fixedly connected to the lower end of the front wheel cover side plate; the front edge of the front shock absorber mounting plate is fixedly connected to the rear edge of the front wheel cover side plate; the connecting plate is fixedly connected with the upper end of the front wheel cover side plate and the upper end of the front shock absorber mounting plate respectively to form a closed cavity; the rear edge of the front fender mounting bracket is fixedly connected with the front edge of the front wheel cover side plate; and the lower end of the front fender mounting bracket is fixedly connected with the upper edge of the front longitudinal beam. The assembly not only rationally and effectively transfers the impact load from the front longitudinal beam to the rear part and the upper part of the automobile body during direct impact and biasing impact, but also ensures the installation strength, the accuracy and the NVH performance of the installation points on the left and the right suspension sides of an engine and the front fender mounting bracket.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

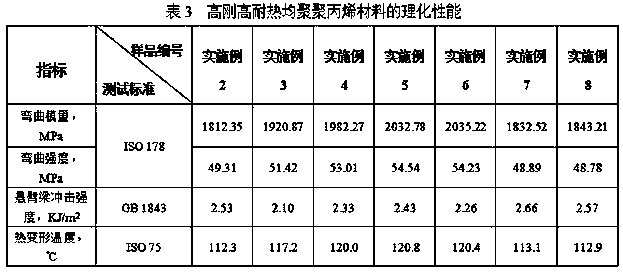

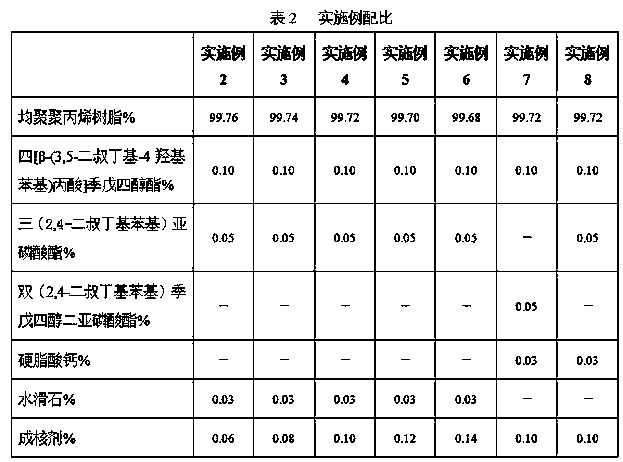

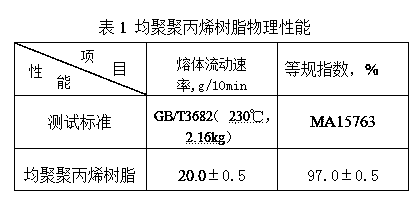

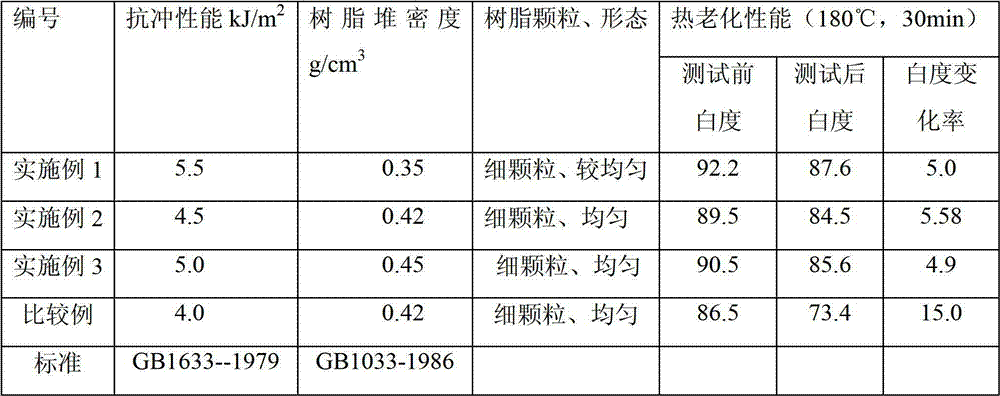

High-rigidity high-heat-resistance homo-polypropylene material and preparation method thereof

ActiveCN103554660AImprove adjustabilityImprove melt fluidityHeat deflection temperaturePtru catalyst

The invention discloses a high-rigidity high-heat-resistance homo-polypropylene material which is prepared from the following raw materials: a homo-polypropylene resin, an antioxidant, a halogen absorbent and a nucleating agent. The homo-polypropylene resin is prepared by the following steps: adding the raw material propylene into a loop reactor, adding the catalyst, cocatalyst, electron donor and antistatic agent, and uniformly stirring, wherein the reaction temperature in the loop reactor is controlled at 70+ / -1 DEG C, the reaction pressure is controlled at 3.4-3.8 MPa, and the hydrogen concentration is controlled at 3500-4500 ppm. The invention also discloses a preparation method of the high-rigidity high-heat-resistance homo-polypropylene material. The high-rigidity high-heat-resistance homo-polypropylene material has higher melt index, bending modulus and heat-deformation temperature, and can satisfy the raw material requirements of injection molding manufacturers of small home appliances, automobiles and the like.

Owner:CHINA PETROLEUM & CHEM CORP

High-tensile-strength impact modifier for PVC (polyvinyl chloride) and preparation technique thereof

The invention belongs to the technical field of preparation of PVC (polyvinyl chloride) impact modifiers, and particularly relates to a high-tensile-strength impact modifier for PVC and a preparation technique thereof. The preparation technique comprises the following steps: grafting epoxypropyl methacrylate onto a polyethylene main chain in the presence of a grafting assistant, and carrying out chlorination modification by an acid-phase process to obtain the high-tensile-strength impact modifier for PVC. The impact modifier for PVC can be widely used in the fields of PVC profiles, tubes and plates, can be used instead of high-price acrylate impact modifiers in the aspects of shock resistance and tensile property, and greatly enhances the weather resistance and working properties of the PVC product. The invention satisfies the performance requirements for rigidity, weather resistance, dimensional stability and the like, and the production process is green and environment-friendly and is easy to control.

Owner:SHANDONG RUIFENG CHEM

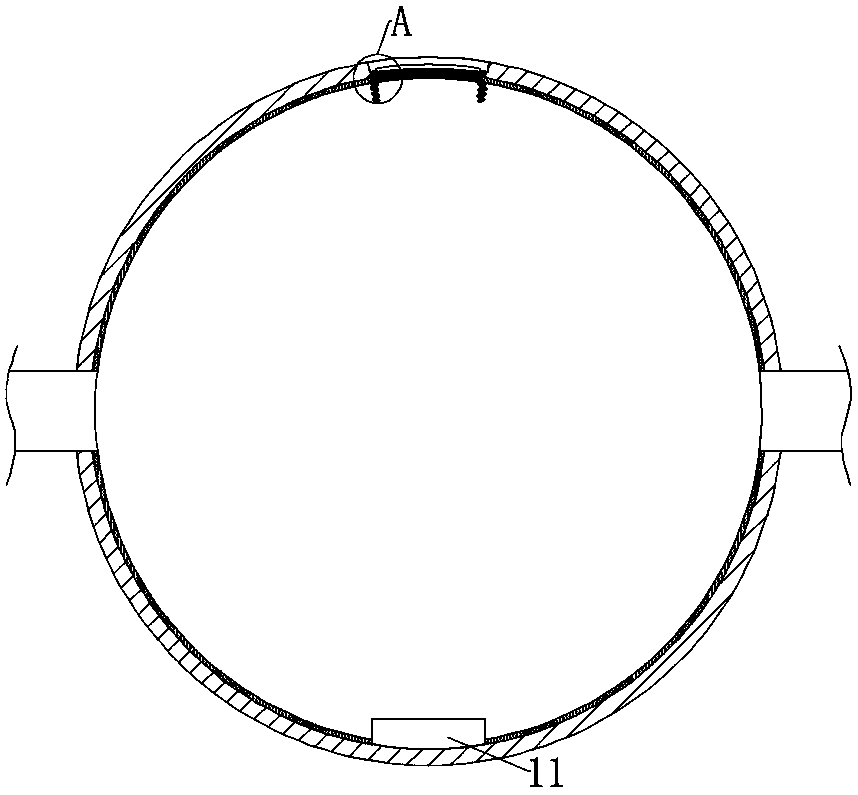

Centrifugal casting process for shell of bimetal compound metallurgical wedge hob

The invention relates to a centrifugal casting process for the shell of a bimetal compound metallurgical wedge hob, which sequentially comprises the steps of moulding, shell modification, spraying, mold shell assembling, molten steel smelting, deoxidization and slag removing, pouring, heat preservation and coring, blasting and sand removal, processing and finishing, heat treatment and the like. The wedge hob produced through the process above not only has the advantages of high hardness, good abrasion-resistance and the like, but also has good comprehensive mechanical properties such as stiffness, toughness and the like, thereby satisfying the requirements for strength and wear resistance of cutter teeth of the wedge hob, ensuring the manufacturability of the hob body, improving the service time of the cutter teeth of the wedge hob, and reducing the production cost.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

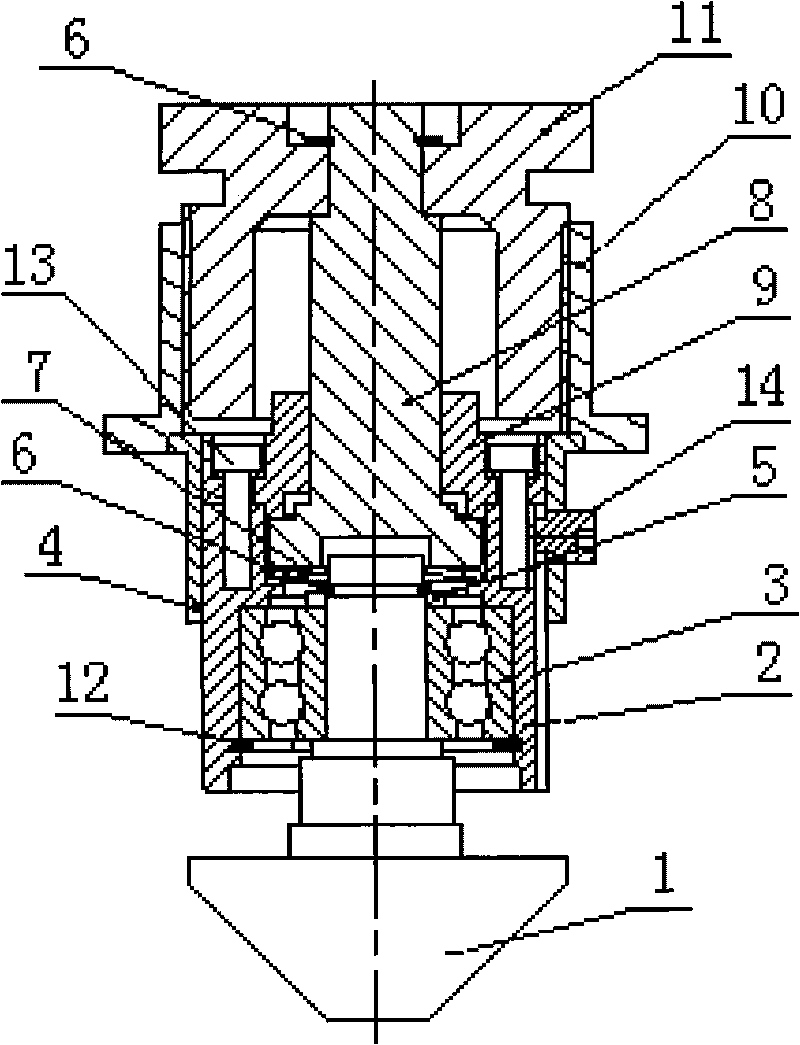

Elastic positioning adjusting device for conical pulley

ActiveCN101691000ARealize a wide range of position adjustment functionMeet the design sizeWelding/cutting auxillary devicesAuxillary welding devicesMiniaturizationEngineering

The invention discloses an elastic positioning adjusting device for a conical pulley, which is applied to the technical field of automatic welding. The elastic positioning adjusting device is characterized by consisting of a conical pulley shaft, a conical pulley shaft sleeve, a double row angular contact bearing, a copper bush, a bearing cone cushion, an elastic retainer ring for shafts, a disc spring, a movable shaft, a shaft sleeve gland, an adjusting mounting base, a regulating hand wheel, an elastic retainer ring for holes, fastening screws and limit screws. The elastic positioning adjusting device has the advantage that: the elastic positioning adjusting device realizes that the conical pulley can reliably and stably rotate, has functions of accurate elastic positioning and wide-range position adjustment, has looseness-proof function, has compact and even structure, meets the design requirements for miniaturization and portability of a welding carriage and a track, and improves the positioning precision and walking reliability of the steel pipe automatic welding carriage.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Aromatic polycarbonate resin composition and molded resin

ActiveCN101346430ASatisfy mobilityMeet the rigidityProductsReagentsPolytetramethylene terephthalatePolybutylene terephthalate

An aromatic polycarbonate resin composition which comprises an aromatic polycarbonate resin (ingredient (A)) and a polybutylene terephthalate resin (ingredient (B)) and optionally further contains a rubbery polymer and / or an inorganic filler, characterized in that the amounts of the aromatic polycarbonate resin (ingredient (A)) and the polybutylene terephthalate resin (ingredient (B)) are 51-99 parts by weight and 1-49 parts by weight, respectively, per 100 parts by weight of the sum of the aromatic polycarbonate resin (ingredient (A)) and the polybutylene terephthalate resin (ingredient (B)) and that the polybutylene terephthalate resin (ingredient (B)) has a titanium compound content of 1-75 ppm, excluding 1 ppm, in terms of titanium atom amount and a terminal carboxy group content of 39 [mu]eq / g or lower. This aromatic polycarbonate resin composition has an excellent balance among various properties, i.e., is satisfactory in all of flowability, rigidity, impact resistance, chemical resistance, fatigue characteristics, heat resistance, thermal stability in residence, and suitability for recycling.

Owner:MITSUBISHI ENG PLASTICS CORP

Method for preparing acrylonitrile-butadiene-styrene copolymer toughened rigid polyvinyl chloride composite material

The invention provides a method for preparing an acrylonitrile-butadiene-styrene copolymer toughened rigid polyvinyl chloride composite material and belongs to the technical field of high molecular material preparation. The method comprises the steps of: firstly, feeding 61-67 parts of polyvinyl chloride resin, 4-7 parts of plasticizer, 8-13 parts of flexibilizer, 12-18 parts of filler, 0.9-1.5 parts of stabilizer, 4-7 parts of cellulose, 0.4-1 part of lubricant and 0.7-1.5 parts of carbon black into a high-speed mixer to obtain a mixture; and then feeding the mixture into a parallel twin-screw extruder for melt extrusion, and finally, subjecting the extruded material to water cooling, sized dicing and drying, thereby obtaining the finished product, wherein the temperatures of the screws of the parallel twin-screw extruder are controlled to 130 DEG C, 135 DEG C, 140 DEG C, 145 DEG C, 155 DEG C, 165 DEG C, 165 DEG C, 165 DEG C, 170 DEG C and 165 DEG C from the first zone to the tenth zone. The method provided by the invention is simple and short in process steps and rational in raw material selection.

