Patents

Literature

67results about How to "Vibration suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

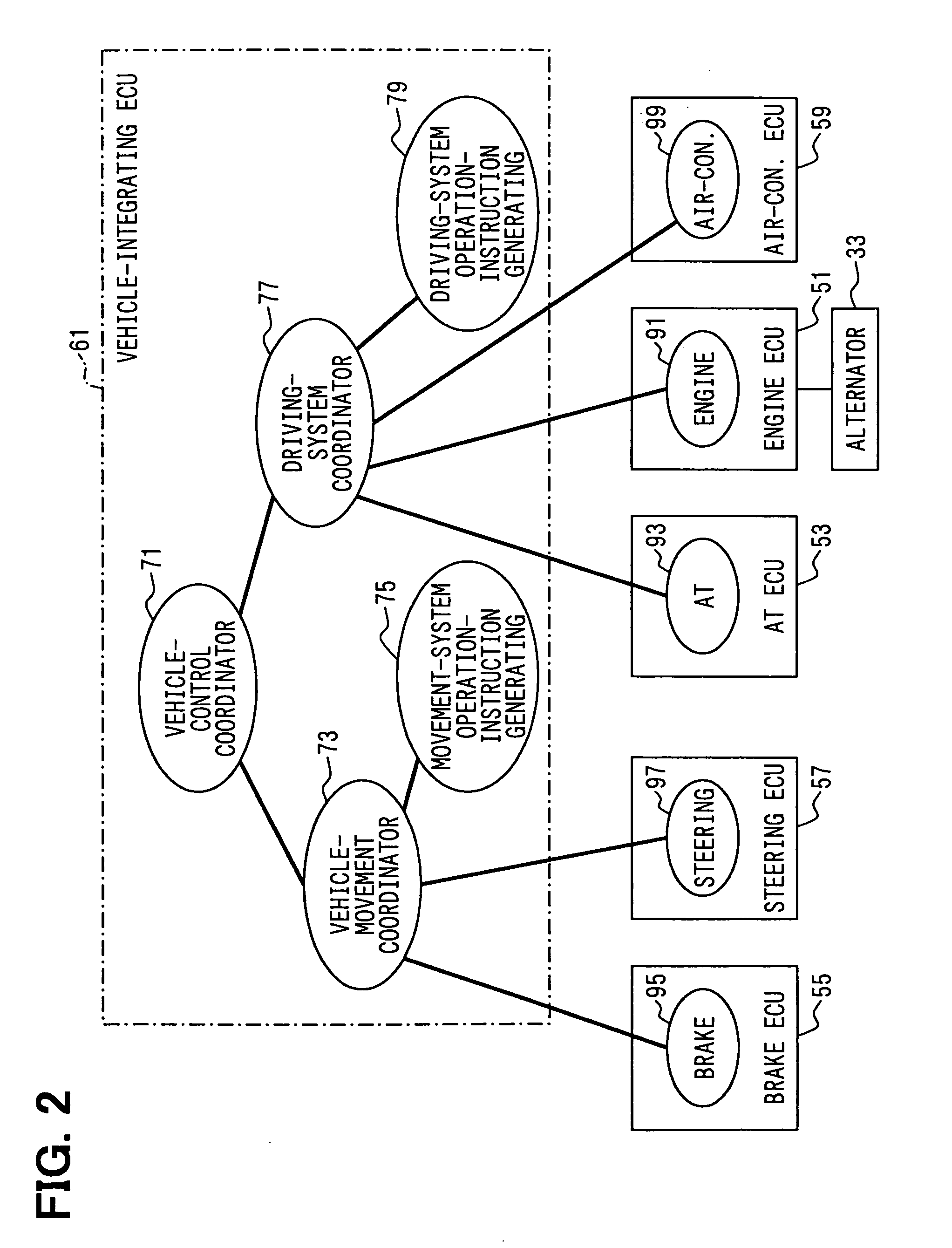

Vehicle control system

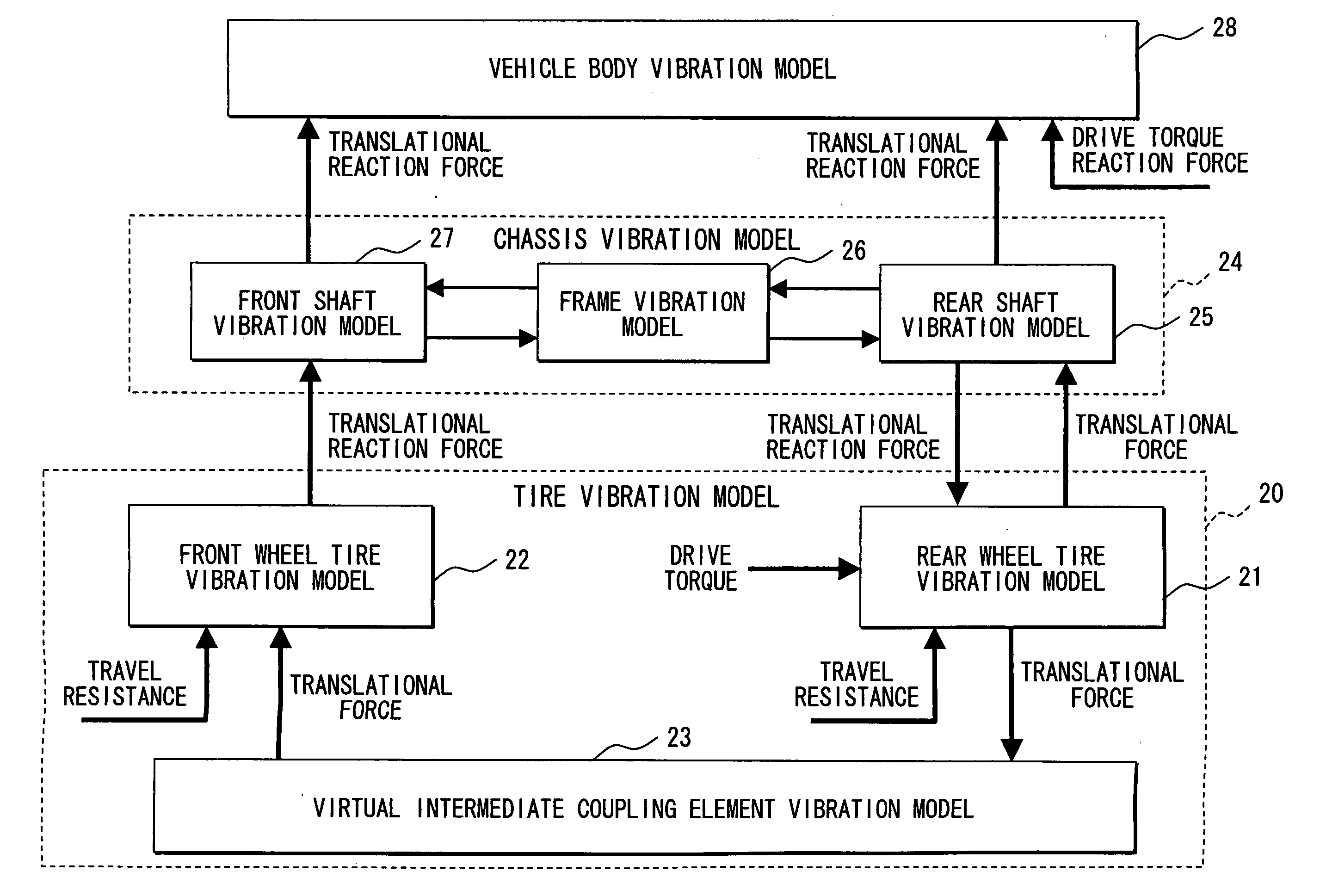

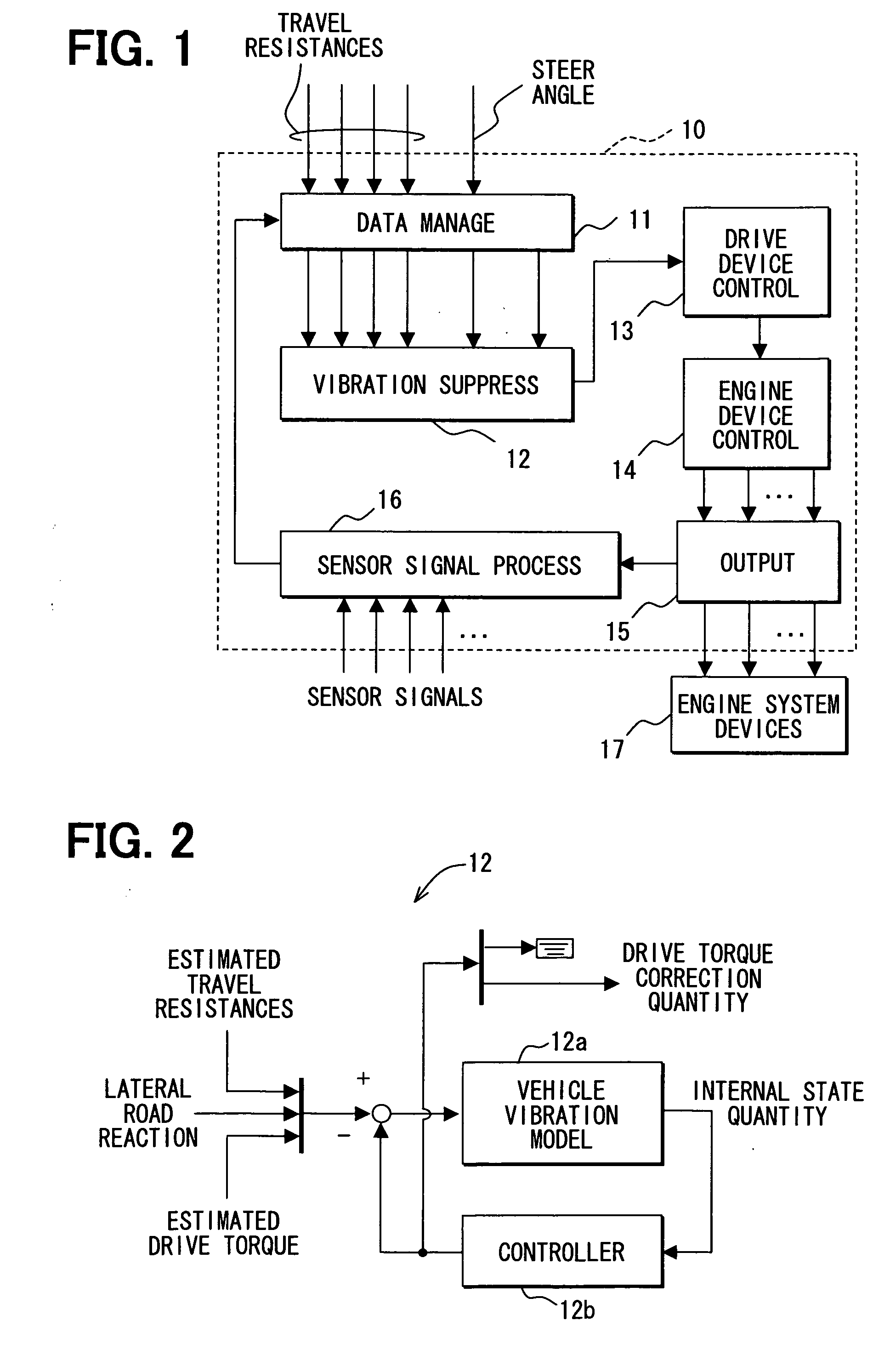

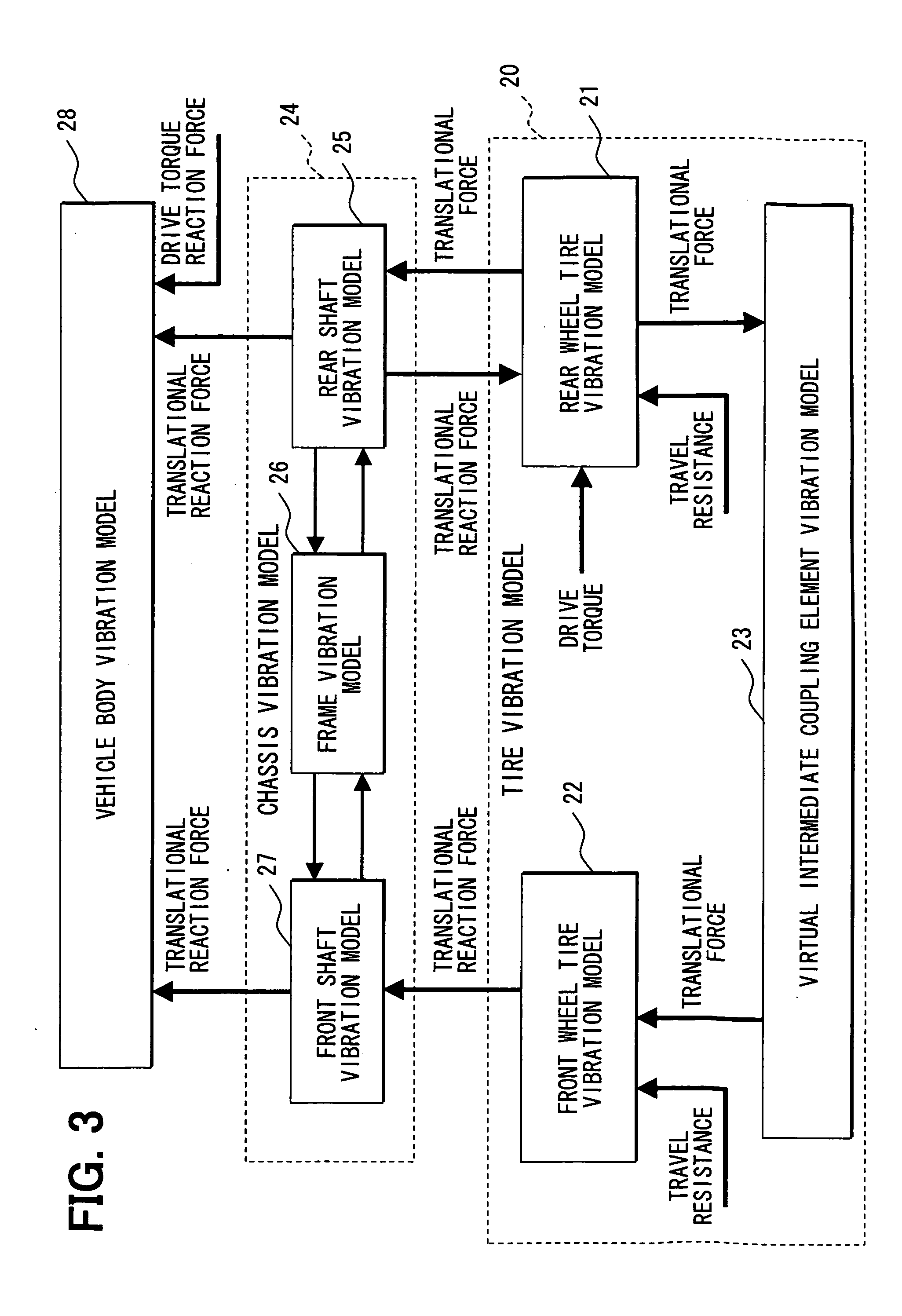

ActiveUS20080249689A1High precisionVibration suppressionVehicle testingTyre partsControl systemBody vibration

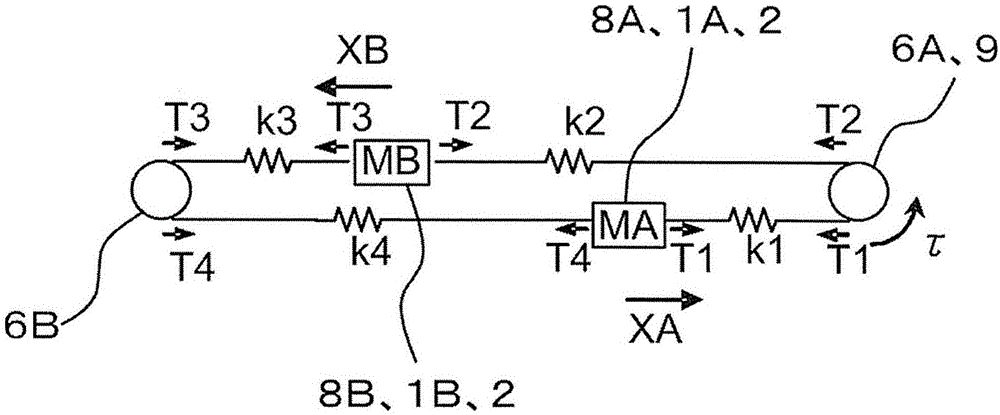

A vehicle control system estimates the vibration states of tires by using a vehicle vibration model that is separated into a vehicle body vibration model, a chassis vibration model, and a tire vibration model with high precision. The tire vibration model in the vehicle vibration model is formed of a rear wheel tire vibration model, a front wheel tire vibration model, and a virtual coupling element vibration model that virtually couples the rear wheel tire vibration model and the front wheel tire vibration model. Influence of the vibration state that is conducted between the front wheel tires and the rear wheel tires is considered while the tire vibration model and the chassis vibration model are separated from each other, thereby making it possible to estimate the vibrations that occur in the front wheel tires and the rear wheel tires.

Owner:DENSO CORP

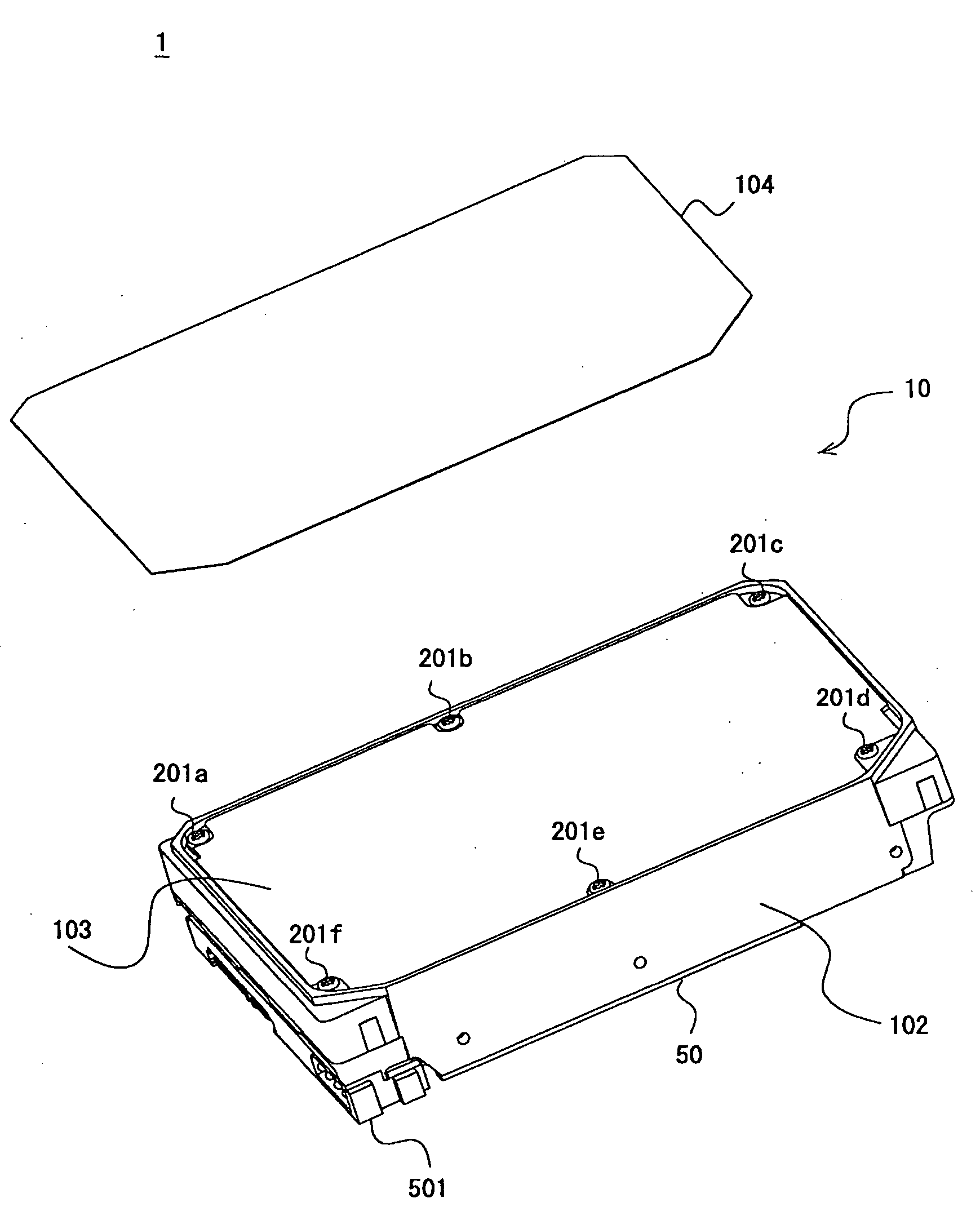

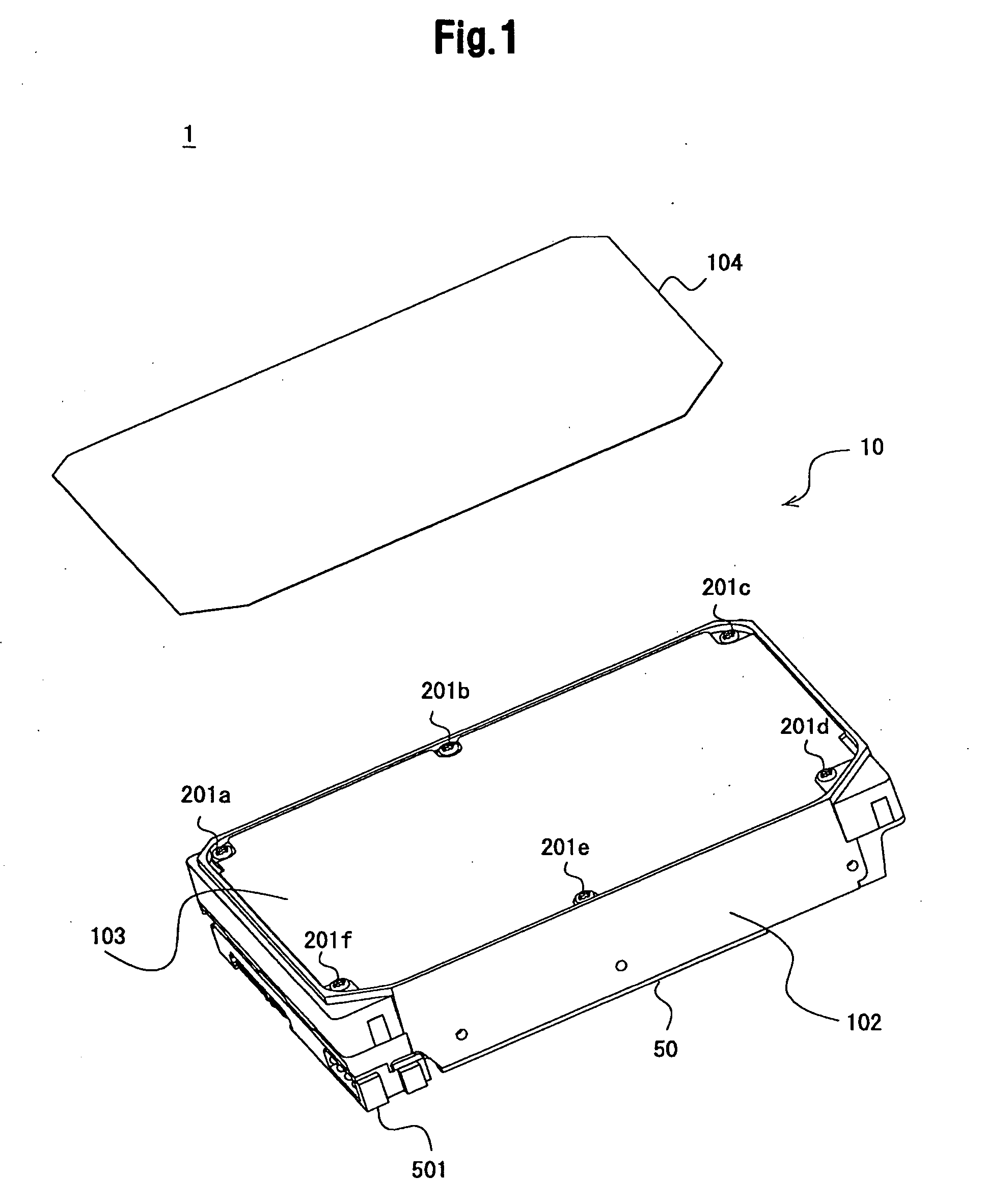

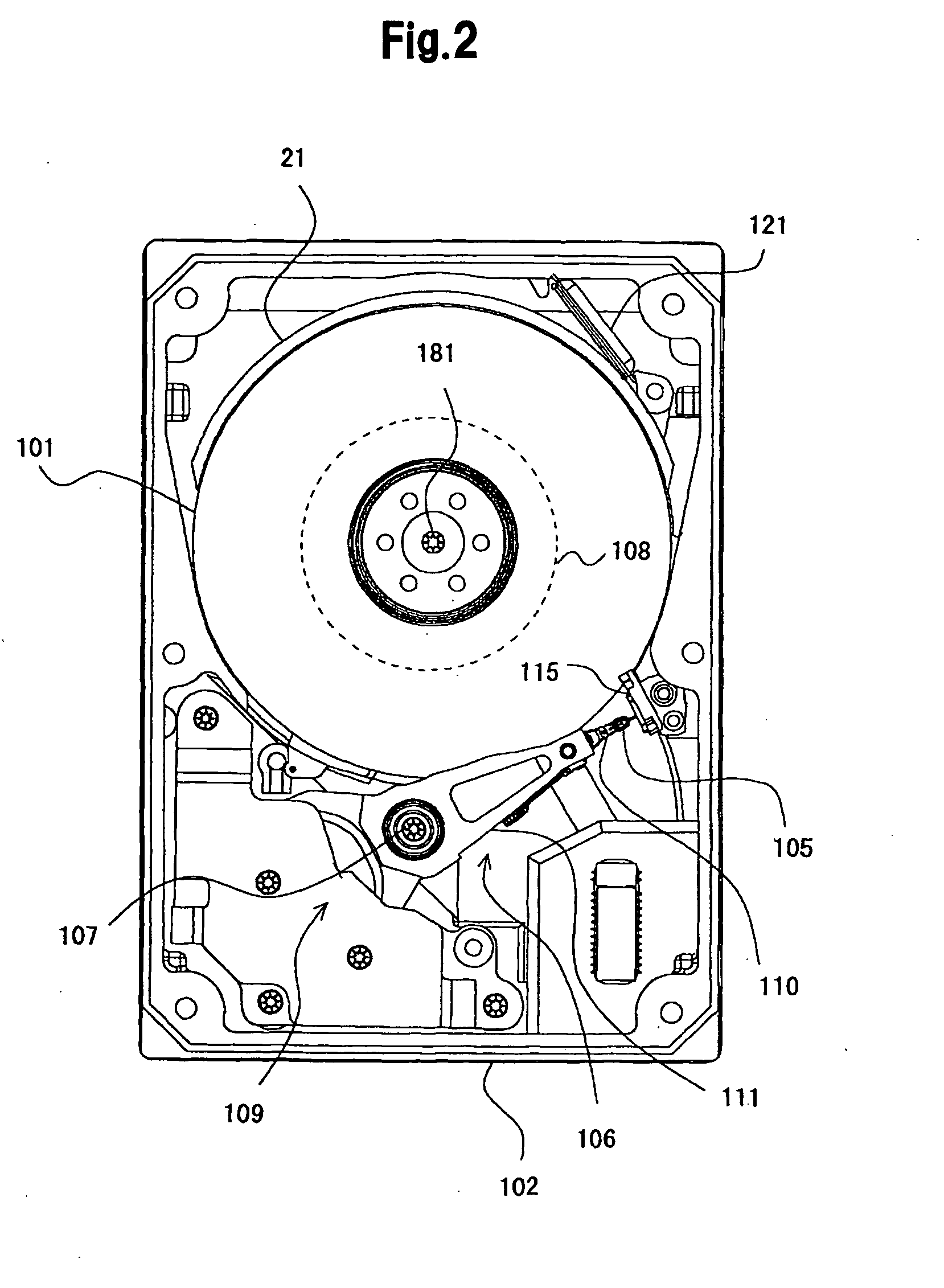

Manufacturing method of base and Manufacturing method of disk drive device

ActiveUS20090241322A1Vibration suppressionPrevent leakageElectrical transducersRecord information storageMagnetic disksHard disc drive

Embodiments of the present invention help to effectively suppress vibration of the disk in a Hard Disk Drive (HDD) with low density gas sealed therein, and securely prevent leakage of the low density gas from the base. In an embodiment, helium gas is sealed in a hermetically sealed enclosure of an HDD, and a shroud is formed integrally with a base. In manufacturing the base, a magnetic disk facing surface of the shroud is shaped by cutting after die-casting. This accomplishes a small and precise size of the gap between the magnetic disk facing surface and the circumferential edge of the disk. Cutting the shroud formed independently from the exterior walls, which ensure the hermeticity with the shroud, suppresses the vibration of the magnetic disk and eliminates the necessity of cutting of the inner surfaces of the exterior walls for the purpose of suppression of the vibration to reduce the risk of helium leakage.

Owner:WESTERN DIGITAL TECH INC

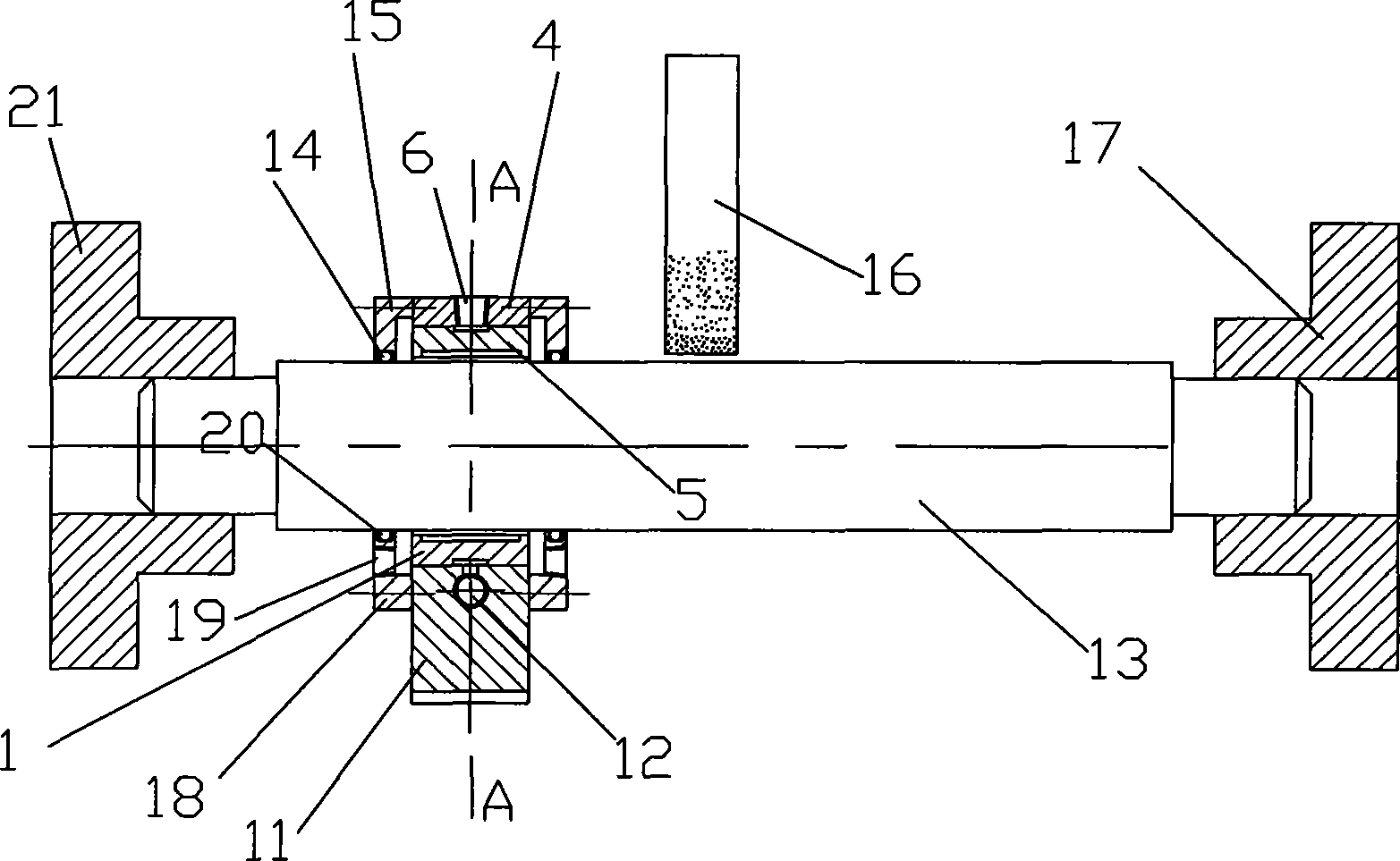

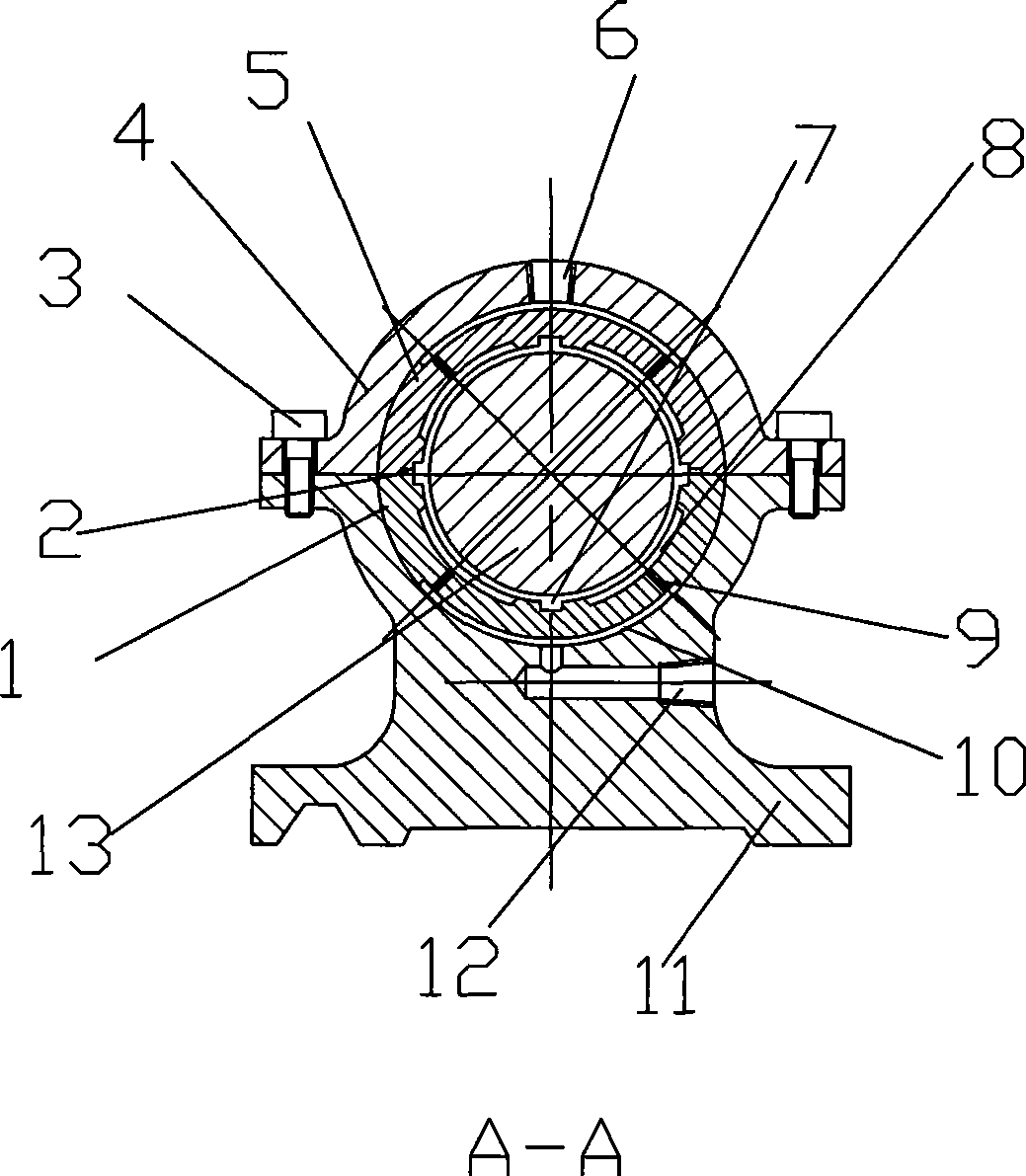

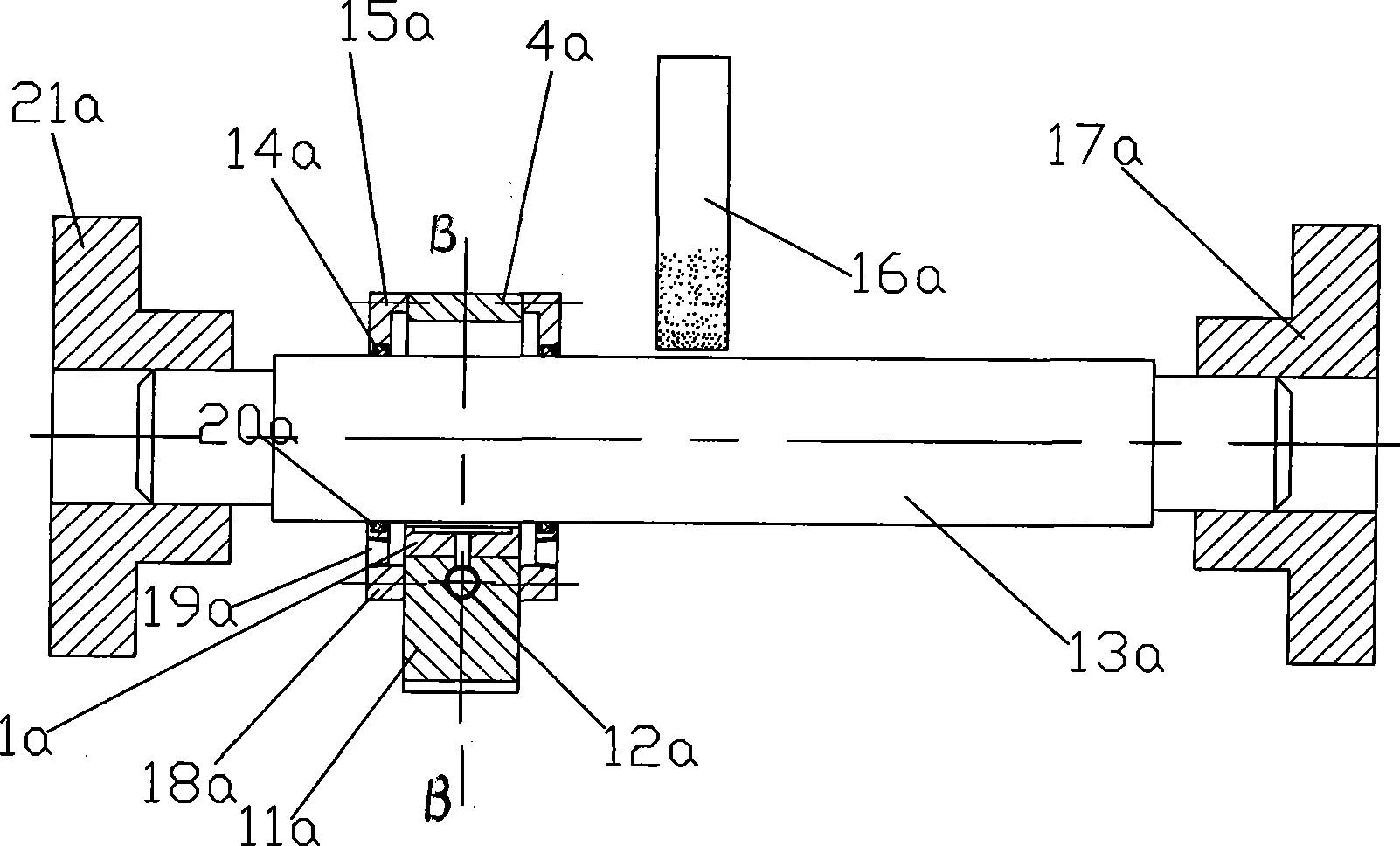

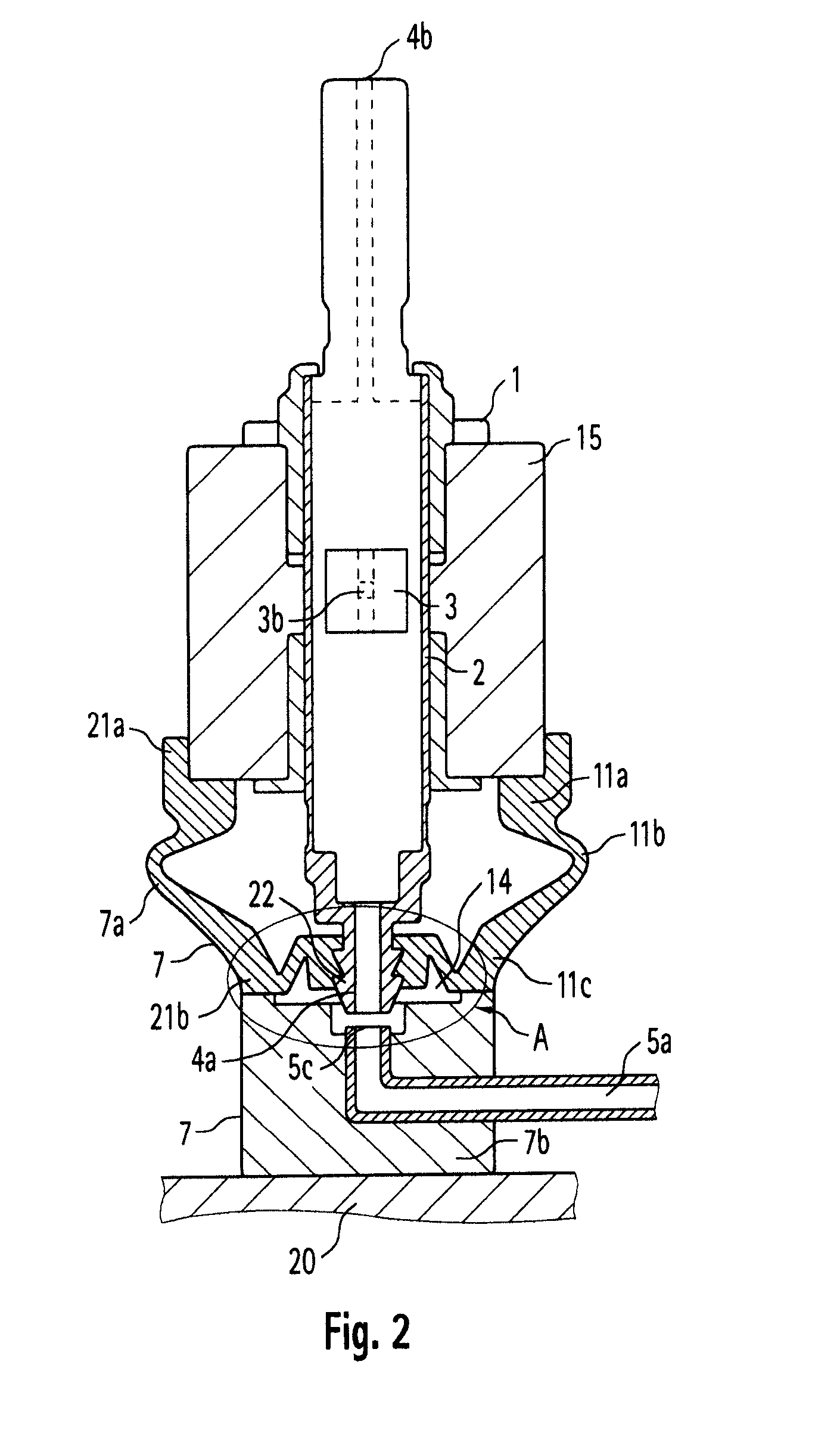

Machine tool fluid pressure center frame

InactiveCN101428393AAbsorb vibrationVibration suppressionRevolution surface grinding machinesAuxillary equipmentEngineeringFluid pressure

