PB composite modified material and preparation method thereof and water heater obtained from PB composite modified material

A technology of composite modification and composite materials, which can be applied to other household appliances, household components, applications, etc., can solve the problems of easy deformation sealing, poor welding performance, and low strength, and achieve good sealing performance, good welding performance, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

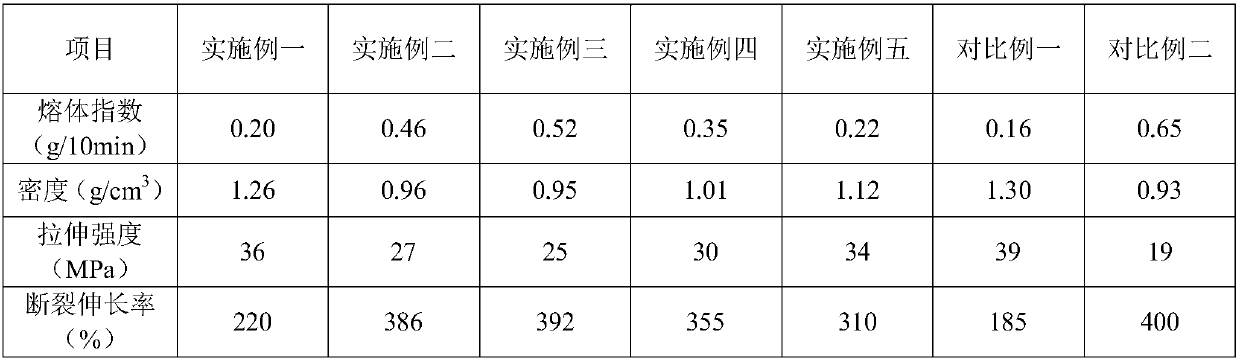

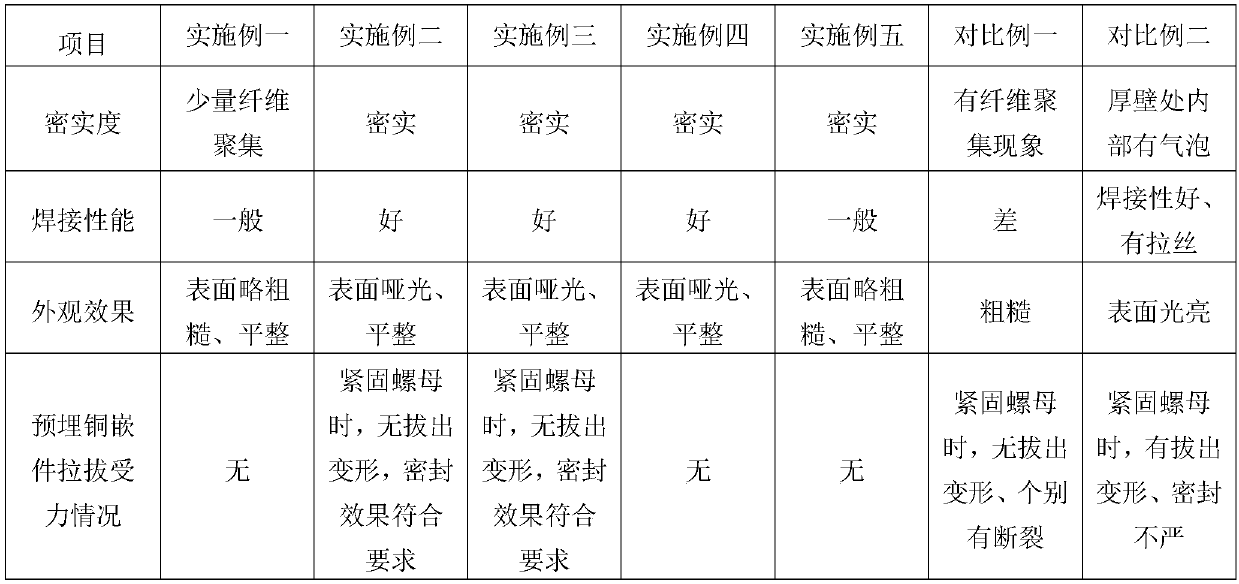

Examples

Embodiment approach

[0021] As a preferred embodiment, the following raw materials are included in parts by weight: 85-90 parts of PB resin, 5-7 parts of long glass fiber, 5-6 parts of calcined aluminum factory waste, and 1-2 parts of processing aid.

[0022] As a preferred embodiment, the processing aid is any one or more of a coupling agent, a lubricant, an antibacterial agent, and an antistatic agent.

[0023] As a preferred embodiment, the coupling agent is a silane coupling agent, the lubricant is a composite lubricant mixed with solid paraffin and stearic acid, and the antibacterial agent is zinc oxide, nano silver, titanium dioxide Any one or more of them, the antistatic agent is any one of stearyl trimethyl quaternary ammonium hydrochloride, sodium alkyl sulfonate, ethoxy lauramide, glycerol monostearate species or several.

[0024] As a preferred embodiment, the calcined aluminum plant waste includes the following components in weight percentage: 30-40% of silicon dioxide, 40-50% of calc...

Embodiment 1

[0031] A kind of preparation method of PB composite modified material of the present invention, comprises the following steps:

[0032] 1) Weigh raw materials according to the following parts by weight: 60 parts of PB resin, 30 parts of long glass fiber, 10 parts of calcined aluminum plant waste, 2 parts of coupling agent;

[0033] The calcined aluminum plant waste includes the following components in percentage by weight: 35% silicon dioxide, 45% calcium oxide, 10% aluminum oxide, 6% iron oxide, and 4% sodium oxide. The calcining method is: first, Dry at 170°C for 40 minutes, then calcined at 1100°C for 15 minutes, and finally, after crushing and winnowing, the calcined aluminum plant waste has a particle size of 18 μm;

[0034] 2) Take PB resin, calcined aluminum plant waste and processing aids and add them into a kneader, and knead to obtain a premixed composite material for future use;

[0035] 3) Add the pre-mixed composite material obtained in step 2) into a twin-screw ...

Embodiment 2

[0042] A kind of preparation method of PB composite modified material of the present invention, comprises the following steps:

[0043] 1) Weigh the raw materials according to the following parts by weight: 85 parts of PB resin, 7 parts of long glass fiber, 6 parts of calcined aluminum plant waste, 1 part of coupling agent, 0.5 part of lubricant, 0.3 part of antibacterial agent, and 0.2 part of antistatic agent;

[0044] The coupling agent is a silane coupling agent, the lubricant is a composite lubricant mixed with solid paraffin and stearic acid in a mass ratio of 1:1, the antibacterial agent is zinc oxide, and the antistatic agent is stearyl trimethyl quaternary ammonium hydrochloride;

[0045] 2) Take PB resin, calcined aluminum plant waste, coupling agent and lubricant and add them into a kneader, knead to 80°C, take out of the pot, and obtain a premixed composite material, which is set aside;

[0046] 3) Add the pre-mixed composite material obtained in step 2) into a tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com