Owner:CHANGSHU JIATAI METAL MATERIAL

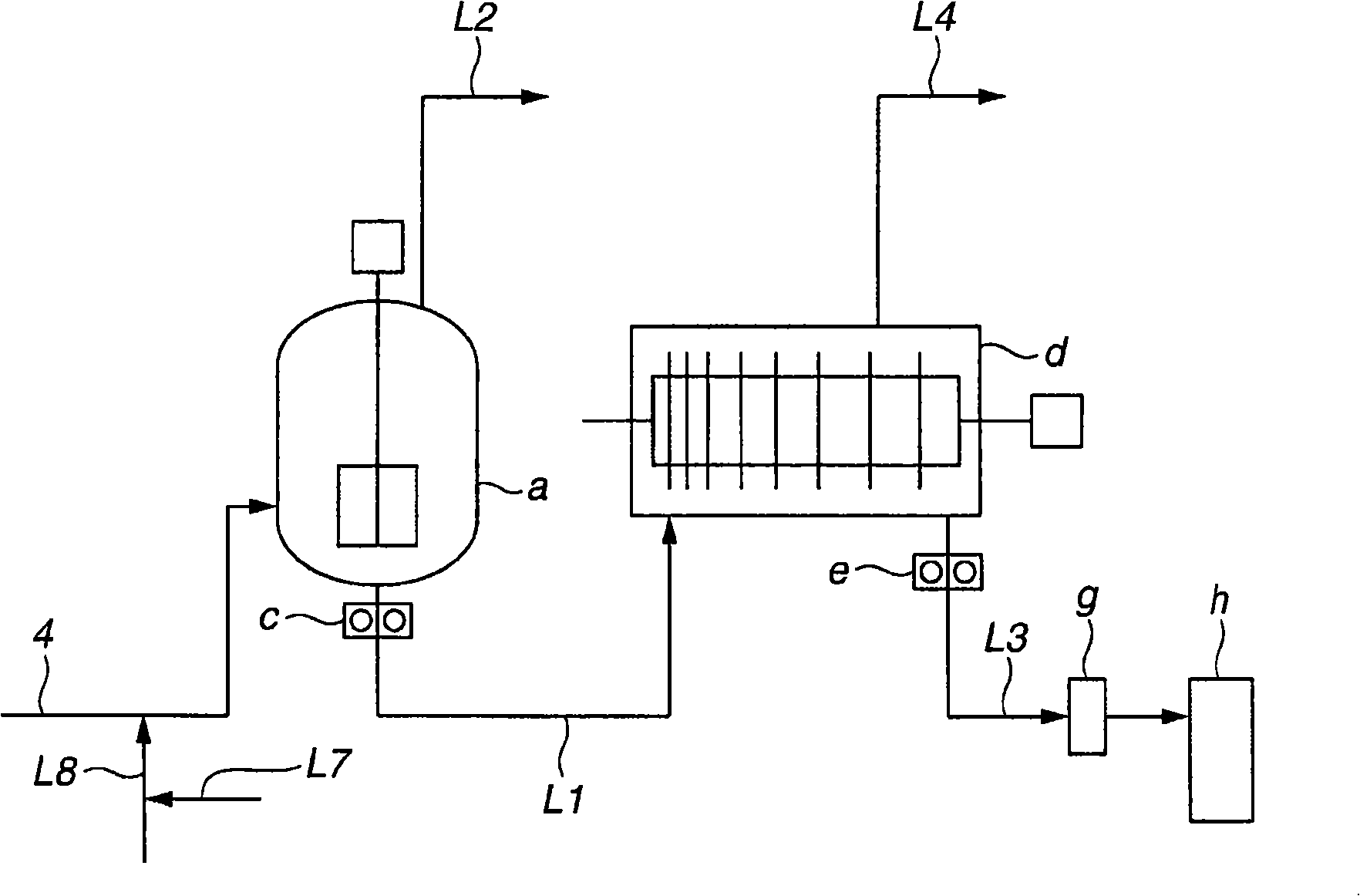

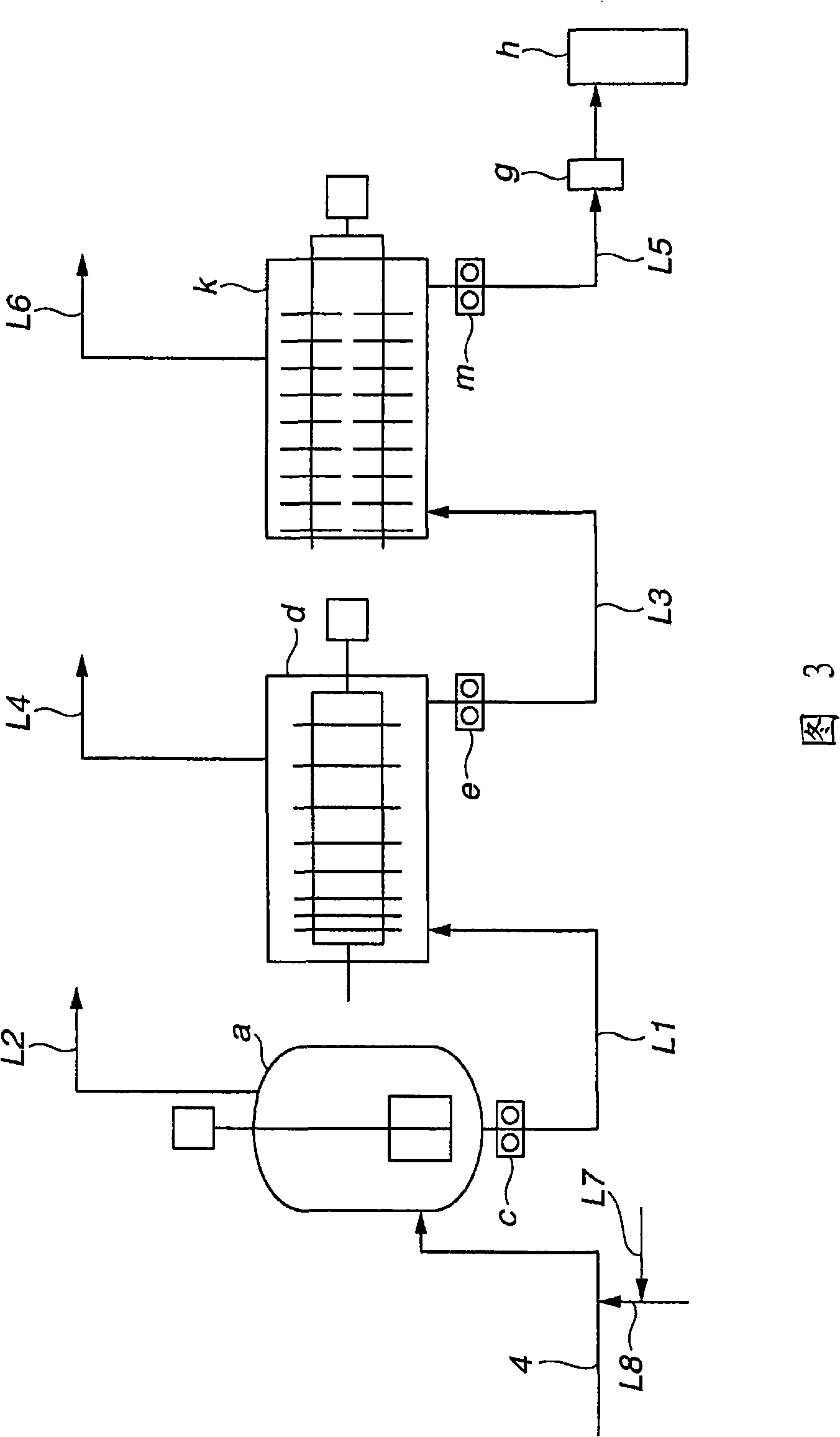

Metal energy absorbing bracket for a dashboard of an automobile

ActiveCN109018019AGood impact energy absorptionGood cushioning for oblique collisionsSuperstructure subunitsDashboardsRear quarterDashboard

Provided is A metal energy absorbing bracket for a dashboard of an automobile. the metal energy absorbing bracket is installed between a rear end of the dashboard and a body sheet metal, the metal energy absorbing bracket comprises a lateral panel and side panels arranged on both sides of the lateral panel, the side panels comprises lower side panels and upper side panels connected together by bending portions, the lower side panels is connected on both sides of the lateral panel; The side plates are symmetrically arranged, and the lower side plates on both sides are provided with an opening angle of 25 DEG to 35 DEG, the upper side plates on both sides are arranged in parallel, and the lower side plates on the same side and the upper side plates are provided with an included angle of 100DEG to 110 DEG. The metal energy-absorbing bracket of the invention changes the straight strip direct structure in the prior art, adopts the bending structure and the open angle structure, and has good collision energy-absorbing effect. The angle between the lower side plate and the upper side plate is 100-110 degrees, and the angle between the lower side plate and the upper side plate is 25 -35degrees, which can well cushion the impact force in the vertical direction.

Owner:FUCHENG AUTO PARTS

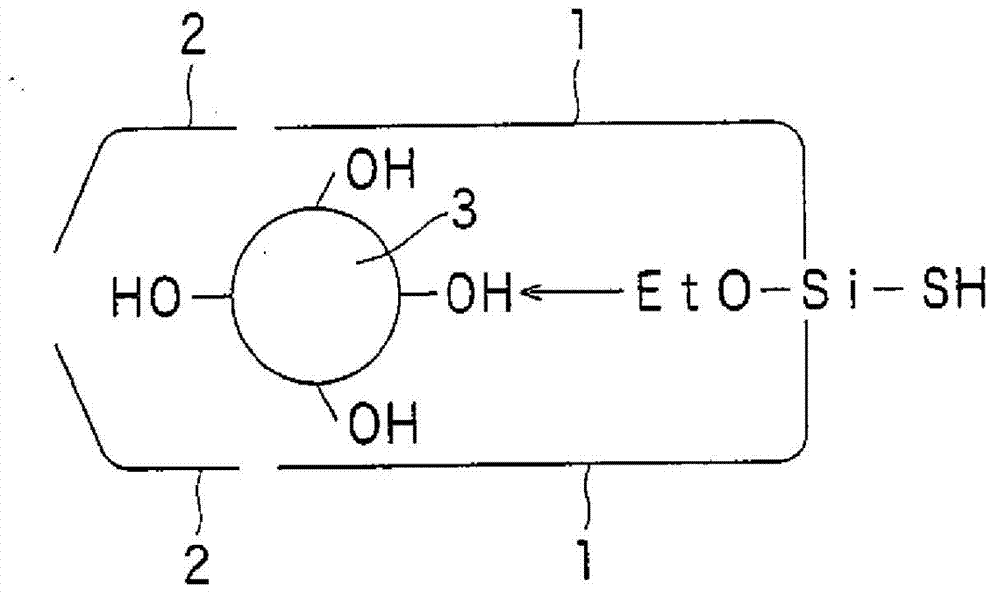

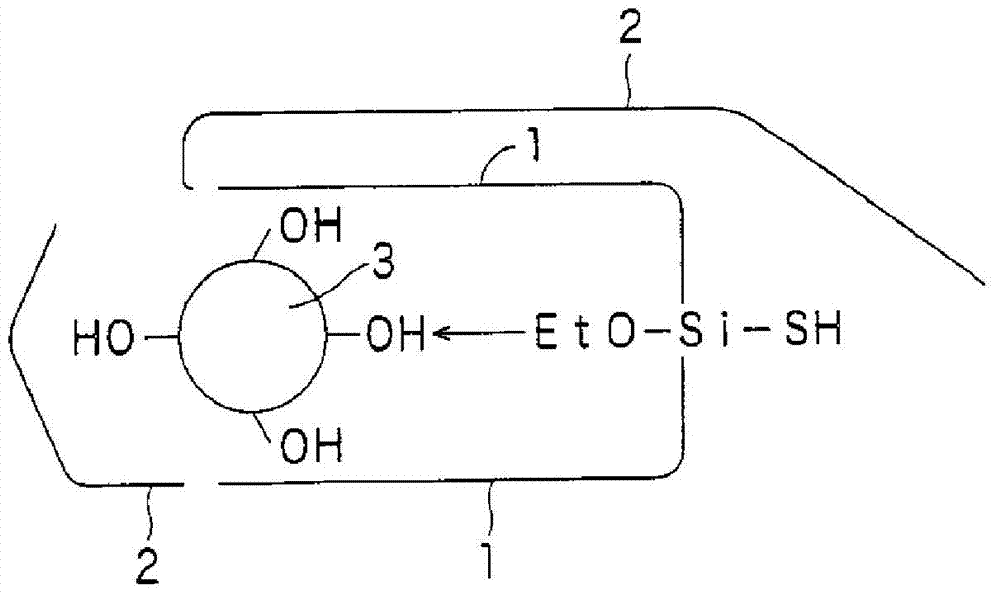

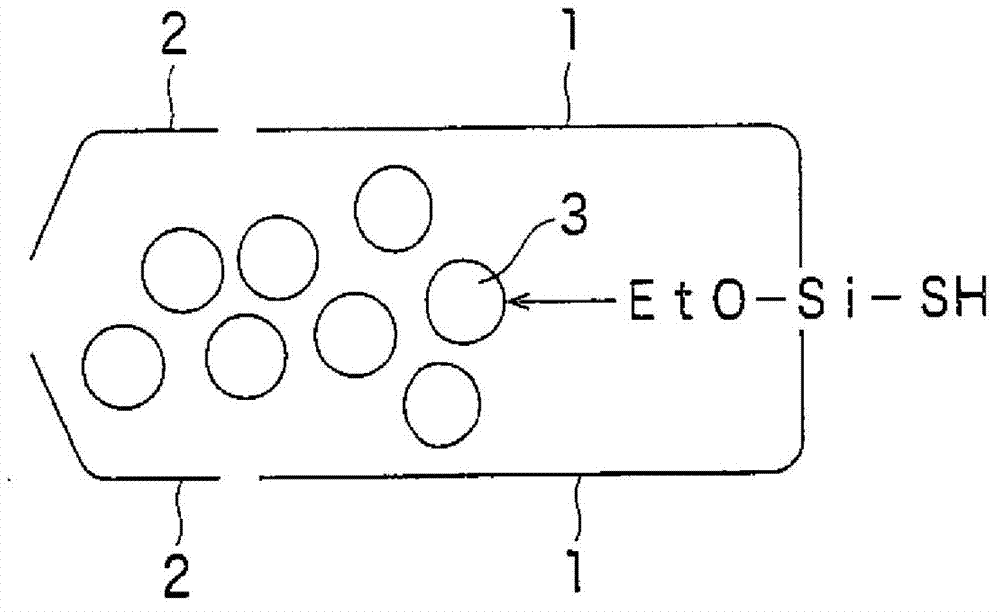

Vibration-isolating rubber composition

InactiveCN102770486AMeet heat resistanceImprove heat resistanceRubber-like material springsLow internal friction springsHeat resistanceSilanes