The invention relates to a liquid static pressure central support of a machine tool for processing shaft-type parts, which solves the problem that the bearing precision in the precision machining of the shaft-type parts is insufficient. The central support is characterized in that a lower bearing bush is arranged on the central support, an upper bearing bush is arranged on the inner lateral surface of an upper gland in the radial direction, bearing grooves are formed on the working planes of the upper bearing bush and the lower bearing bush, and an oil returning groove is formed between adjacent bearing grooves; arc oil grooves are formed on the back of the upper bearing bush and the lower bearing bush; orifices are formed on the bearing grooves, and the orifices are communicated with the bearing grooves and the arc oil grooves; a lower oil inlet is formed on the central support; upper semi-end covers are arranged on both lateral surfaces of the upper gland in the axial direction respectively, and lower semi-end-covers are arranged on both lateral surfaces of the lower concave semicircular surface of the central support in the axial direction respectively. The liquid static pressure central support adopts the liquid static pressure technology to directly support work pieces, and the rigid direct contact does not exist between the central support and the work pieces; therefore, the invention has the following advantages: the abrasion is not generated on the surface of the work pieces, the vibration of the work pieces supported can be absorbed and refrained, the bearing precision is higher, and the liquid static pressure central support is suitable for the precision machining of the shaft-type parts.

Owner:HEFEI UNIV OF TECH

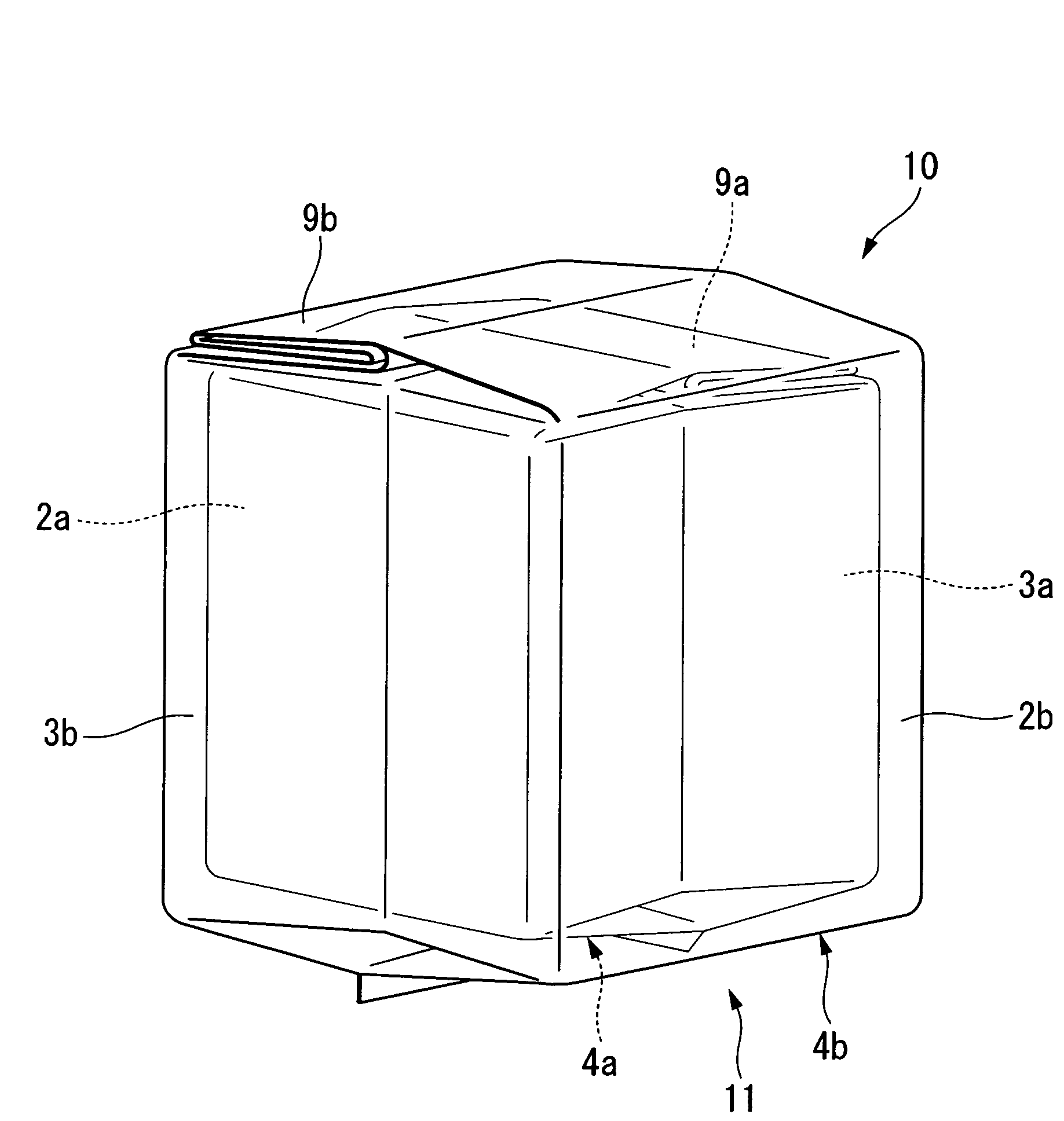

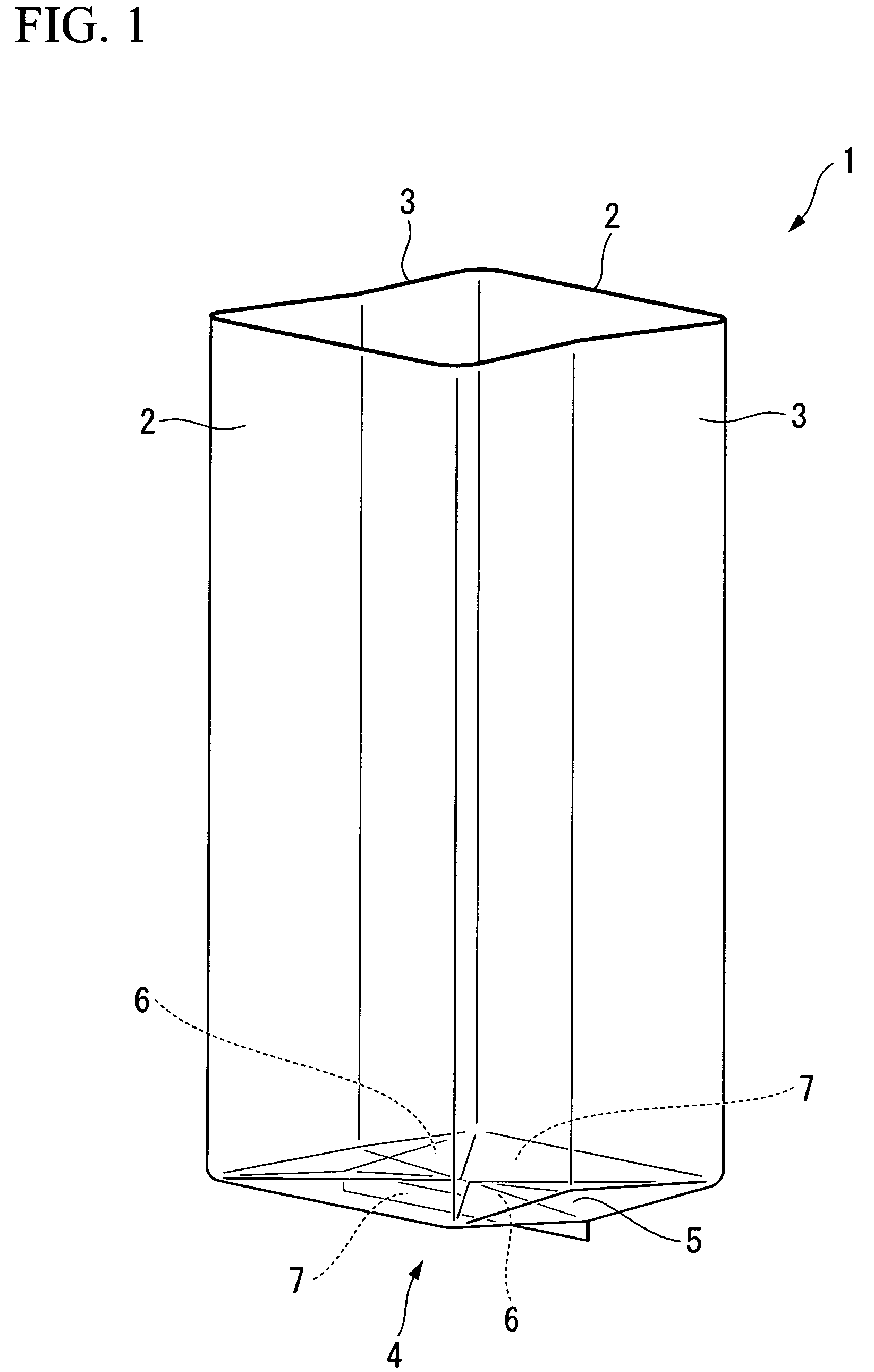

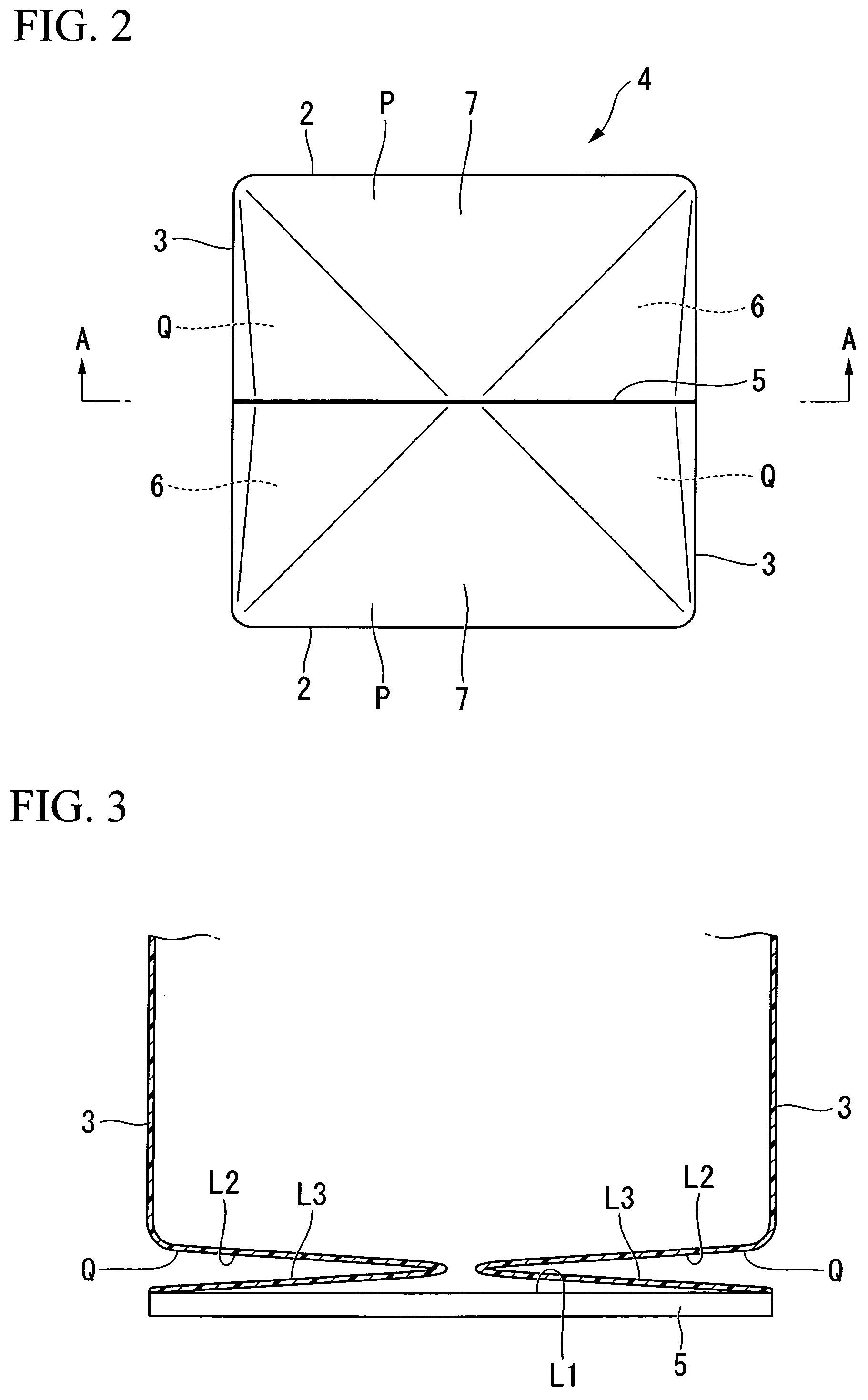

Method of packing silicon and packing body

ActiveUS20090056279A1Reduce generationVibration suppressionWrapping material feeding apparatusBagsPolycrystalline siliconEngineering

When packing a polycrystalline silicon with a two-layer structured packing body comprising an inner bag (1a) and an outer bag (1b), there are used the inner bag (1a) and the outer bag (1b) having bottom sections (4a, 4b) provided with a pair of tucked sections, the shape of which is substantially a triangle in plan view, formed by inward-folding the portions continued from both of rectangular side face sections (3a, 3b), and when storing the inner bag (1a) that stores the polycrystalline silicon therein into the outer bag (1b), the bottom sections (4a, 4b) are superimposed with the respective tucked sections (6a, 6b) of the inner bag (1a) and the outer bag (1b) displaced from each other by 90° so that they do not overlap on each other.

Owner:MITSUBISHI MATERIALS CORP

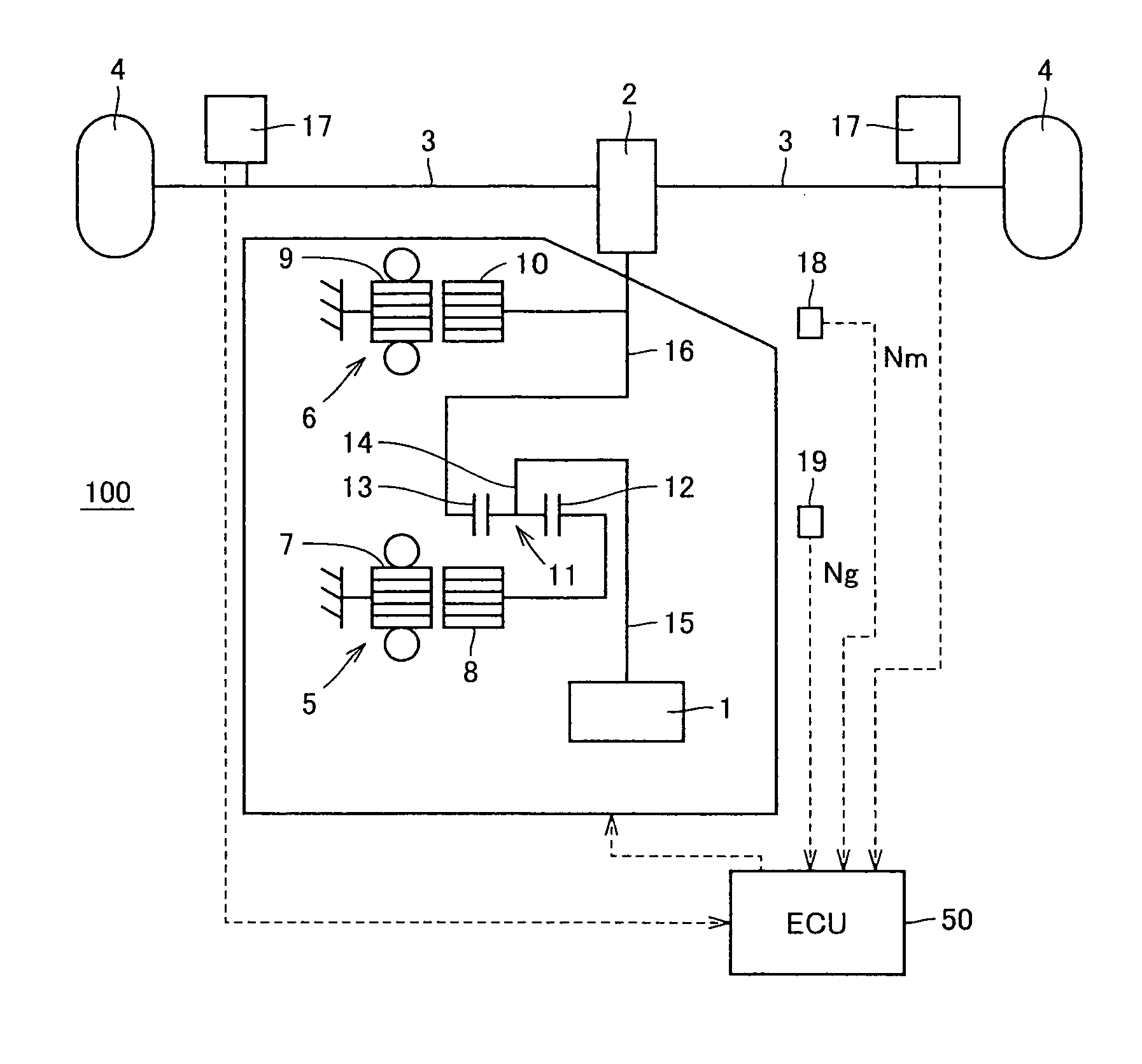

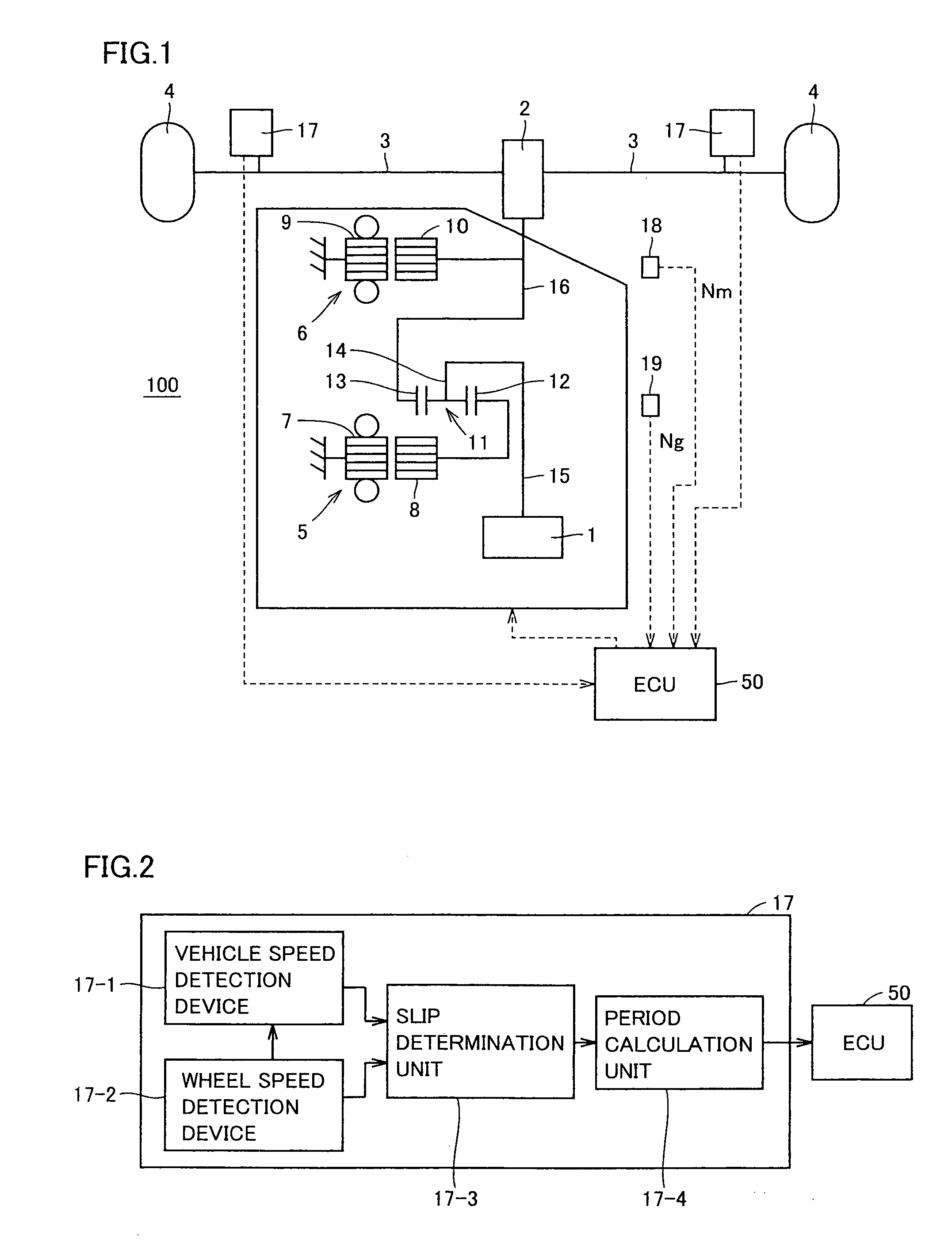

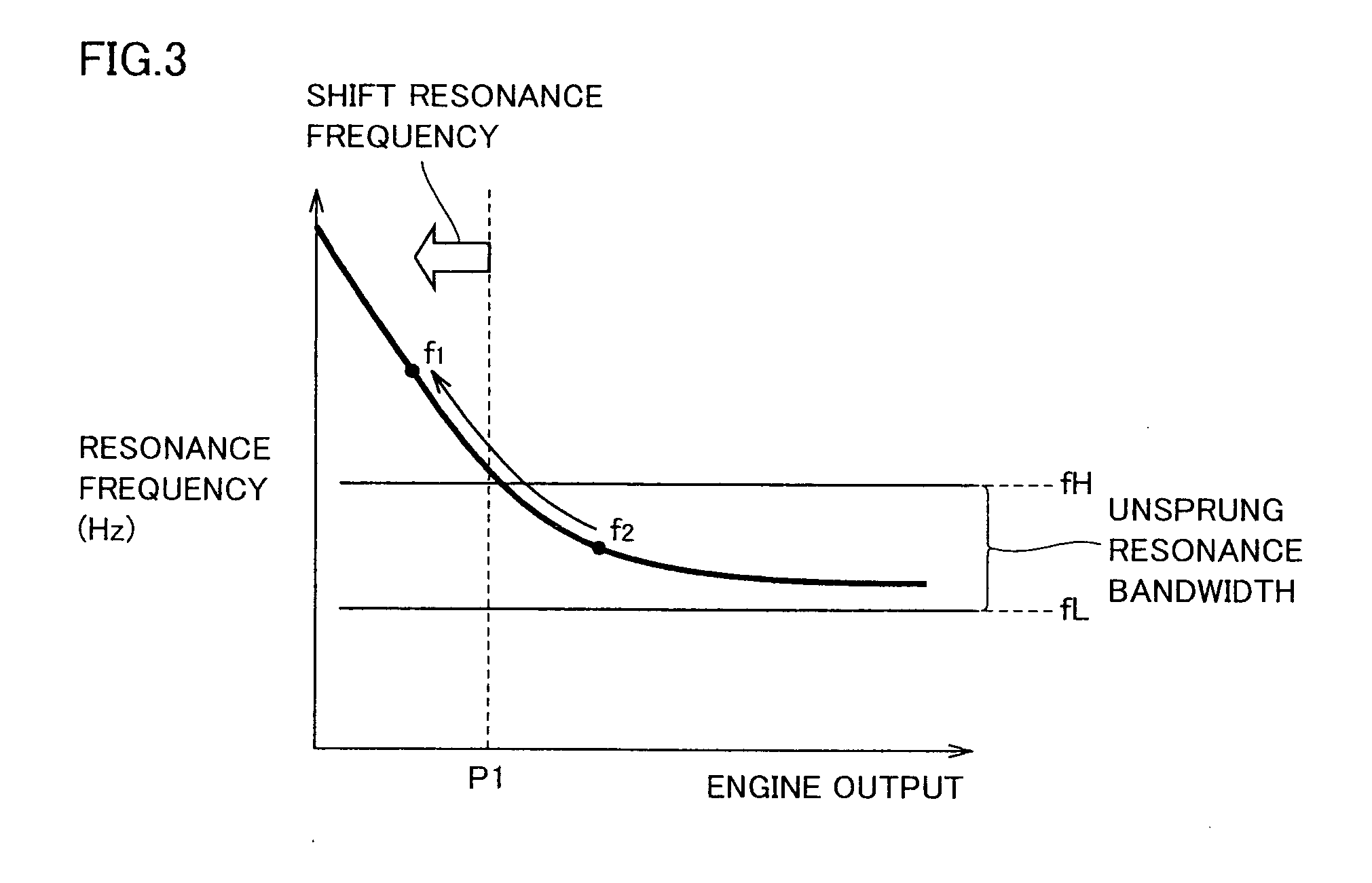

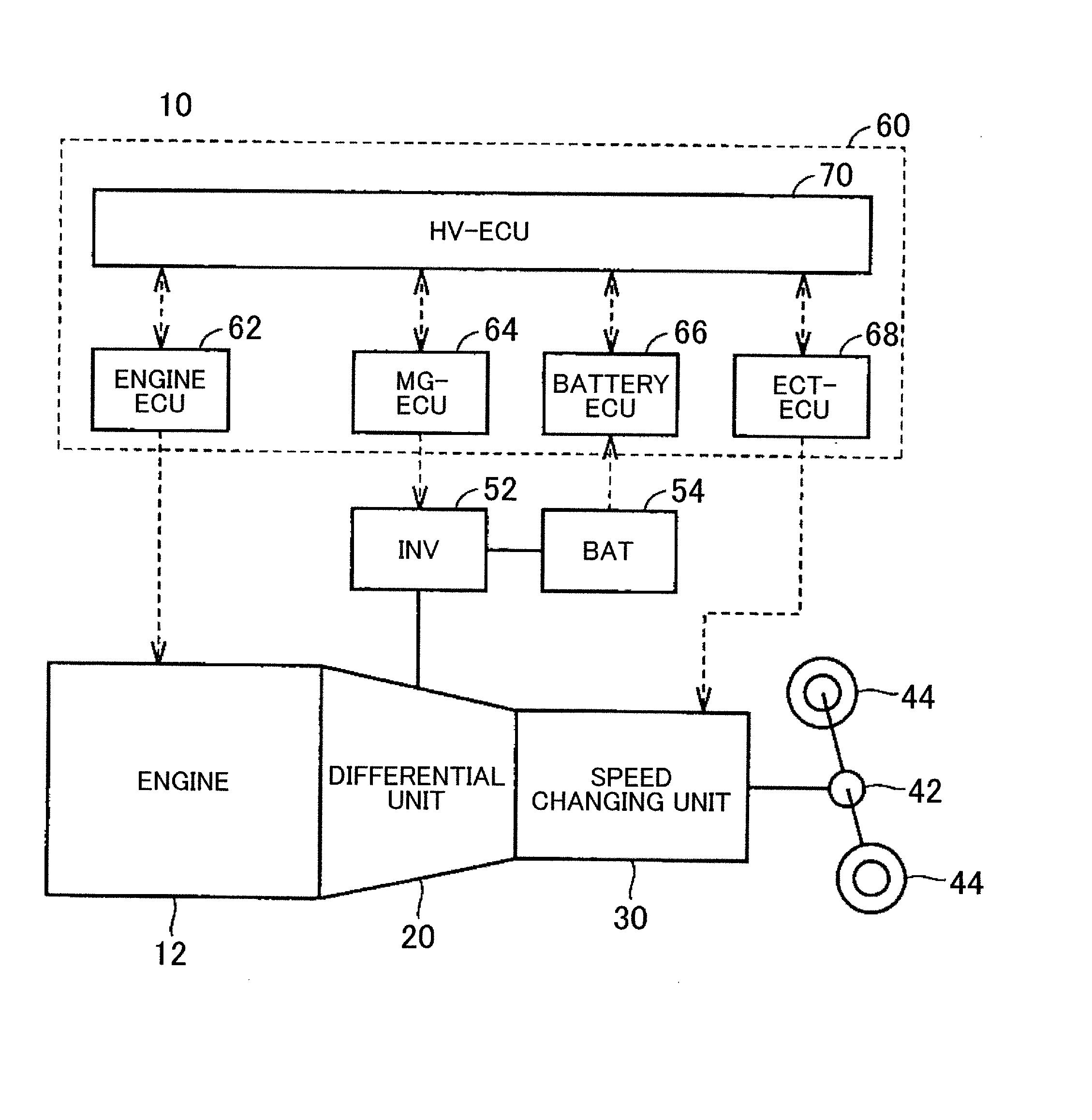

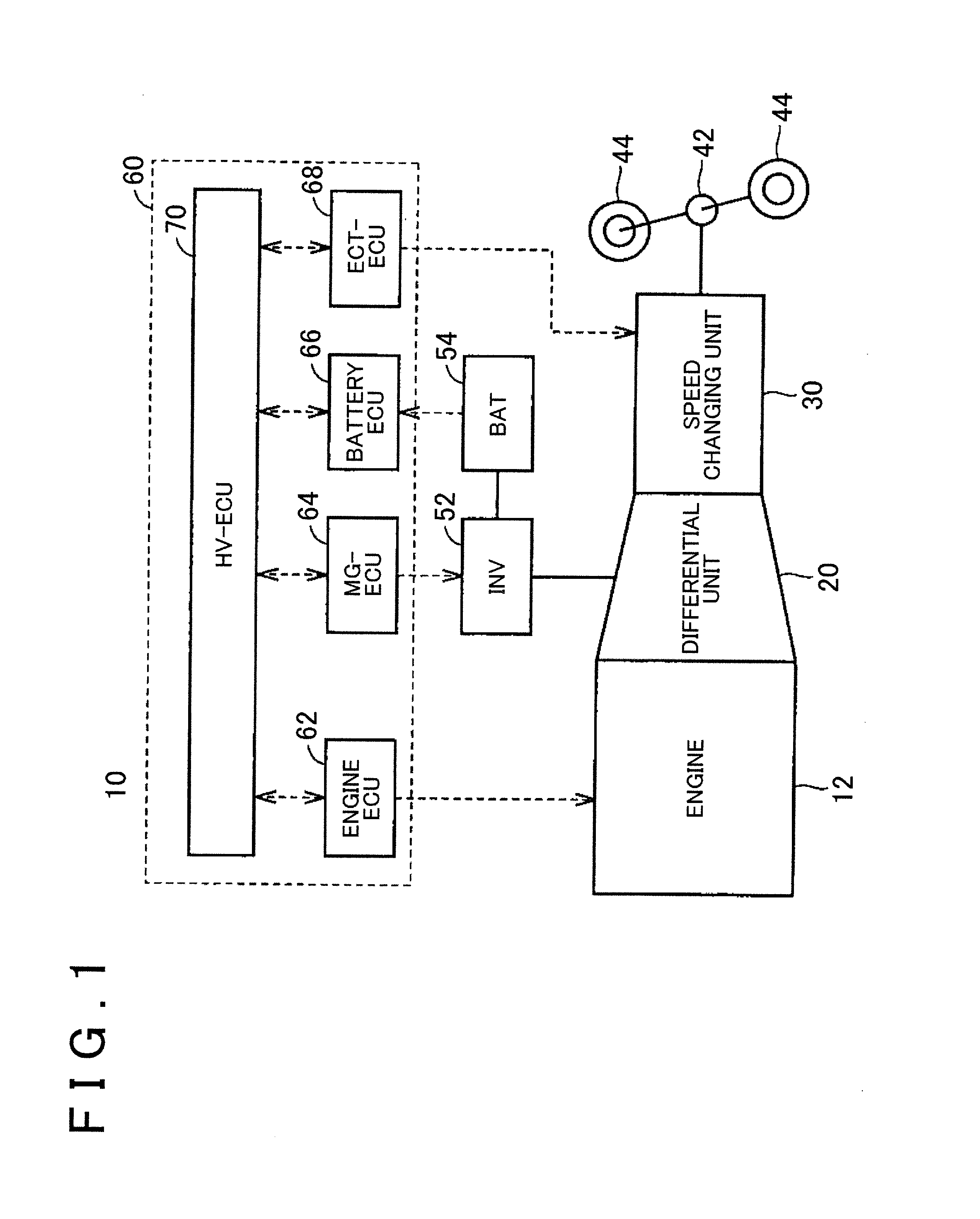

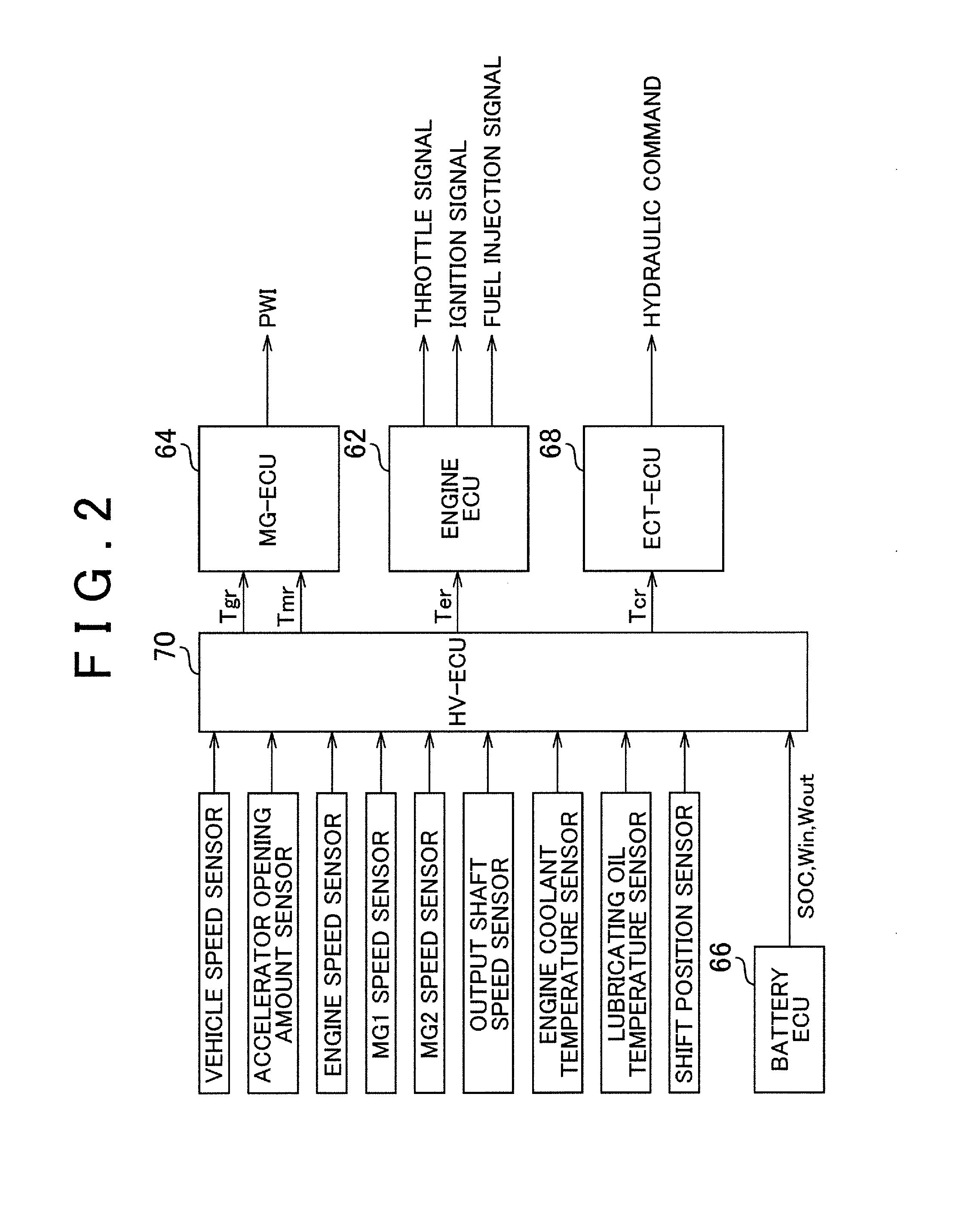

Hybrid vehicle

InactiveUS20100185351A1Vibration suppressionReduce vibrationHybrid vehiclesDigital data processing detailsVariatorElectric generator

A hybrid vehicle includes an engine that is an internal combustion engine, a motor generator that is a rotating electric machine used together with the engine for driving the vehicle, an output shaft transmitting power to a wheel, a transmission member coupled to the output shaft, a power split device splitting the output from the engine to the motor generator and transmission member, a detection device detecting irregularities on a road, and a control unit reducing, when the detected result by the detection device indicates generation of periodic torque variation at the output shaft, the output from the engine based on the detected result. Accordingly, a hybrid vehicle that does not require a torque limiter is provided.

Owner:NIPPON SOKEN +1

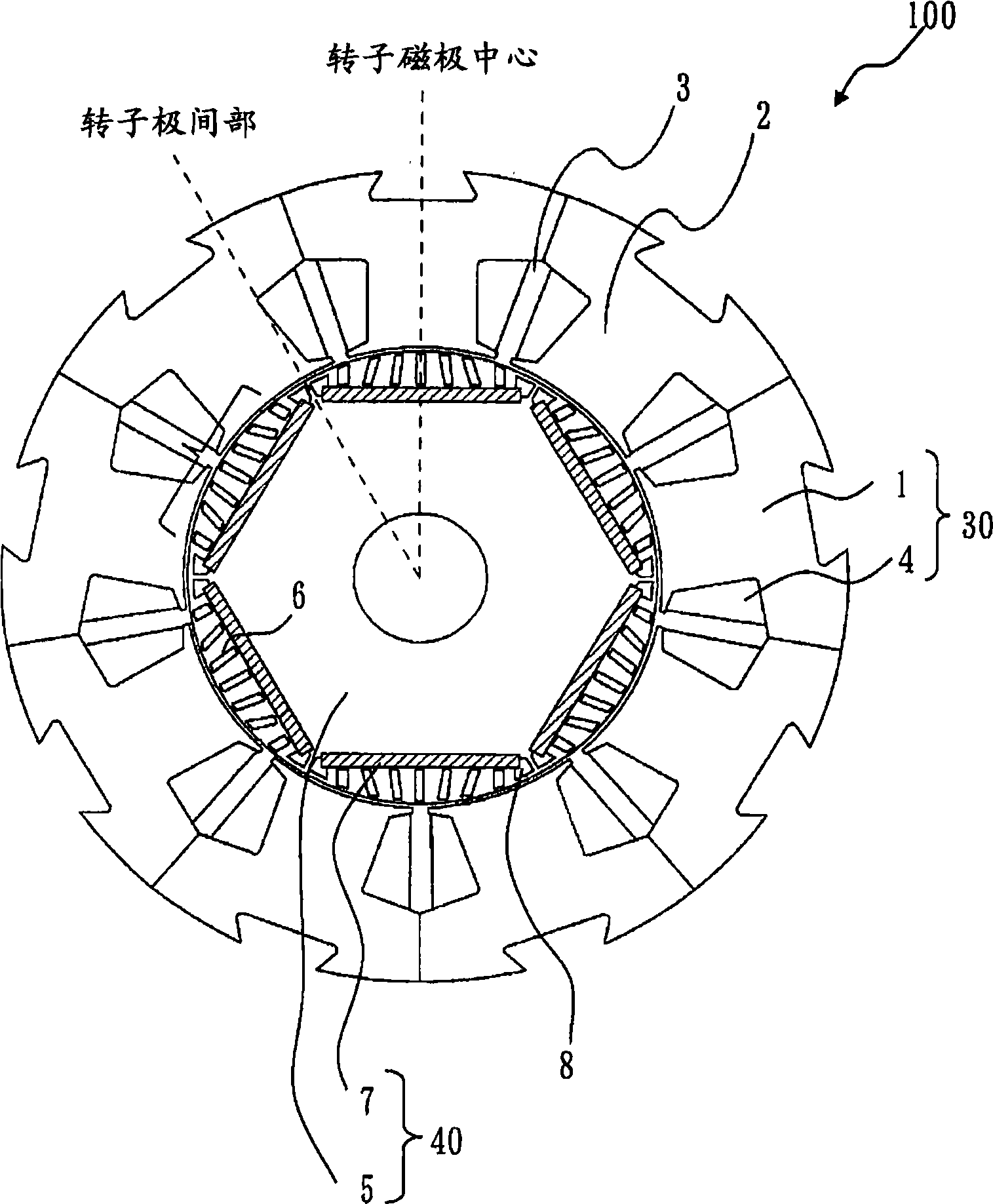

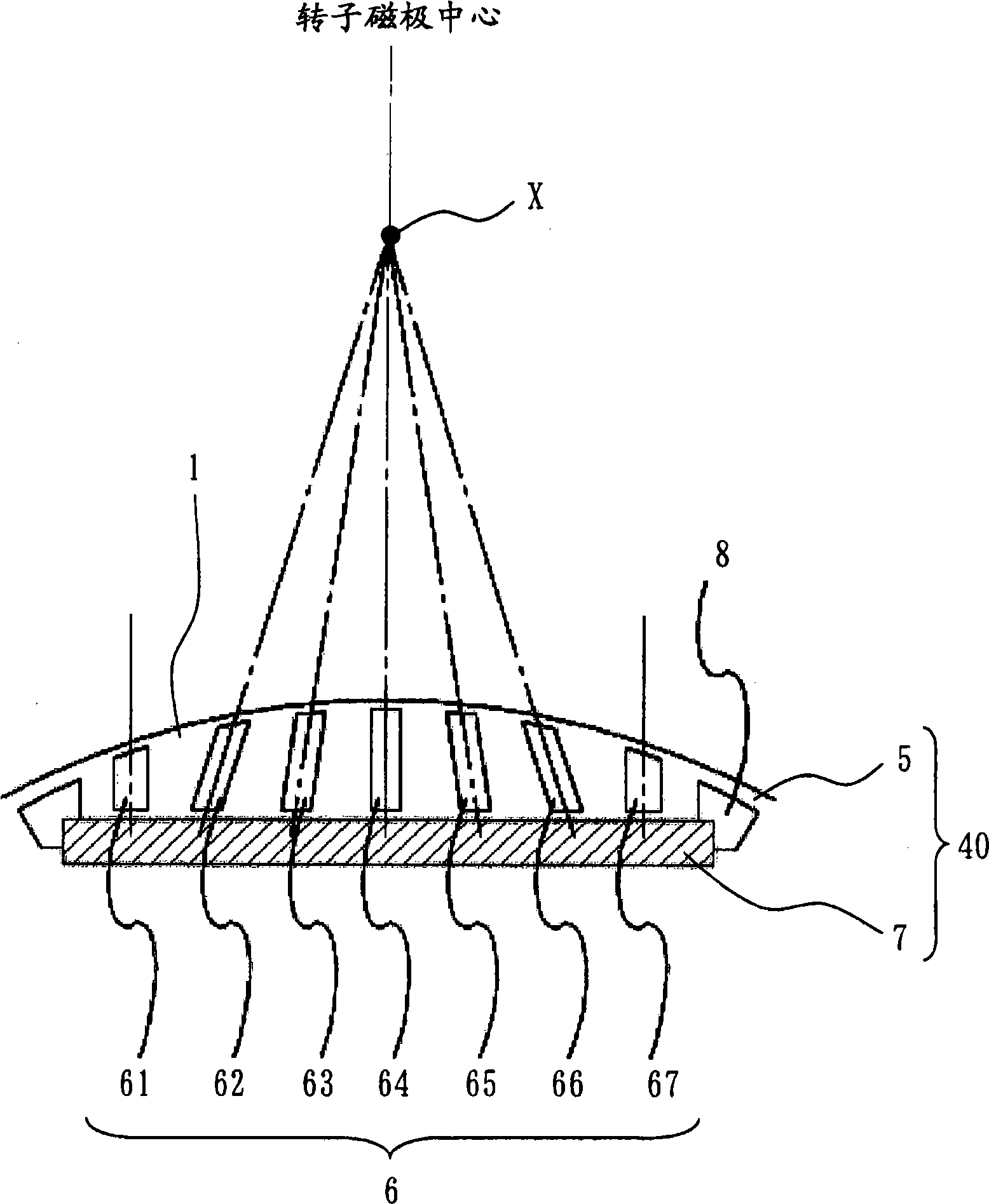

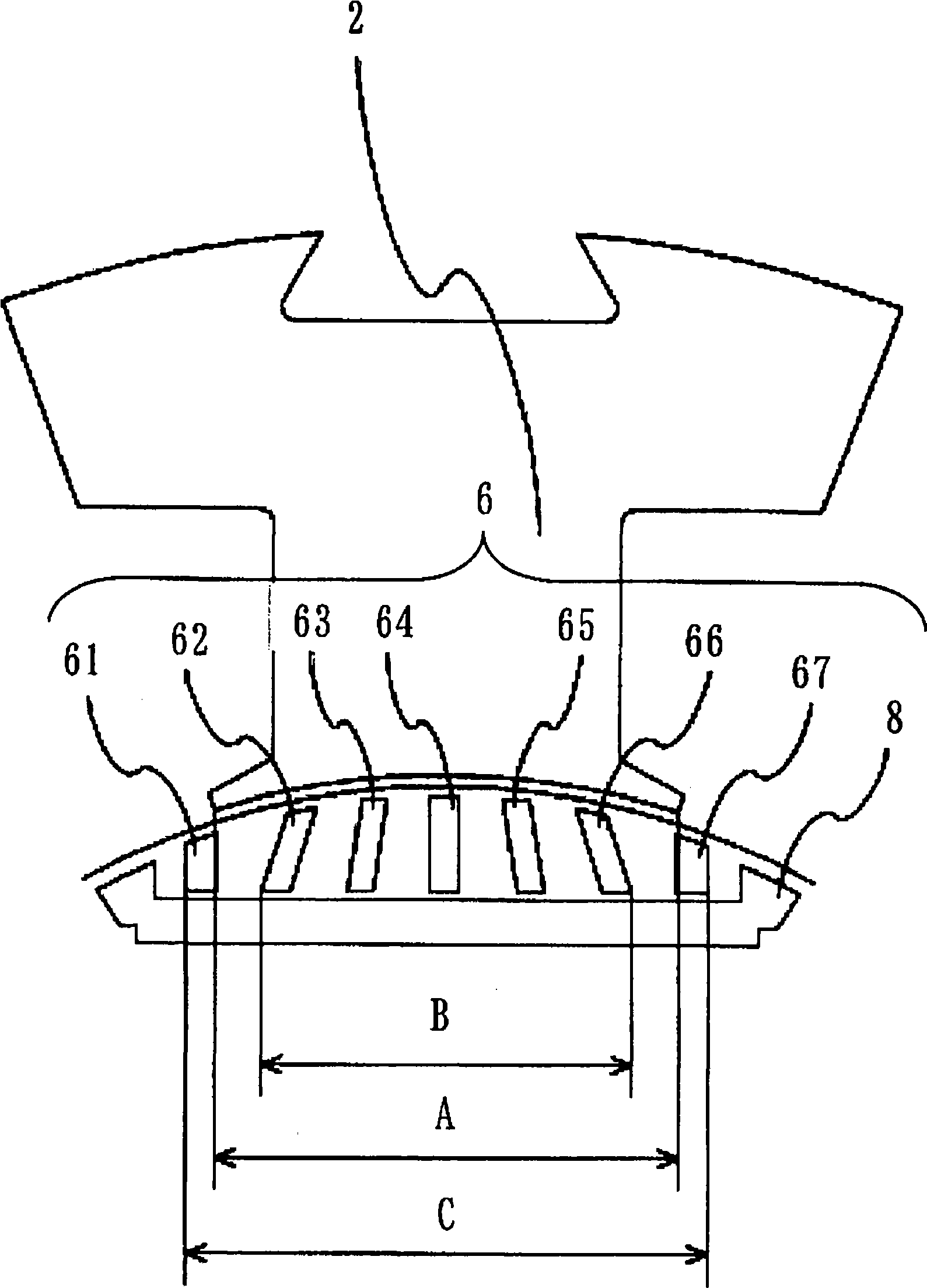

Permanent magnet synchronous motor and enclosed compressor

ActiveCN101536293AVibration suppressionNoise Low VibrationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPhysicsMagnetic flux

A high efficiency, low vibration and low noise permanent magnet synchronous motor. The invention is characterized in: the stator (30) comprises a stator core (1) having a magnetic pole tooth (2) formed between adjoining slots (3), and a stator winding (4) arranged in the slot (3) of the stator core (1), and the rotor (40) comprises a rotor core (5), a plurality of magnet insertion holes (8), permanent magnets (7) being inserted into the magnet insertion holes (8), and a plurality of slits (6) formed in the rotor core (5) on the outer circumferential side of the magnet insertion holes (8); a plurality of slits (6) in the vicinity of the magnetic pole center of the stator core (1) out of the slits (6) are arranged such that the magnetic flux generated from the permanent magnets (7) is directed in a direction to converge on the outside of the stator core (1), and the slits (6) in the vicinity of the interpole portion of the rotor core (5) are arranged to be directed in a direction different from that of the plurality of slits (6) in the vicinity of the magnetic pole center of the rotor core (5).

Owner:MITSUBISHI ELECTRIC CORP

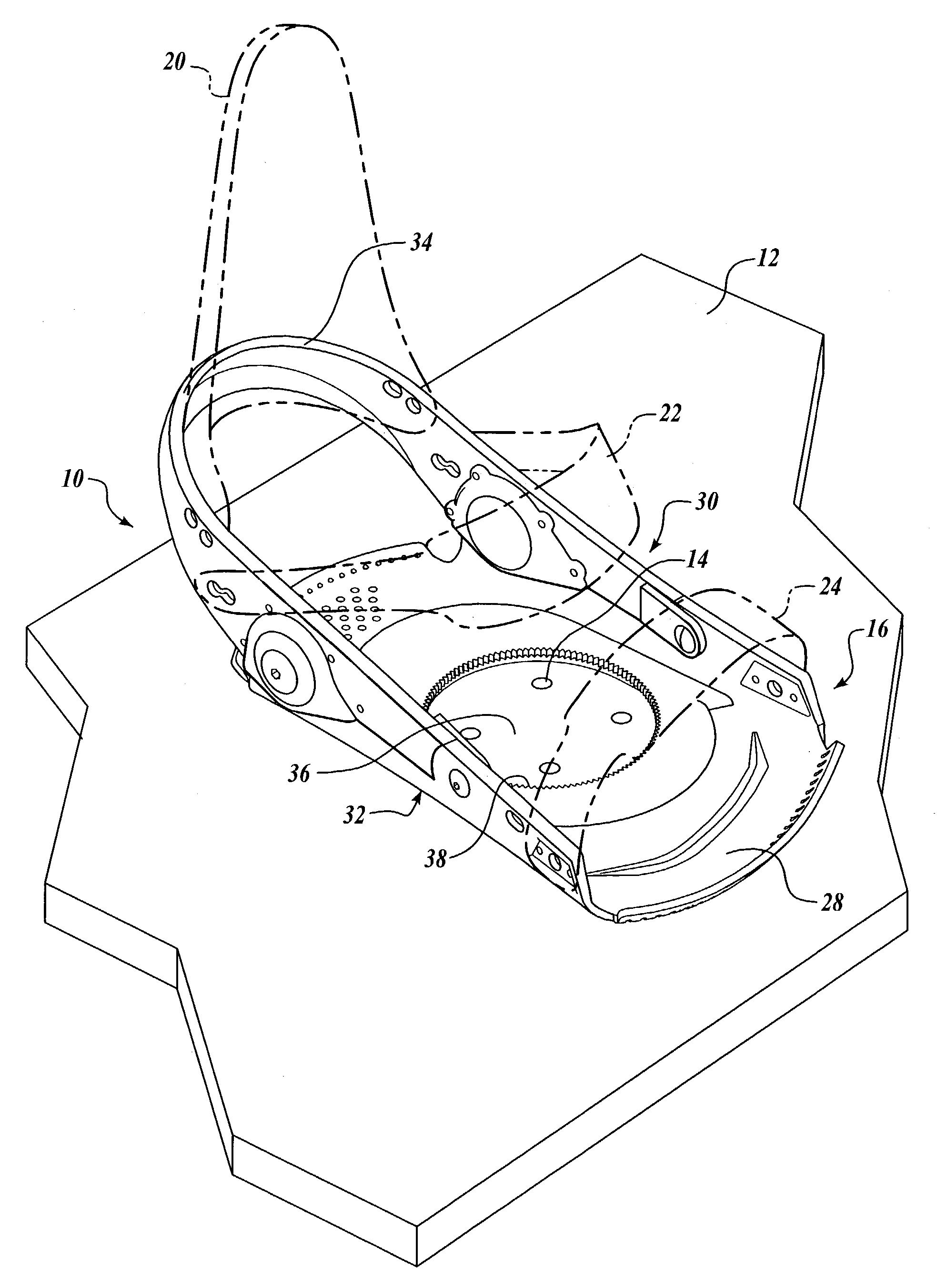

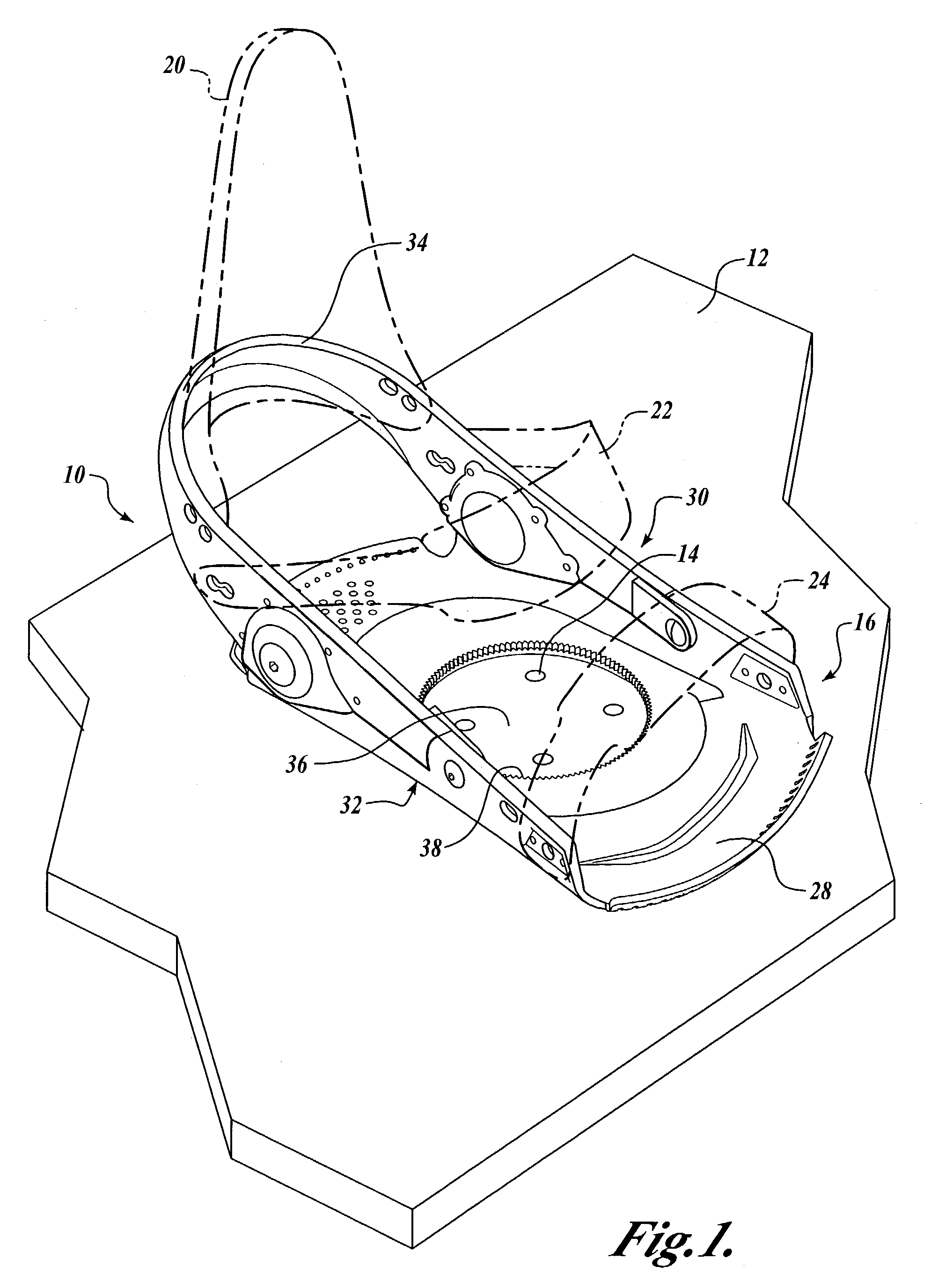

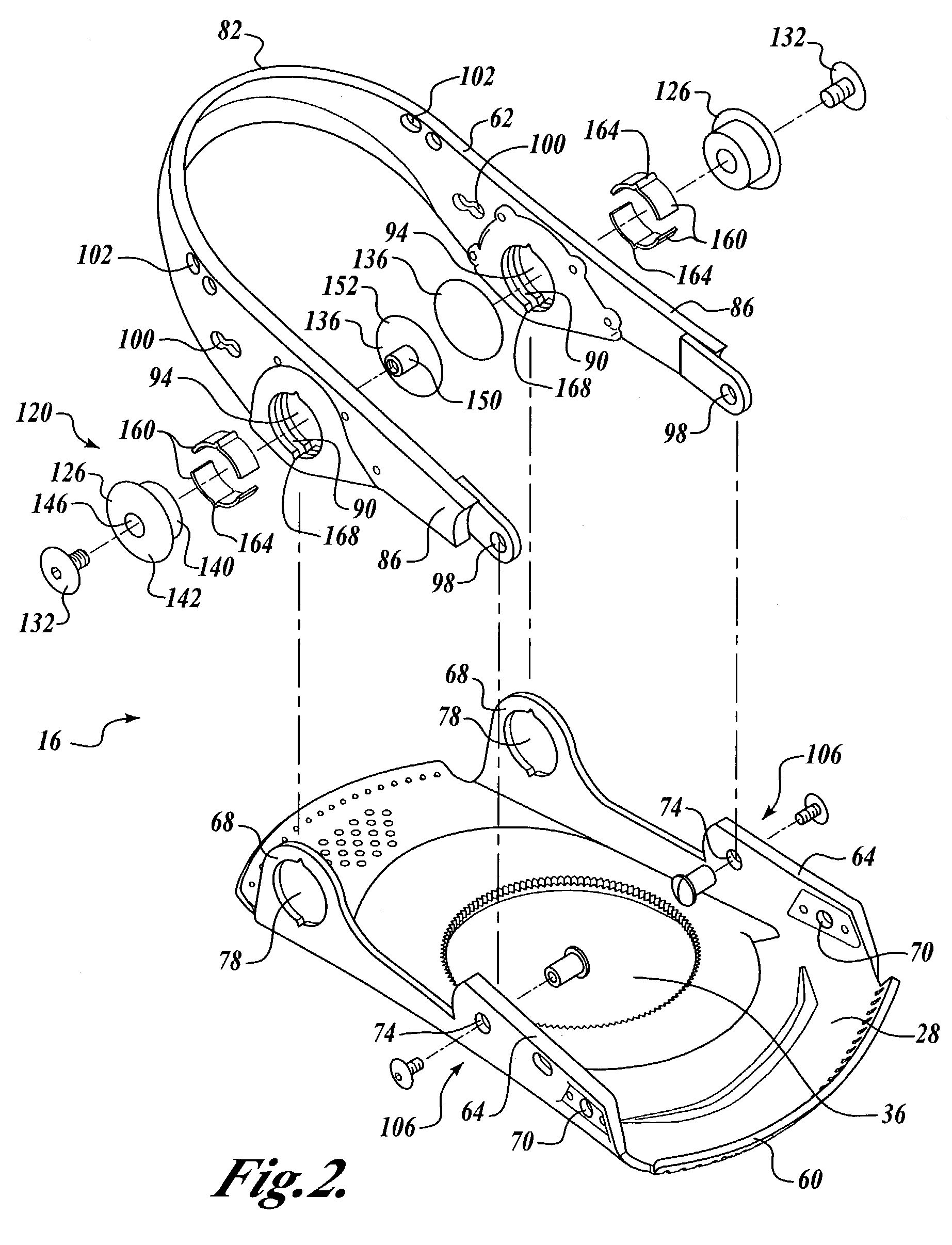

Snowboard binding with suspension heel loop

InactiveUS7159892B2Vibration suppressionDampens movementCarriage/perambulator accessoriesSki bindingsEngineeringControl manner

A binding includes a suspension heel loop formed by an upper member pivotally connected to the base of the binding frame. The heel loop flexes or moves in a controlled manner with respect to the binding base at the heel end of the binding. A binding having the suspension heel loop provides greater maneuvering and board control, and thus improves rider performance, while providing shock and vibration absorption capabilities for increasing the overall comfort of the binding during use.

Owner:K 2 CORP

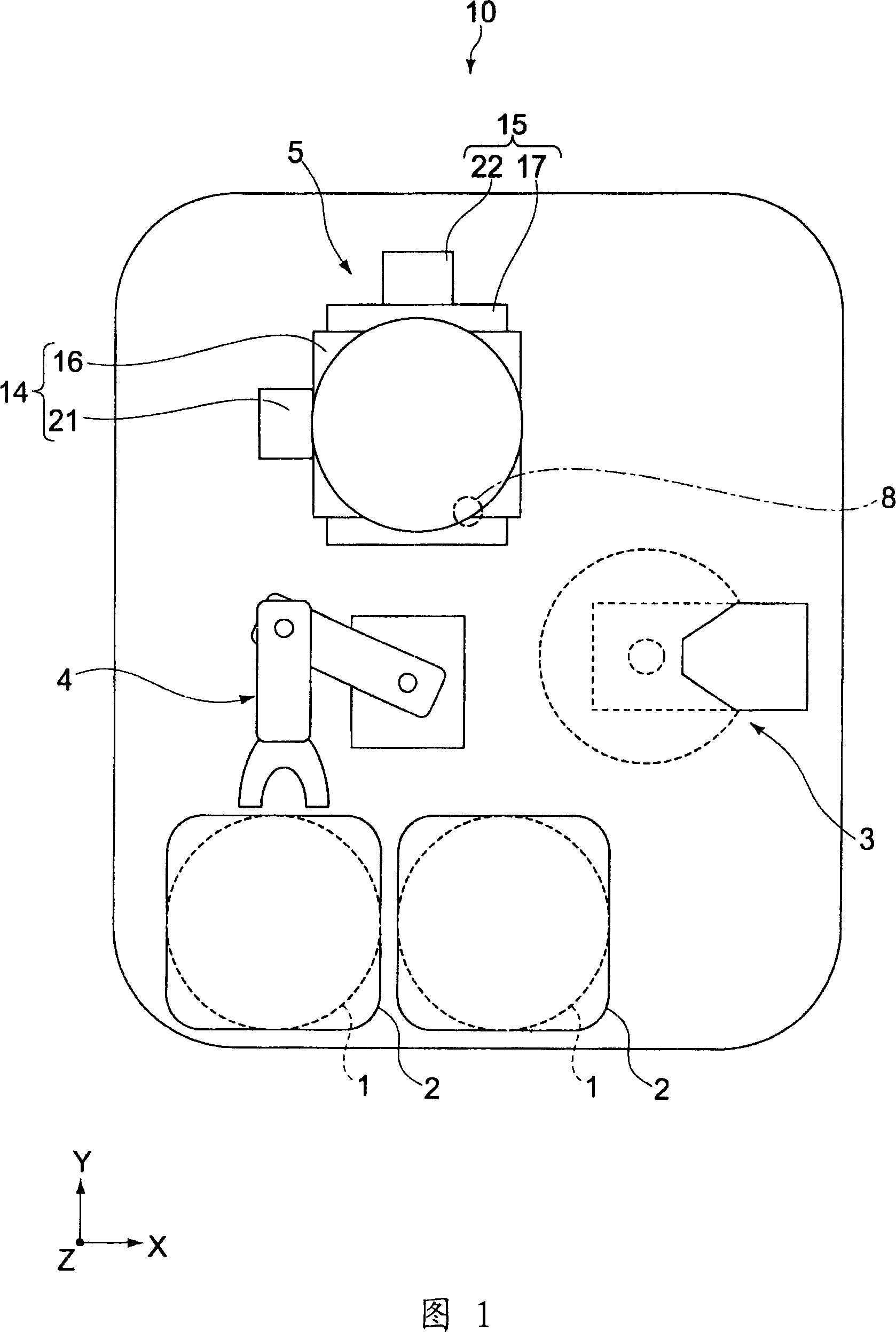

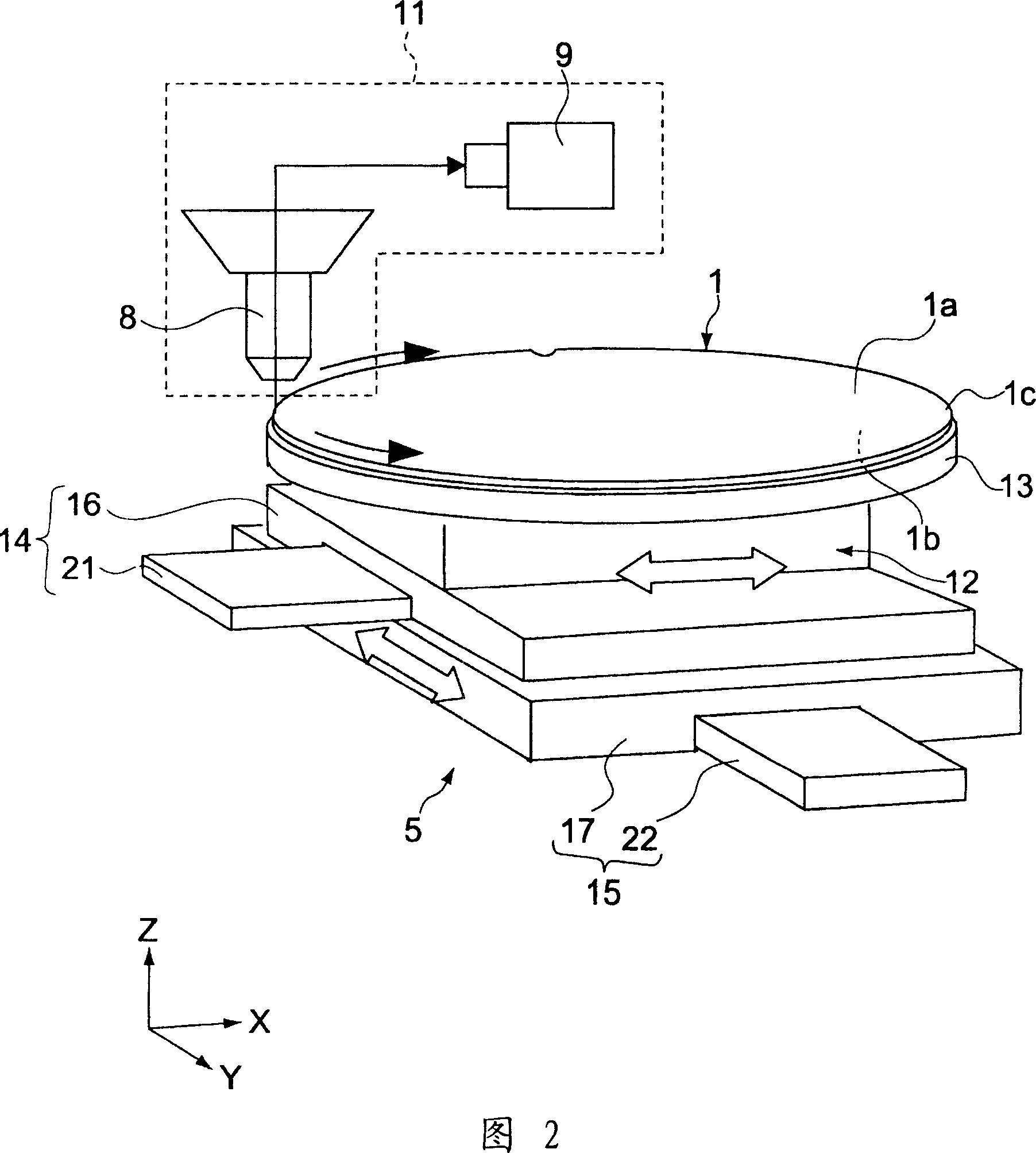

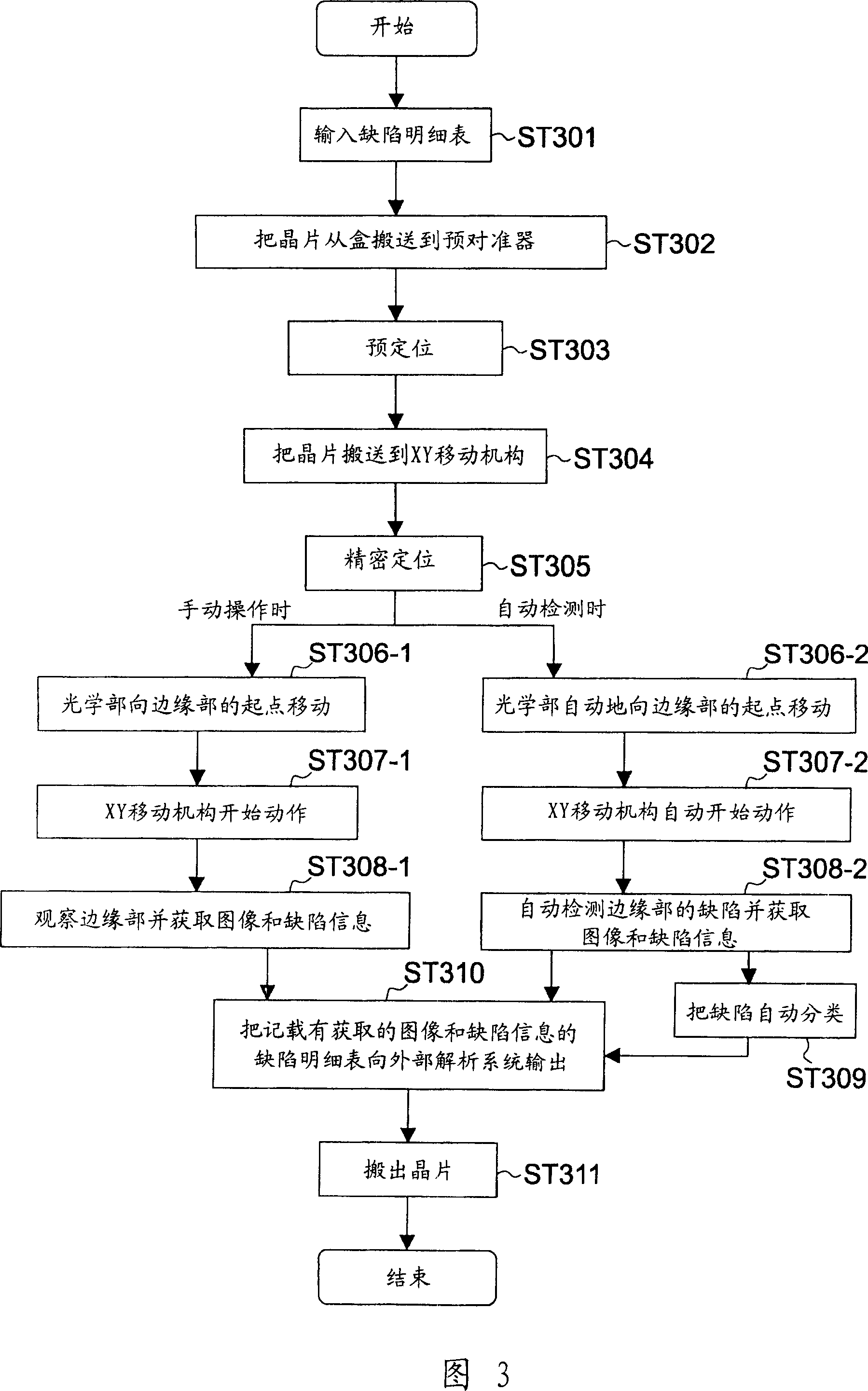

Defects detection device and method

InactiveCN101000311AVibration suppressionReliable detectionSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationEngineeringSemiconductor chip

The invention provides a defect detecting device and a defect detecting method for reliably detecting a defect on an edge part of a semiconductor chip substrate. A XY travel mechanism (5) comprises: a supporting part (12) for supporting the chip (1); a X axis travel mechanism (14) for moving the supporting part (12) upwards along the direction of the X axis; and a Y axis travel mechanism (15) for moving the supporting part (12) and the X axis travel mechanism (14) upwards along the direction of the Y axis perpendicular to the X axis. The supporting part (12) has a disk shape supporting table (13) for supporting a whole back face (1b) of the chip (1) to hold the chip (1) by, e.g., vac sorb. Due to at least the edge part (1c) of the back face (1b) of the chip (1) is supported by the supporting part (13), oscillating of the edge part (1c) can be prevented, thus defect of the edge part (1c) can be reliably detected.