Owner:SUMITOMO RIKO CO LTD

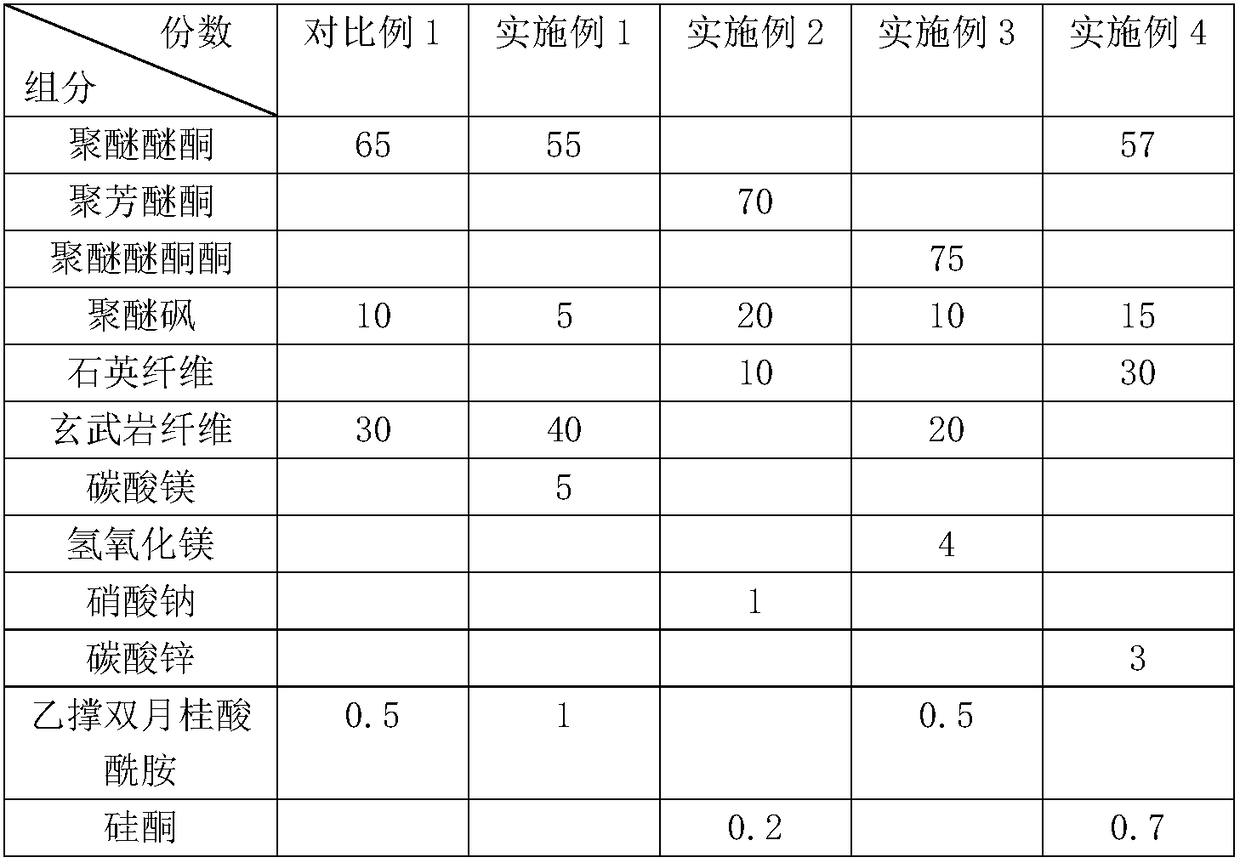

Light high-wave-transmissivity composite material and preparation method thereof

The invention discloses a light high-wave-transmissivity composite material and a preparation method thereof, and belongs to the technical field of materials. The light high-wave-transmissivity composite material is prepared from the following components in parts by weight: 55-75 parts of a polyether ketone material, 5-20 parts of polyether sulfone, 10-40 parts of a reinforcement, 1-5 parts of a foaming agent and 0.2-1 part of a dispersing agent. According to the light high-wave-transmissivity composite material and the preparation method thereof, the thermoplastic polyether ketone material with high heat resistance and high strength is adopted as a base body, inorganic fiber with high strength and modulus and high wave transmissivity is attached to the base body to serve as the reinforcement, so that the high-wave-transmissivity thermoplastic composite material is prepared, moreover, a micro-foaming technology is adopted, so that the high-wave-transmissivity material which is lighteris obtained on the premise that the performance requirements of high wave transmissivity, low loss, high temperature resistance, high rigidity, high strength, stable size and the like of a radome material are met, the specific gravity of the material is decreased by 25% or more, and the weight reduction requirement for a product is met; in addition, the material can be directly subjected to extrusion and injection molding, and the product efficiency is high.

Owner:NANJING JULONG SCI&TECH CO LTD

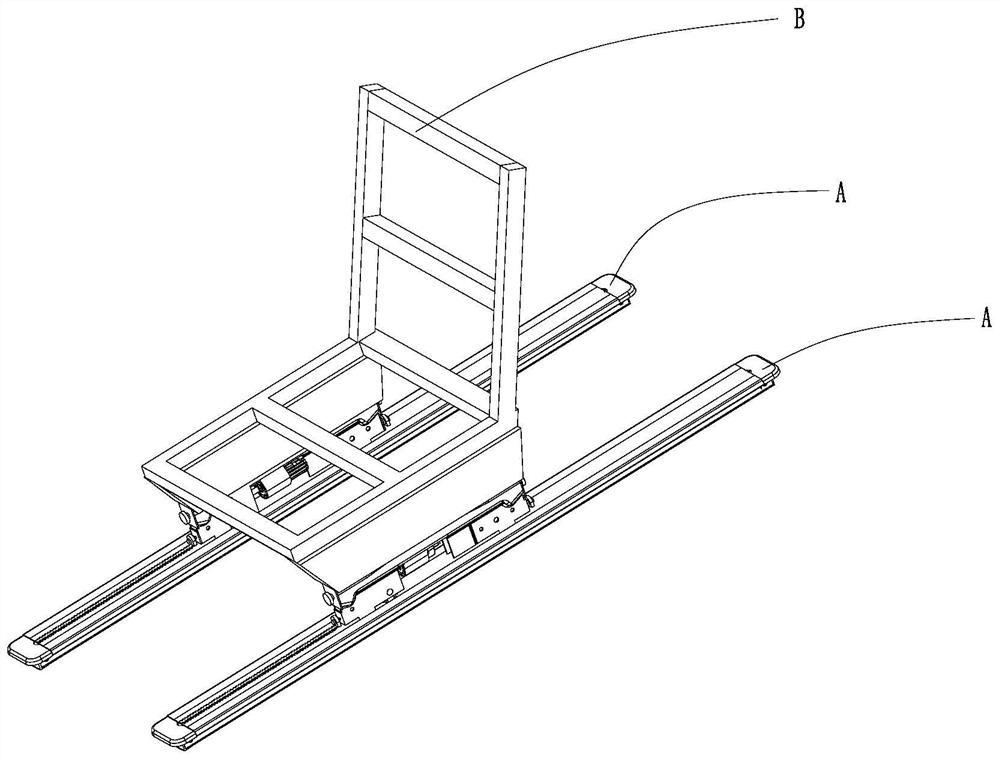

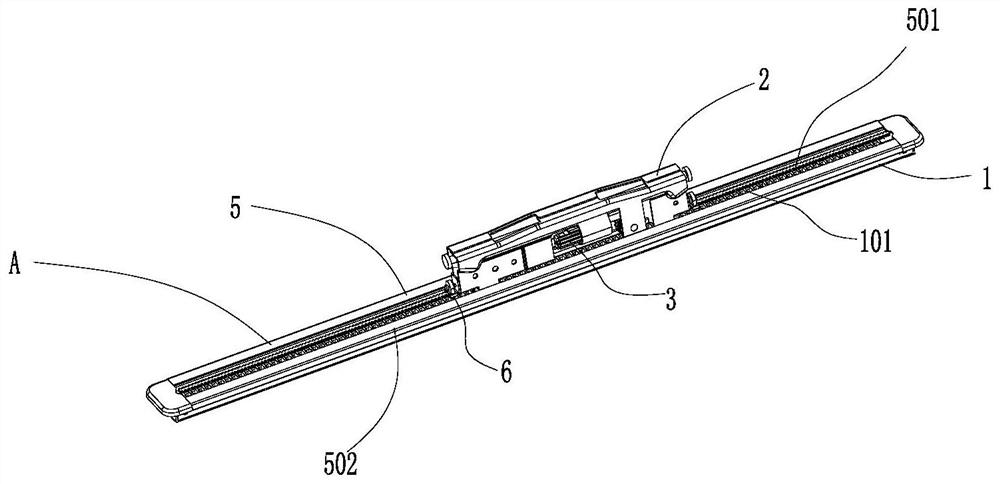

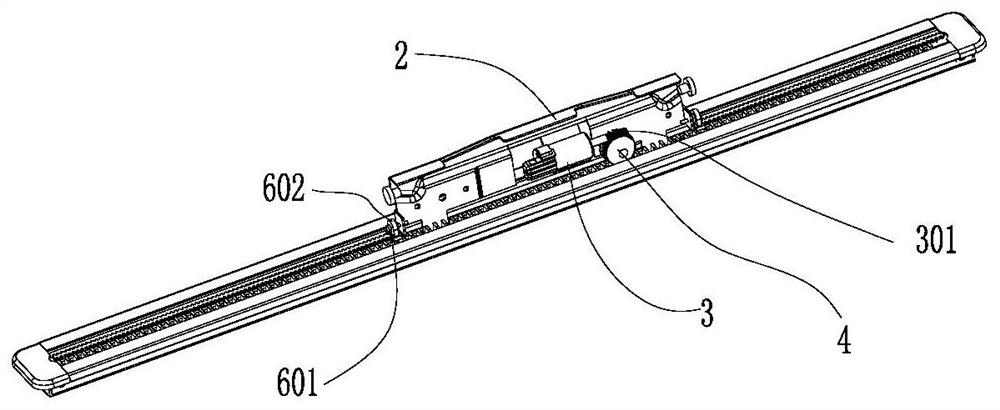

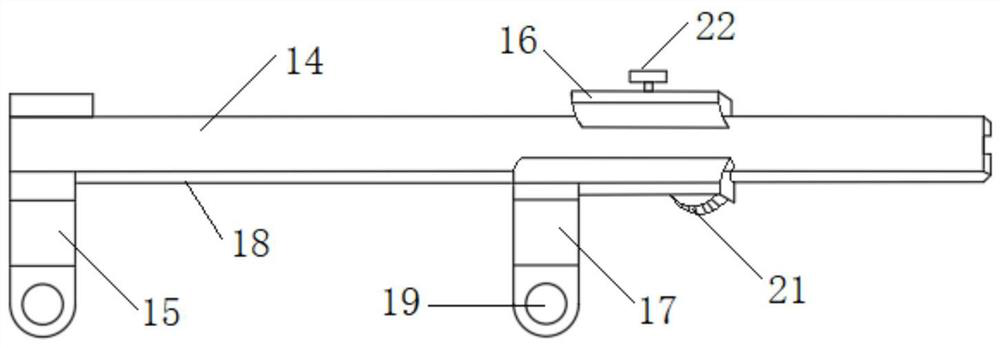

Automobile seat sliding rail device

The invention provides an automobile seat sliding rail device, which comprises a sliding rail which is provided with a rack; a seat supporting seat which is arranged on the sliding rail in a sliding mode, and a containing cavity is formed in the seat supporting seat; an automobile seat which is fixedly mounted on the seat supporting seat; a driving motor which is arranged in the accommodating cavity and is fixedly connected with the seat supporting seat; an output shaft of the driving motor is a threaded screw rod; a transmission mechanism which is arranged in the accommodating cavity and is fixedly connected with the seat supporting seat; the transmission mechanism comprises a helical gear and a straight gear which are coaxial and integrated, the helical gear is meshed with the threaded lead screw, and the straight gear is meshed with the rack on the sliding rail. By arranging the self-locking transmission mechanism, the structure is simplified, the preparation weight is reduced, theproblem of response delay of unlocking / locking is avoided, and follow-up stopping is achieved; by arranging the zipper type surface sealing structure, potential safety hazards caused by foreign matterfalling into the sliding rail are avoided, and the situation that dust and foreign matter fall off and are difficult to clean is avoided; meanwhile, the appearance is free of seams and hidden objects, so that the quality is improved.