Owner:SONY CORP

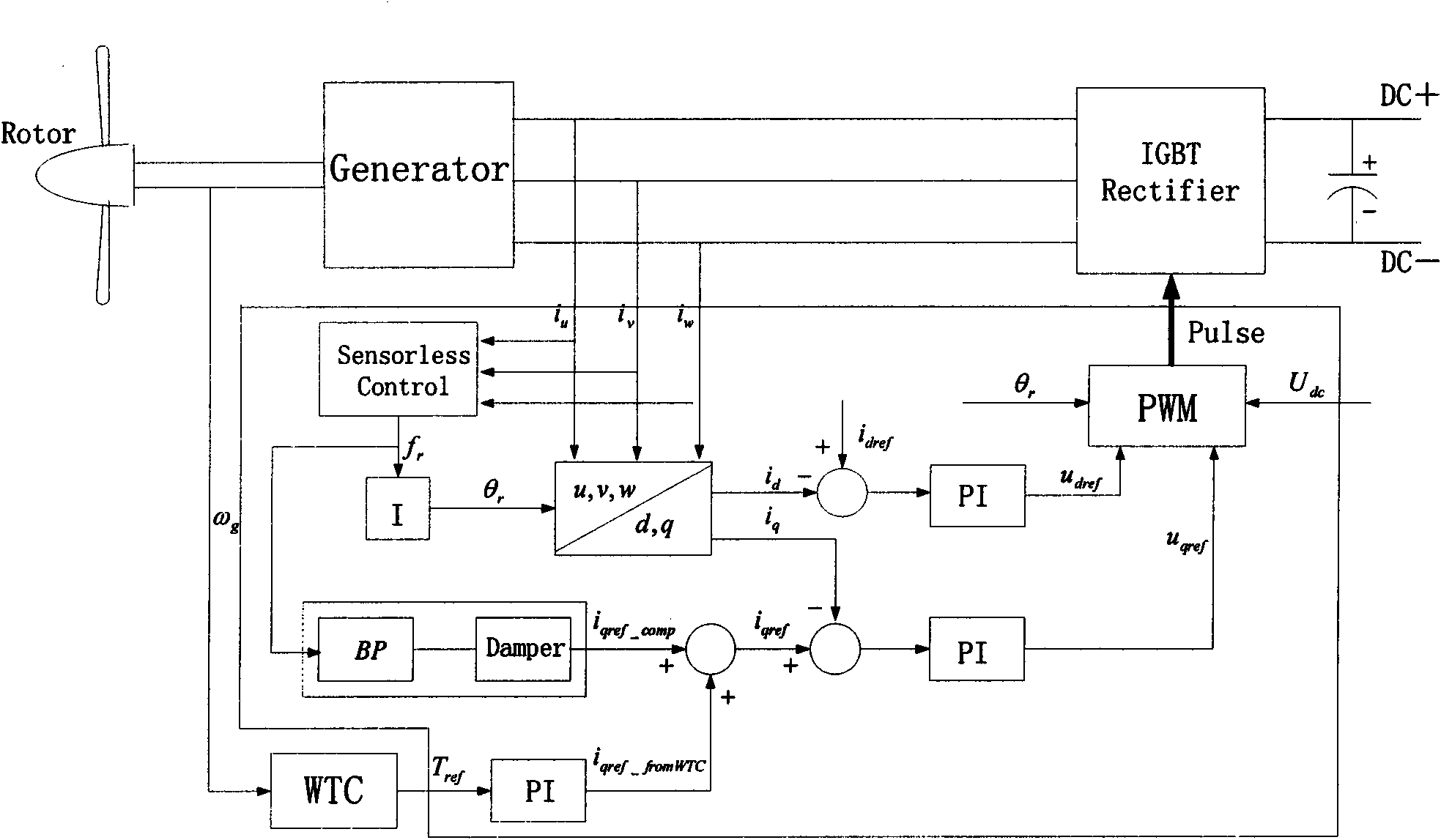

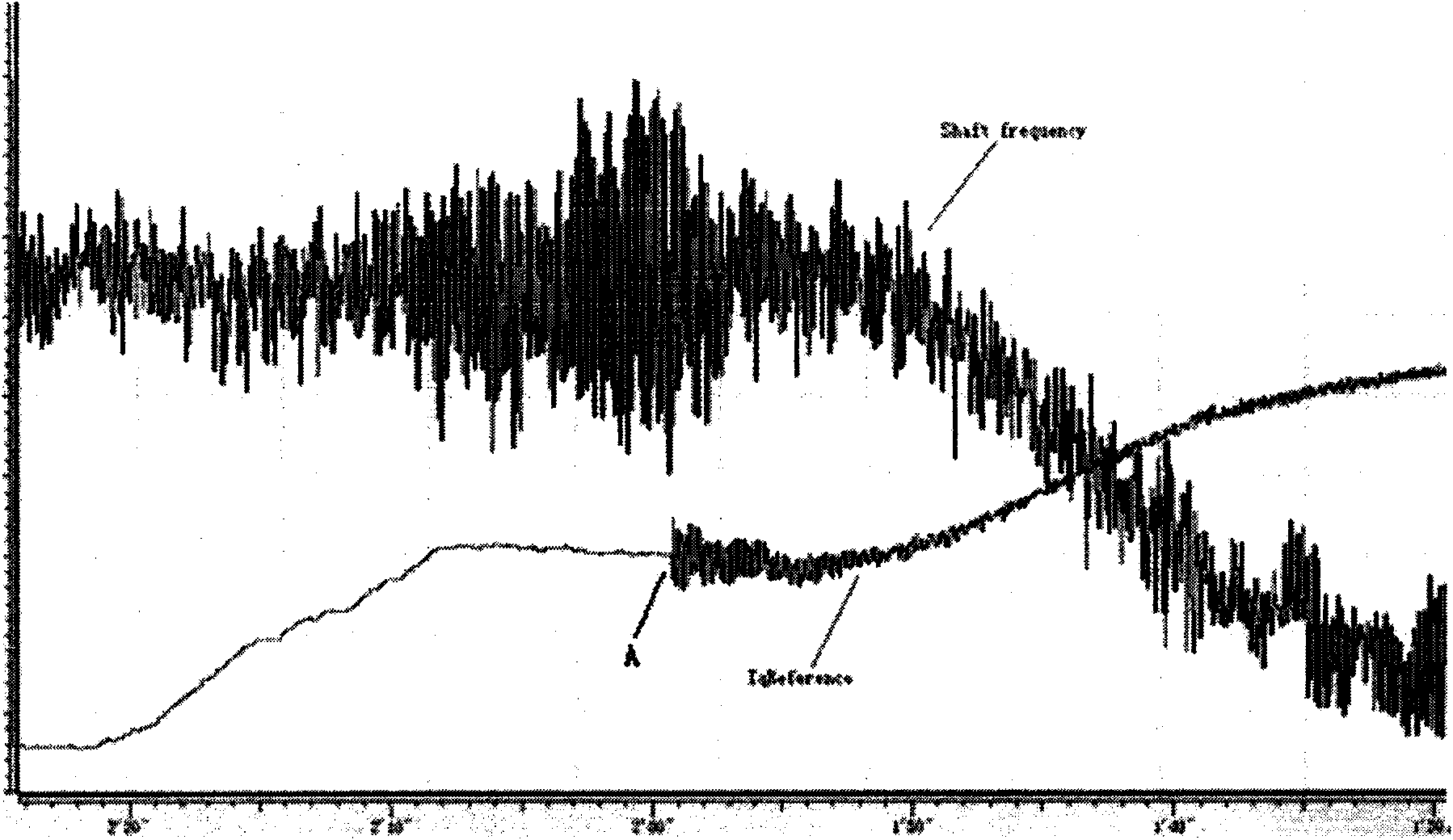

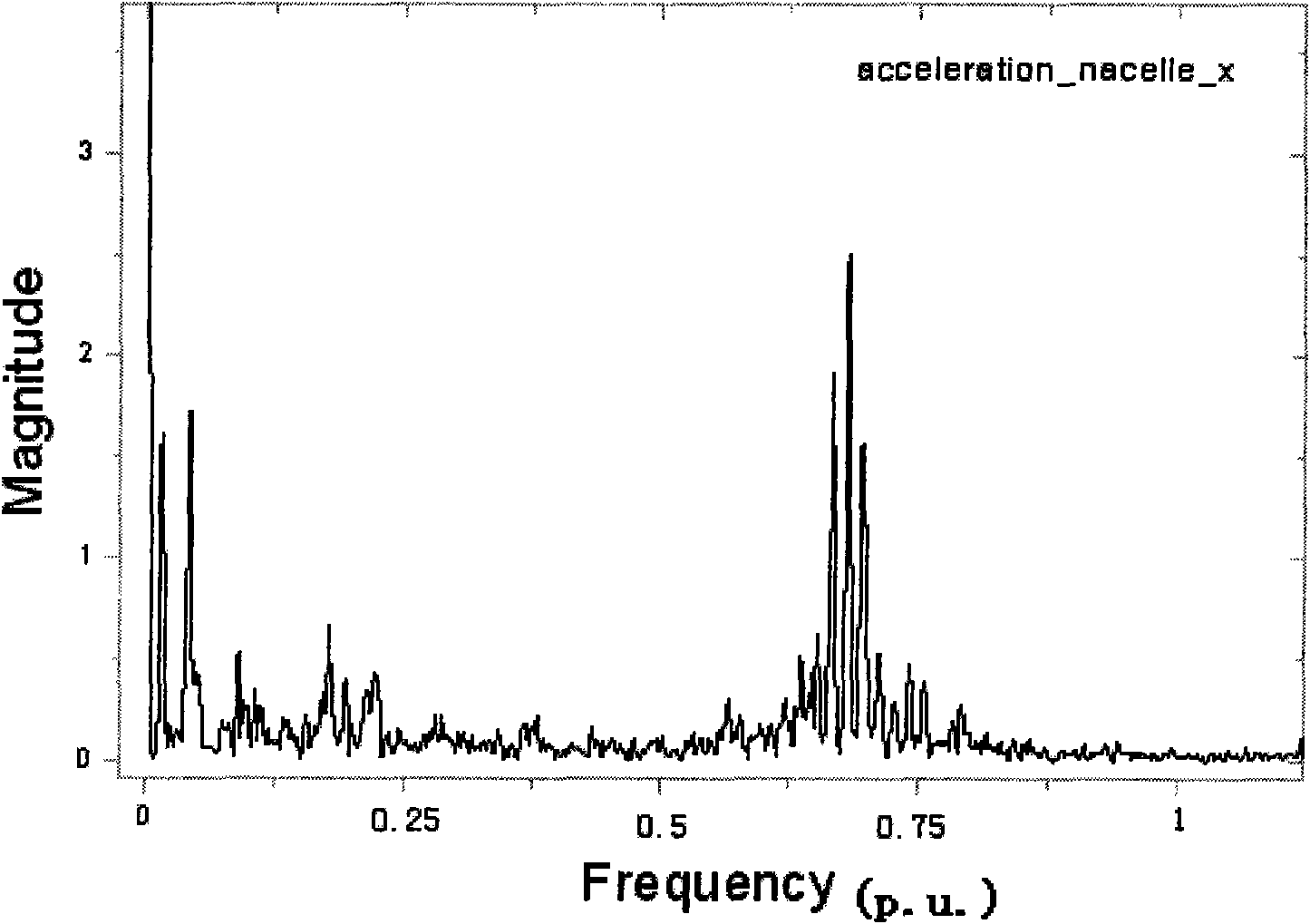

System and method for inhibiting vibration of direct-driven wind generator set

InactiveCN101557191AIncrease dampingVibration suppressionElectric generator controlActive rectificationMagnet

The invention provides a system and a method for inhibiting the vibration of a direct-driven wind generator set, pertaining to the field of the control of a million-Watt class direct-driven permanent-magnet wind generating set. The system comprises a flow conversion device and a wind turbine host-controller (WTC), wherein the flow conversion device comprises a convertor, a band-pass filter and a damping controller. The convertor is a full-power convertor, and the rectification process of the convertor is an active rectification method comprising a controllable device IGBT; and rotor field-oriented control (FOC) is adopted. The invention increases the band-pass filter and the damping controller in the flow conversion device so that the damping controller outputs a compensating torque when the generating set vibrates, thereby being capable of effectively reducing the vibration of the generating set and prolonging the service life of the generating set.

Owner:XINJIANG GOLDWIND SCI & TECH

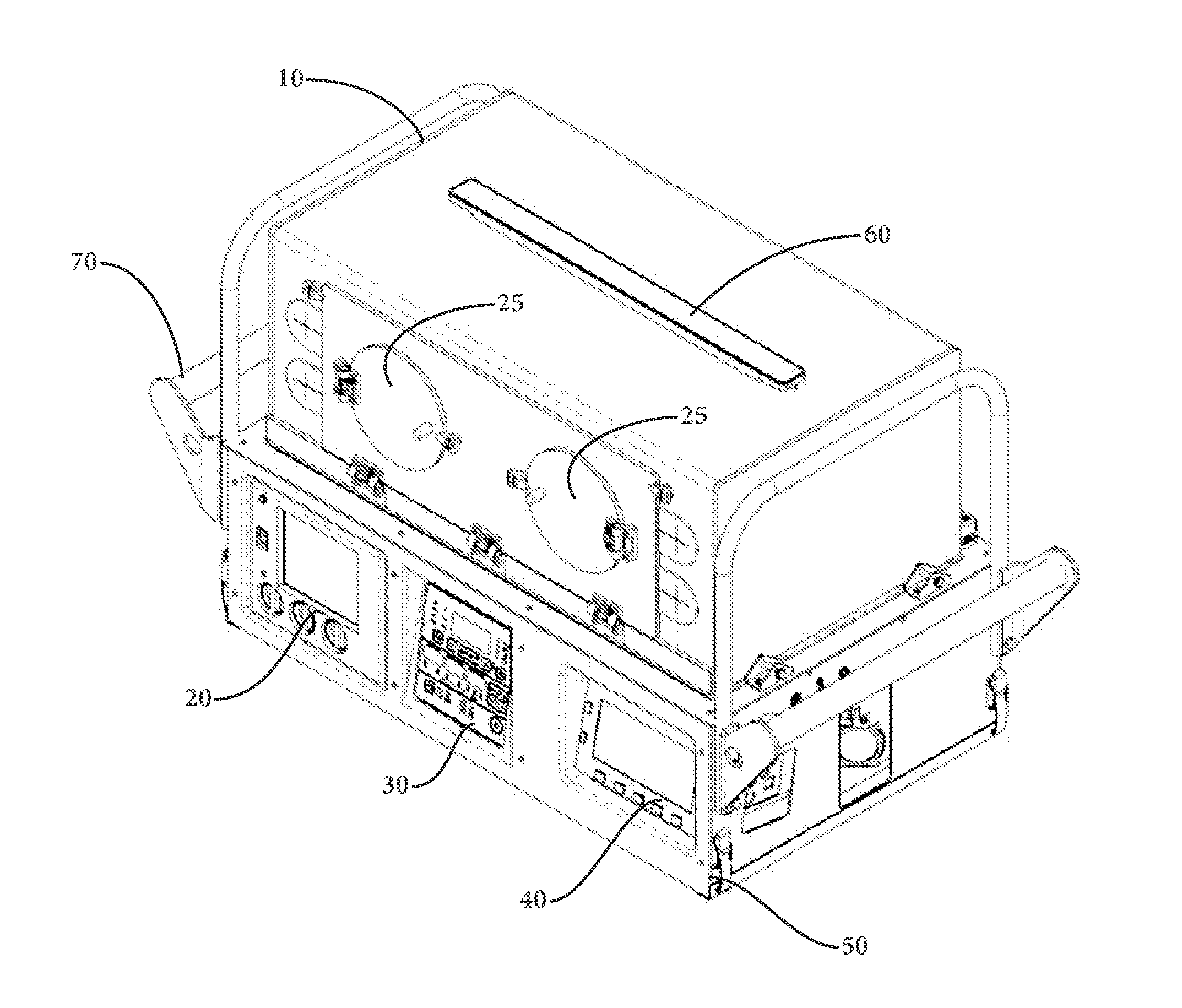

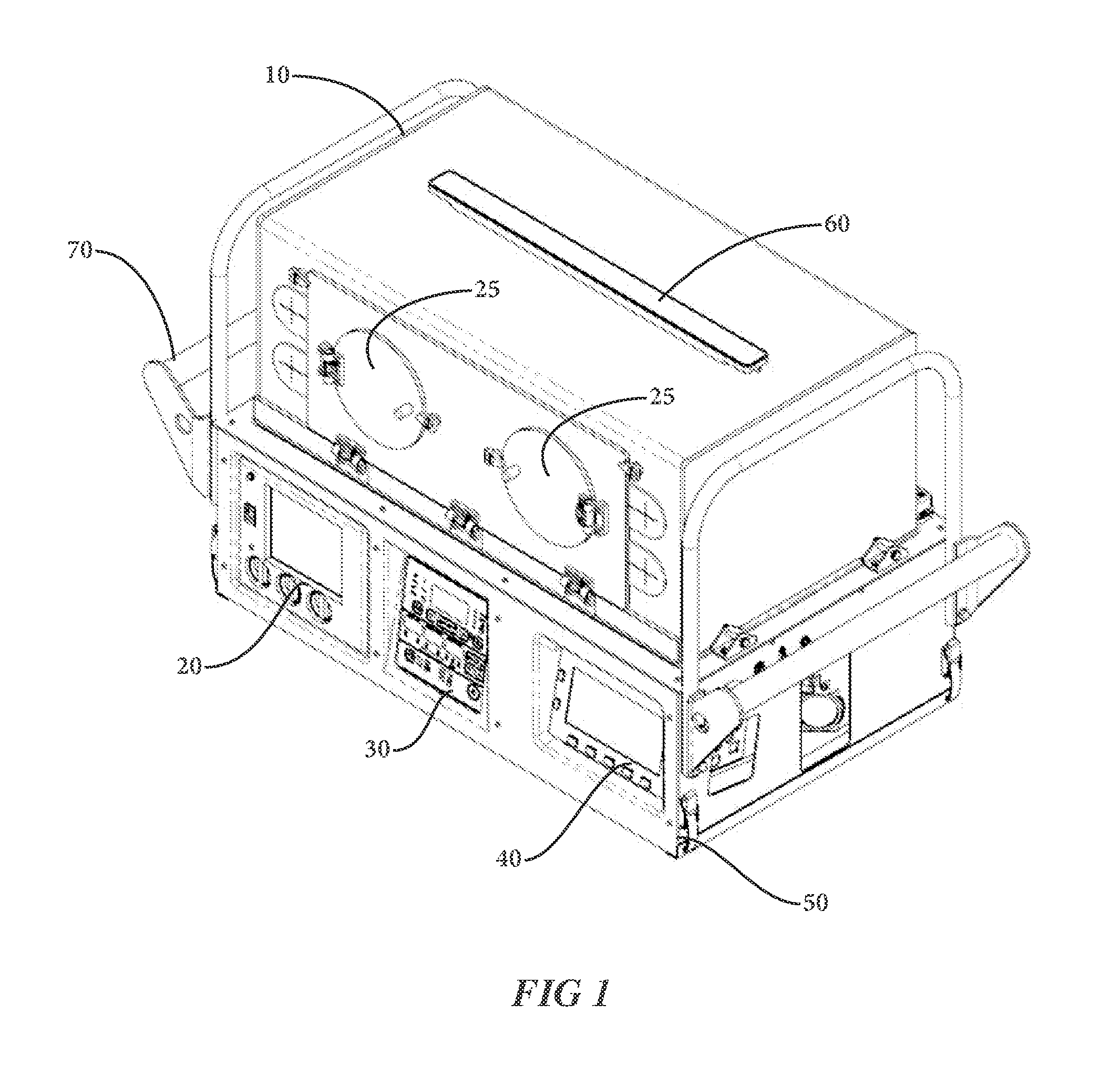

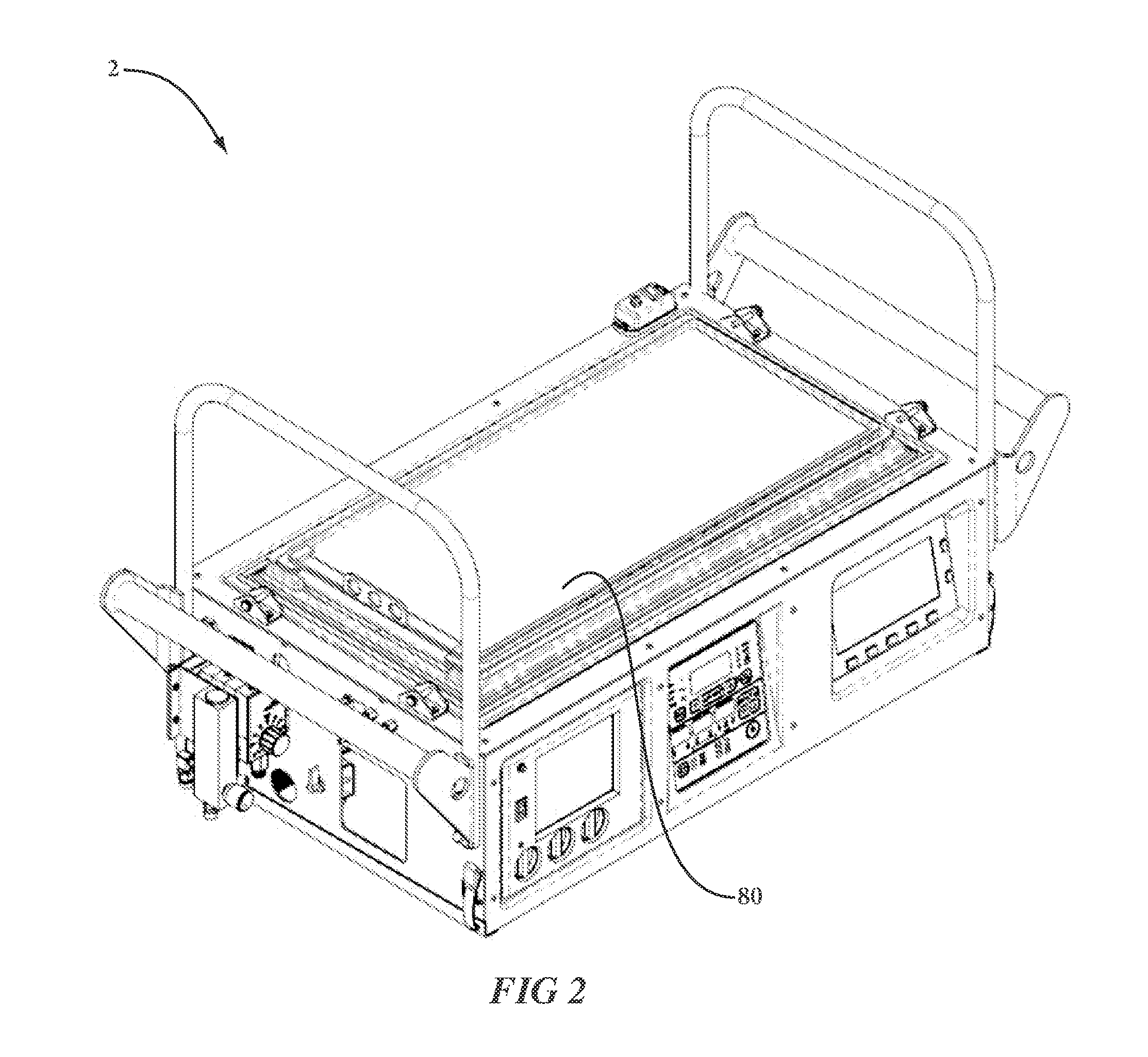

Infant Care Transport Device with Shock and Vibration System

ActiveUS20160015586A1Vibration suppressionMinimizing conditionRespiratorsBaby-incubatorsPatient supportSubstructure

A shock and vibration system for an infant care transport system with an enclosed infant care device. The shock and vibration system utilizes multiple damping systems that create a floating patient support system that allows the infant care device to move in the various axes of motion instead of being rigidly mounted to the frame or sub-frame, or any substructure.

Owner:INT BIOMEDICAL LTD

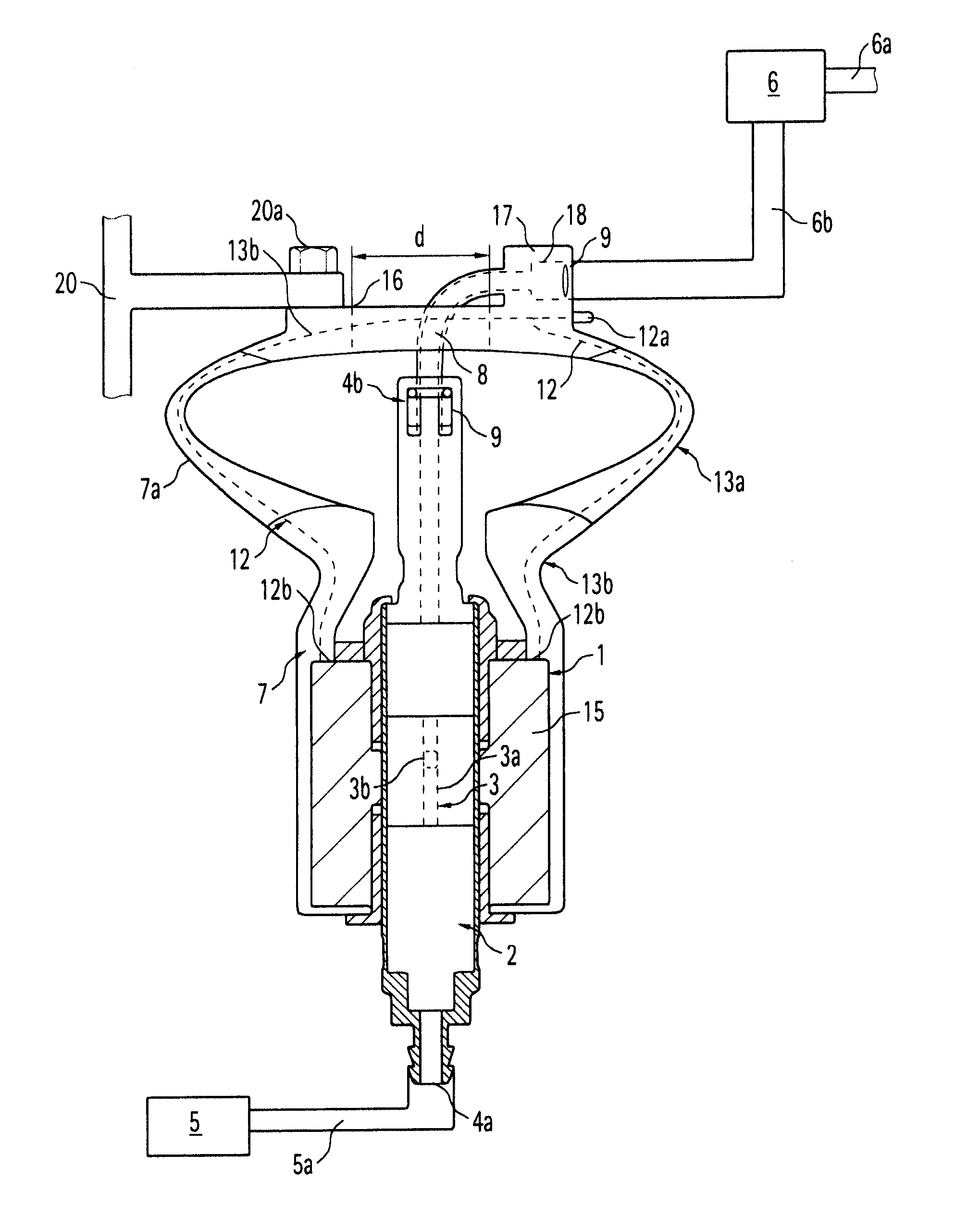

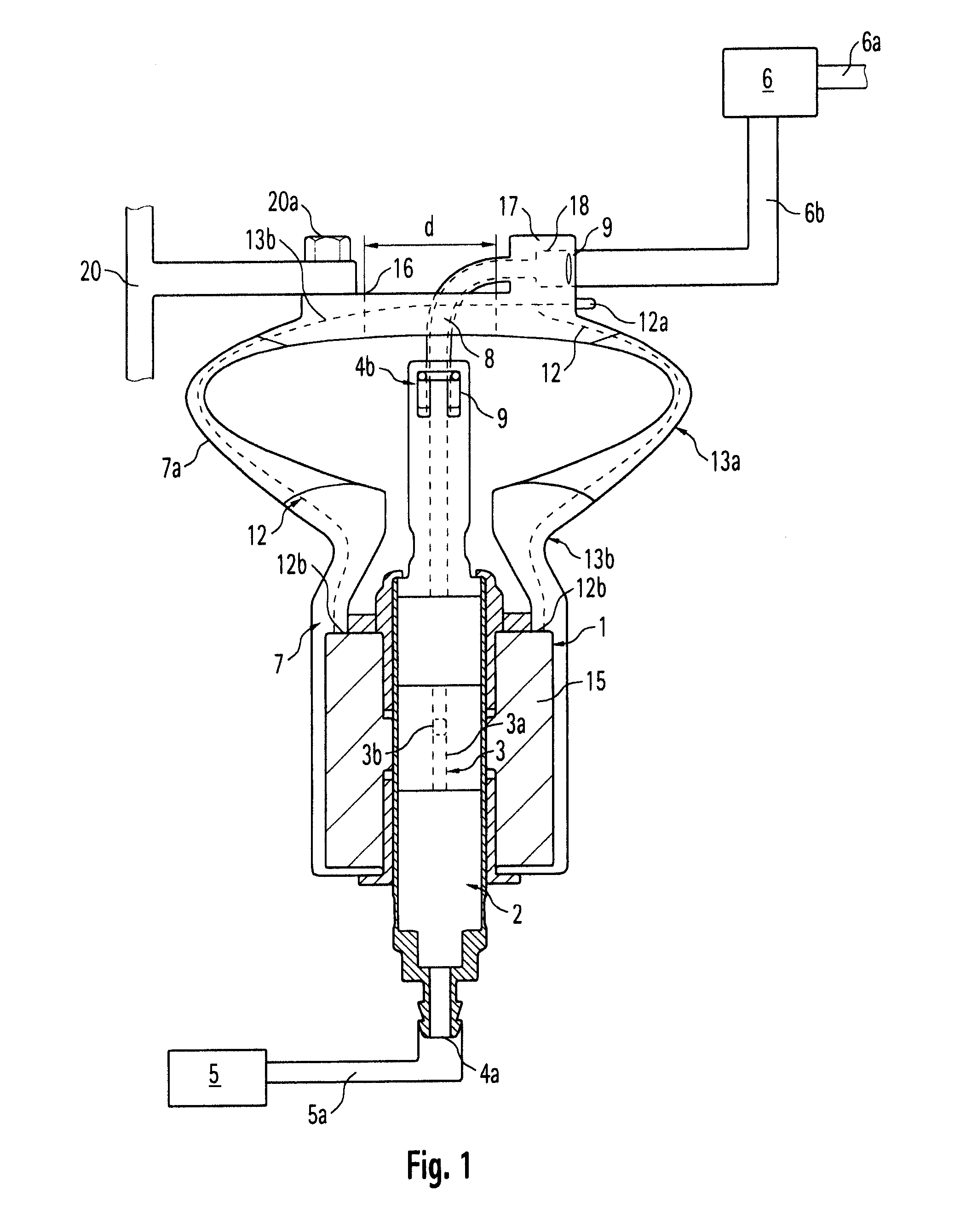

Pump for liquid beverage preparation devices

ActiveUS20110107920A1Vibration suppressionAvoid spreadingPositive displacement pump componentsAdjustable jointsPhysicsLiquid food

Devices for the preparation of a liquid food or beverage. One device includes a housing, pump, pump support for securing the pump to the housing, a rigid duct that is connected by an elastic sealing member to the housing and to an inlet or outlet of the pump. The pump support includes an elastic support member for resiliently supporting the pump chamber in the housing. Another device includes a pre-suction chamber connected to a liquid inlet of a pump and being designed to intermittently provide liquid to said liquid inlet. A further device includes a connector of at least one elastic sealing member designed to absorb vibrations from a pump of the device and to enable a relative movement of a duct and a liquid inlet or outlet of the pump.

Owner:SOC DES PROD NESTLE SA

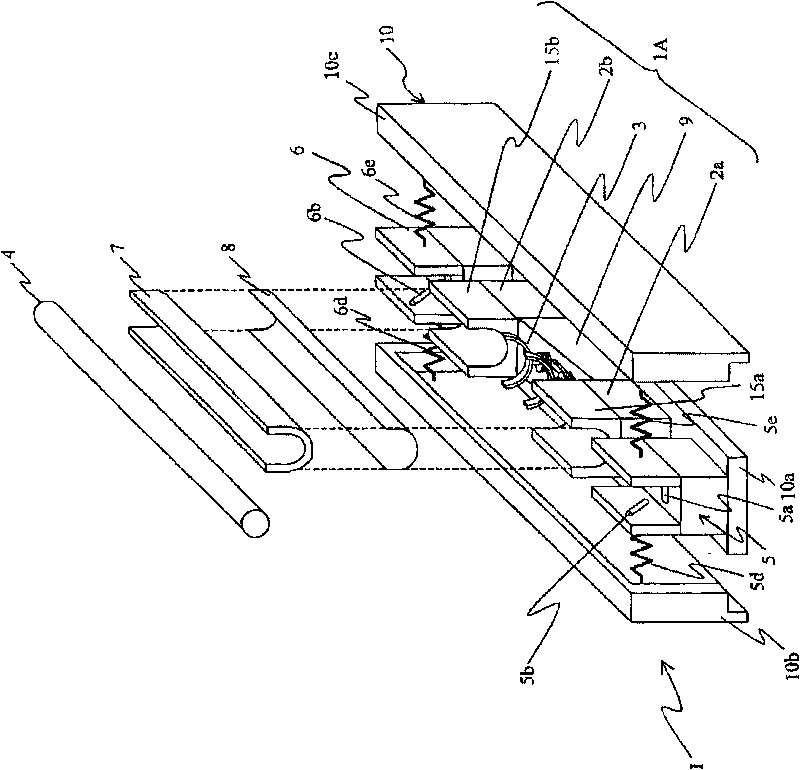

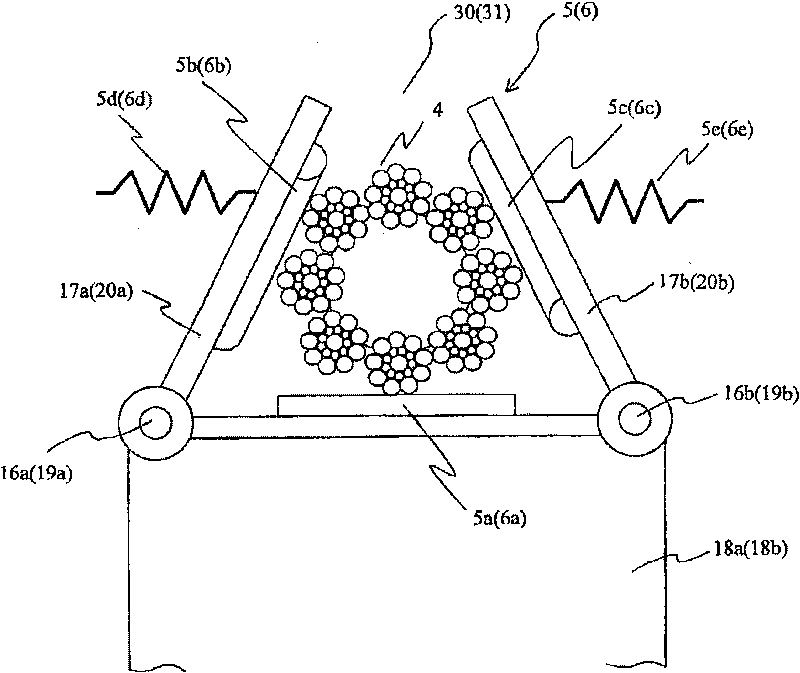

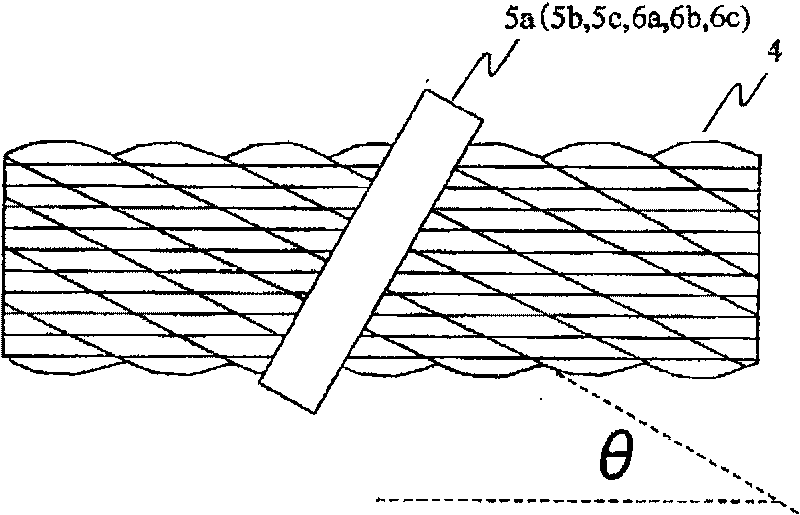

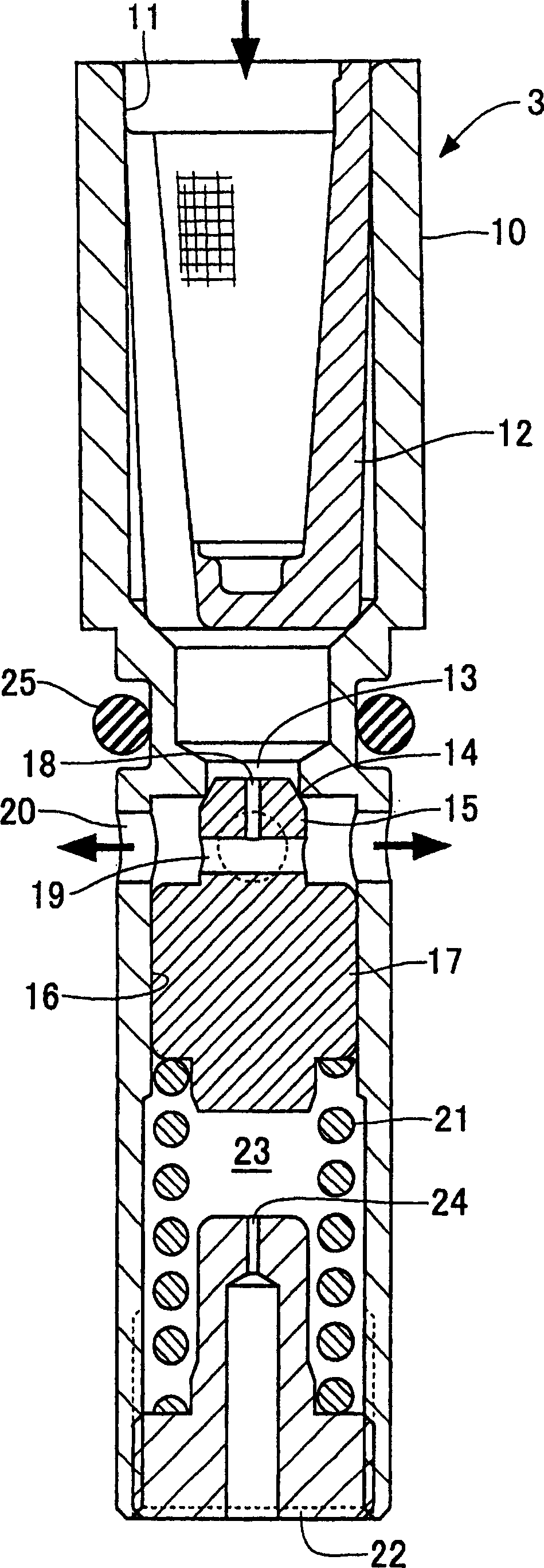

Flaw detector for wire rope

ActiveCN101750451AVibration suppressionSuppresses fluctuations in outputMaterial magnetic variablesMagnetEngineering

The present invention provides a flaw detector for wire rope, which can less maintain the pushing force relatively to the radial direction of wire rope and can restrain the vibration of the wire rope. The flaw detector comprises the following components: a pair of permanent magnets (2a,2b) which perform magnetization in the length direction of the wire rope (4); a magnetic sensor (3) which is configured near the part of wire rope (4) magnetized by the permanent magnets (2a,2b) for detecting the leakage flux leaded from the magnetized part of the wire cable (4); and a pair of positioning mechanisms (5,6) which are used for positioning the permanent magnets (2a,2b) and the magnetic sensor (3) relatively to the wire rope (4). Each of the positioning mechanisms (5,6) comprises the following components: rotating members (5a,5b,5c,6a,6b,6c) which contact with a mode of surrounding three respective positions on the periphery of the wire rope (4); and spiral springs (5d,5e,6d,6e) which cause the rotating members (5a,5b,5c,6a,6b,6c) to generate compact contact forces relatively to the wire rope (4).

Owner:HITACHI BUILDING SYST CO LTD

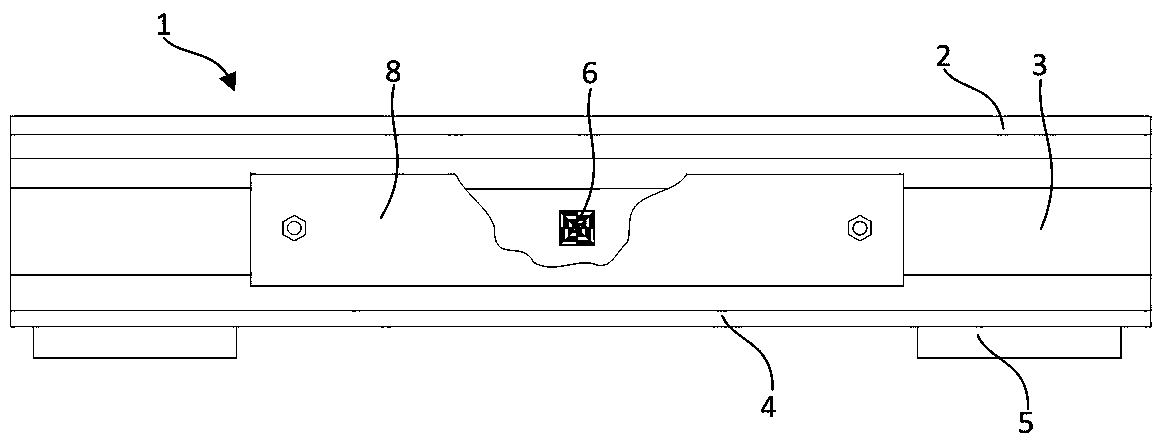

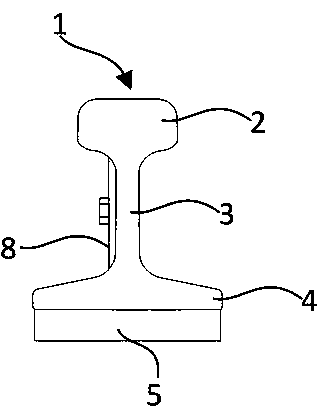

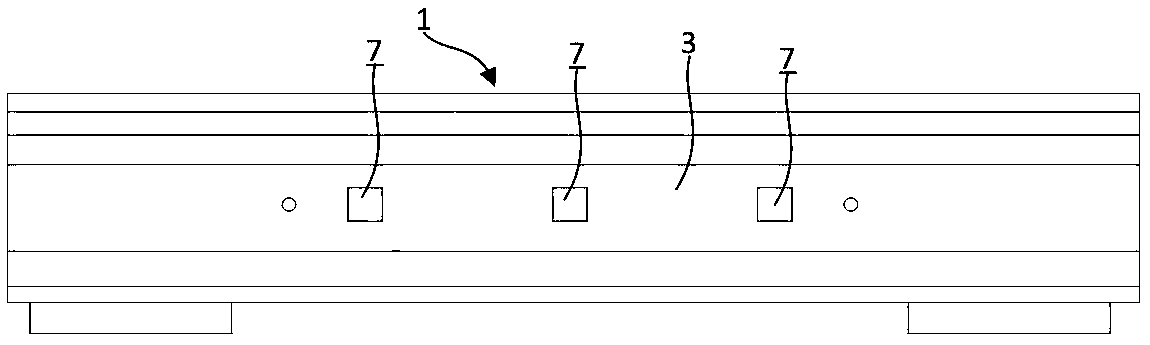

Steel rail using three-dimensional quasi photonic crystals to reduce vibration and noise

The invention discloses a steel rail using three-dimensional quasi photonic crystals to reduce vibration and noise. The steel rail comprises a rail head, a rail waist and a rail base, wherein the railwaist is connected between the rail head and the rail base; multiple three-dimensional quasi photonic crystals are mounted on the rail waist; the three-dimensional quasi photonic crystals are splicedby at least two photonic crystal units. The steel rail has the advantages that the three-dimensional quasi photonic crystals at the rail waist of the steel rail have the features of an elastic wave forbidding band and can effectively stop the propagation of elastic waves in the steel rail, and accordingly the vibration at the rail waist can be inhibited, and the radiation noise of the steel railcan be reduced.

Owner:EAST CHINA JIAOTONG UNIVERSITY

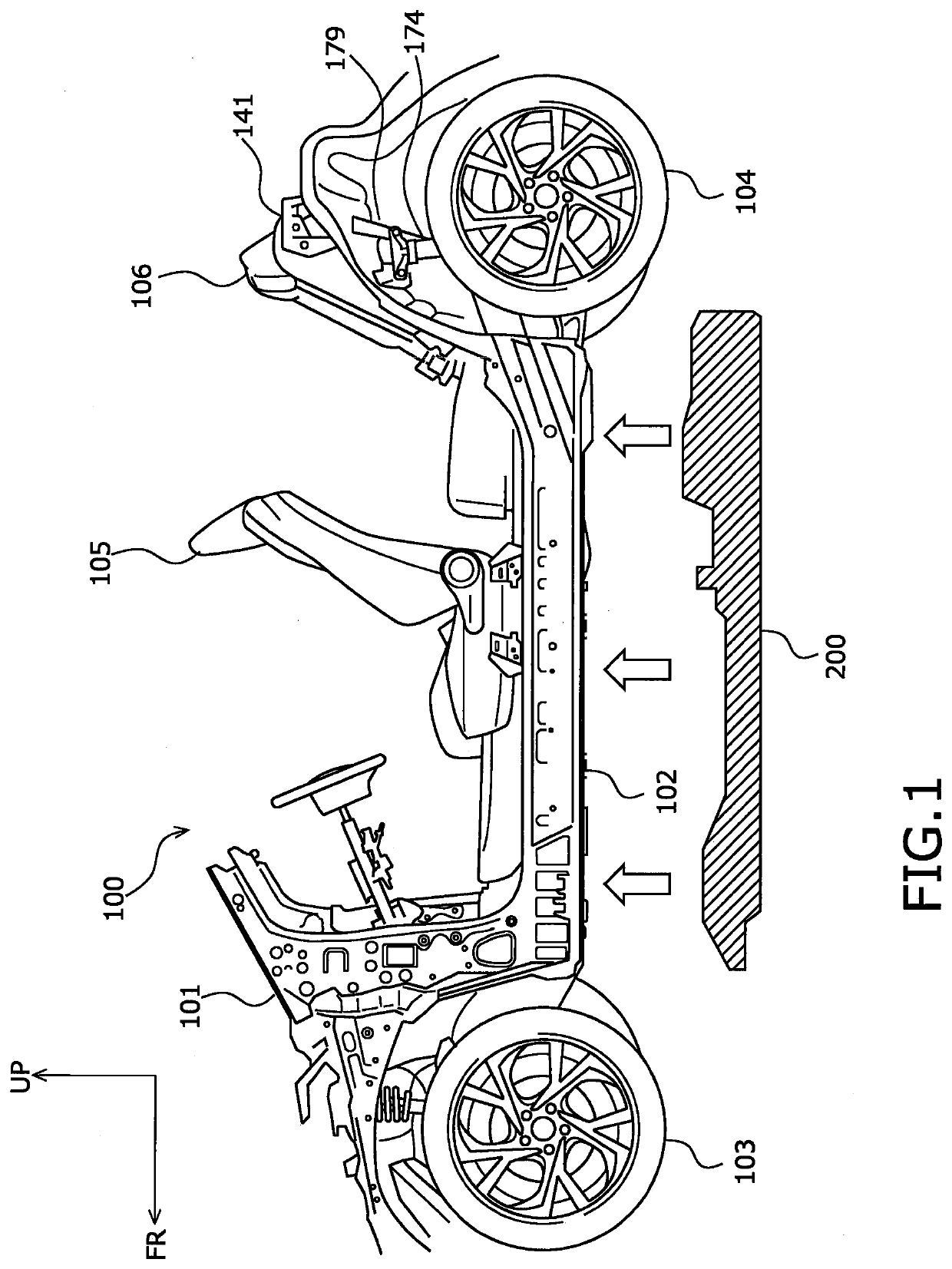

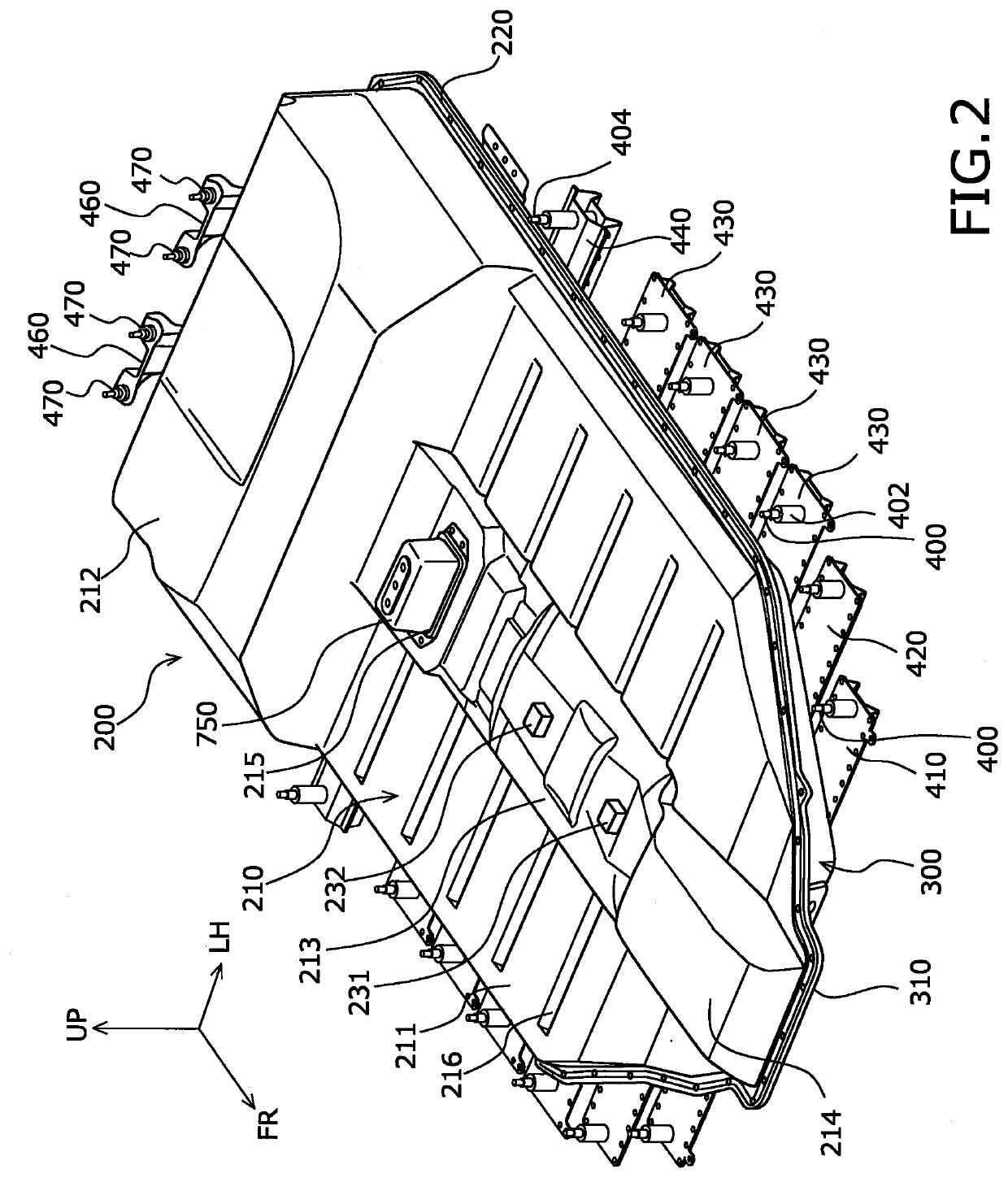

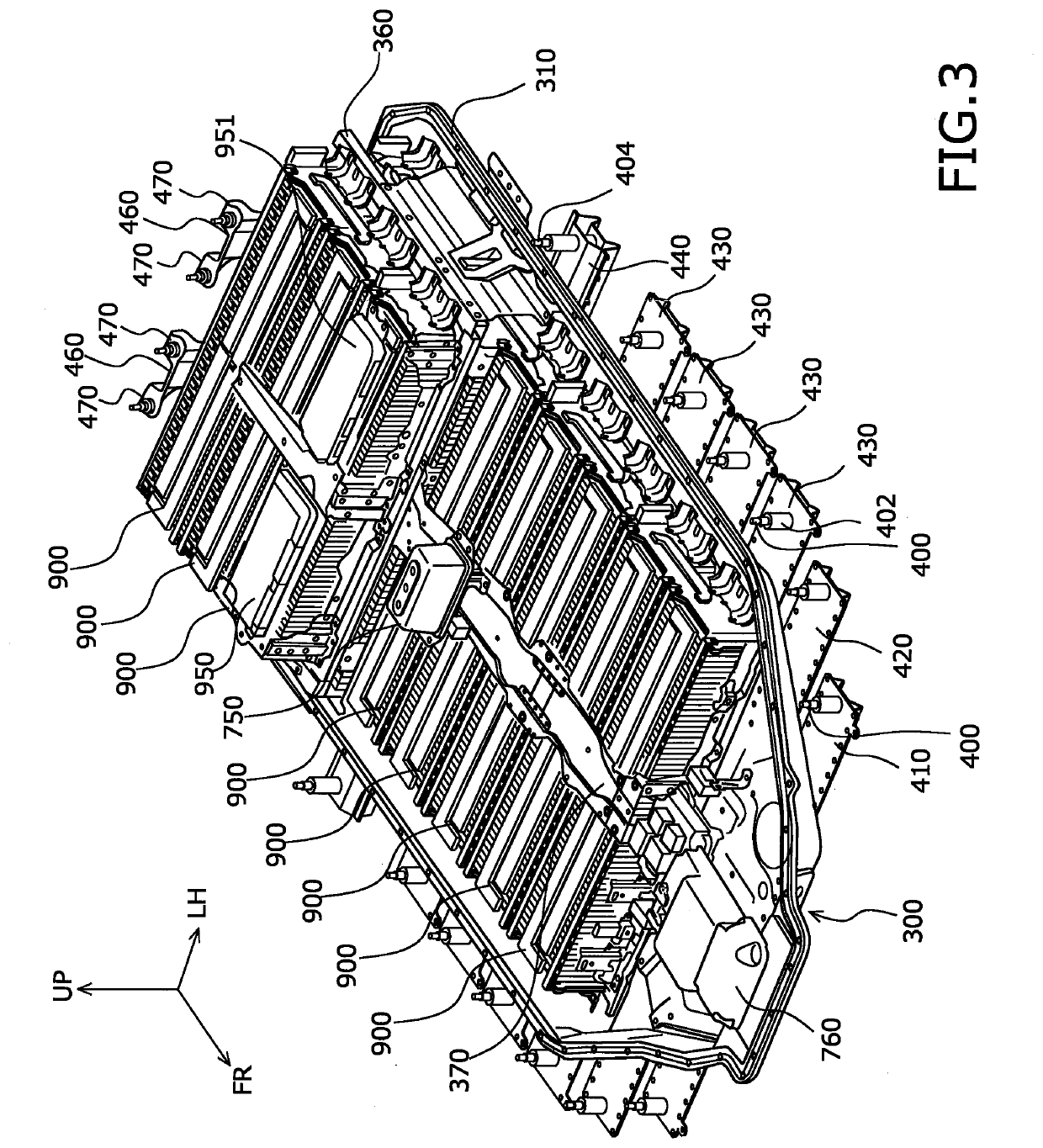

Battery pack and vehicle for mounting the same

ActiveUS20200227706A1Vibration suppressionReduce vibrationElectric propulsion mountingVehicle sub-unit featuresAutomotive engineeringElectrical and Electronics engineering

The battery pack according to the present disclosure is a battery pack mounted under a floor of a vehicle. The battery pack comprises a lower case fixed under the floor and on which a battery stack is placed, an upper case attached to the lower case, and a support member extending upwardly from a rigid body provided inside the lower case to support a back surface of the upper case. The battery pack may further comprise an elastic member disposed on a surface of the upper case and sandwiched between the upper case and a lower surface of the floor. In such a configuration, it is possible to suppress the upper case of the battery pack from vibrating.

Owner:TOYOTA JIDOSHA KK

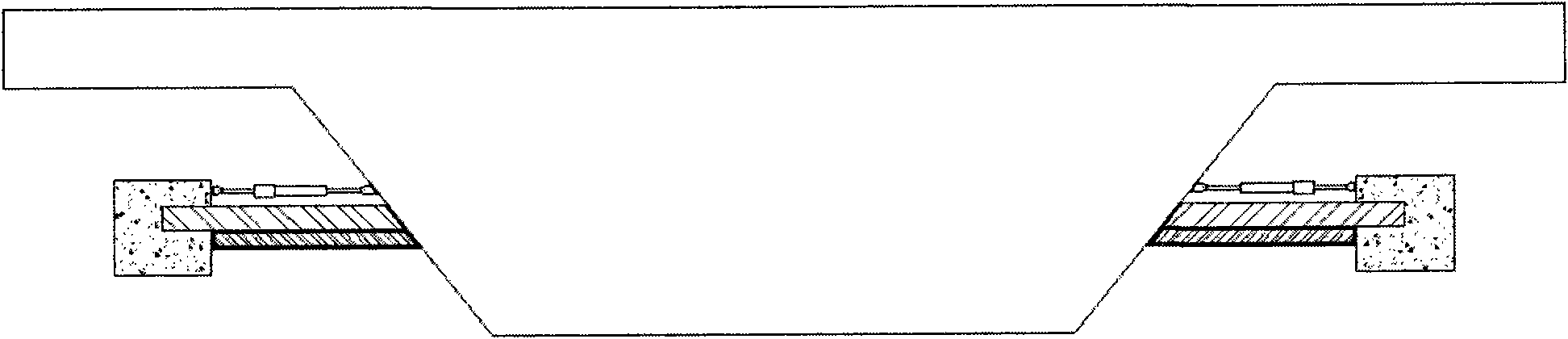

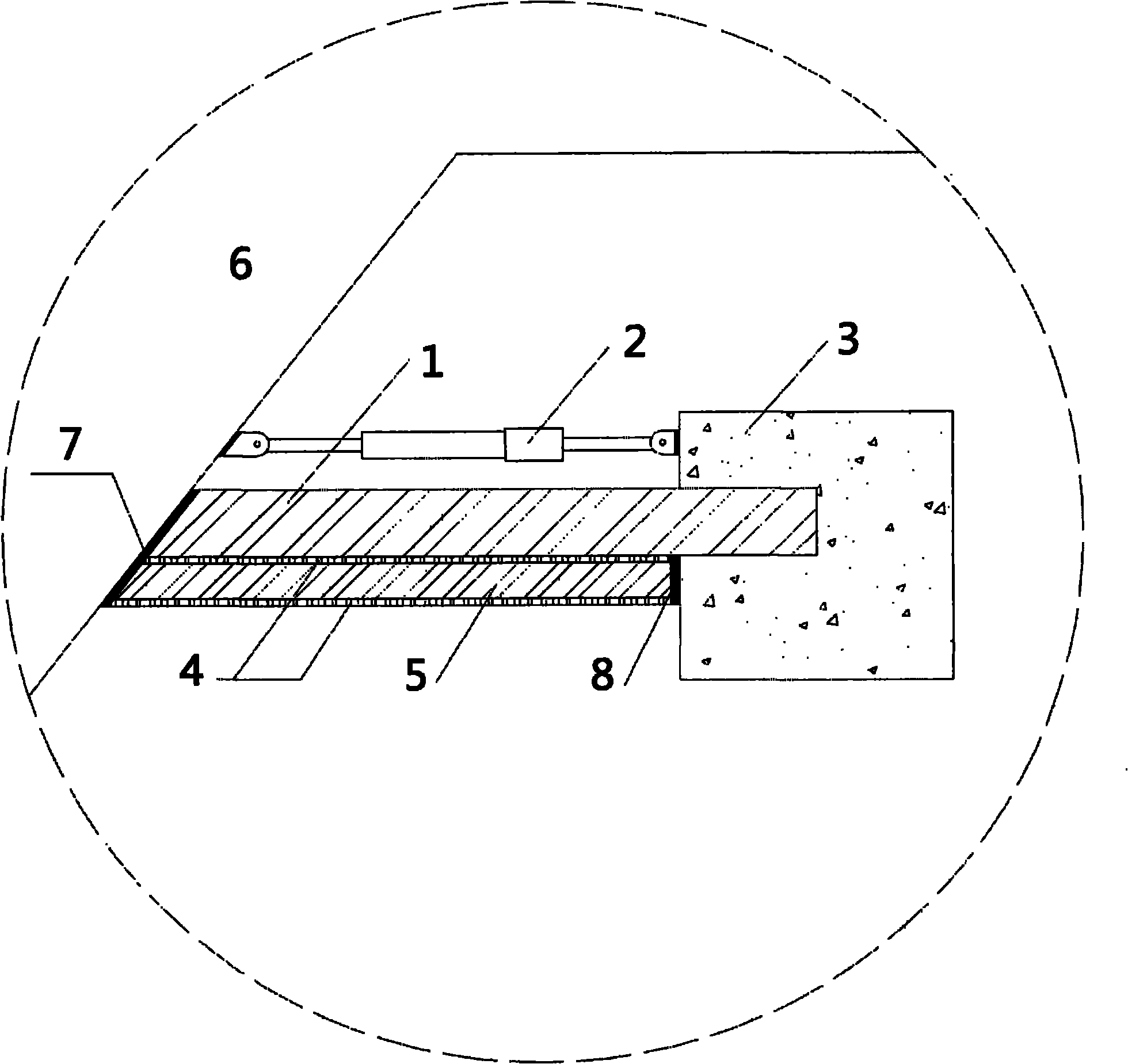

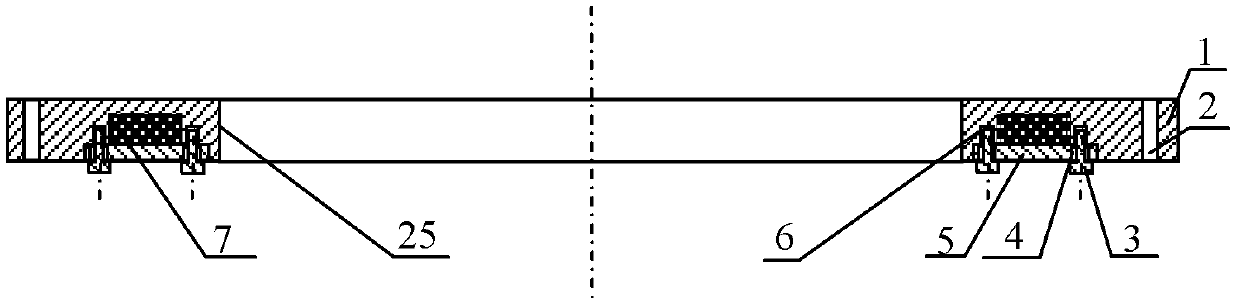

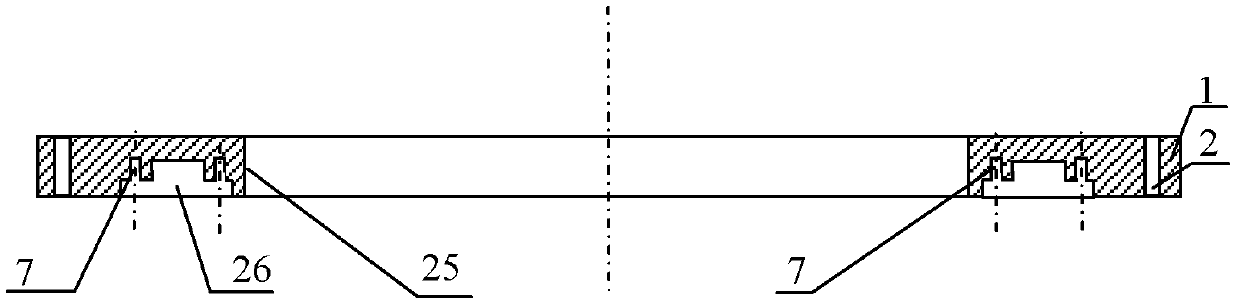

Piezoelectric Energy Harvesting Tuned Mass Absorber

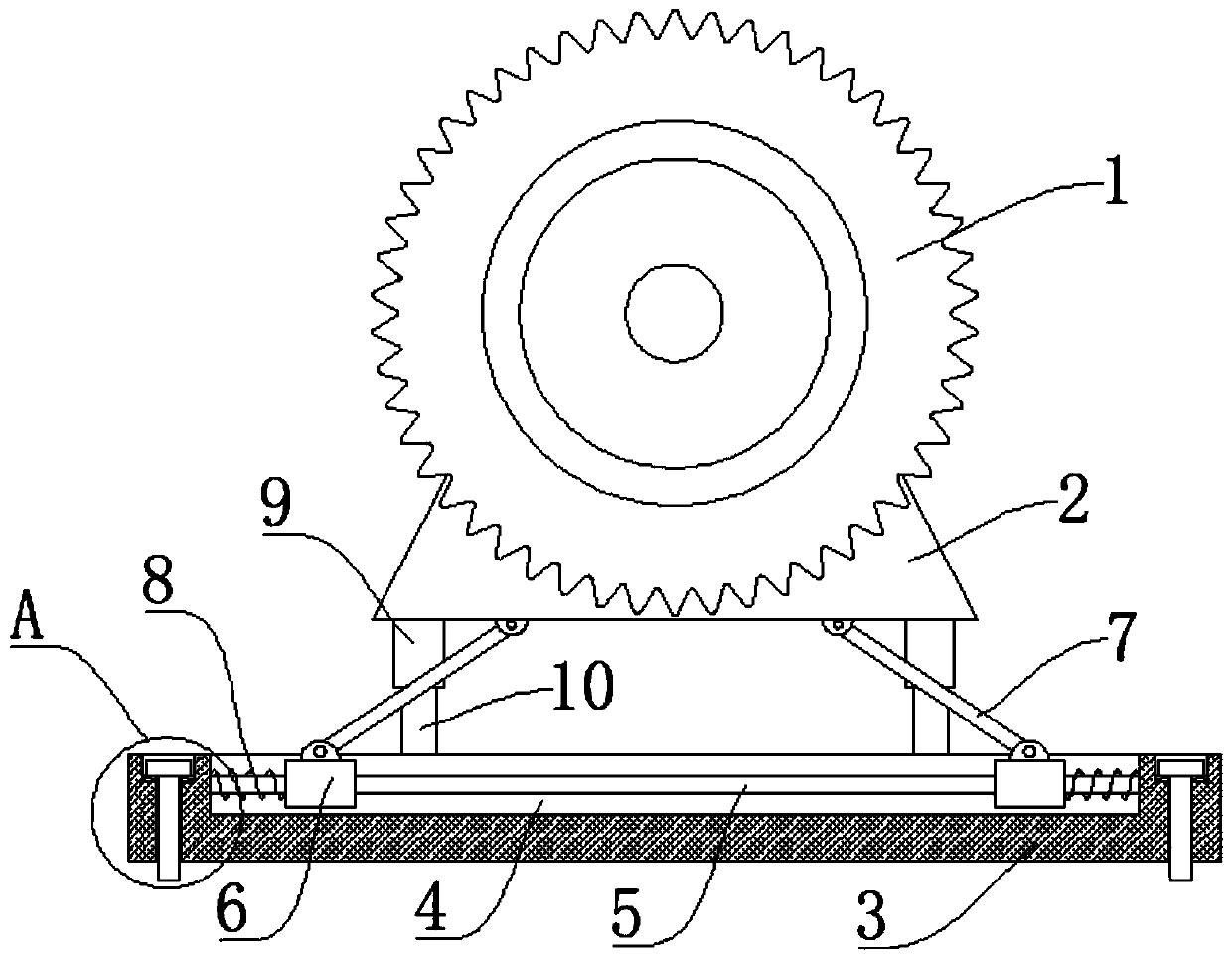

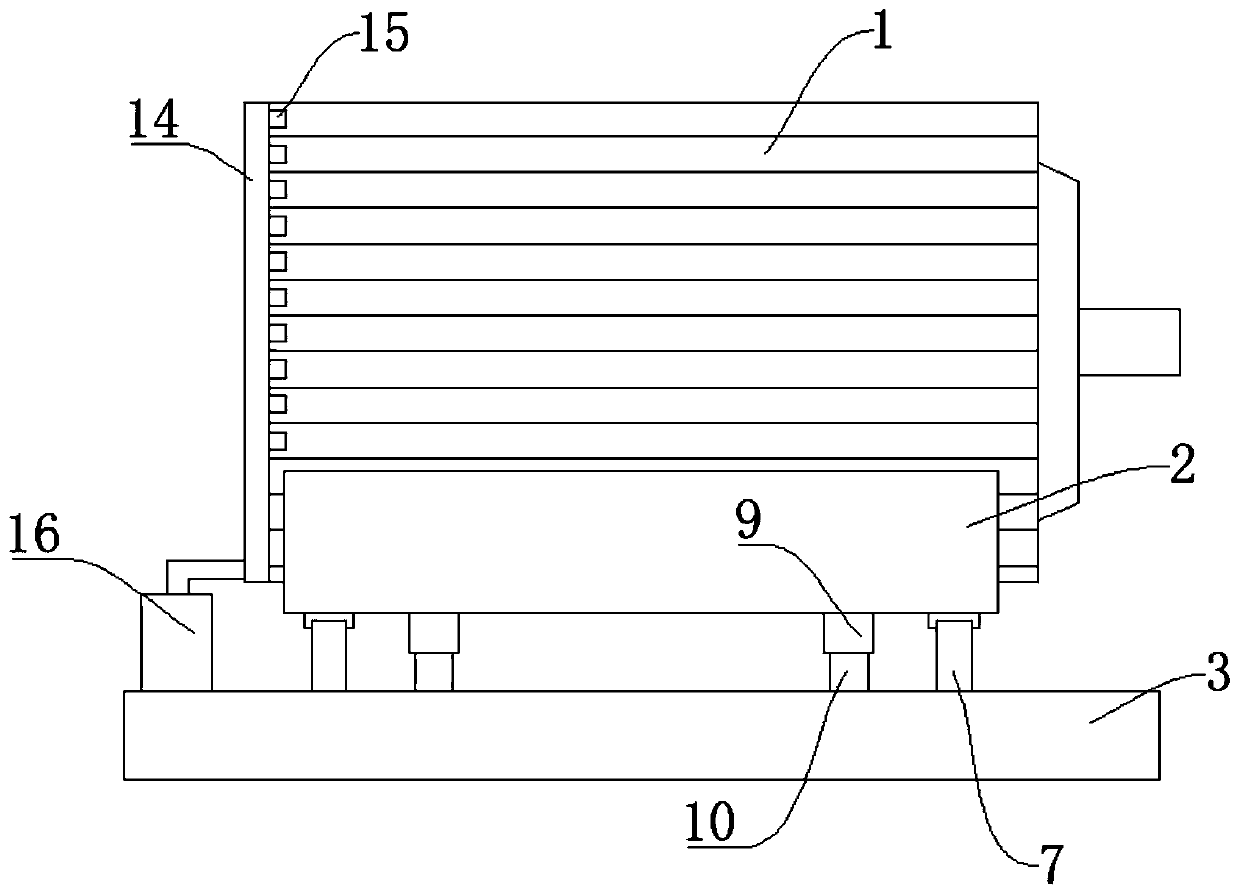

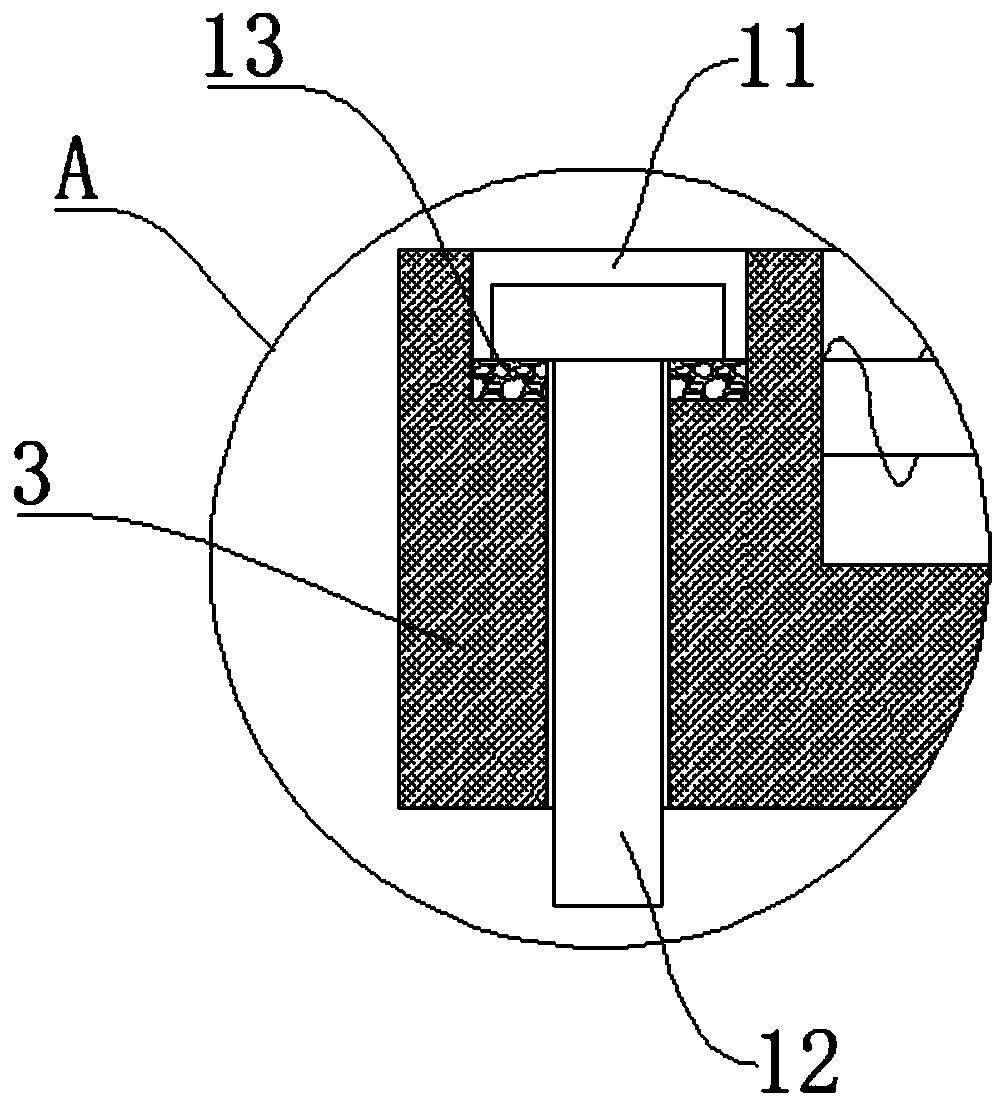

ActiveCN102277827AVibration suppressionReduce bridge vibrationPiezoelectric/electrostriction/magnetostriction machinesBridge structural detailsSteel frameBimorph

The invention discloses a piezoelectric energy-capturing type tuning quality shock absorber belonging to the technical field of civil engineering structures. The piezoelectric energy-capturing type tuning quality shock absorber is characterized by being symmetrically arranged at two sides of a bridge along the length direction of the bridge and comprising a girder connected with the side wall of the bridge and a mass block, wherein a damper is arranged above the girder, and piezoelectric vibrators are arranged on the downside of the girder in a cling manner and comprise single chips, parallel connection bimorphs and serial connection bimorphs. The piezoelectric energy-capturing type tuning quality shock absorber is also characterized by being arranged right below the bridge along the length direction of the bridge and comprising an I-shaped steel frame fixed at the lower end of a bottom plate of the bridge, wherein the wing edge of the lower end of the bottom plate of the bridge is used for supporting the girder, a high-strength spring and a hinging damper are fixed at the upper part of the girder; and a steel frame is connected to upsides of the high-strength spring and the hinging damper, the mass block is placed on the steel frame, and the piezoelectric vibrators are placed between the mass block and the steel frame. The invention has the advantages of reasonable and novel structure, easiness in machining, flexibility and convenience for use, strong applicability, capabilities of effectively improving shock resistance property of the bridge structure and saving energy resources, wide application prospect and popularization value.