Owner:DONGFENG MOTOR CO LTD

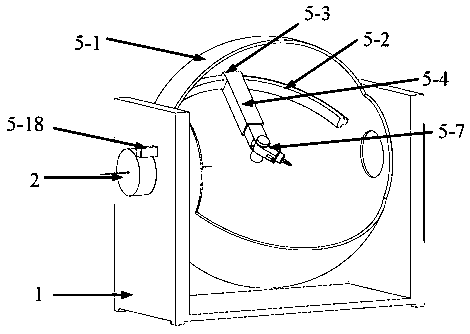

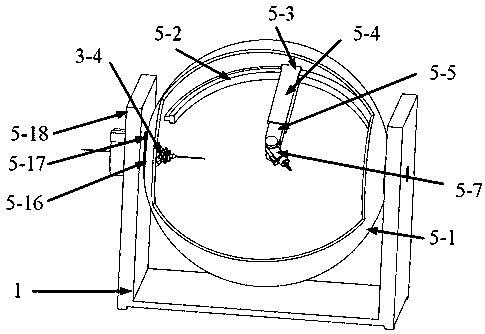

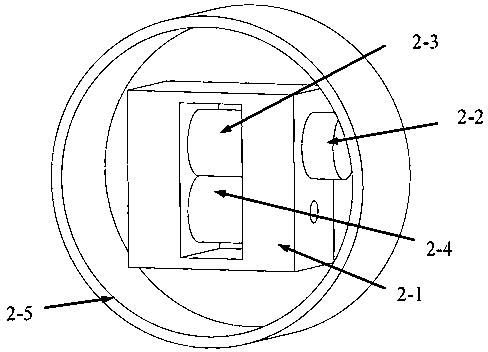

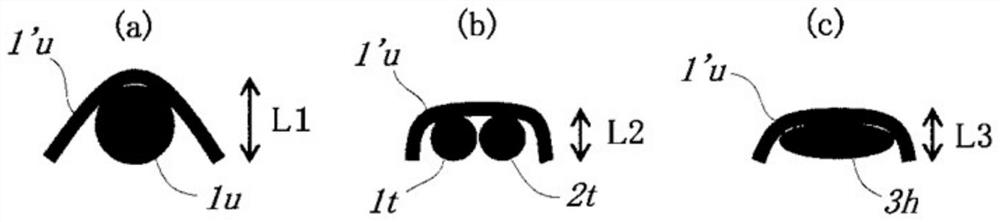

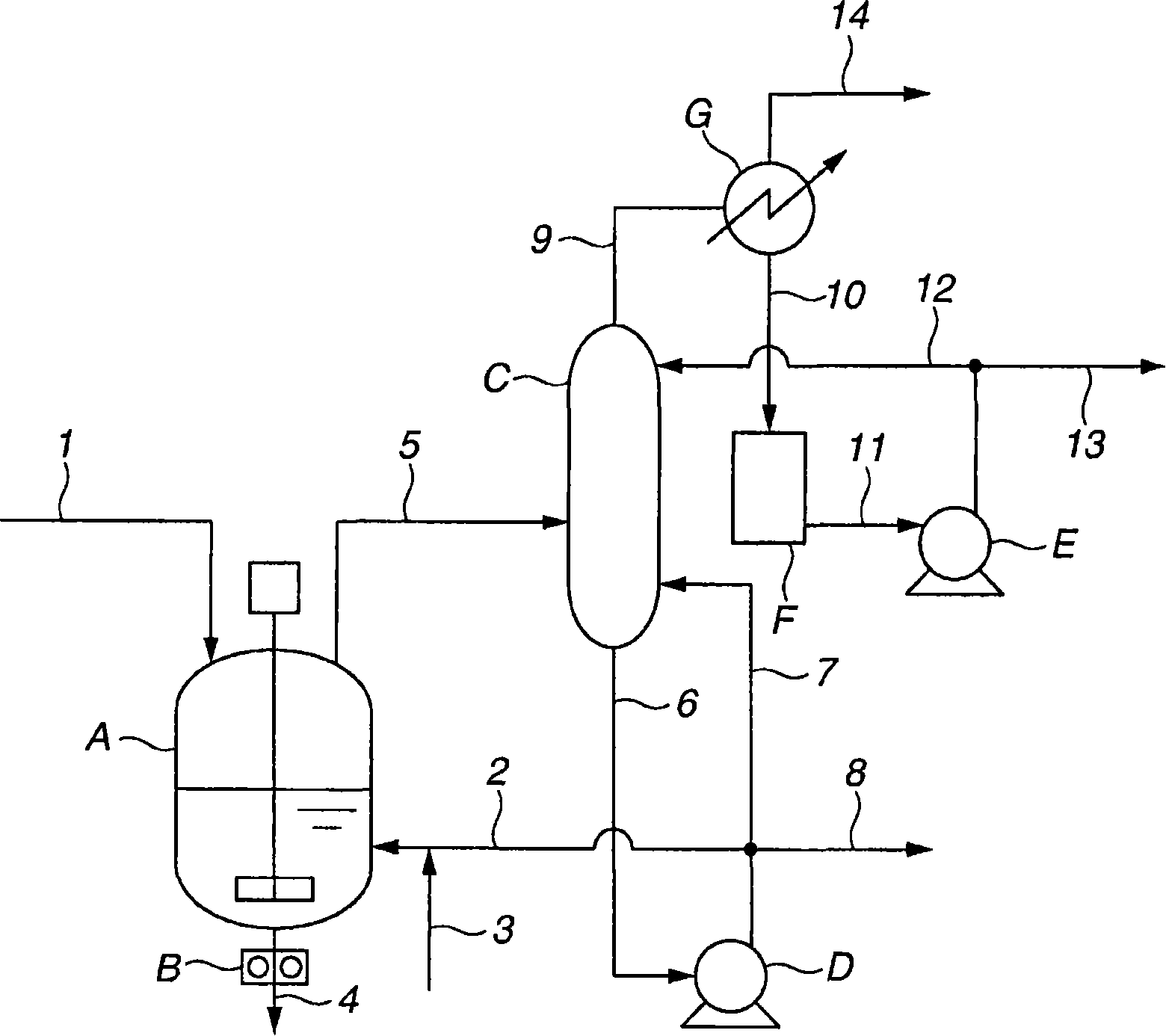

Spherical orthodontic arch wire bending robot and use method thereof

The invention discloses a spherical orthodontic arch wire bending robot and a use method thereof and belongs to the field of orthodontic arch wire bending. The robot comprises a base bracket, a wire feeding mechanism, an angle adjusting mechanism, an arch wire clamping mechanism and a bending wire mechanical arm; the base bracket mainly serves as a supporting function; the wire feeding mechanism continuously feeds arch wires into the angle adjusting mechanism; the angle adjusting mechanism adjusts the positions and postures of the arch wires sent by the wire feeding mechanism, so that the interference of the arch wires during arch wire bending can be avoided; the arch wire clamping mechanism fixes and clamps the arch wires; and the wire bending mechanical arm is the main part of the wholerobot; and the wire bending mechanical arm adopts a spherical coordinate system, is flexible in movement and can avoid interference. With the spherical orthodontic arch wire bending robot and the usemethod thereof of the present invention adopted, the bending of multi-functional bends during arch wire bending can be realized, wherein the multi-functional bends include first sequential bends andsecond sequential bends; a plurality of bends can be formed on one arch wire, and therefore, the bending of the whole arch wire can be realized; and the spherical coordinate system and a parallel mechanism are combined, and therefore, the flexibility of bending and the rigidity of the robot can be ensured.

Owner:HARBIN UNIV OF SCI & TECH

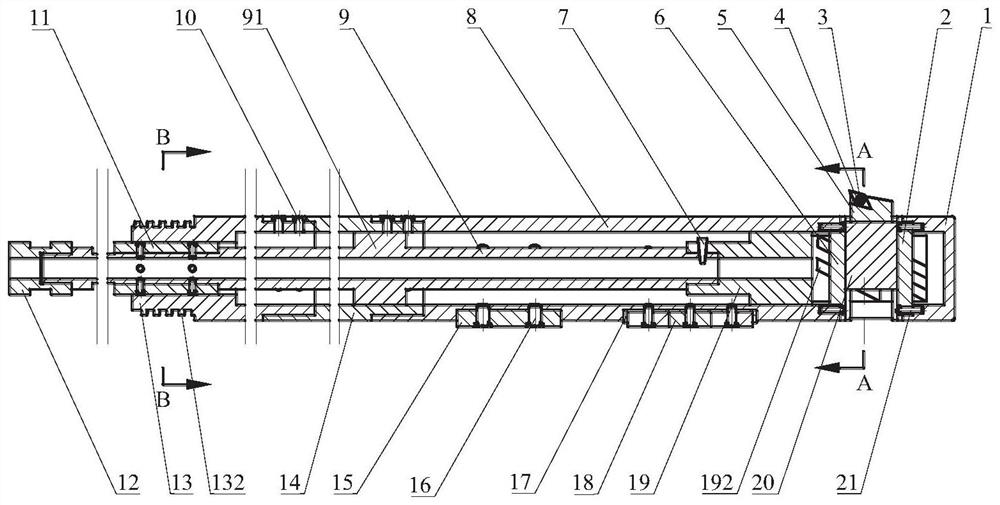

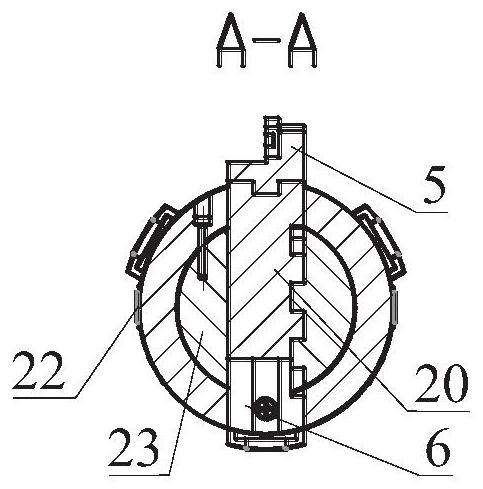

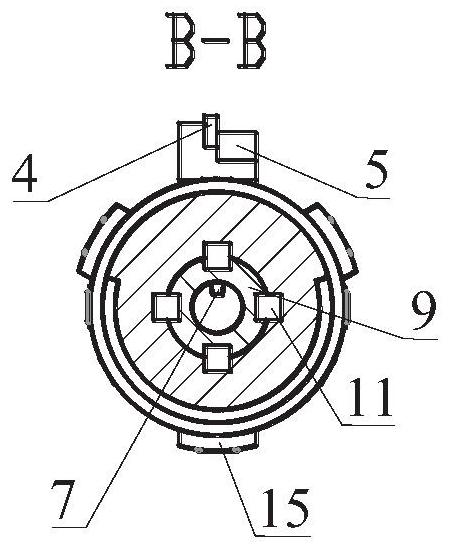

Precise boring cutter for machining inner contour of deep hole of bottle cavity

The invention relates to a precision boring cutter for machining the inner contour of a deep hole of a bottle cavity. The precision boring cutter comprises a boring rod, a reducing structure and a pull rod. The pull rod penetrates through the boring rod and is connected with a transmission positioning block, the pull rod is connected with the transmission positioning block through a lead screw nut pair transmission system controlled by an external servo, the pull rod is driven to do axial linear telescopic motion, the pull rod transmits the axial motion to the mandrel through the pin, and the mandrel converts the axial telescopic motion into radial telescopic motion of the sliding block through the inclined face. Therefore, radial extension and retraction of the tool apron and the blade in the variable-diameter structure are realized. Meanwhile, the radial driving ratio of the reducing structure of the device is 2: 1, driving is accurate and reliable, the guiding blocks and the vibration reduction strips are arranged outside, the self-guiding and vibration suppression effects can be achieved, and the first sliding block guide rail, the second sliding block guide rail and the sliding block guide rail support are arranged inside, so that the requirement for the rigidity of bevel transmission of the reducing structure can be met. The device has the characteristics of reasonable structure, accuracy, reliability and the like, and can be widely used for processing various bottle cavity holes with complex internal profiles.