Owner:TSINGHUA UNIV

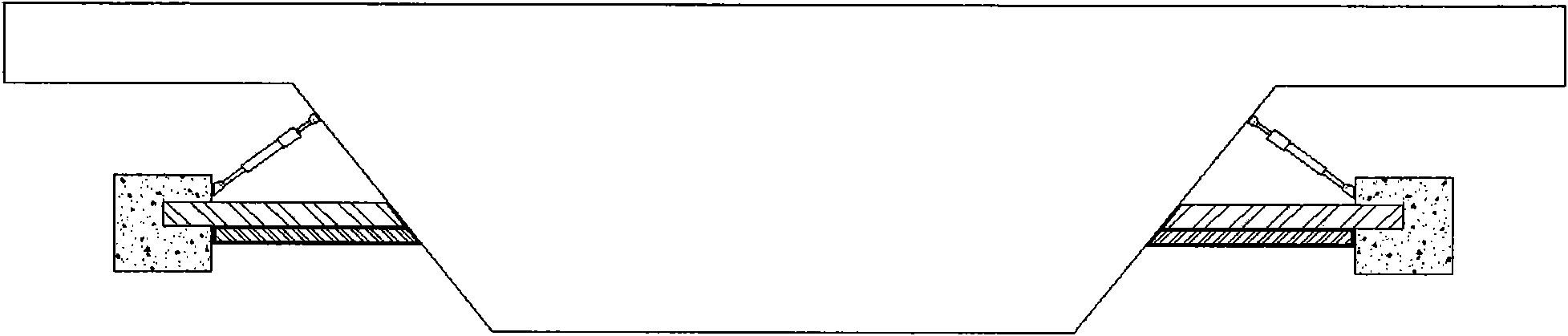

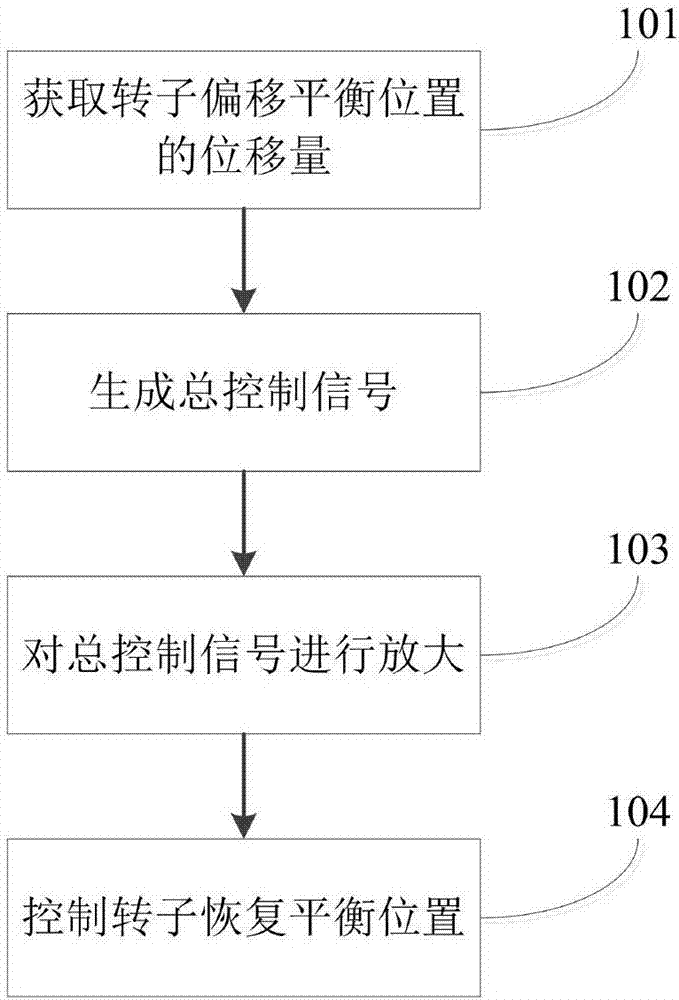

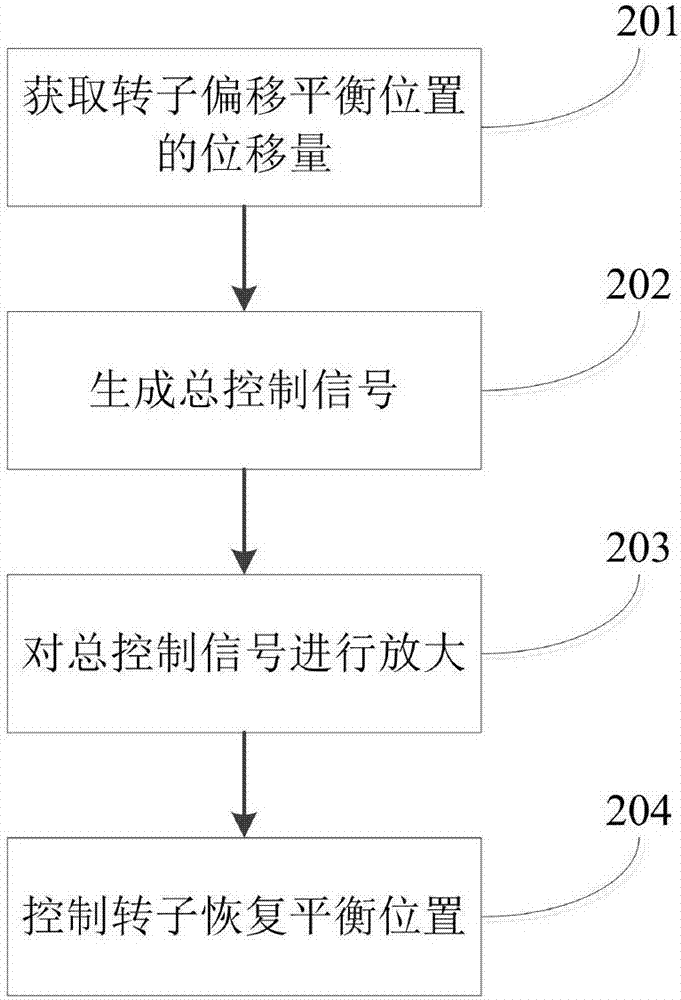

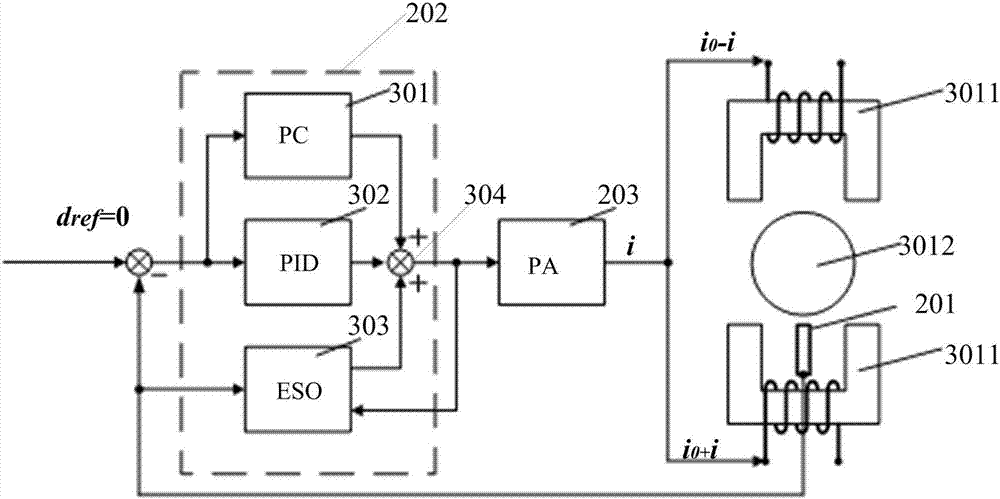

Control method and system for magnetic suspension motor rotor

ActiveCN107104618ASuppression of rotor vibrationVibration suppressionElectronic commutation motor controlVector control systemsPhase compensationSignal amplification

The invention discloses a control method and a control system for a magnetic suspension motor rotor. The method comprises the steps of acquiring the displacement amount of a rotor offset equilibrium position of a magnetic suspension motor, and generating a displacement signal according to the displacement amount; performing proportion-integral-differential control, phase compensation and disturbance compensation on the displacement signal to generate an overall control signal by cooperatively working of the three kinds of operation; amplifying the overall control signal, so as to control the rotor of the motor to recover to the equilibrium position. By using the control method provided by the invention, rotor vibration caused by external disturbance and vibration of the rotor close to a critical rotation speed are effectively suppressed, vibration of the magnetic suspension rotor close to the critical rotation speed is also effectively suppressed, and thus the rotor can be in a stable suspension state.

Owner:浙江中源磁悬浮技术有限公司

Hybrid vehicle

ActiveUS20160023648A1Vibration suppressionLower combustion speedHybrid vehiclesDigital data processing detailsHybrid vehicleCombustion

When an engine start command is generated to an engine that is in a stopped state, engine start control for cranking the engine and starting fuel combustion after increasing the engine speed is performed. In the engine start control, one of a first start pattern in which an initial combustion speed is higher than a resonance speed of the engine, and a second start pattern in which the initial combustion speed is lower than the resonance speed of the engine is selected according to the speed ratio (gear position) of a transmission. Cranking torque in the second start pattern is lower than the cranking torque in the first start pattern.

Owner:TOYOTA JIDOSHA KK

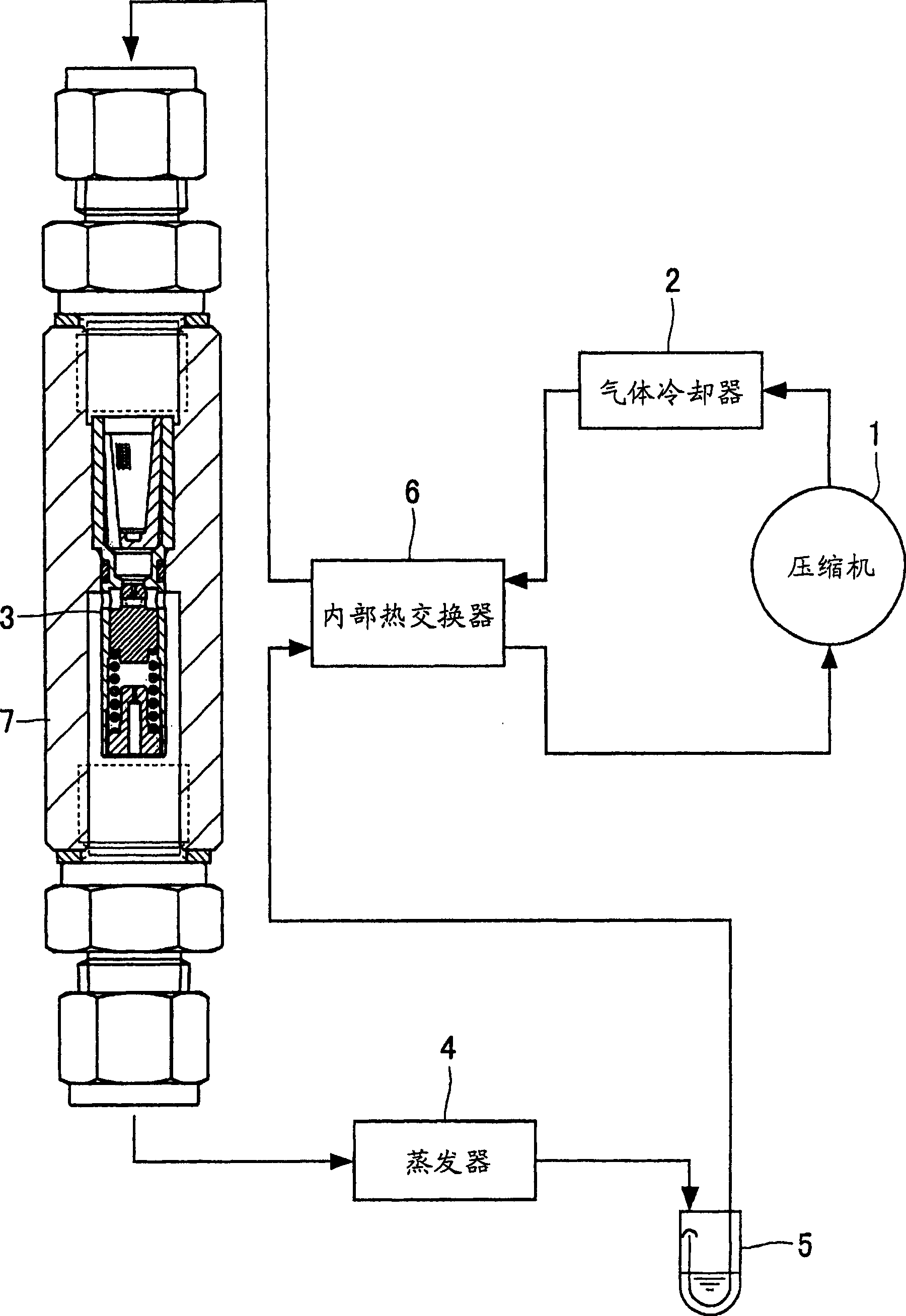

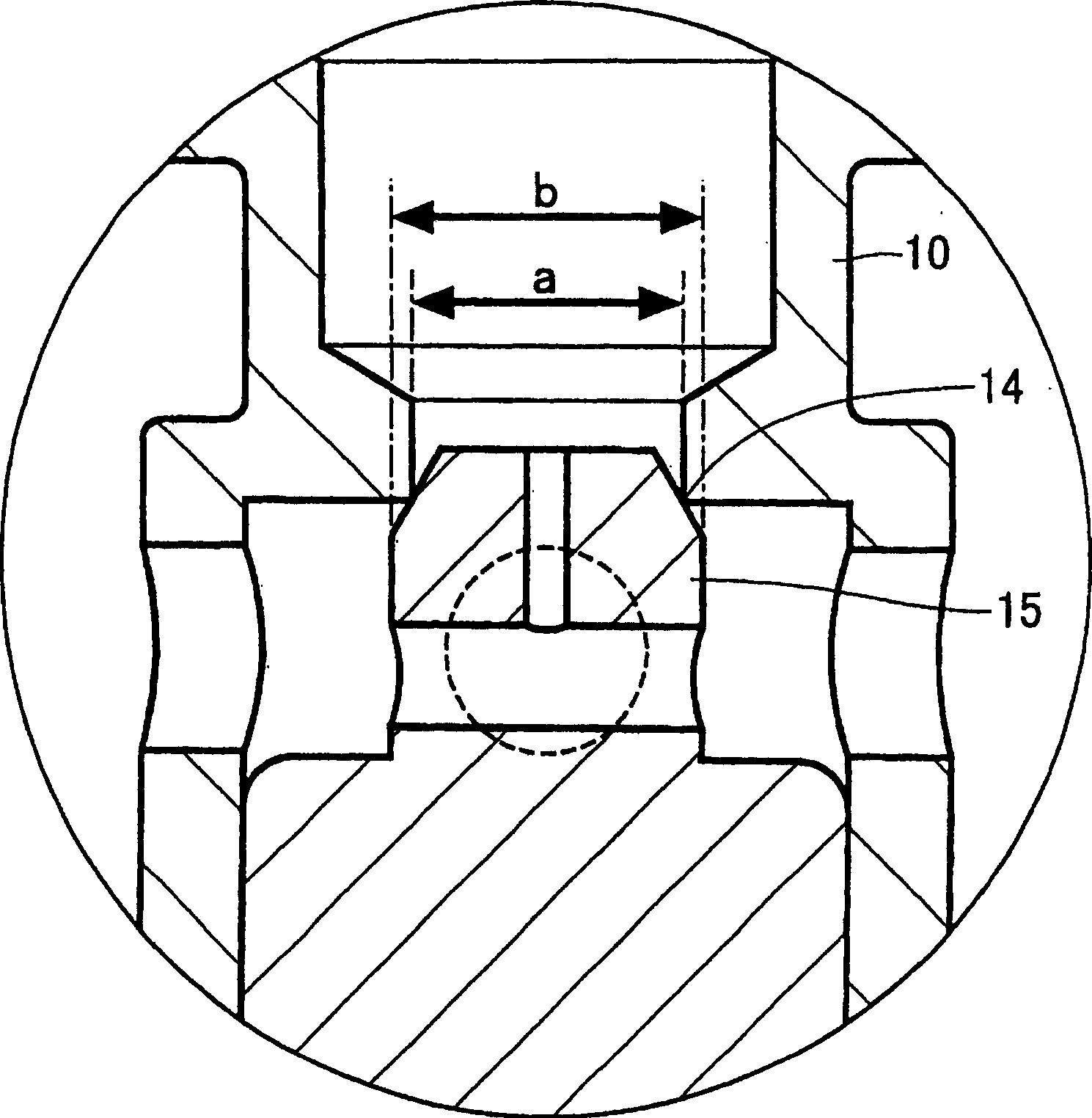

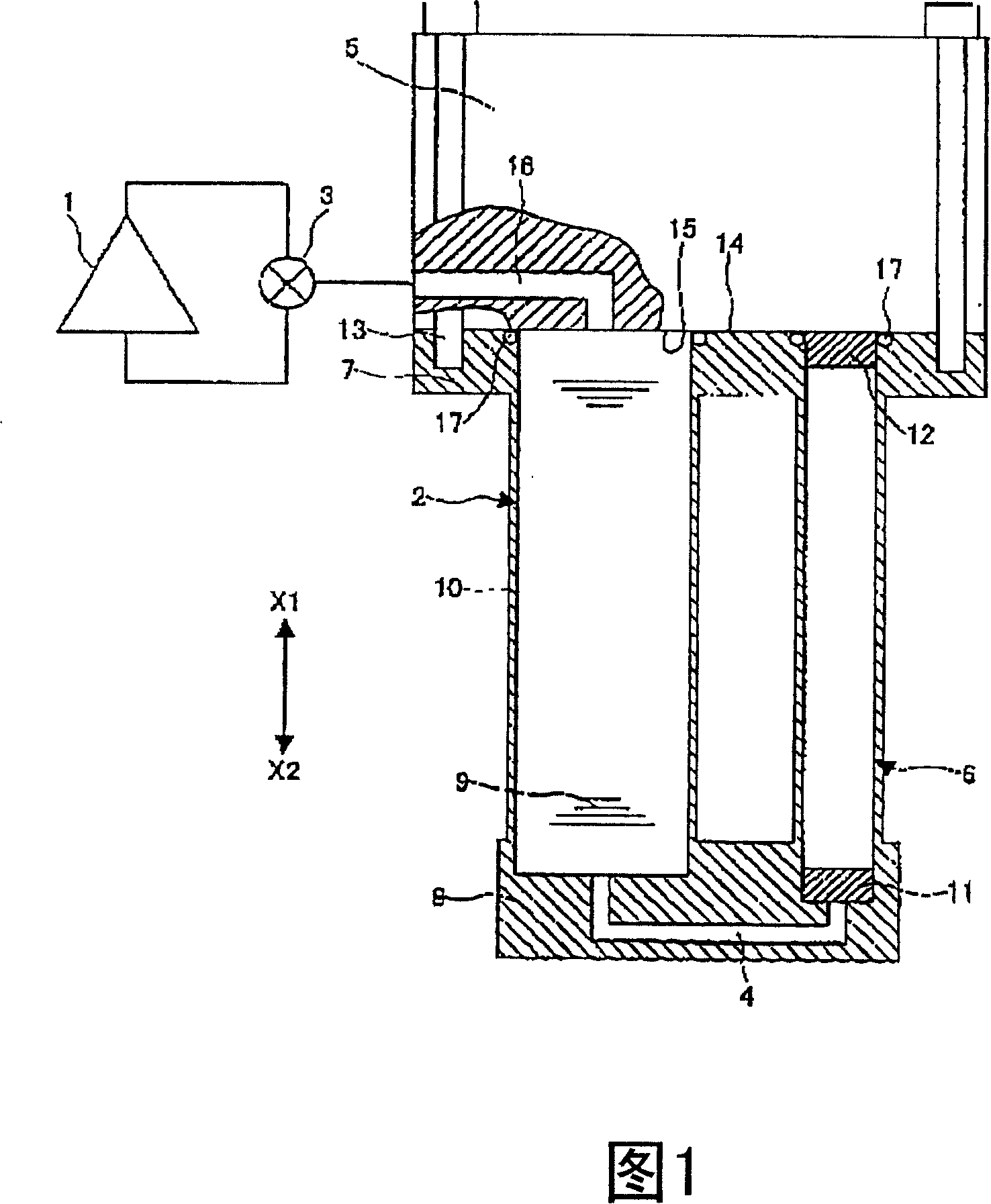

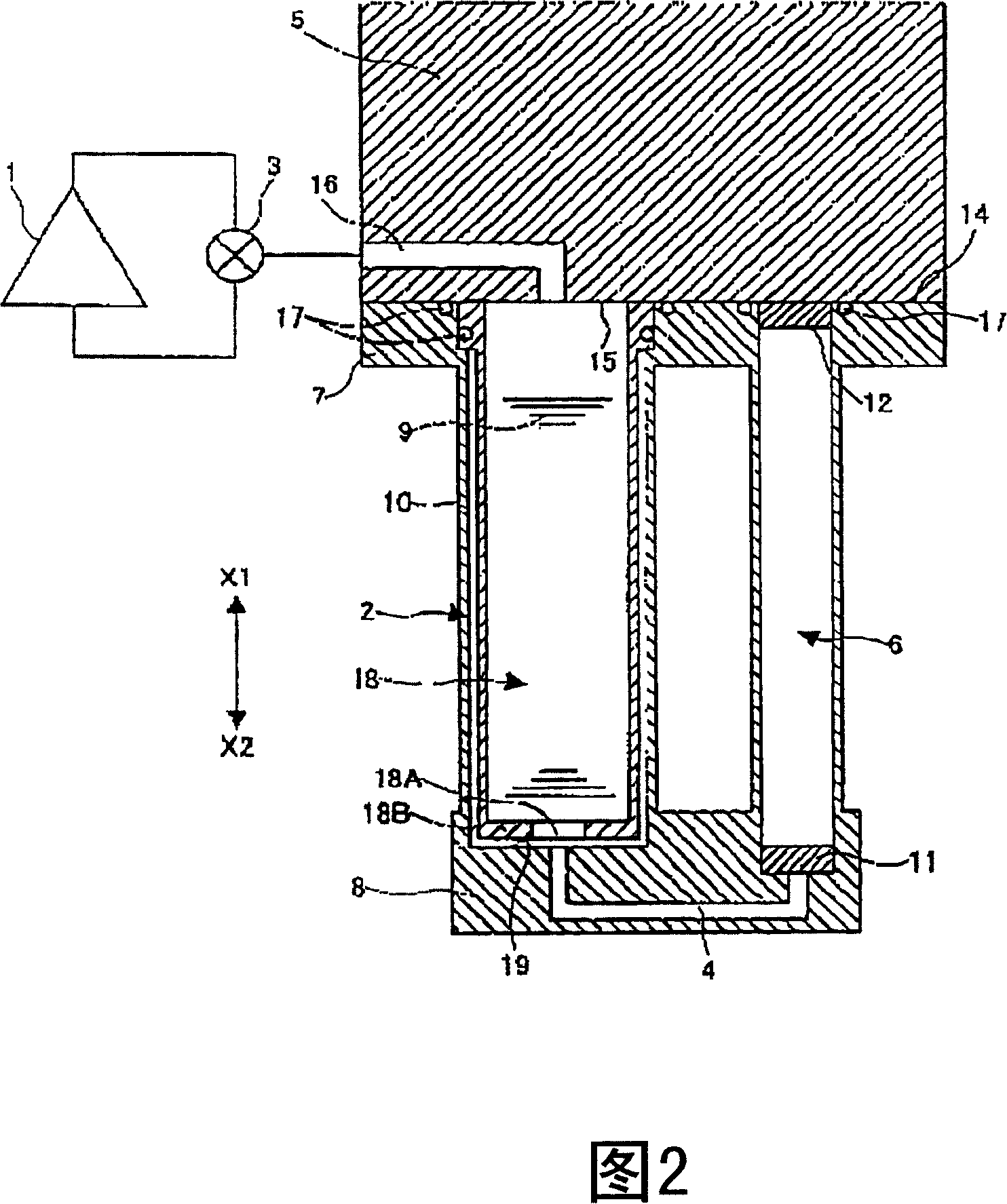

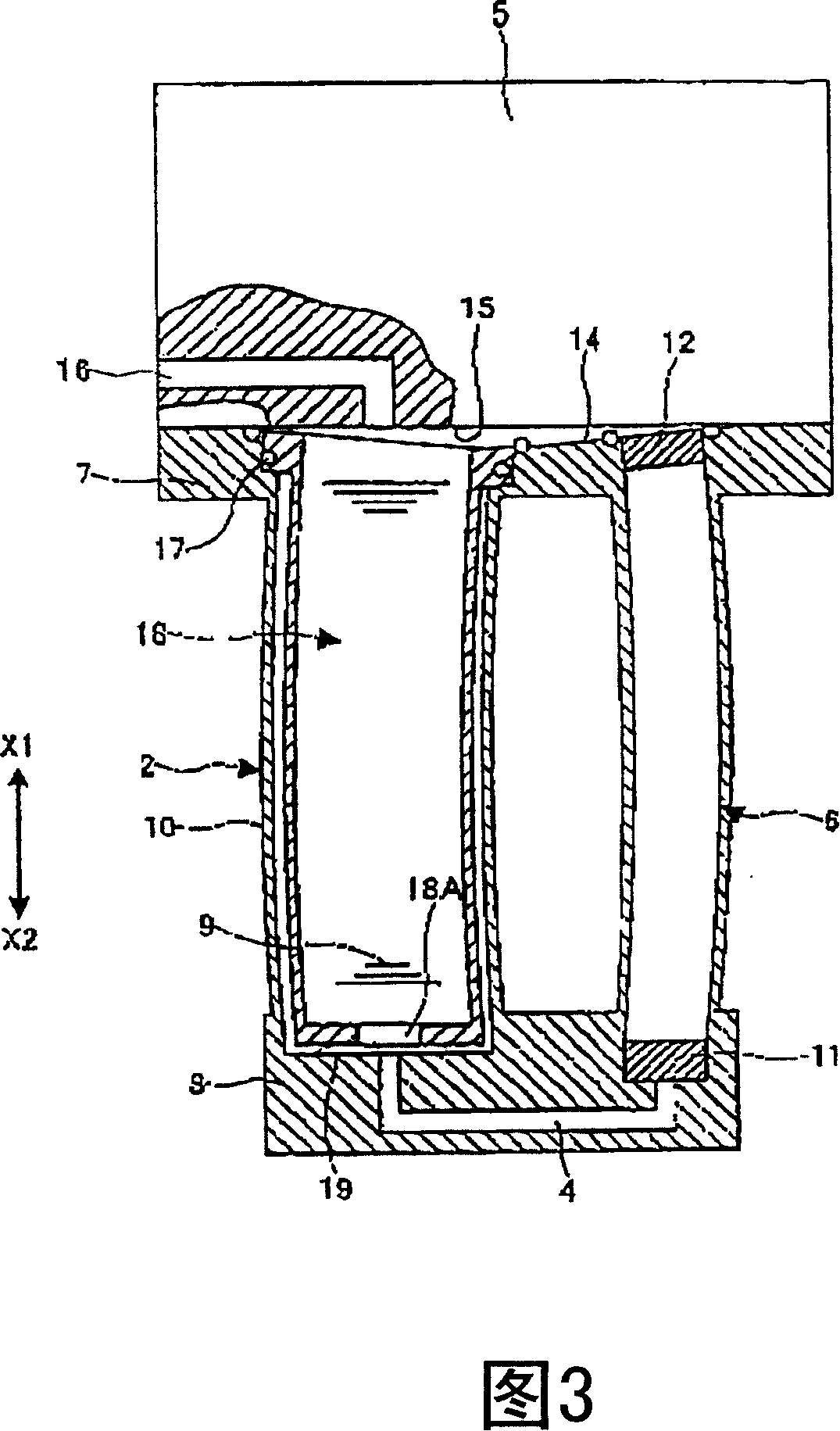

Expansion device

InactiveCN1786625AVibration suppressionReduce abnormal noiseFluid circulation arrangementPistonTraffic volume

An expansion device that reduces abnormal noise due to vibration of a valve body and reduces valve body suction phenomenon caused by high-pressure refrigerant flowing through a variable hole formed between a valve seat and the valve body produced. In the expansion device, the buffer chamber (23) is composed of the following components: cylinder (16), formed in the housing (10) forming the valve seat (14); piston (17), which is formed with the valve body (15) as One piece; the adjusting screw (22), when the valve body is subjected to the sudden pressure change of the introduced refrigerant, absorbs the violent action of the valve body through the volume change of the buffer chamber, thereby suppressing the vibration of the valve body (15), thereby reducing Unusual noise generation. Make the ratio (b / a) of the valve body diameter (b) of the valve body (15) to the valve port diameter (a) of the valve hole less than or equal to 1.5, so as to reduce the suction phenomenon of the valve body, and make the refrigerant flow with the primary pressure and The pressure difference between the secondary pressures corresponds to the flow through.

Owner:TGK

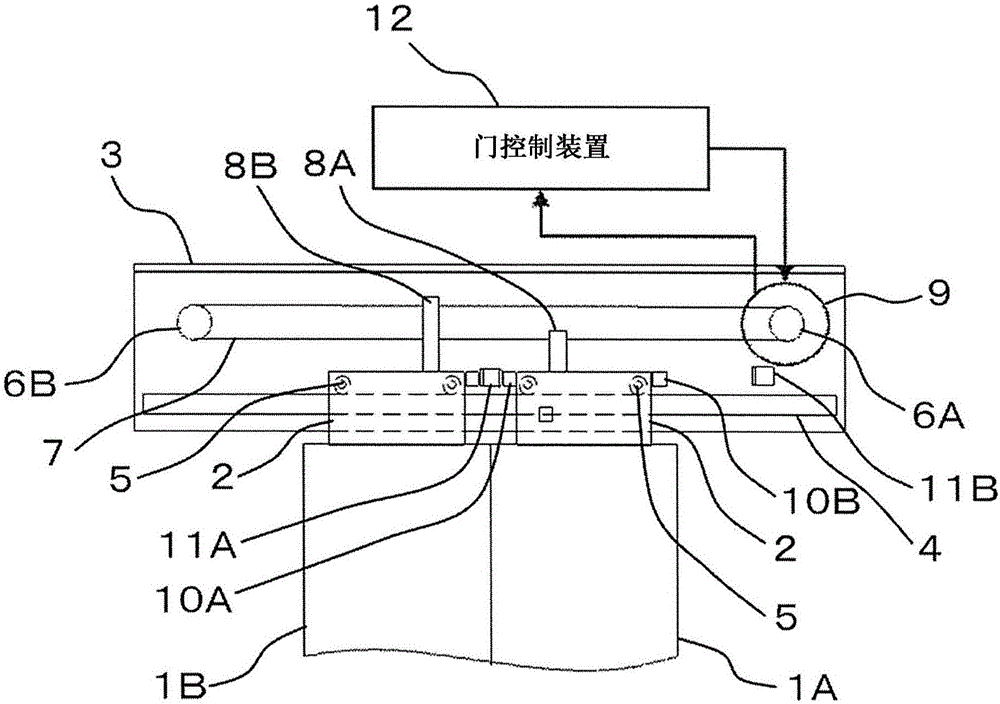

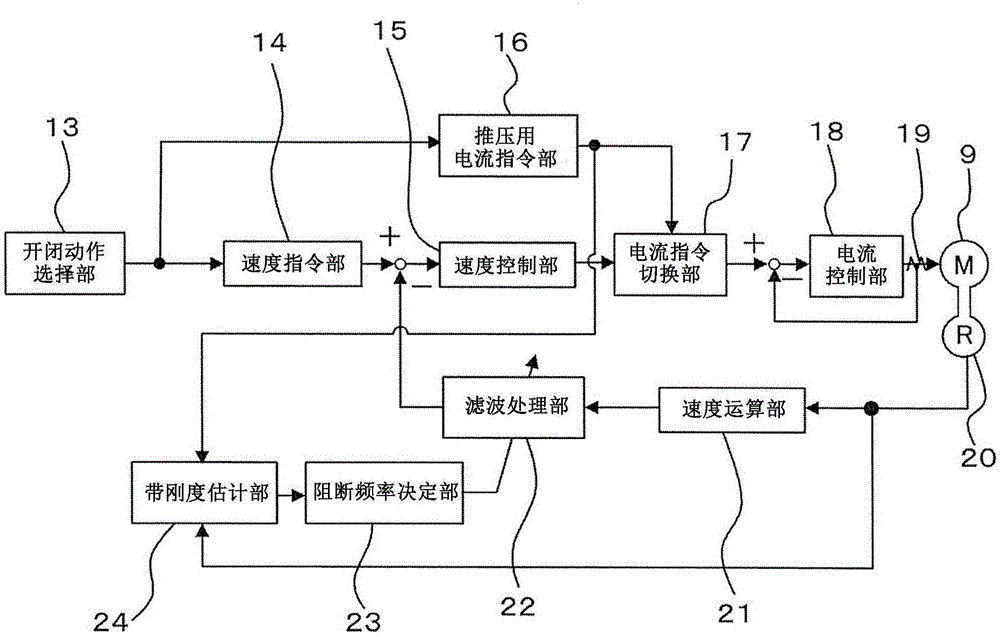

Door control device and elevator device

ActiveCN106467266AVibration suppressionSmooth opening and closingBuilding liftsElectric machineryMoving speed

Disclosed is a door control device and an elevator device. A door is allowed to be opened and closed smoothly by appropriate filtering of detection results of door opening and closing speed. The door control device includes an opening and closing operation selecting unit for selectively outputing an operation command for a door plate connected to a motor driven belt; a speed control unit that outputs a current value supplied to a motor to control the moving speed of the door plate; a current instruction portion for pressing, which changes the current value so that the torque generated by the motor changes; a speed calculating unit that calculates a rotational speed of the motor based on the rotational position of the motor; and a belt stiffness estimating unit that estimates belt stiffness using the change amount of the current value outputted by the current instruction unit for pressing and the change amount of the rotational position of the motor; a blocking frequency determination unit configured to determine a blocking frequency based on the estimated belt stiffness of the belt stiffness estimating unit; and a filter processing unit that outputs a signal after of the frequency component of the blocking frequency is removed from the signal of the rotational speed and feeding the signal back to the speed control unit.

Owner:MITSUBISHI ELECTRIC CORP

Variable-frequency motor with damping effect

InactiveCN110868010AVibration suppressionGood cushioning effectSupports/enclosures/casingsMechanical engineeringControl theory

Owner:HUBEI WANBANG ELECTROMECHANICAL DEV

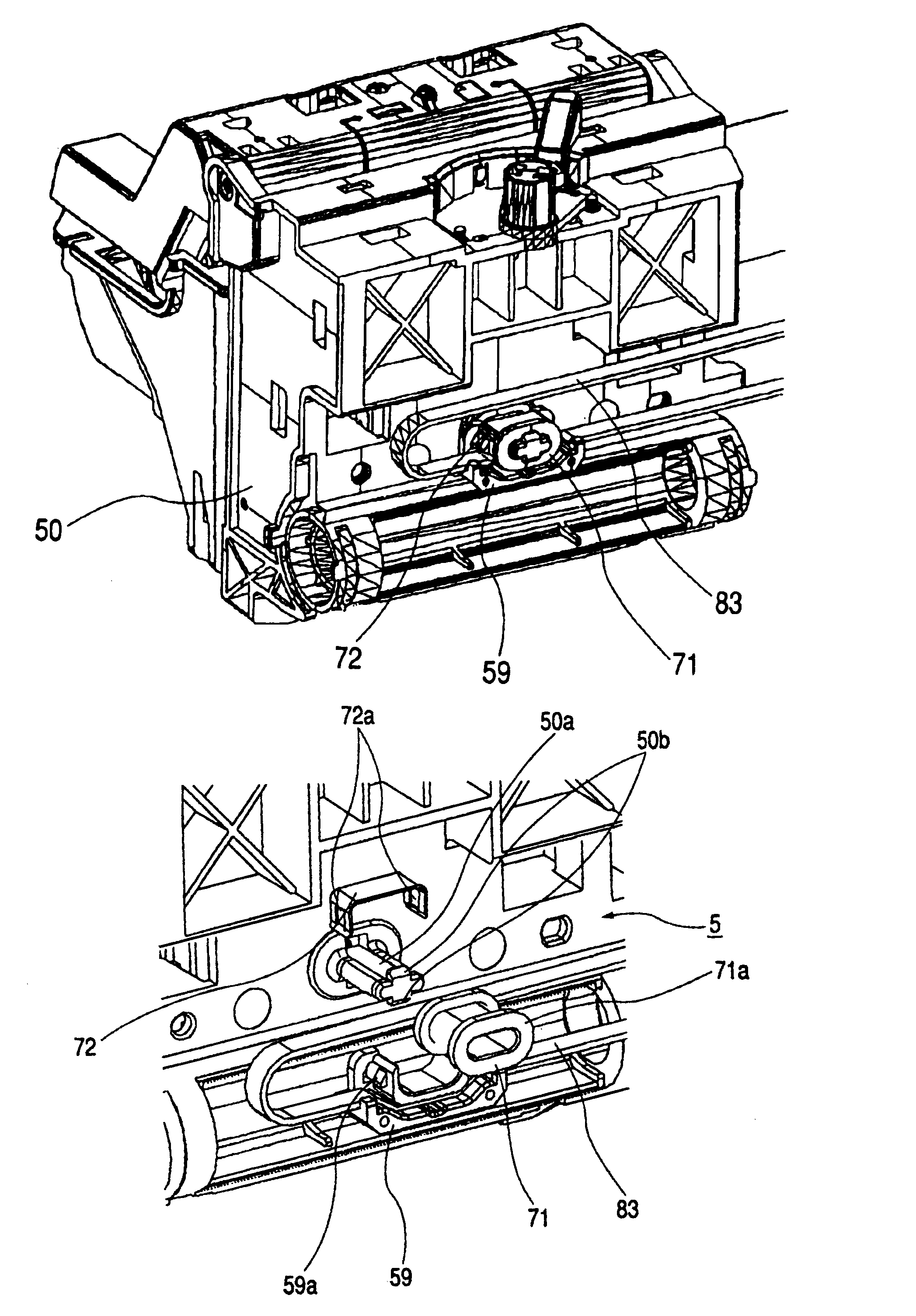

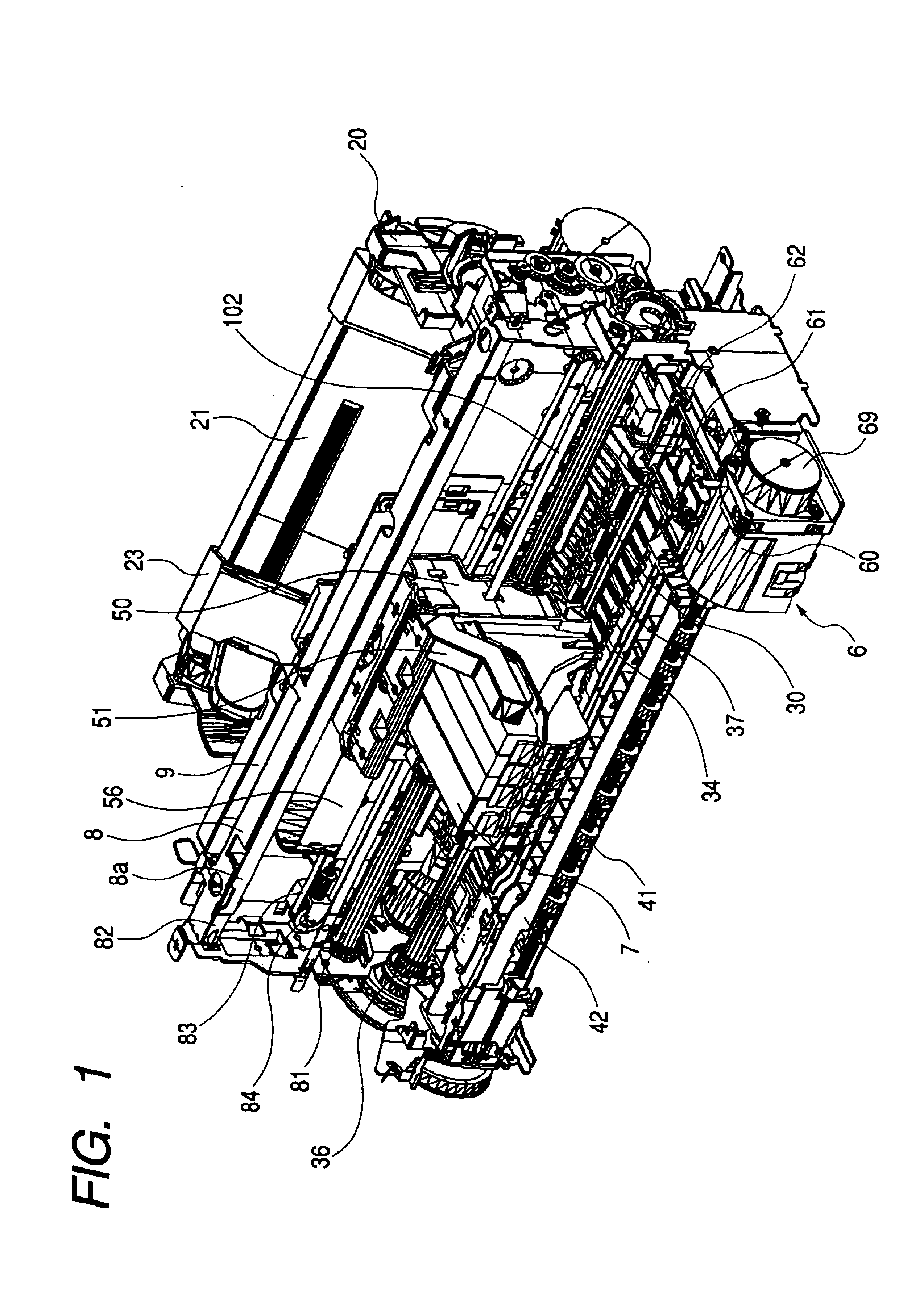

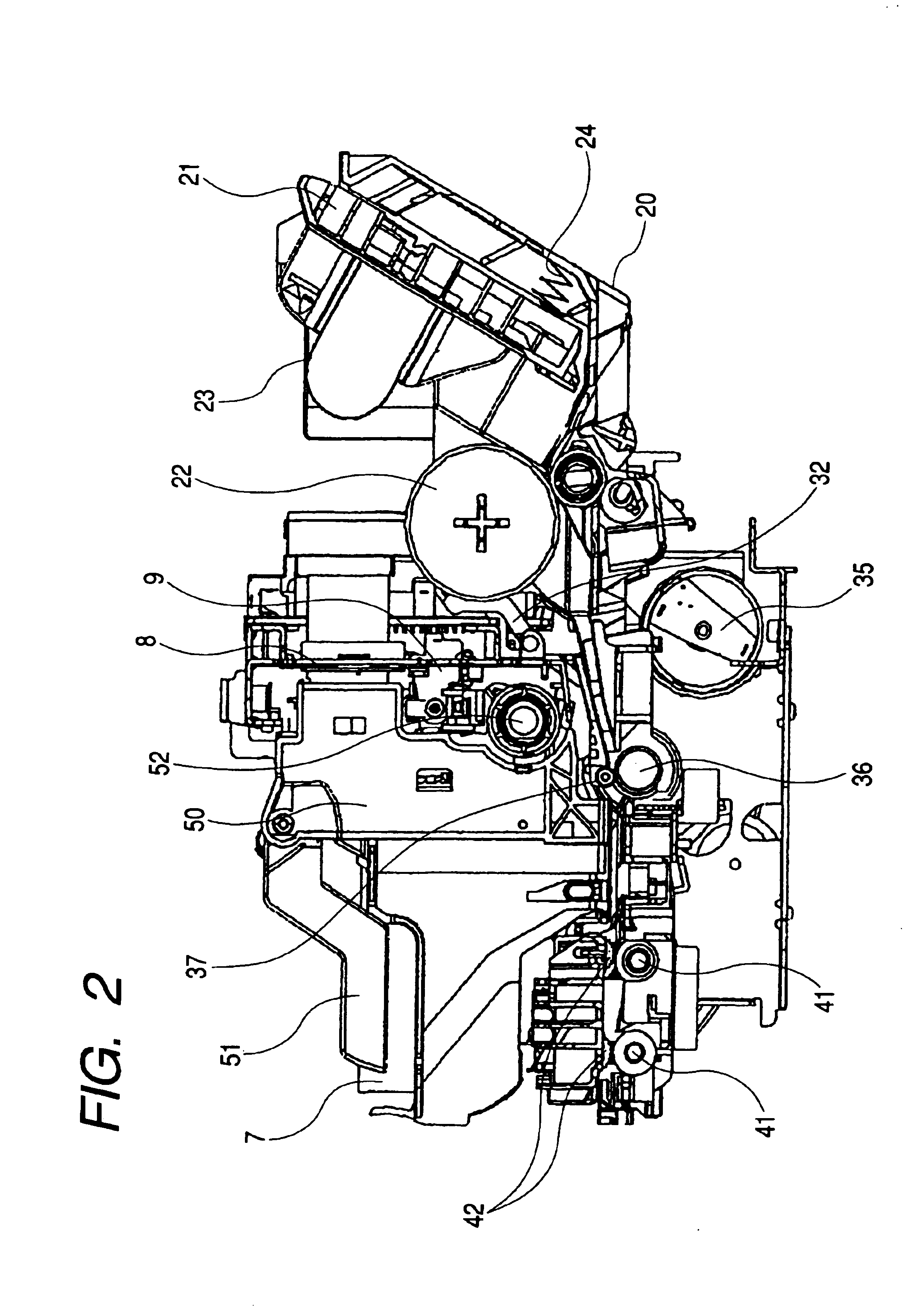

Recording apparatus

ActiveUS7025431B2Vibration suppressionDampening effectSpacing mechanismsTypewritersRecording headEngineering

A recording apparatus for effecting recording on a recording medium by a recording head includes a carriage for reciprocally scanning with the recording head carried thereon, a guide member for guiding the reciprocal scanning of the carriage, a drive source for driving the reciprocal scanning of the carriage, a transmitting member for transmitting a driving force from the drive source to the carriage, a holding member for holding the transmitting member, a projected portion disposed on the carriage and having the holding member mounted thereon, and an attenuating member for attenuating vibrations from the drive source between the carriage and the holding member, the attenuating member being of a shape surrounding the projected portion of the carriage, and the holding member holding the transmitting member being mounted on the projected portion with the attenuating member interposed therebetween.

Owner:CANON KK

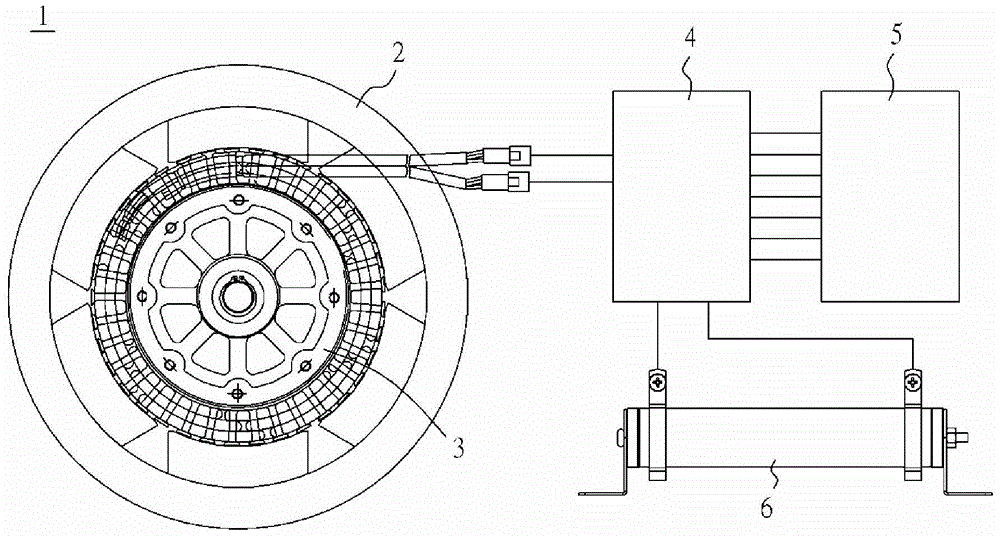

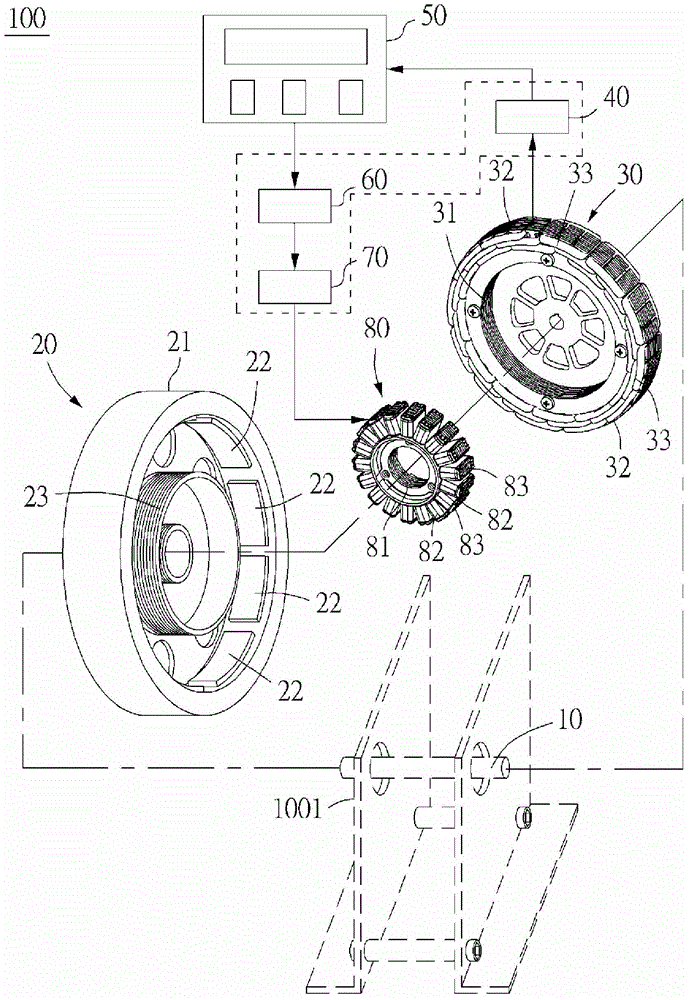

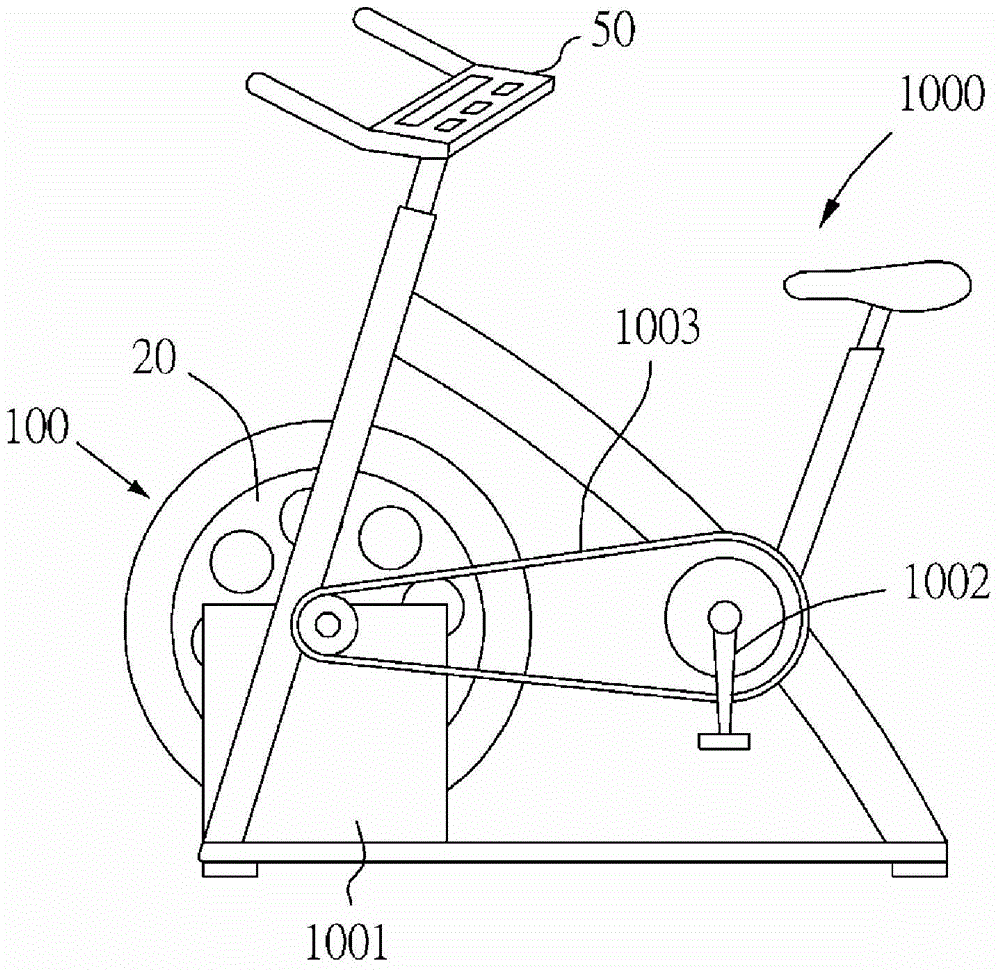

Power generation and brake apparatus, and foot treading fitness equipment

ActiveCN105816992AAvoid wasting powerVibration suppressionMovement coordination devicesMuscle exercising devicesMagnetStator

The present invention discloses a power generation and brake apparatus disposed on a shaft. The power generation and brake apparatus comprises a wheel body disposed to the shaft, wherein the wheel body comprises an outer ring portion, magnets and an inner ring portion; a stator unit disposed to the shaft, wherein the stator comprises a stator main body, tooth portions and coils wound to the tooth portions, and when the wheel body rotates, the magnets rotate relative to the stator unit to generate alternating current; a rectifier unit connected to the stator unit so as to convert the alternating current into direct current; a control panel connected to the rectifier unit; a waveform generation unit connected to the control panel so as to generate a reverse torque input signal; a DC source adjusting unit connected to the waveform generation unit; and a brake unit disposed to the stator main body, wherein the brake unit receives the direct current and the reverse torque input signal and has a brake main body, another tooth portions and another coils wound to the another tooth portions, and the brake unit brakes the wheel body. Therefore, vibration is suppressed and noise is reduced.

Owner:曾源揆

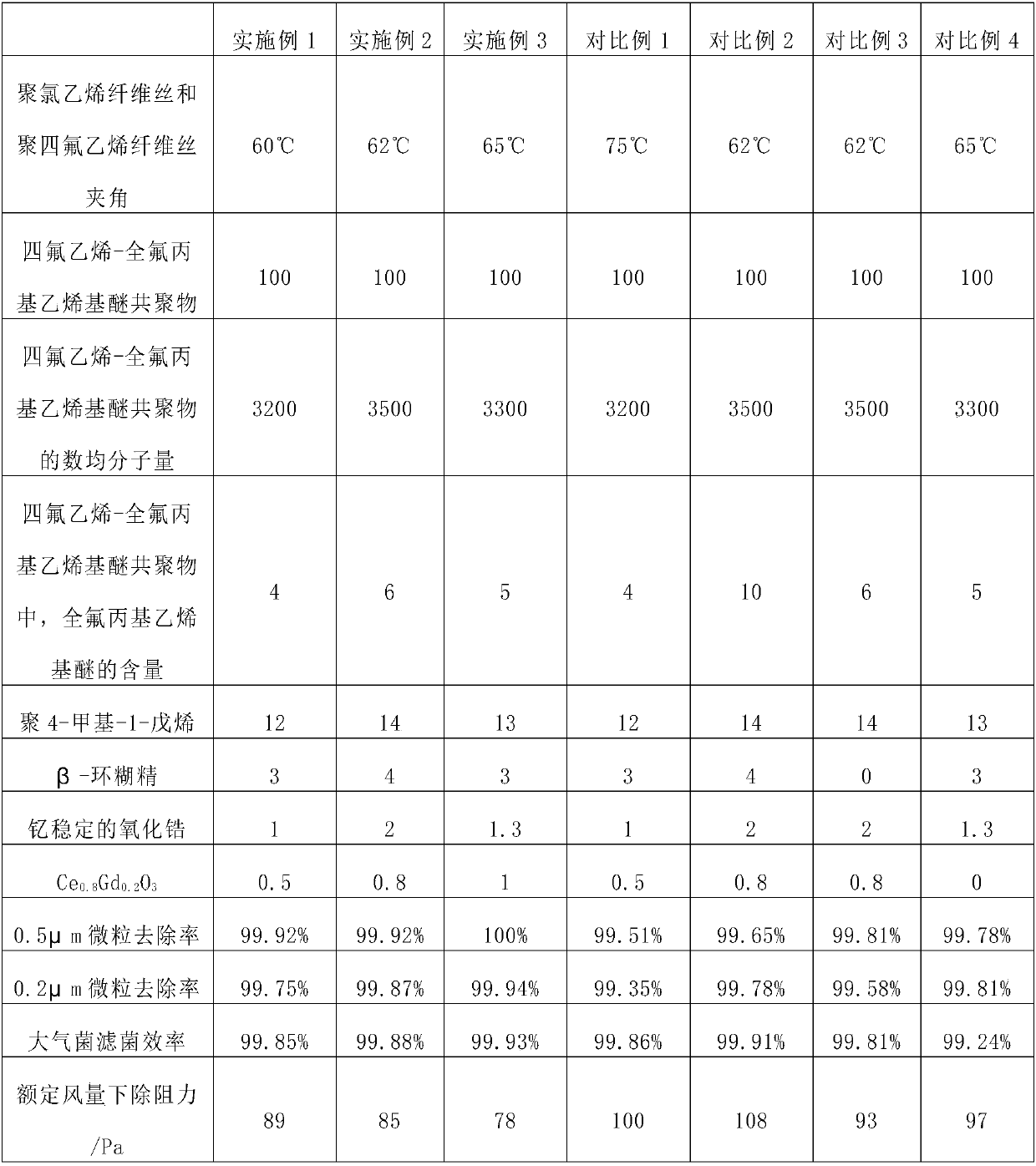

High-efficiency filter sheets for air microfiltration membrane filters

InactiveCN108031209AVibration suppressionImprove filtering effectDispersed particle filtrationFiltration separationChemistryFiber layer

The present invention relates to a high-efficiency filter sheet for air microfiltration membrane filters. The high-efficiency filter sheet comprises a polyvinyl chloride fiber layer and a polytetrafluoroethylene fiber layer, wherein fiber filaments in the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer are respectively in a unidirectional arrangement, and an included angle between the fiber filaments in the polyvinyl chloride fiber layer and the fiber filaments in the polytetrafluoroethylene fiber layer is 60-65 DEG. According to the high-efficiency filter sheet, a double layer combination of the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer is used, and a specific angle between the fiber filaments is set, so that windage resistance and filtering effect of the filter sheet are improved; the introduced polytetrafluoroethylene fiber layer has superhigh mechanical strength and structural toughness, so that vibration caused by strongwind can be effectively suppressed, and airflow in a dust collection chamber of a vacuum cleaner is stabilized; and a filling layer is additively arranged, so that the filtering effect of the filter sheet is further improved.

Owner:SUZHOU QINGRUI AIR SYST

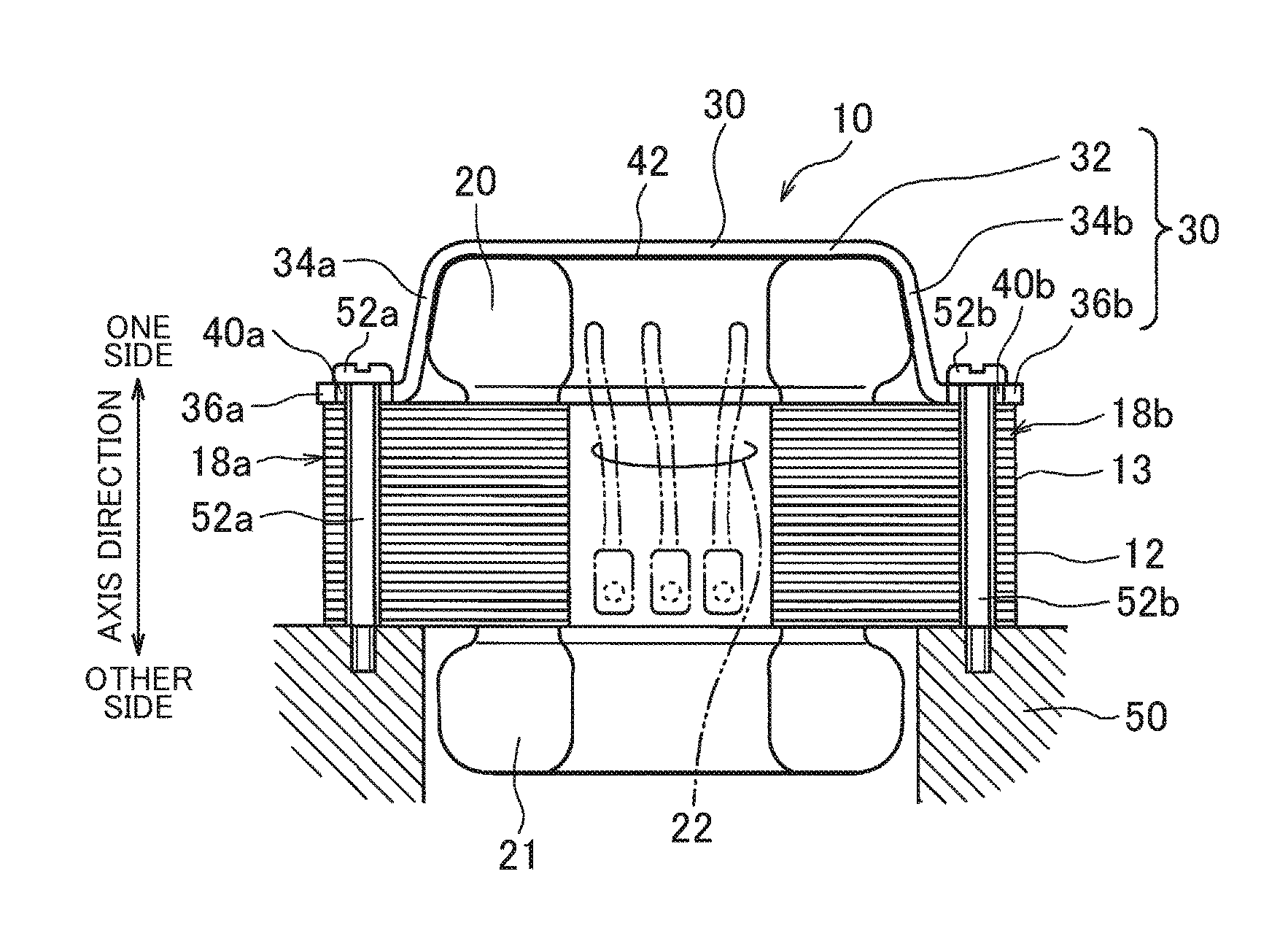

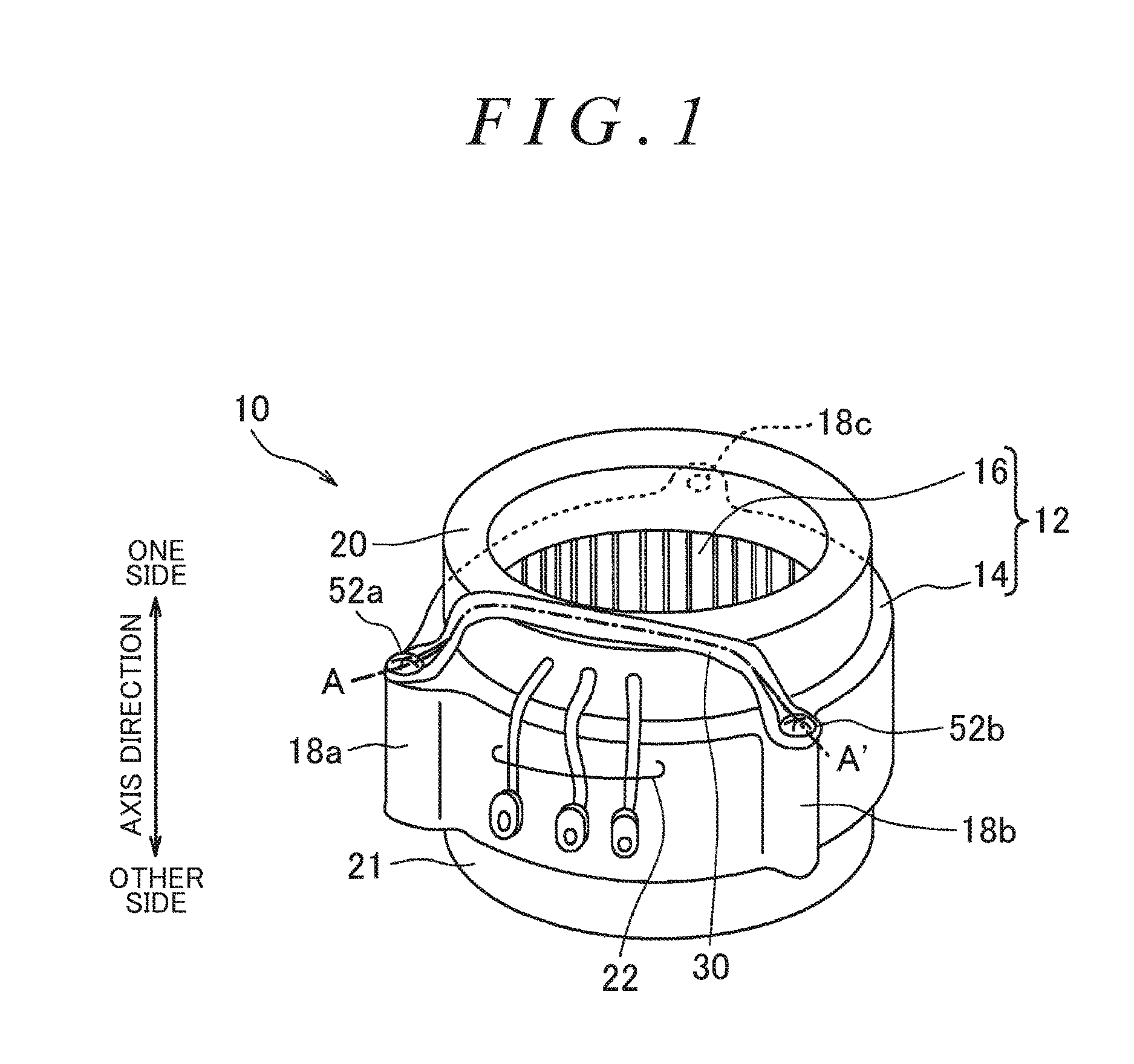

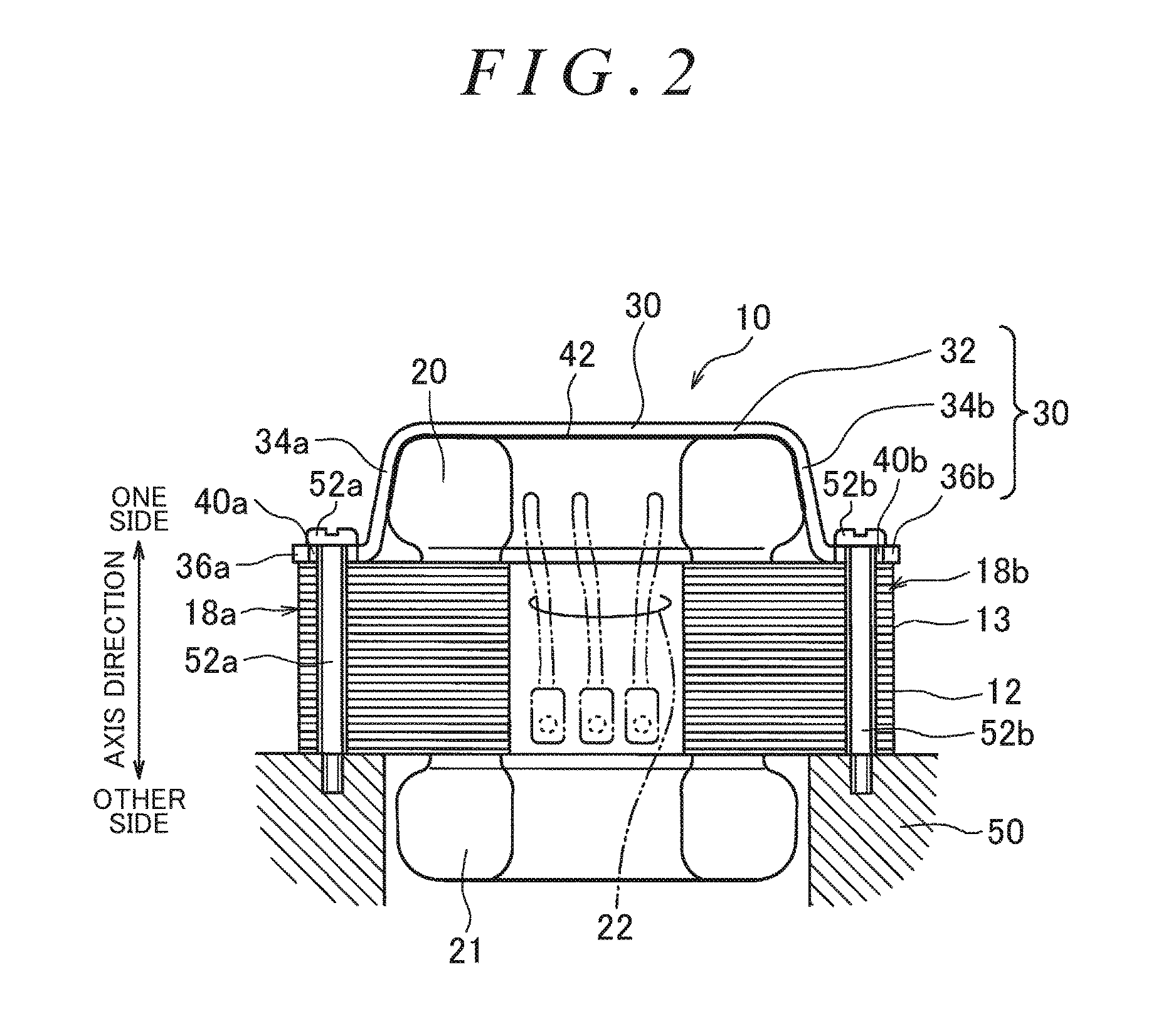

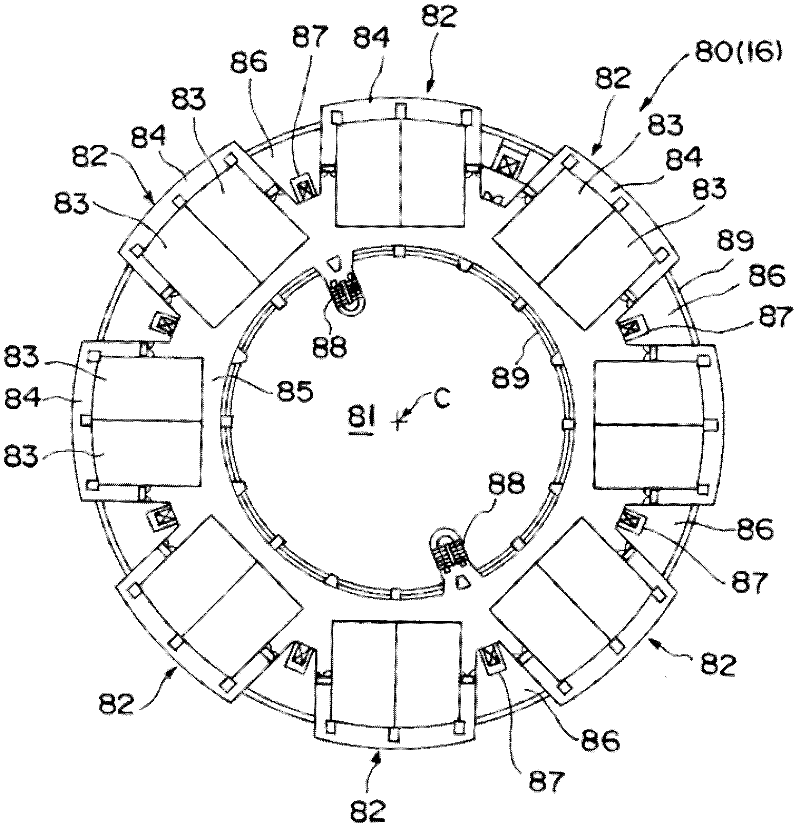

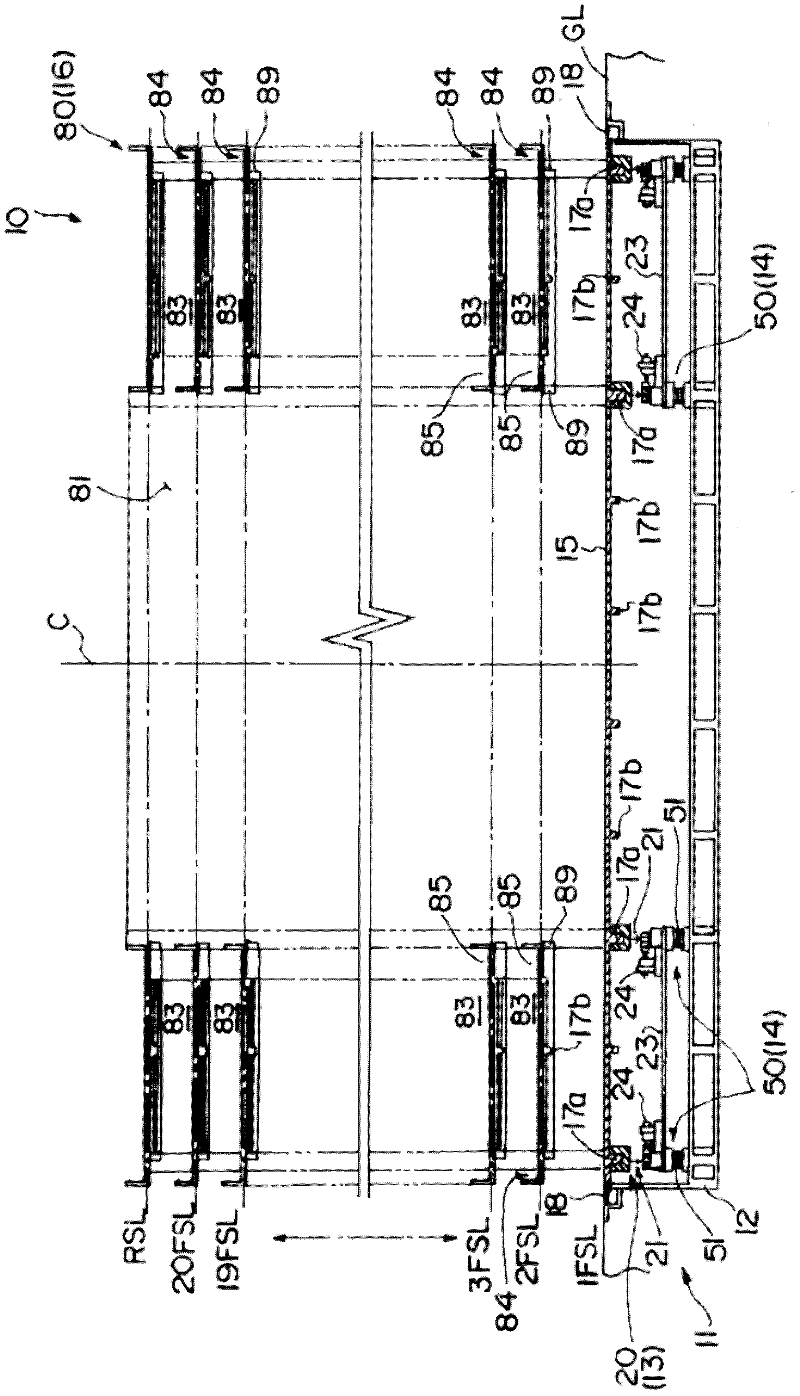

Rotary electric machine stator

ActiveUS20170012486A1Reliable suppressionVibration suppressionWindingsSupports/enclosures/casingsEngineeringMechanical engineering

A rotary electric machine stator includes a stator core including a plurality of teeth, a coil wound around the teeth, a power wire being drawn out from the coil, and a retainer member that presses the coil end against the stator core. The retainer member includes a pressing portion disposed on an end surface in an axis direction of the coil end, leg portions extending from respective end portions on opposite sides of the pressing portion toward respective attachment portions provided at the stator core, and attachment ends provided at the respective leg portions and fixed to the respective attachment portions, and the power wire is drawn out from between the leg portions on the opposite sides of the pressing portion.