Owner:XI'AN PETROLEUM UNIVERSITY

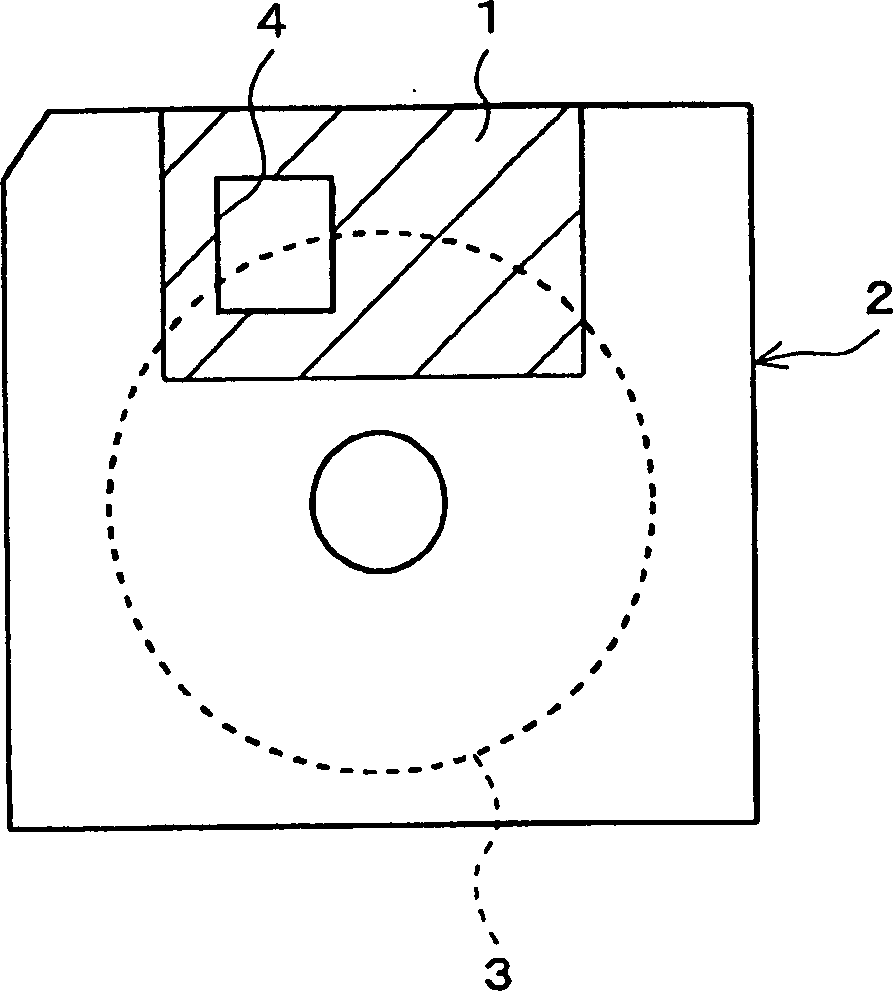

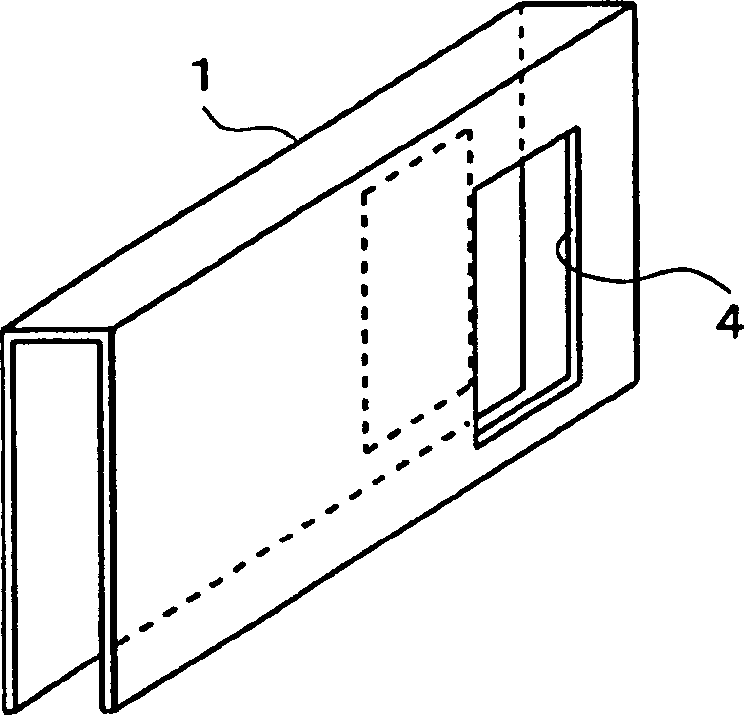

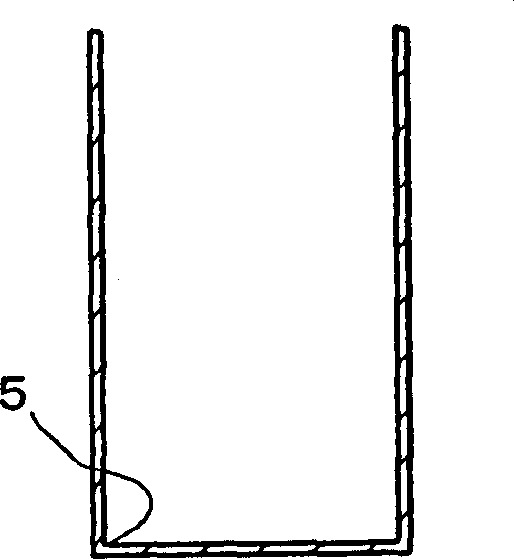

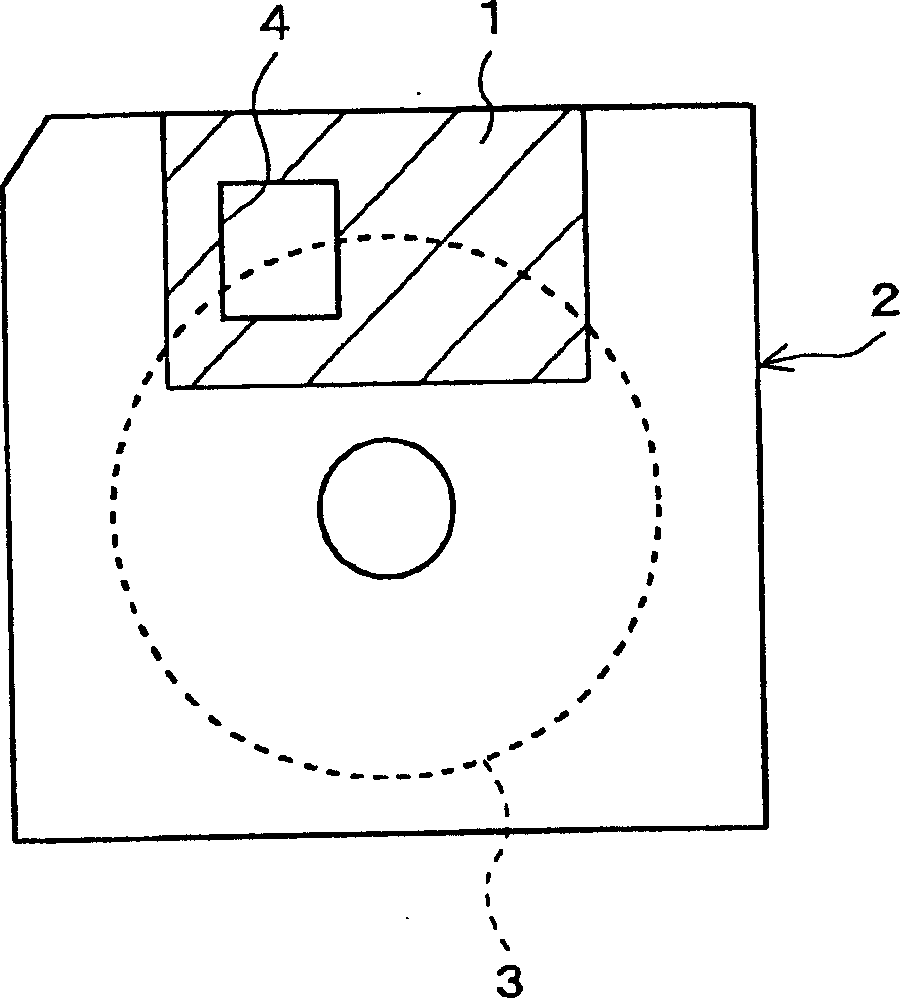

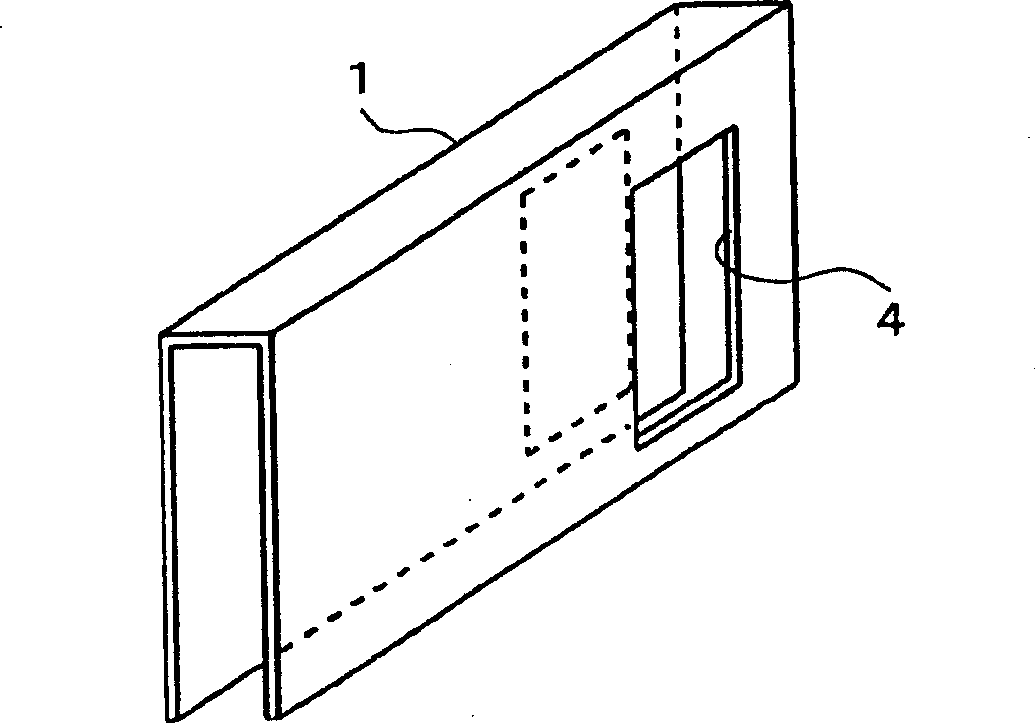

Open-and-close device made of aluminium alloy plate for recording medium shell

The present invention provides a shutter using a recording medium case of an aluminum alloy plate satisfying all the characteristics required for the shutter. The switch is composed of: an aluminum alloy substrate containing Mg: 2.2 to 2.8% by mass, Mn: 0.35 to 0.55% by mass, and Fe: 0.1 to 0.4% by mass; A chromate film provided as a first layer on the surface of the outer side of the shutter of the above-mentioned recording medium case, the above-mentioned chromate film is provided so that the amount of chromium deposited is 5 to 50 mg / m2 in conversion; A film made of acrylate-modified polyester urethane resin is provided as the second layer on the outer surface of the device, and the film thickness of the film made of acrylate-modified polyester urethane resin is 0.5 to 3 μm. Inorganic microparticles having an average particle diameter of 10 μm or less are contained in an amount of 5 to 20 parts by weight relative to 100 parts by weight of the above-mentioned acrylate-modified polyester-urethane resin, so as to be 100 parts by weight of the above-mentioned acrylate-modified polyester-urethane resin. The oxidized polyethylene-based lubricant is contained in a proportion of 0.5 to 3 parts by weight.

Owner:KOBE STEEL LTD

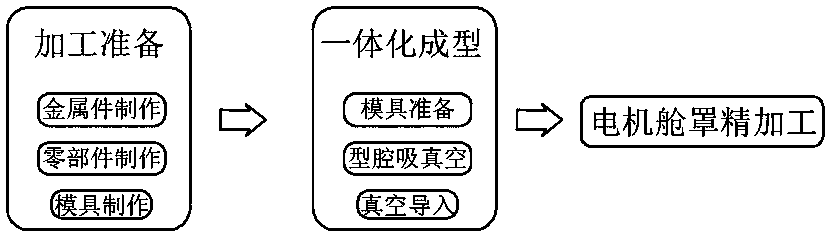

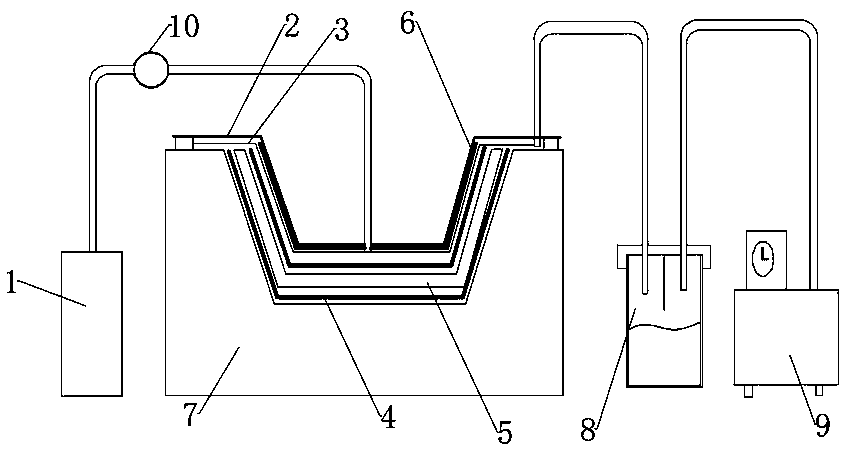

Integrated forming process of high-power wind power motor cabin cover

InactiveCN110789148AHigh strengthQuality improvementFinal product manufactureHeat deflection temperatureThermal deformation

The invention discloses an integrated forming process of a high-power wind power motor cabin cover, and belongs to the field of wind power motor cabin cover forming processes. According to the integrated forming process of the high-power wind power motor cabin cover, the high-power wind power motor cabin cover is integrally formed by utilizing a vacuum introduction process, so that the performanceof the motor cabin cover is greatly improved; the bending strength of the resin of the adopted gel coat can reach 310MPa after being cured, the tensile strength is not lower than 180MPa, the elongation is not larger than 4%, and the thermal deformation temperature reaches up to 80 DEG C; the flame-retardant resin coating on the surface of the cabin cover has good water resistance, alkali resistance, scrubbing resistance, pollution resistance, temperature change resistance, flame retardance and the like, the oxygen index is not lower than 28, the performance requirements of the cabin cover onrigidity strength, corrosion resistance and ultraviolet resistance can be well met, in the vacuum introduction integrated forming process, hidden bubbles in the formed main material resin are removedby utilizing a bubble removing device, and the strength of the motor cabin cover is greatly improved.

Owner:江苏华纳环保科技有限公司

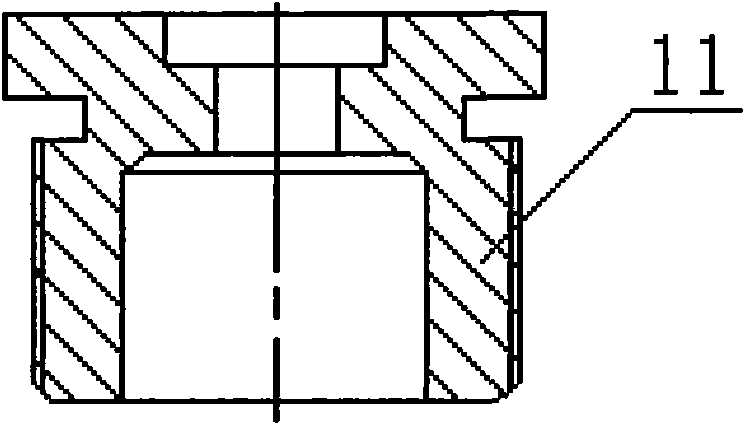

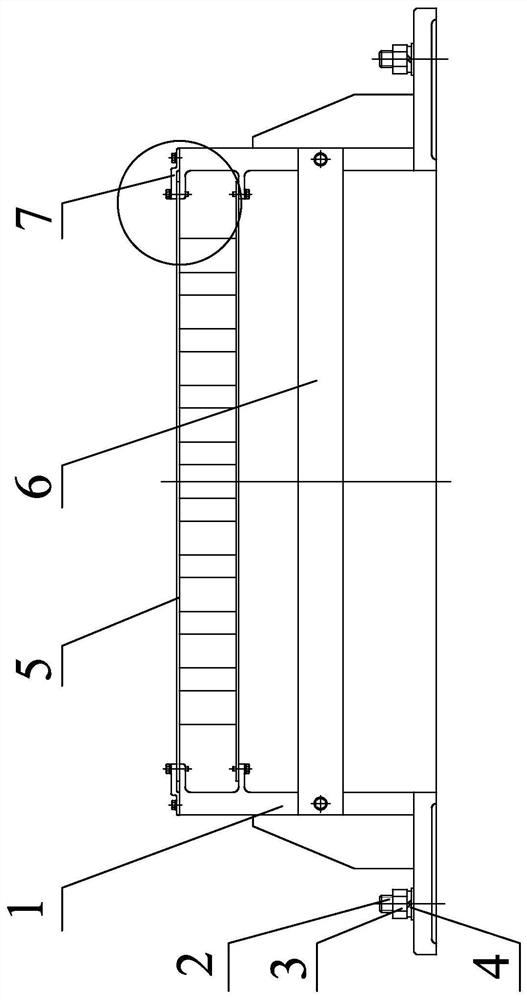

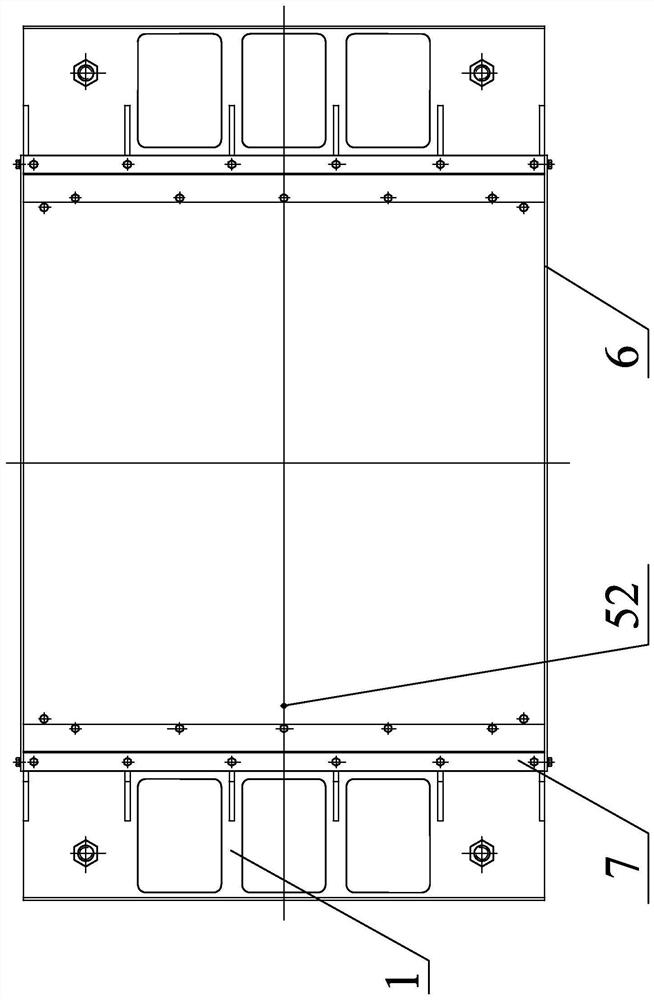

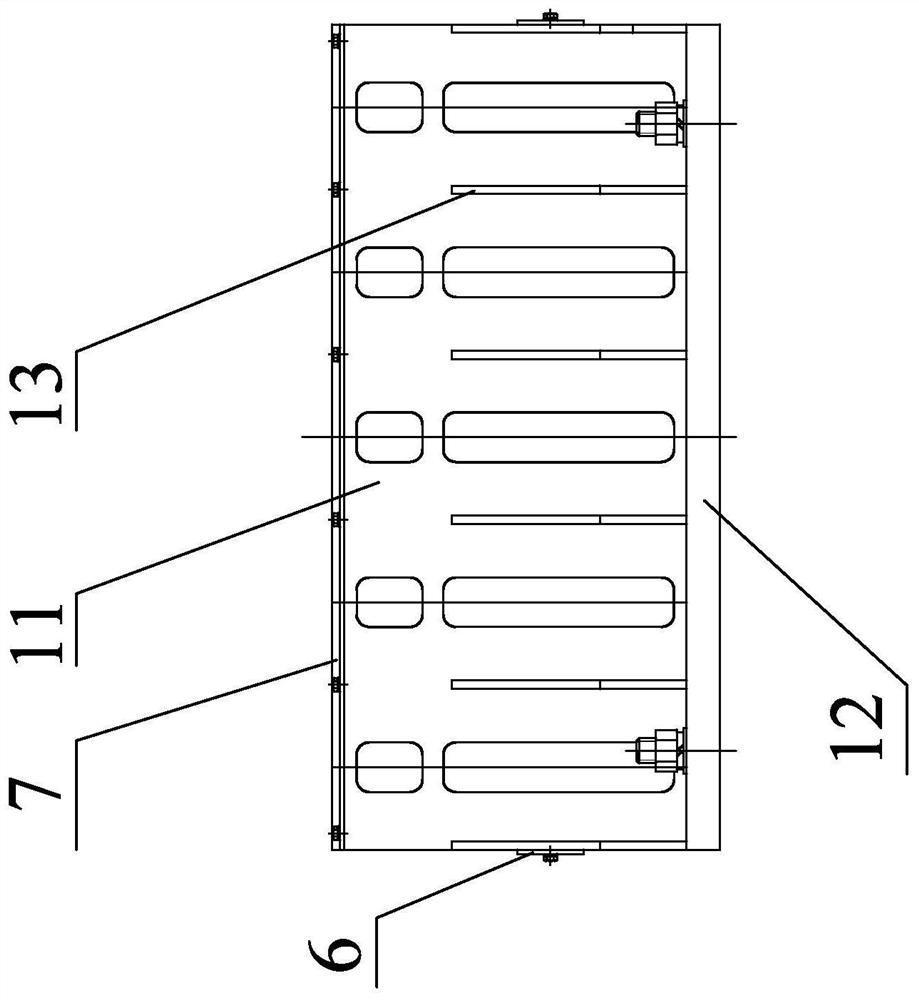

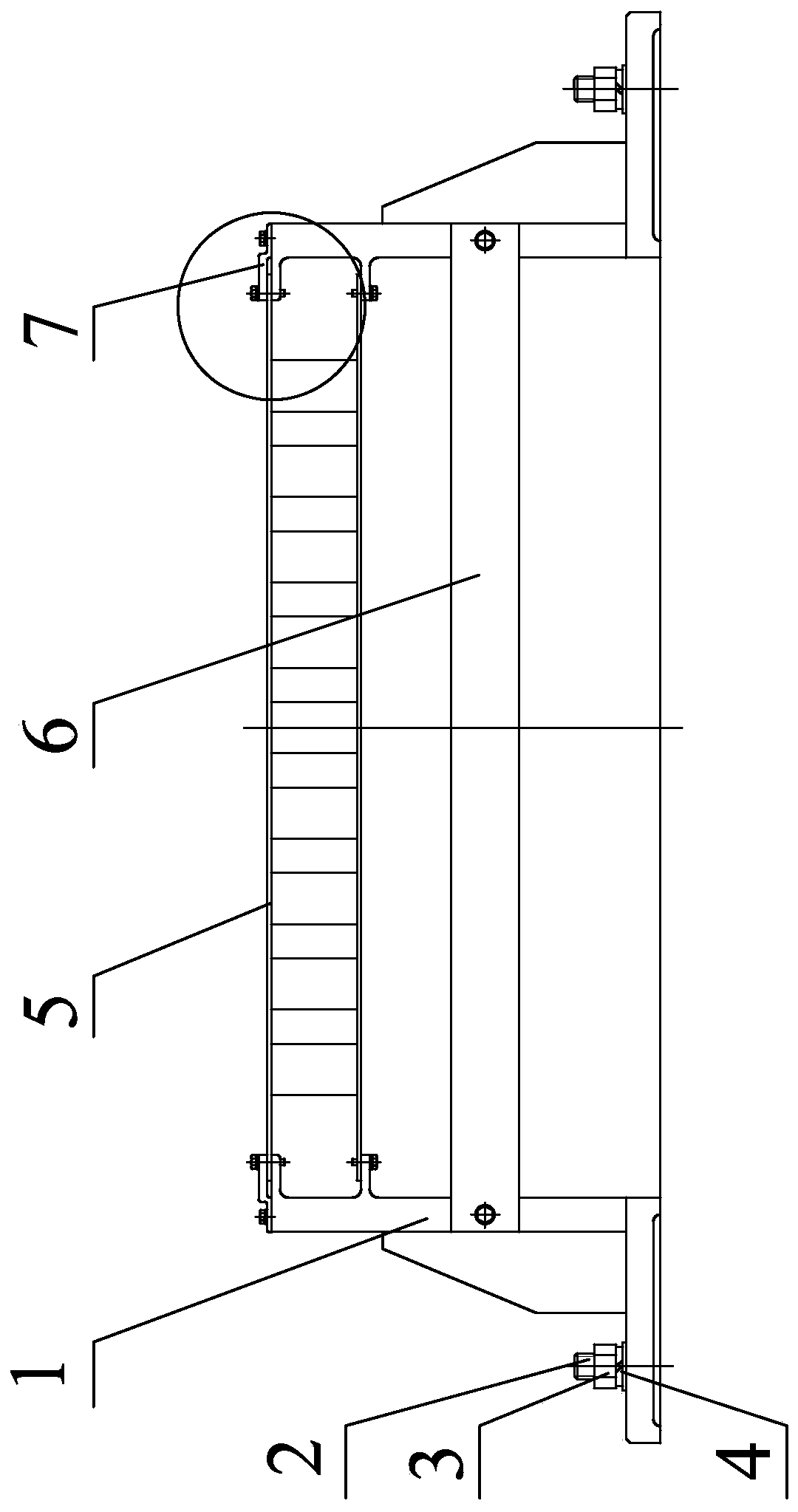

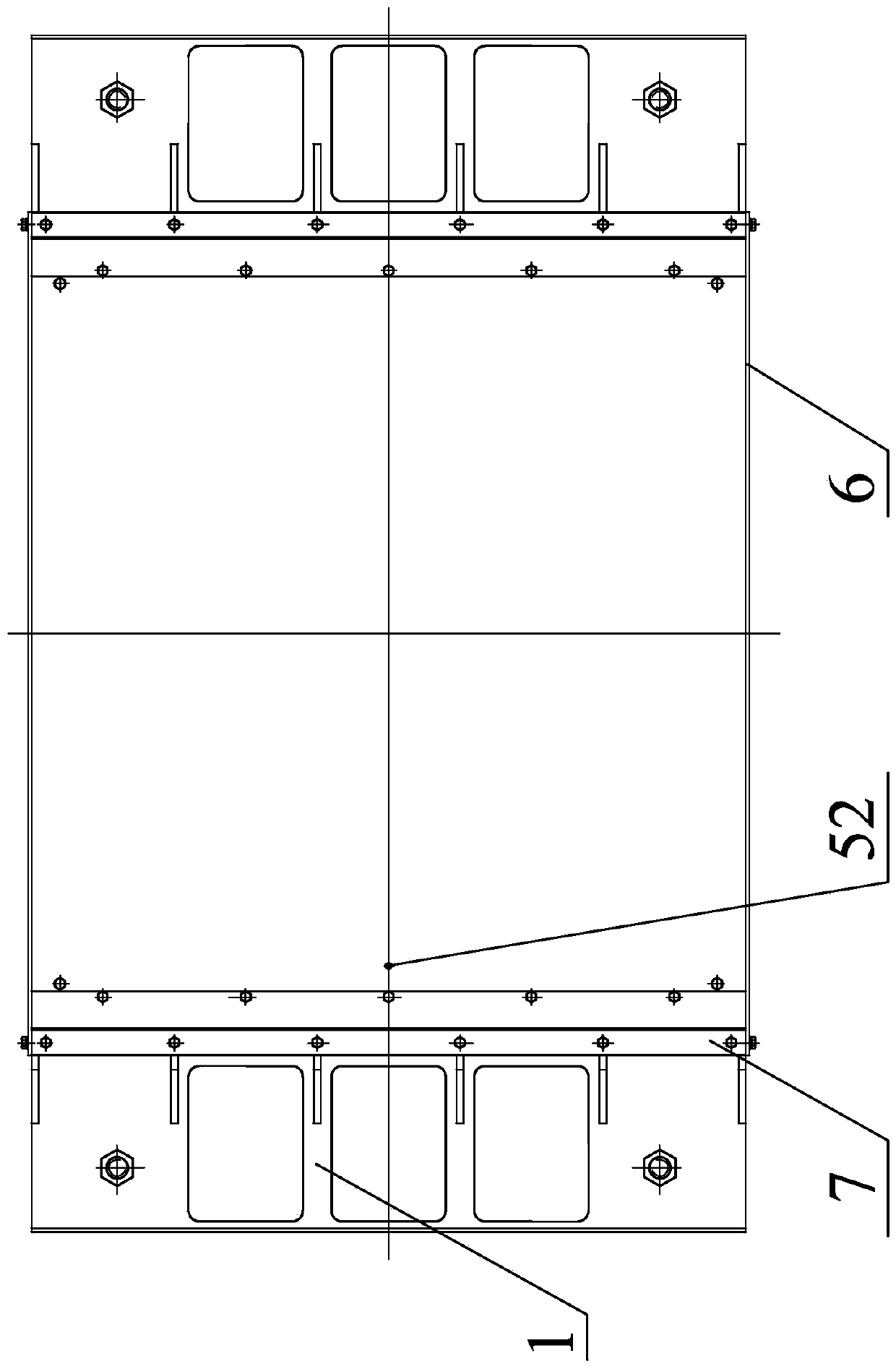

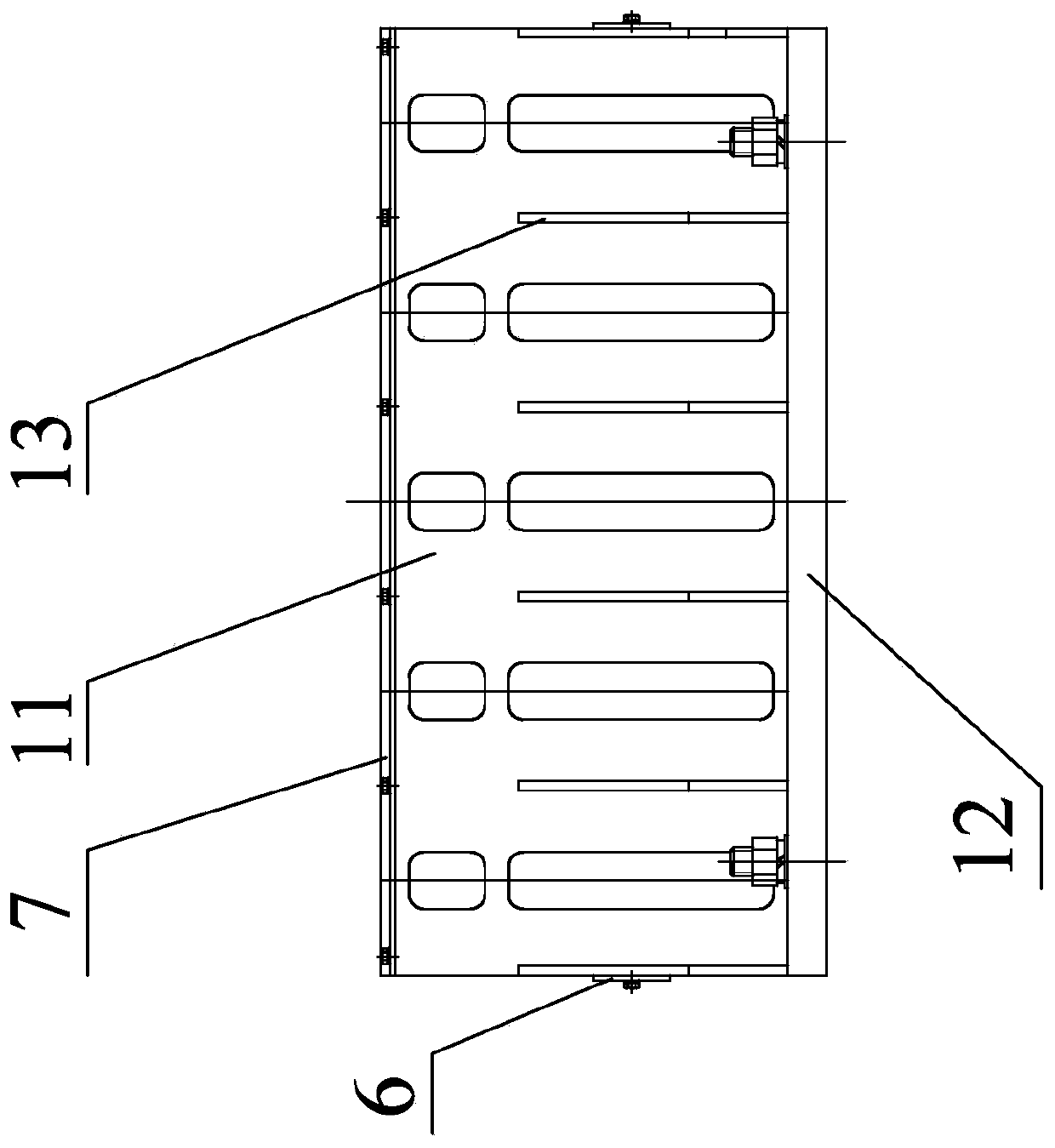

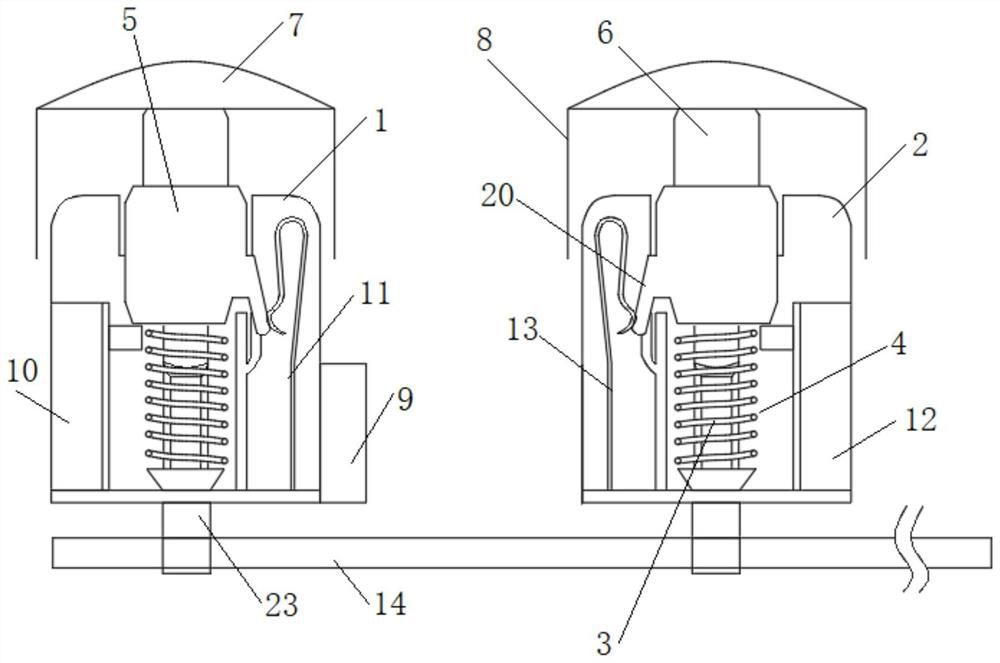

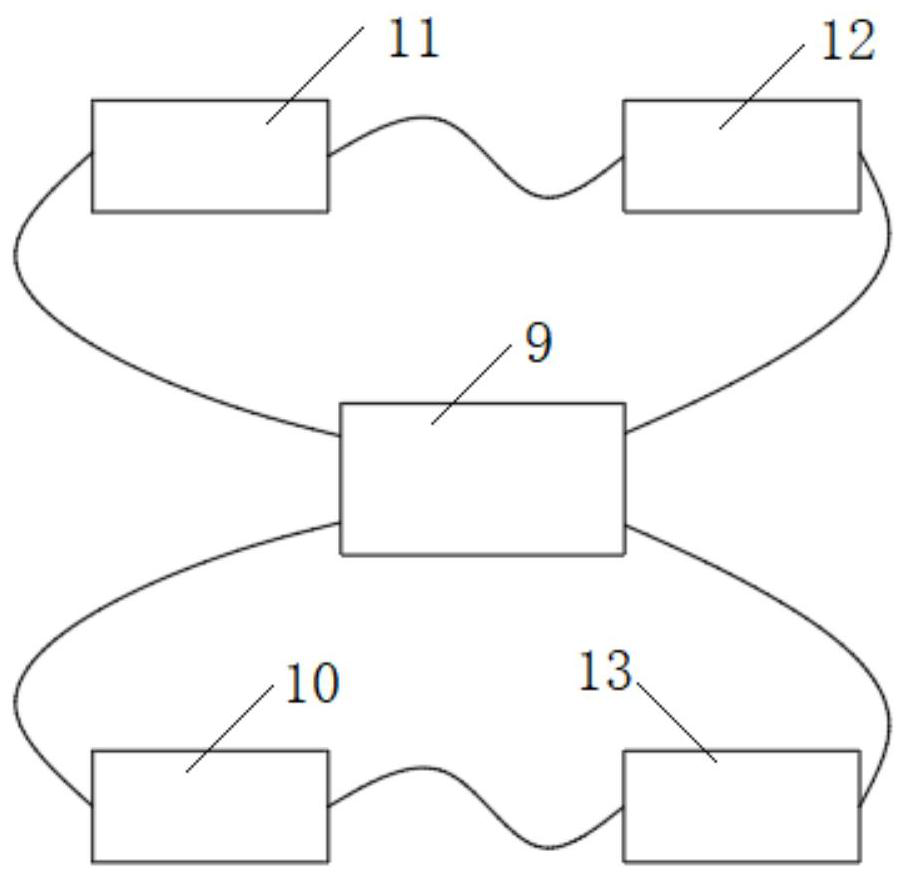

An experimental setup for acoustic metamaterial plate structure

ActiveCN110609086BRealize the boundary conditionsGuaranteed Fixed Support ConstraintsAnalysing solids using sonic/ultrasonic/infrasonic wavesExperimental researchEngineering

An experimental device for an acoustic metamaterial plate structure belongs to the technical field of structural elements, and is mainly used to solve the problem that the prior art lacks a dedicated experimental device in the process of dynamic experimental research on an acoustic metamaterial plate structure, thereby affecting the accuracy of experimental data. In the present invention, two fixture brackets are arranged on both sides of the metamaterial plate oppositely, each fixed pressure plate is installed on the top of a fixture bracket, and a substrate in the metamaterial plate is arranged between the fixture bracket and the fixed pressure plate, and The metamaterial board is fixedly installed on the fixture bracket, each positioning rod is arranged on one side of the two fixture brackets, and each positioning rod is fixedly connected with the two fixture brackets, and each fixture bracket is connected to the vibration isolation through N connectors. The foundation track is fixedly connected. The invention is mainly used as an experimental device for testing the dynamic performance of the acoustic metamaterial plate structure.