Owner:TOYOTA JIDOSHA KK

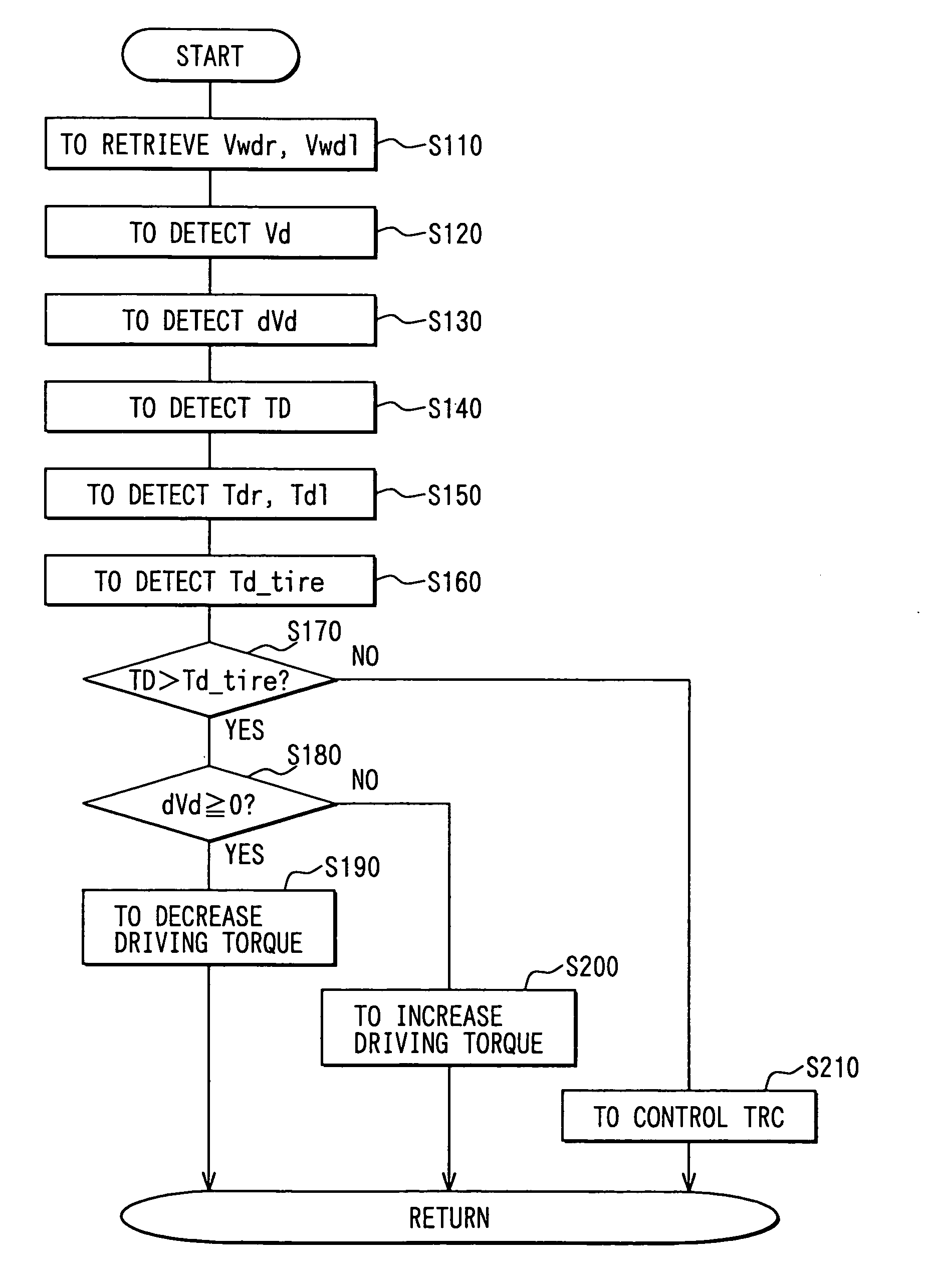

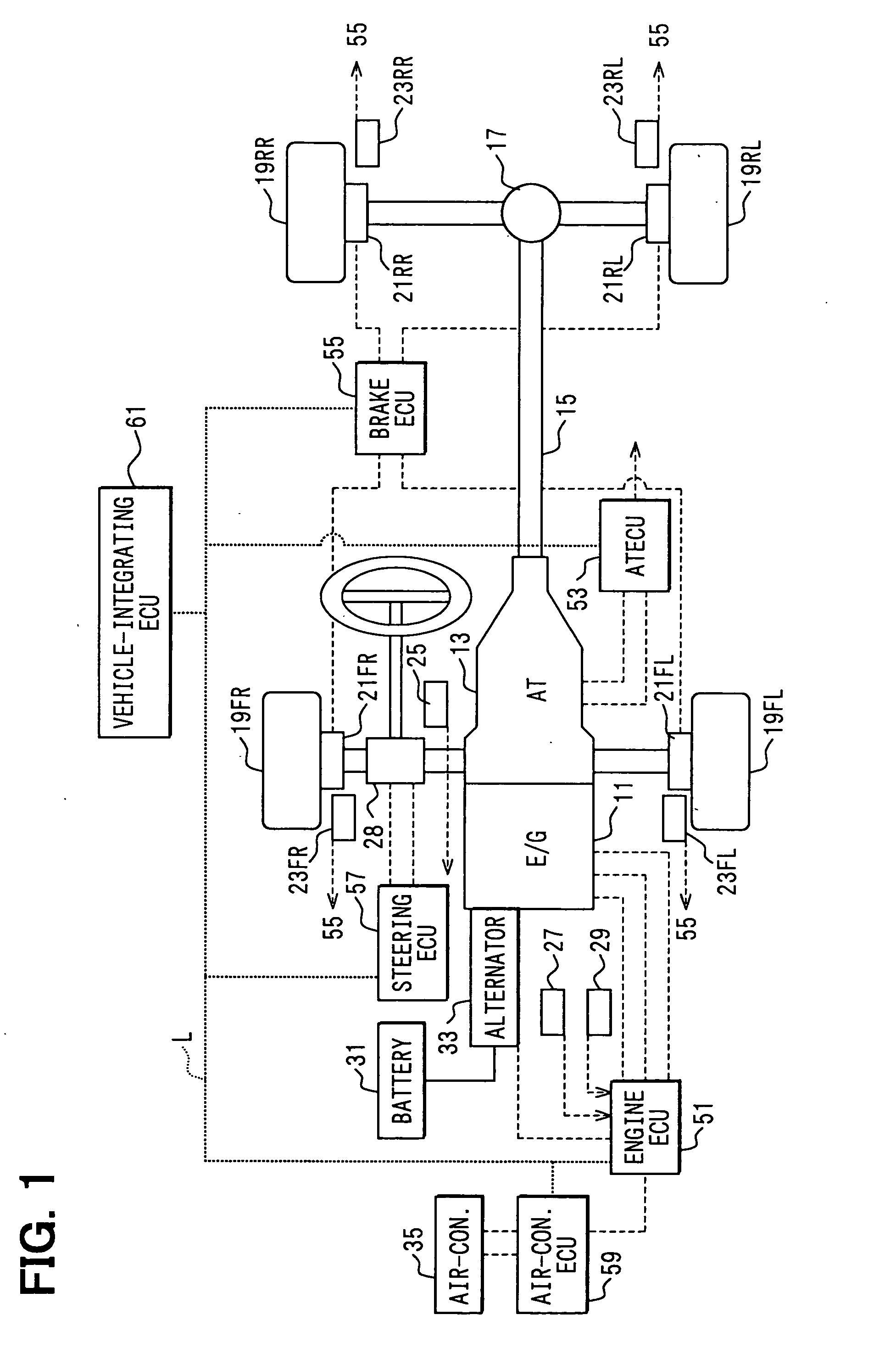

Vehicle behavior estimating device and vehicle behavior controlling device

InactiveUS20050102087A1Vibration suppressionSimple processElectrical controlAnalogue computers for trafficEngineeringVehicle behavior

While a driving torque TD outputted to a driving shaft via an AT from an engine is detected, a road-surface transmitting torque Td_tire is detected based on rotation speeds Vwdr, Vwdl of vehicle driving wheels, a vehicle body speed Vd, and driving torques Tdr, Tdl, all of which are previously detected. The driving torque TD and the road-surface transmitting torque Td_tire are then compared to each other. When TD>Td_tire, the driving torque from an engine is controlled so as to decrease a value of (TD−Td_tire). The vibrations of individual vehicle parts are thereby decreased.

Owner:DENSO CORP

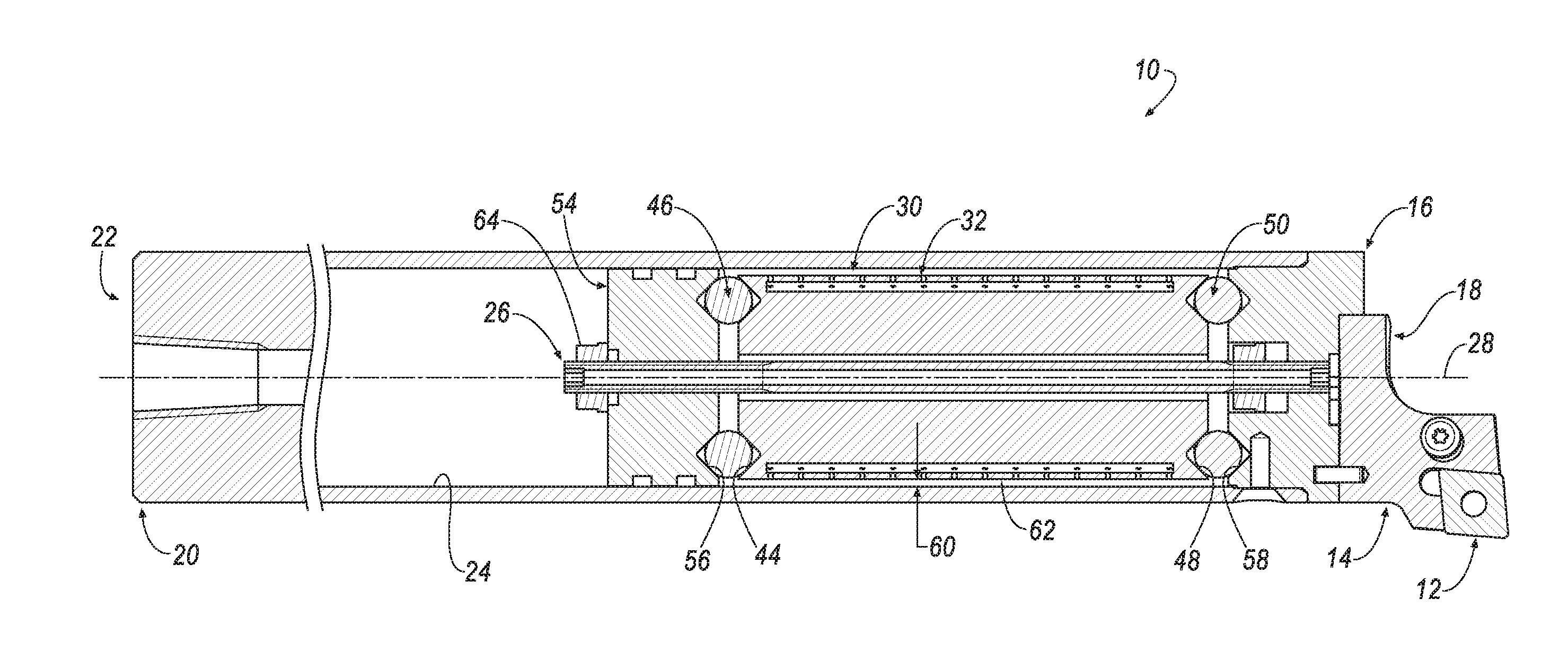

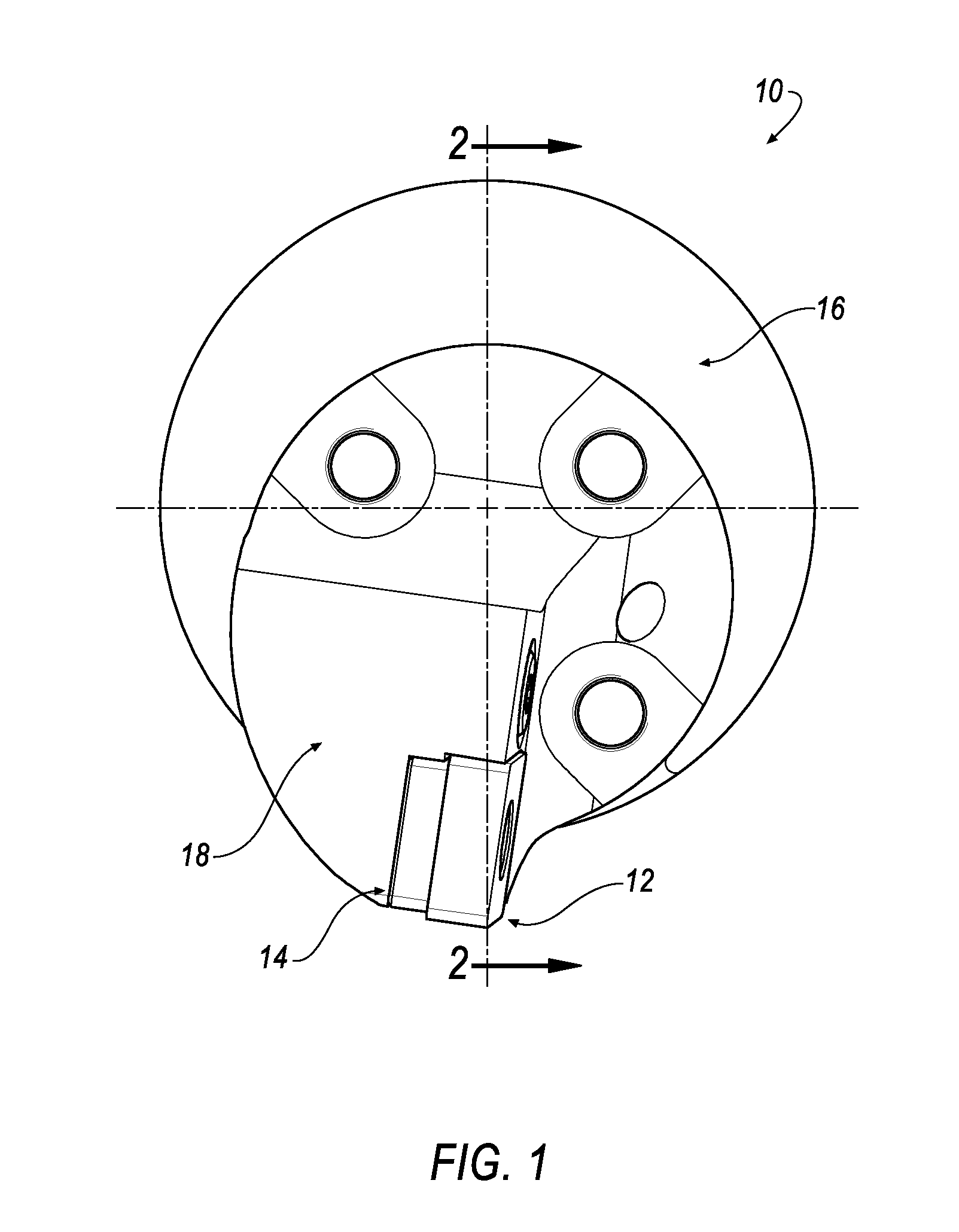

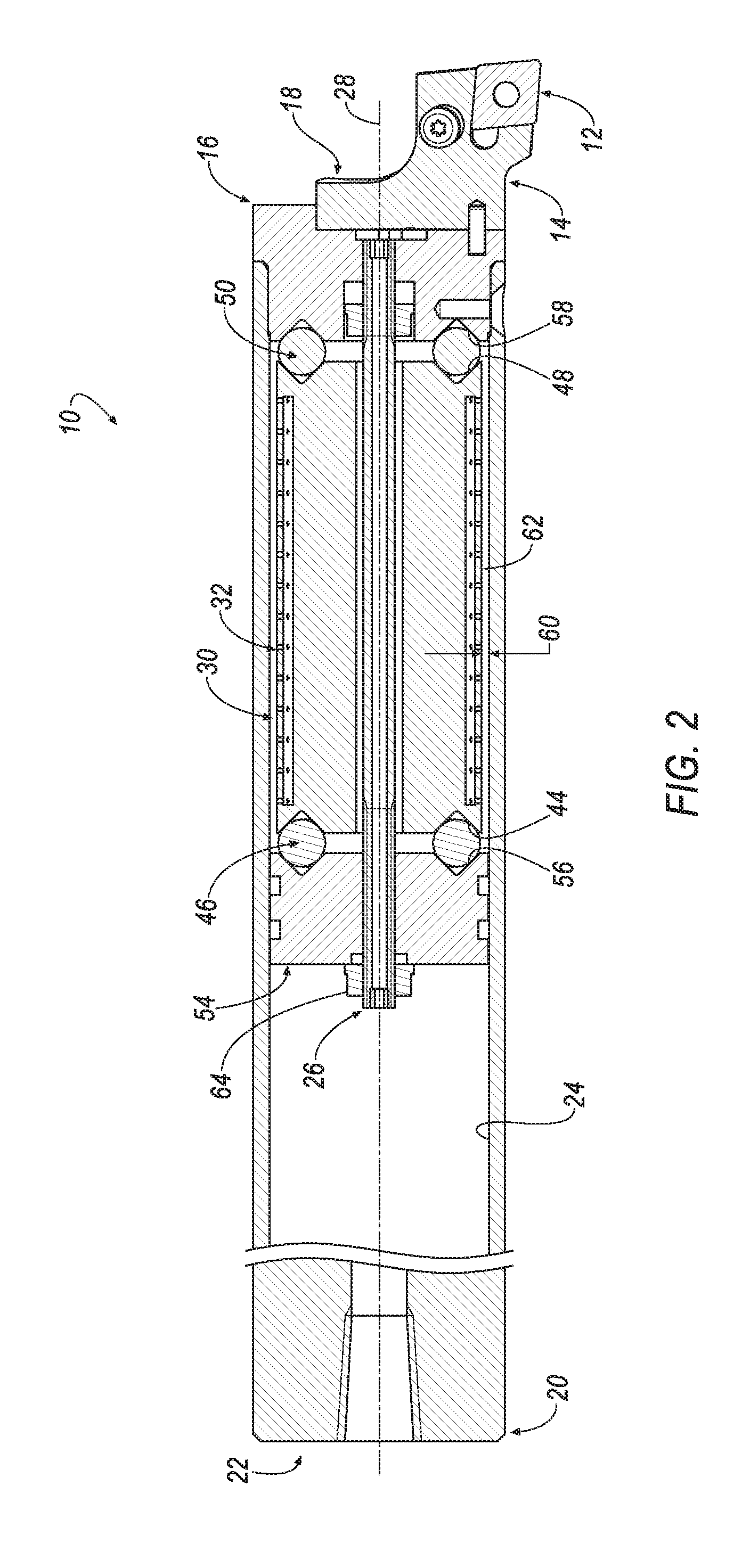

Toolholder with viscous fluid inertial mass damper

ActiveUS20170056977A1Vibration suppressionReduce vibrationBoring barsTurning toolsEngineeringInertia

A toolholder includes a cutting tool mounted to a head attached to a collar at a first end of the toolholder. A shank is located at a second, opposite end of the toolholder. A central cavity extends inwardly from the first end toward the shank. A viscous fluid inertia mass damper is disposed within the central cavity. The viscous fluid inertia mass damper includes an absorber body having a first end, a second end opposite the first end, a fluid reservoir formed in the damper body for containing a viscous fluid, and a plurality of apertures formed in the damper body for allowing the viscous fluid to flow from the fluid reservoir and through the apertures to suppress vibration of the toolholder. A method for suppressing vibrations in a toolholder is also disclosed.

Owner:KENNAMETAL INC

Refrigerator of pulse tube

ActiveCN101153756AVibration suppressionReduce vibrationCompression machinesGas cycle refrigeration machinesRefrigerated temperatureVacuum flange

The invention provides a pulse tube refrigerating machine which uses a regenerator box, even a structure of regenerator box is arranged in a regenerator cylinder, the regenerator cylinder and multilevel parts can be restrained to generate vibration. The pulse tube refrigerating machine comprises a regenerator box (40), a pulse tube (26), a phase adjustment mechanism (25) for phase adjusting helium which is working gas; a regenerator cylinder (30) which is arranged between a vacuum flange (27) and a refrigeration platform (28) for containing the regenerator box (40) inside. A low temperature end of the regenerator box (40) is provided with a knob (42) with connecting holes (43), the refrigeration platform (28) is provided with a mounting concave part (50) which can movably mount the knob (42), and a section area of the mounting concave part (50) is set to be smaller than a section area of the regenerator box (40).

Owner:SUMITOMO HEAVY IND LTD

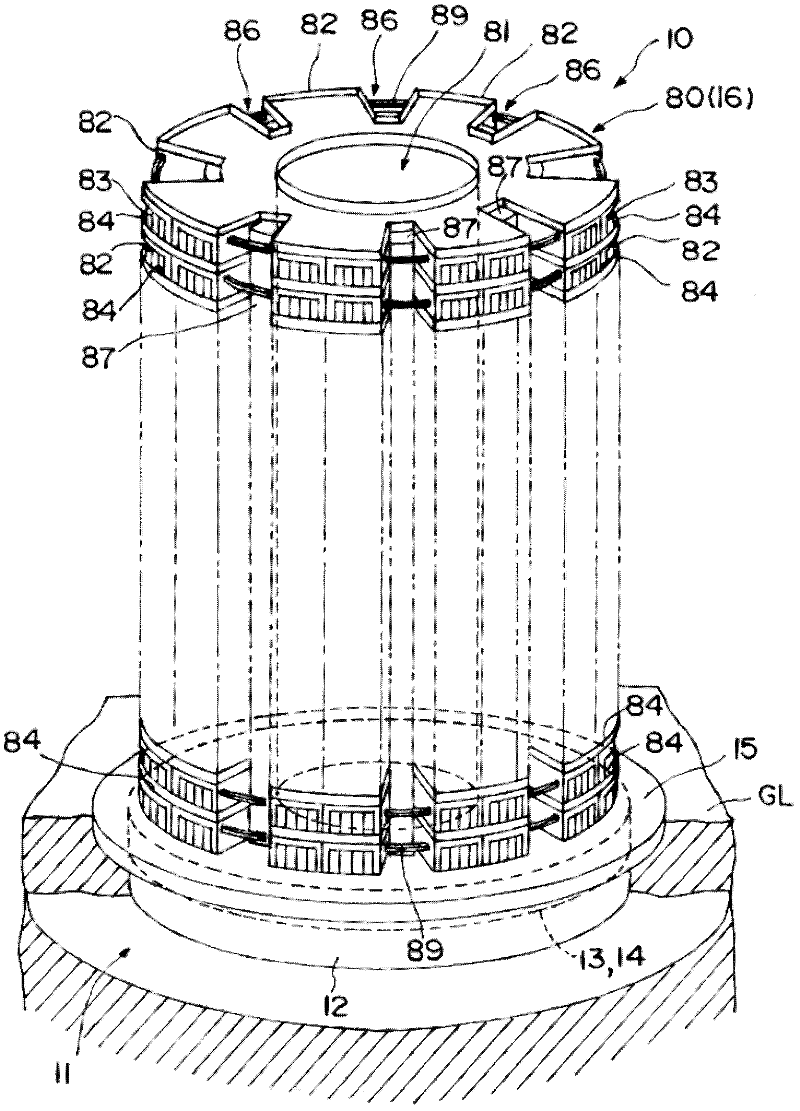

Rotation seismic isolation device for buildings and rotation seismic isolation building structure

InactiveCN102459786AVibration suppressionWith shockproof functionRotating vibration suppressionSpringsEngineeringEnvironmental change

Disclosed is a safe, comfortable, and functional rotation seismic isolation building structure for rotating the whole of a building so that the building is adaptable to a variation of the environment, such as the sunniness and the room temperature and providing a seismic isolation function irrespective of the size of the building. The rotation seismic isolation building structure (10) is configured from a base unit (12) secured underground, a platy rotation base unit (15) horizontally rotatable by means of a rotation device (13) and a seismic isolation device (14) disposed on the top of the base unit (12), and a building structural body (16) provided with multiple houses on the top of the rotation base unit (15) around the rotation center (C) of the rotation base unit (15). The rational device (13) is of a rail roller type (20), a side roller type (30), or a linear motor type (40). The seismic isolation device (13) is of an isolator type (50), a bearing type (60), or a linear motor type (70). The rotation seismic isolation building structure is characterized by being configured from a combination of one of types of the rotation device (13) and one of the types of the seismic isolation device (14).

Owner:TOSHIKENCHIKUJIMUSHO

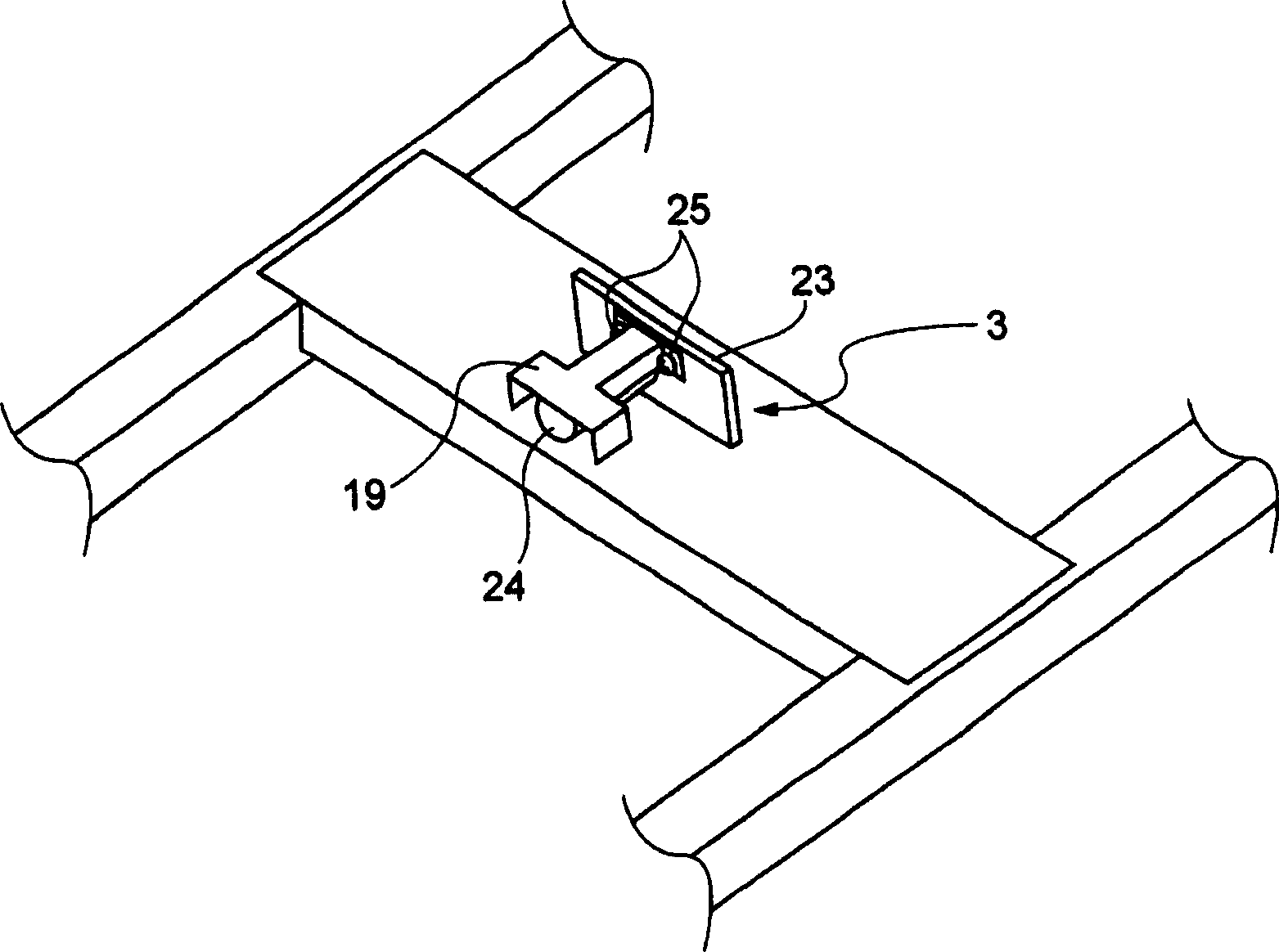

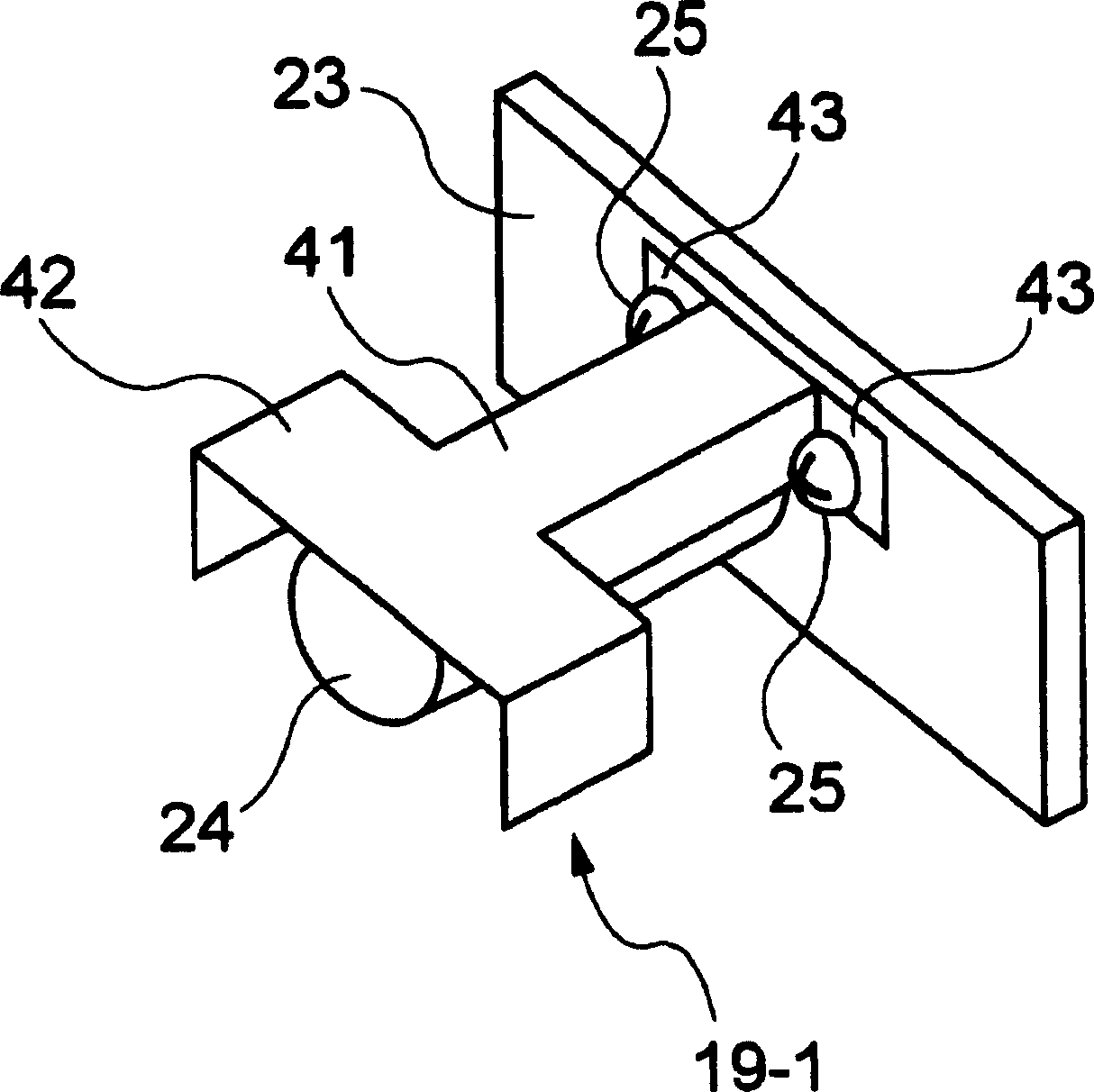

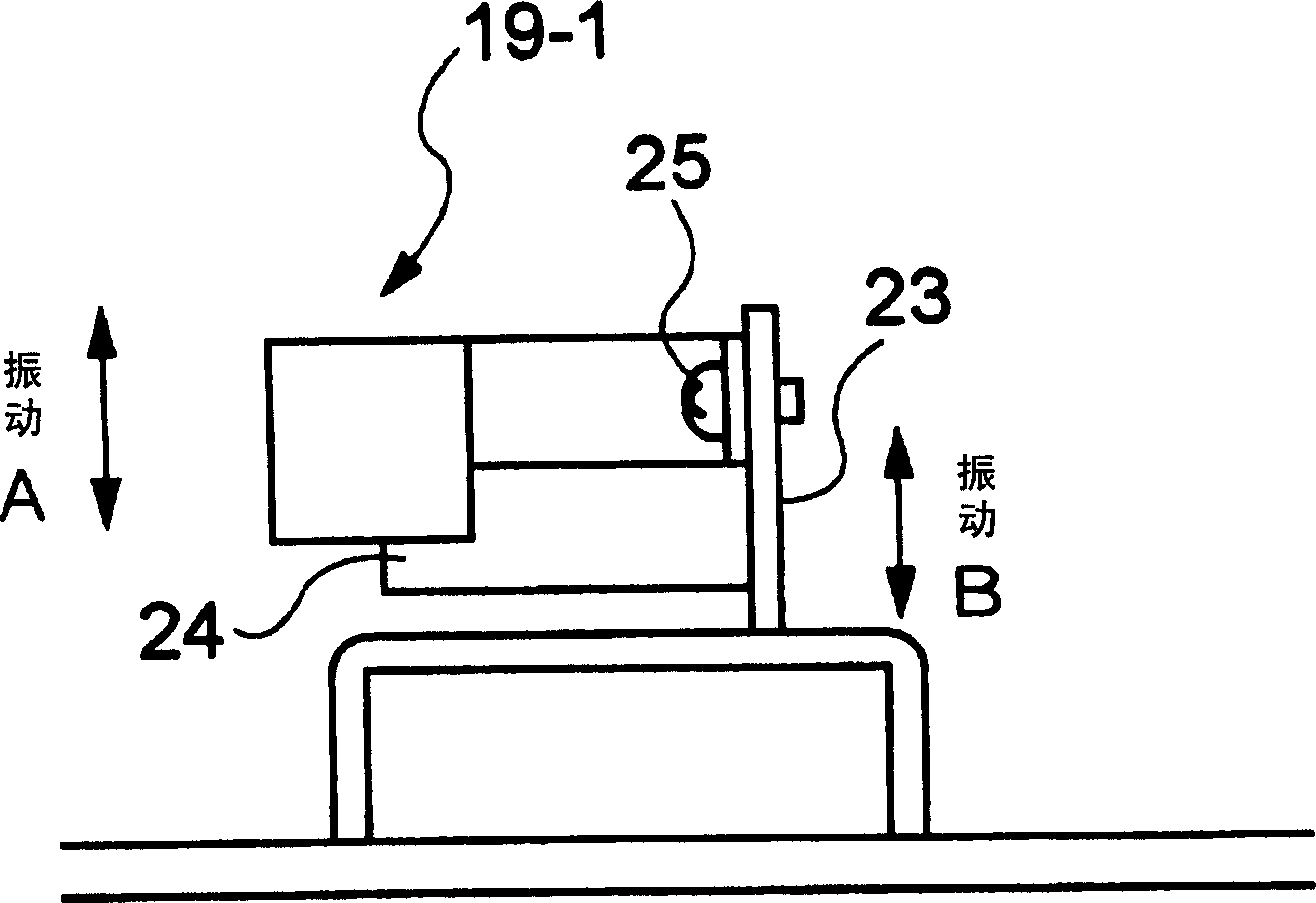

Image read device and vibration prevention device using same

InactiveCN1854802AVibration suppressionSimple structurePictoral communicationOptical elementsUltrasound attenuationFlywheel

The present invention provides an image reading device that does not require a flywheel attached to a motor and a weight attached to a transmission shaft, and can prevent vibration of an optical member. By means of screws (25), a weight (19) in the shape of a cantilever beam with a front-end load corresponding to the number of vibrations of the vibration amplitude from a vibration source such as a motor (15) and attenuating the vibration amplitude (19) is attached to the image reading device. On the CCD substrate (23) of the optical member (3) inside. The weight (19) is made of the following members: the first member (41) has a U-shaped cross section; the second member (42) is located at the end of one end of the first member (41), and the cross-section is U-shaped and The width is wider than that of the first member (41); the third member (43) is arranged at the end of the other end of the first member (41), and the first member (41) to the third member (43) are integrally formed.

Owner:NEC CORP

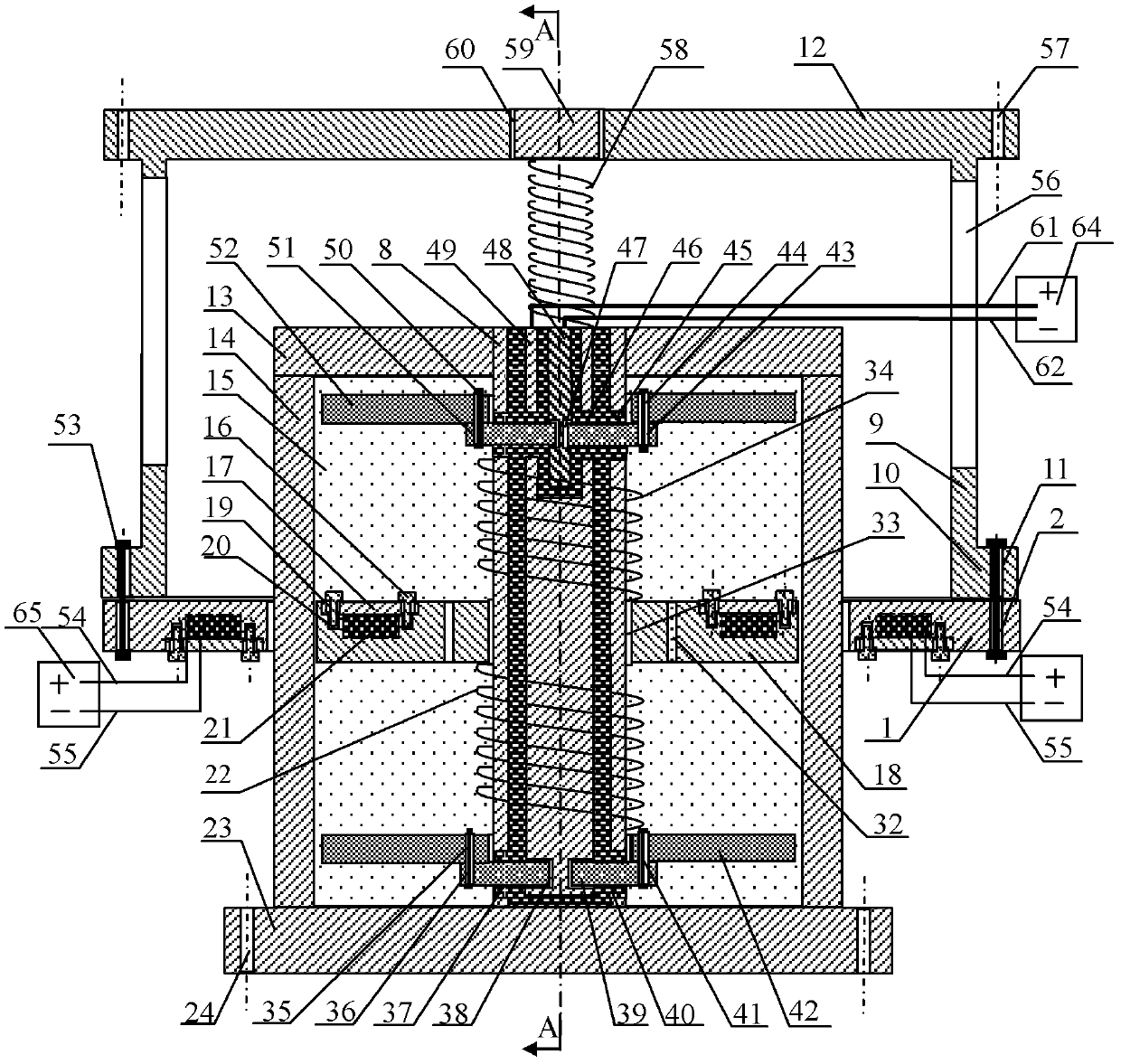

Leakage-free electromagnetic fluid damper with electro-rheological fluids

InactiveCN102537189AVibration suppressionLarge damping forceNon-rotating vibration suppressionPhysicsPiston

A leakage-free electromagnetic fluid damper with electro-rheological fluids comprises a disk (13), a bottom disk flange (23), a hydraulic cylinder (14), a disk flange (1) and a cylinder (9) with an opening, wherein the bottom disk flange (23) is opposite to the disk (13), the hydraulic cylinder (14) is used for leakage-free connection of the disk (13) and the bottom disk flange (23), the disk flange (1) is provided with a third unthreaded hole (25), two ends of the cylinder (9) are provided with disk flanges, the upper end of the cylinder (9) is provided with the upper end disk flange (12), the lower end of the cylinder (9) is provided with the lower end disk flange (10), and a lateral cylinder body of the cylinder (9) is provided with a circular through hole (56). When a piston in the magnetic traction damper moves, the electro-rheological fluids flow through a small circular through hole on the piston and simultaneously consume energy, and the viscosity of the electro-rheological fluids is changed by changing voltage between a positive plate and a negative plate according to the requirement on vibration control, so that vibration can be actively controlled.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com