Owner:HARBIN ENG UNIV

Experimental device for acoustic metamaterial plate structure

ActiveCN110609086ARealize the boundary conditionsGuaranteed Fixed Support ConstraintsAnalysing solids using sonic/ultrasonic/infrasonic wavesStructural dynamicsEngineering

The invention discloses an experimental device for an acoustic metamaterial plate structure, and belongs to the technical field of structural elements. The problem that the accuracy of the experimental data is influenced due to the lack of dedicated experimental device in the process of performing dynamics experiment research on the acoustic metamaterial plate structure in the prior art is mainlysolved. Two clamp brackets are oppositely arranged at two sides of the metamaterial plate, each fixed pressing plate is arranged at a top of one clamp bracket, one substrate in the metamaterial plateis arranged between the clamp bracket and the fixed pressing plate, and the metamaterial plate is fixedly arranged on the clamp brackets; each positioning rod is arranged at one side of each of two clamp brackets, and each positioning rod is fixedly connected with two clamp brackets; and each clamp bracket is fixedly connected with a vibration-isolation foundation track through N connectors. The device is mainly used as an experimental device for testing the dynamic performance of the acoustic metamaterial plate structure.

Owner:HARBIN ENG UNIV

A municipal engineering deceleration belt

ActiveCN109487716BReduce distressAct as an impediment to drivingTraffic signalsRoad signsSpeed bumpStructural engineering

The invention discloses a speed bump for municipal engineering. The speed bump comprises a shaft body base body and a shaft body base split body, and is of a square cavity structure, the shaft body base body and the shaft body base split body are symmetrically distributed and have the same internal structure, a telescopic shaft body is fixed to the center of the bottom of the shaft body base body,a reset spring sleeves the outer side of the telescopic shaft body, a shaft cap sleeves the top of the telescopic shaft body, a supporting pillar is arranged at the top of the shaft cap, and a speedbump body is connected to the top of the supporting pillar. In the running process of a vehicle which runs at a normal speed, the hindering effect of the speed bump on the vehicle cannot occur, and trouble of a driver in normal driving is reduced; a vehicle which overspeeds cannot be hindered at the first speed bump but is hindered from running by the second speed bump, inconvenience is brought topassengers and a driver in the vehicle, and the driver is effectively reminded to abide by the traffic rule of speed limiting.

Owner:灵璧县浩翔信息科技有限公司

Front wheel cover side plate assembly for automobile

InactiveCN101863288BMeet the rigidityGuaranteed installation strengthSuperstructure subunitsMonocoque constructionsAgricultural engineeringFront edge

The invention discloses a front wheel cover side plate assembly for an automobile. The assembly comprises a front wheel cover side plate, a front longitudinal beam, a front shock absorber mounting plate, a connecting plate and a front fender mounting bracket which are arranged on the automobile body in a lateral symmetry way, wherein the front wheel cover side plate has a cavity structure with a top opening; the upper edge of the front longitudinal beam is fixedly connected to the lower end of the front wheel cover side plate; the front edge of the front shock absorber mounting plate is fixedly connected to the rear edge of the front wheel cover side plate; the connecting plate is fixedly connected with the upper end of the front wheel cover side plate and the upper end of the front shockabsorber mounting plate respectively to form a closed cavity; the rear edge of the front fender mounting bracket is fixedly connected with the front edge of the front wheel cover side plate; and the lower end of the front fender mounting bracket is fixedly connected with the upper edge of the front longitudinal beam. The assembly not only rationally and effectively transfers the impact load from the front longitudinal beam to the rear part and the upper part of the automobile body during direct impact and biasing impact, but also ensures the installation strength, the accuracy and the NVH performance of the installation points on the left and the right suspension sides of an engine and the front fender mounting bracket.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Open-and-close device made of aluminium alloy plate for recording medium shell

This invention provides an aluminum alloy sheet for a recording medium case shutter which satisfies all the characteristics.The shutter comprises following materials: aluminum alloy substrate, in which the aluminum alloy contains 2.2-2.8 mass % of Mg, 0.35-0.55 mass % of Mn and 0.1-0.4 mass % of Fe; on a surface which is the shutter outer surface side of an aluminum alloy substrate, a chromate film of 5 to 50 mg / m<2> in terms of chromium coating weight is formed as a first layer, and a acrylate modified polyester urethane based resin coating film is formed as a second layer on the surface of the shutter outer surface side; the synthetic resin coating film contains an acrylate modified polyester urethane based resin, inorganic particles with an average particle size of 10 mum or less, and of 5 to 20 parts by weight based on 100 parts by weight of the acrylate modified polyester urethane based resin, and a polyethylene oxide based lubricant of 0.5 to 3 parts by weight based on 100 parts by weight of the acrylate modified polyester urethane based resin. The synthetic resin coating film is formed with a film thickness of 0.5 to 3 mum.

Owner:KOBE STEEL LTD

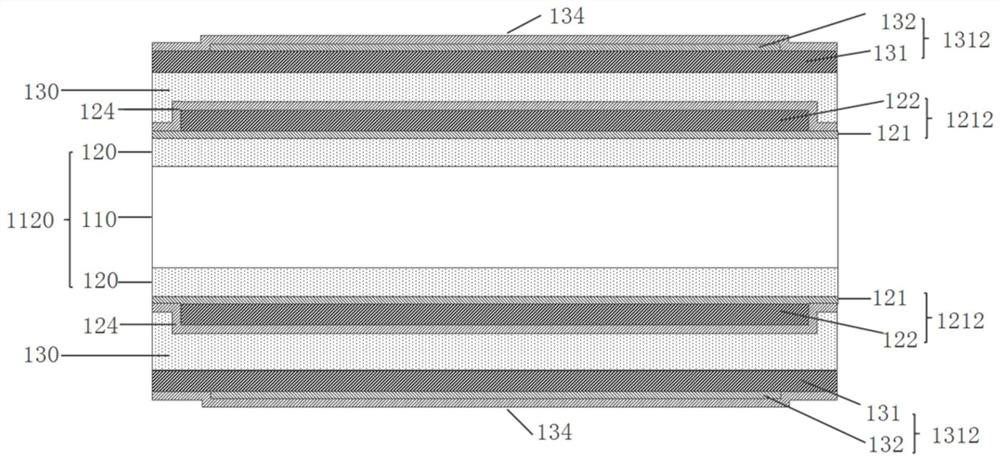

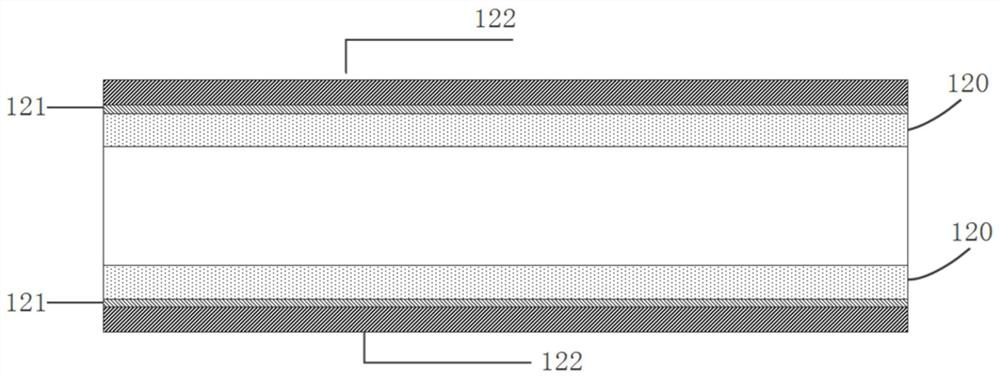

Temporary bearing plate, manufacturing method thereof and manufacturing method of packaging substrate

ActiveCN113066767AEasy to operateImprove yieldSemiconductor/solid-state device detailsSolid-state devicesMetallurgyCopper foil

The embodiment of the invention provides a temporary bearing plate, a manufacturing method of the temporary bearing plate and a manufacturing method of a packaging substrate. Specifically, the temporary bearing plate comprises a first bearing core layer, a first copper foil layer on the first bearing core layer, a second bearing core layer on the first copper foil layer and a second copper foil layer on the second bearing core layer; the first copper foil layer comprises a first outer-layer copper foil and a first inner-layer copper foil which are physically laminated, and the second copper foil layer comprises a second outer-layer copper foil and a second inner-layer copper foil which are physically laminated.

Owner:NANTONG ACCESS SEMICON CO LTD

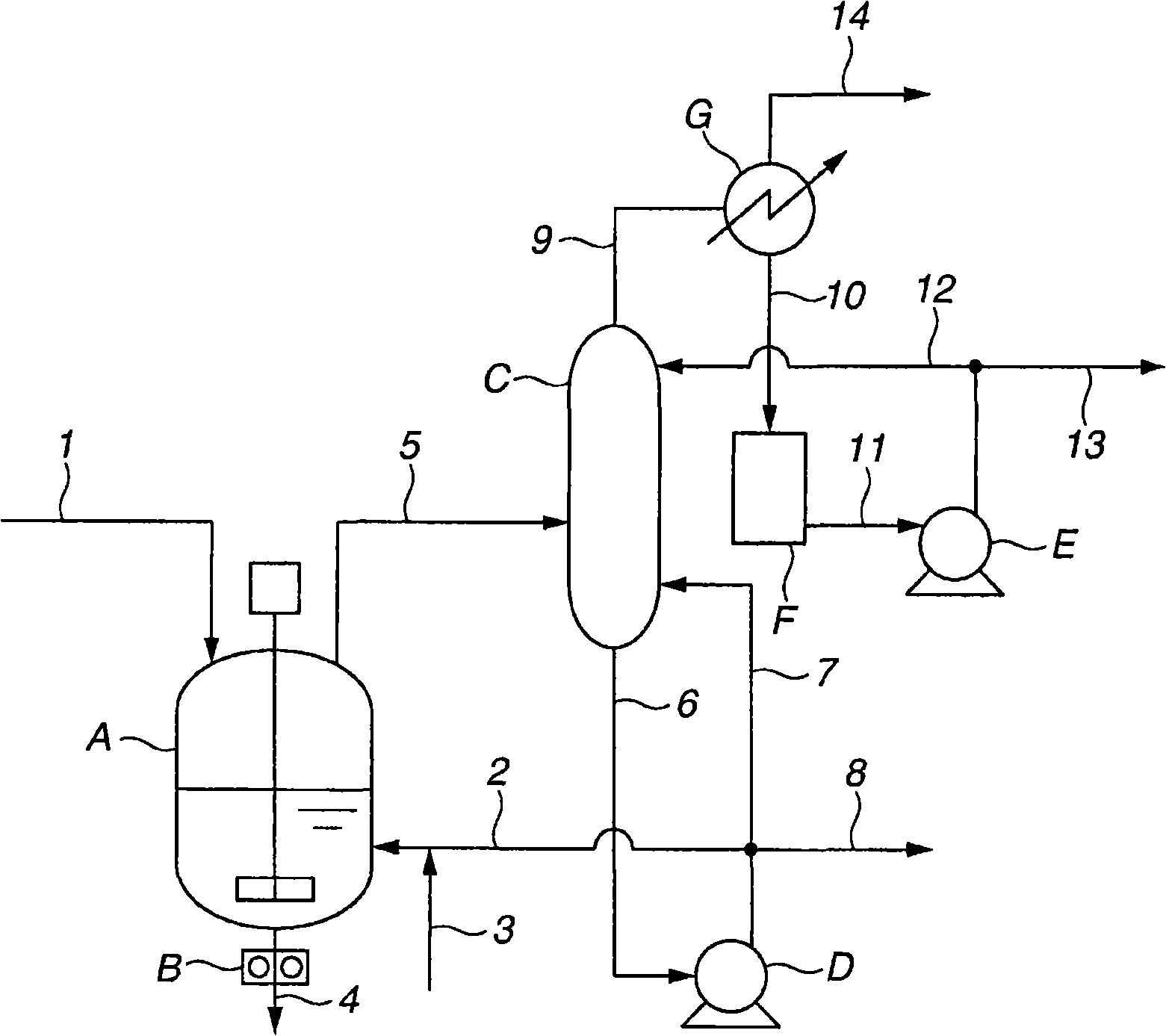

Method for converting disordered carbon into high-energy crystal carbon material by using inorganic compound

PendingCN113371691AEasy to handleImprove conversion rateCarbon preparation/purificationAlcoholPhysical chemistry

The invention discloses a method for converting disordered carbon into a high-energy crystal carbon material by using an inorganic compound, and relates to the technical field of extraction of biological hair macroelements. The method comprises the following nine process steps: 1, cleaning, disinfecting and crushing a hair sample; 2, performing ultraviolet treatment; 3, performing heat treatment; 4, performing fine grinding and secondary ultraviolet treatment; 5, performing vacuum roasting in a furnace; 6, soaking in alcohol, and drying for the second time; 7, mixing with an inorganic compound NaOH + H2O, and calcining; 8, performing acid leaching and drying in a normal-temperature environment; and 9, detecting the content of the high-energy crystal carbon material. The inorganic compound is used for converting macroelement disordered carbon in hair into the high-energy crystal carbon material, the process is simple, the time is short, the operation is safe, the production environment is loose, the production cost is low, the conversion rate is high, the purity is high, toxic and harmful waste is not generated, conventional waste liquid treatment is easy, environmental pollution is not caused, and the high-energy crystal carbon material with the purity of 98-99% or above is effectively obtained.

Owner:昆廷珠宝成都有限公司

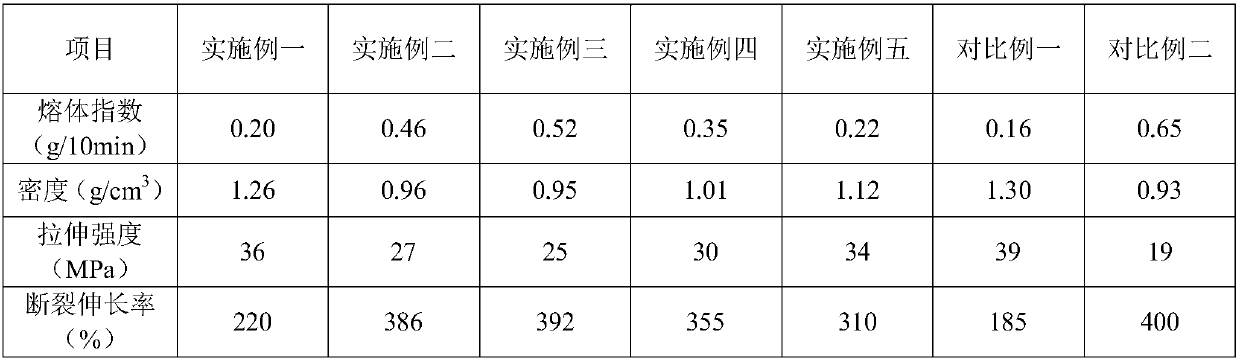

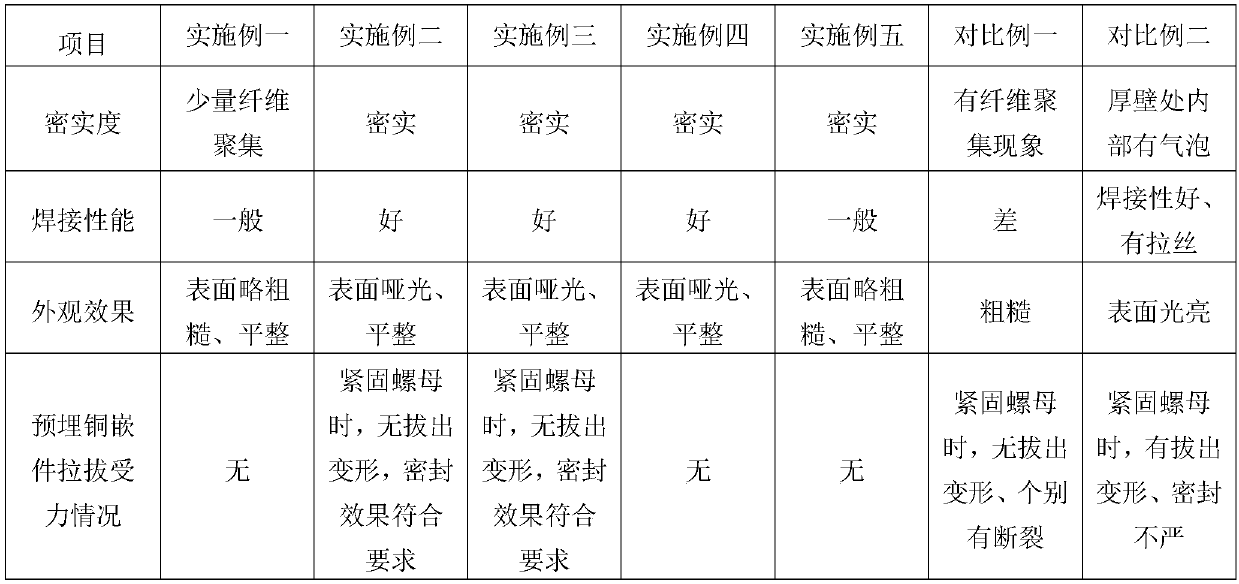

PB composite modified material and preparation method thereof and water heater obtained from PB composite modified material

ActiveCN110387088AImprove injection molding effectEasy injection moldingDomestic articlesGlass fiberUltimate tensile strength

The invention discloses a PB composite modified material and a preparation method thereof and a water heater obtained from the PB composite modified material. The PB composite modified material is prepared from the following raw materials in parts by weight: 60-90 parts of PB resin, 5-30 parts of long glass fibers, 5-10 parts of calcined aluminum factory waste and 1-2 parts of processing aid. Theinvention further provides the preparation method of the PB composite modified material and water heater spare parts and the water heater obtained from the PB composite modified material. The long glass fibers and the calcined aluminum factory waste are adopted to modify the PB resin, the performance of the glass fibers is effectively protected from being damaged, the tensile strength of the materials is improved, the shrinkage deformation of the materials is reduced, the problem of pressure deformation of hot water system parts is solved, meanwhile, the flatness of the surfaces of the parts is improved, internal shrinkage holes of the parts are reduced, the compactness of the parts is improved, the strength of the parts is improved, and the sealing performance of connecting parts in a hotwater system is effectively improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

Double-sided composite card paper and preparation method thereof

InactiveCN101818466BFeel thickCrisp paperWaste product additionSpecial paperEconomic benefitsPulp and paper industry

The invention provides a double-sided composite card paper and a preparation method thereof. A lining pulp layer is covered on one side of a core pulp layer, a bottom pulp layer is covered on the other side of the core pulp layer and a surface pulp layer is covered on the lining pulp layer; or lining pulp layers are covered on two sides of a core pulp layer, a surface pulp layer is covered on the lining pulp layer on one side, and a bottom pulp layer is covered on the lining pulp layer on the other side. Common waste paper pulp (office waste paper, common waste paper boards and the like) is used for replacing wood pulp to serve as core pulp, and waste paper de-inking pulp and waste white paper edge pulp are used for replacing wood pulp to serve as lining pulp so as to save the cost; each layer is specifically quantified. The obtained double-sided composite card paper has heavy handfeel and crisp paper surface, press molding and embossing processes required for processing and molding have better implementing effects, the expressed levels are richer, the dependency of the product on operating workers is furthest reduced, and effective expansion of the capacity and increment of the economic benefit are furthest realized.

Owner:CHANGSHA TIANTIAN PAPER

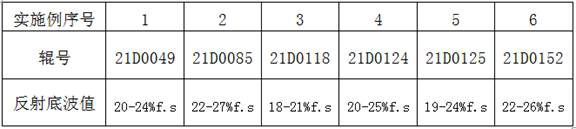

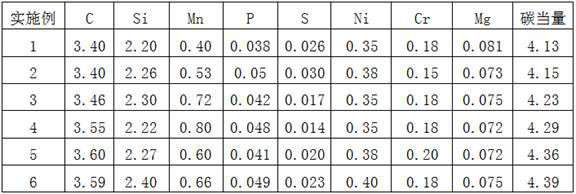

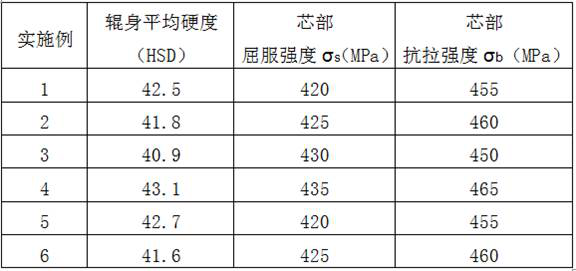

Method for preventing nodular cast iron roller core from loosening

The invention discloses a method for preventing a nodular cast iron roller core from loosening, and belongs to the technical field of metallurgy. The production process comprises the working procedures of smelting, molten iron modification treatment, pouring, heat preservation and heat treatment. In the heat treatment process, a high-temperature normalizing and two-stage destressing annealing heat treatment process is adopted, the normalizing temperature is 970-990 DEG C, and the normalizing time is 15-17 hours; the first-stage annealing temperature is 515-535 DEG C, and the heat preservation time is 11-13 hours; and the second-stage annealing temperature is 550-570 DEG C, and the heat preservation time is 11-13 hours. The problem that shrinkage cavities and shrinkage porosity are generated in the centrifugal composite nodular cast iron roller core is solved, the attenuation phenomenon of ultrasonic flaw detection is avoided, and the use requirements of users are met.

Owner:唐山钢铁集团重机装备有限公司 +2

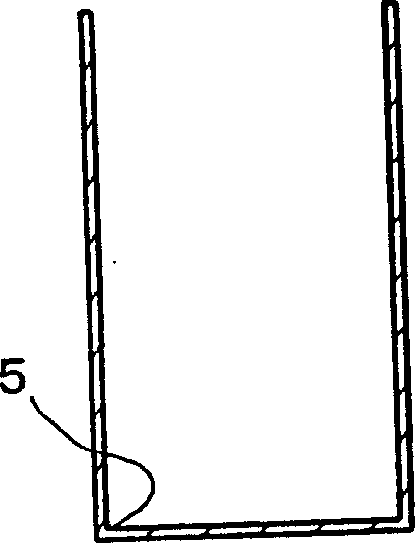

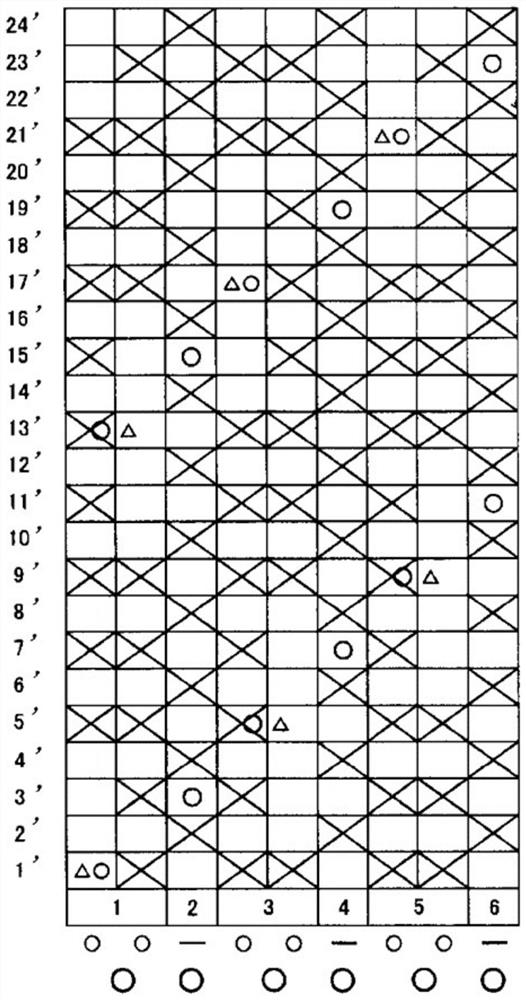

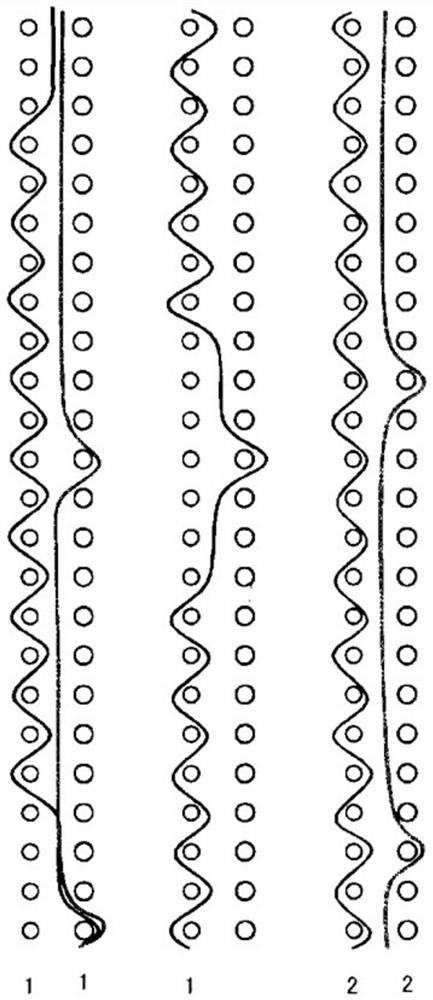

Industrial two-layer fabric

InactiveCN112513354AMeet the rigidityMeet wear resistanceMachine wet endMulti-ply fabricsYarnEngineering

Provided is an industrial two-layer fabric satisfying basic characteristics of a fabric, such as rigidity, wear resistance, dewaterability, mark suppression, and low water retention for reducing the amount of water retained. The industrial two-layer fabric pertaining to the present invention has at least a first structure and a second structure in the weave repeat thereof, the first structure being formed by a combination of two upper-surface-side warps and a single lower-surface-side warp, the second structure being formed by a single upper-surface-side warp and a single lower-surface-side warp, the first structure and the second structure being disposed adjacent to each other, the upper-surface-side warps in the first structure being formed by a warp binding yarn having the function of binding an upper-surface-side fabric and a lower-surface-side fabric, the combination of two upper-surface-side warps forming the first structure being disposed adjacent to each other and constitutinga partial rib weave at the surface of the upper-surface-side fabric, the diameter of the lower-surface-side warp being larger than the diameter of the upper-surface-side warp forming the first structure, and the upper-surface-side warp in the second structure being formed by a flat warp.

Owner:FILCON

Aromatic polycarbonate resin composition and molded resin

ActiveCN101346430BSatisfy mobilityMeet the rigidityProductsReagentsPolytetramethylene terephthalateHeat resistance

An aromatic polycarbonate resin composition which comprises an aromatic polycarbonate resin (ingredient (A)) and a polybutylene terephthalate resin (ingredient (B)) and optionally further contains a rubbery polymer and / or an inorganic filler, characterized in that the amounts of the aromatic polycarbonate resin (ingredient (A)) and the polybutylene terephthalate resin (ingredient (B)) are 51-99 parts by weight and 1-49 parts by weight, respectively, per 100 parts by weight of the sum of the aromatic polycarbonate resin (ingredient (A)) and the polybutylene terephthalate resin (ingredient (B))and that the polybutylene terephthalate resin (ingredient (B)) has a titanium compound content of 1-75 ppm, excluding 1 ppm, in terms of titanium atom amount and a terminal carboxy group content of 39 [mu]eq / g or lower. This aromatic polycarbonate resin composition has an excellent balance among various properties, i.e., is satisfactory in all of flowability, rigidity, impact resistance, chemicalresistance, fatigue characteristics, heat resistance, thermal stability in residence, and suitability for recycling.

Owner:MITSUBISHI ENG PLASTICS CORP

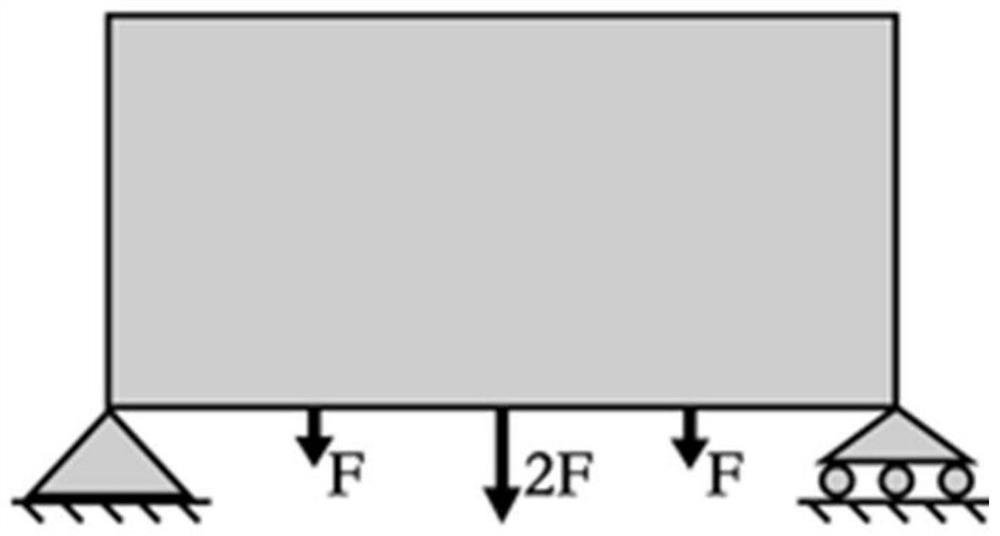

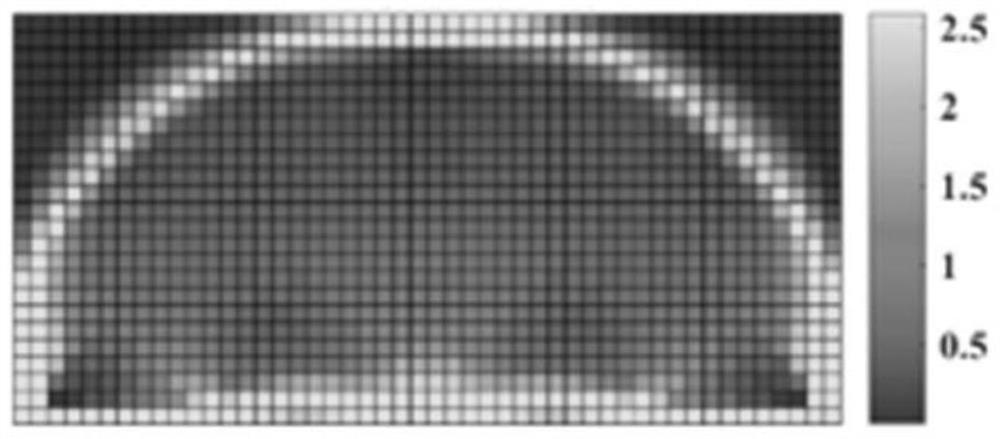

Optimization method for designing multi-lattice structure meeting local buckling constraint

PendingCN114519253AMeet local buckling requirementsMeet the rigidityCharacter and pattern recognitionDesign optimisation/simulationMacroscopic scaleMesh grid

The invention provides an optimization method for designing a multi-lattice structure meeting local buckling constraint. The method comprises the following steps: firstly, introducing a concept of free material optimization, and finding out optimal elastic tensor distribution in all feasible elastic continuum; a matched grid structure is embedded in each macroscopic element through an elastic tensor approximately containing buckling constraint. In order to obtain a better structure, stresses in local units are introduced in particular. Finally, the lattice structure with good overall rigidity and local buckling resistance is obtained through the method, and therefore the mechanical property of the structure is improved.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com