Defects detection device and method

A defect inspection and defect technology, which is applied in the direction of optical test defect/defect, semiconductor/solid-state device test/measurement, etc., can solve the problem that the defect image cannot be directly confirmed, and achieve the effect of suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

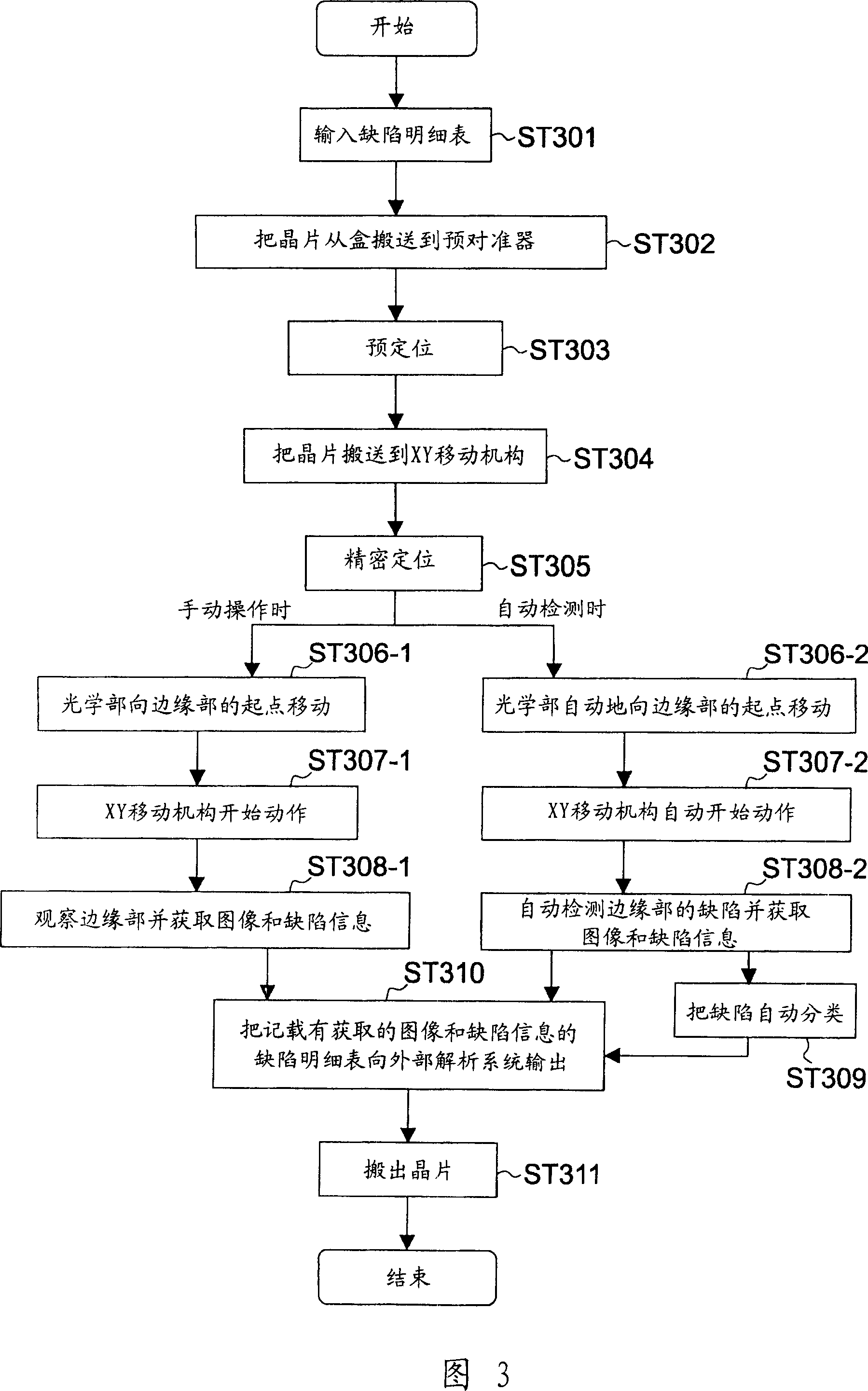

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

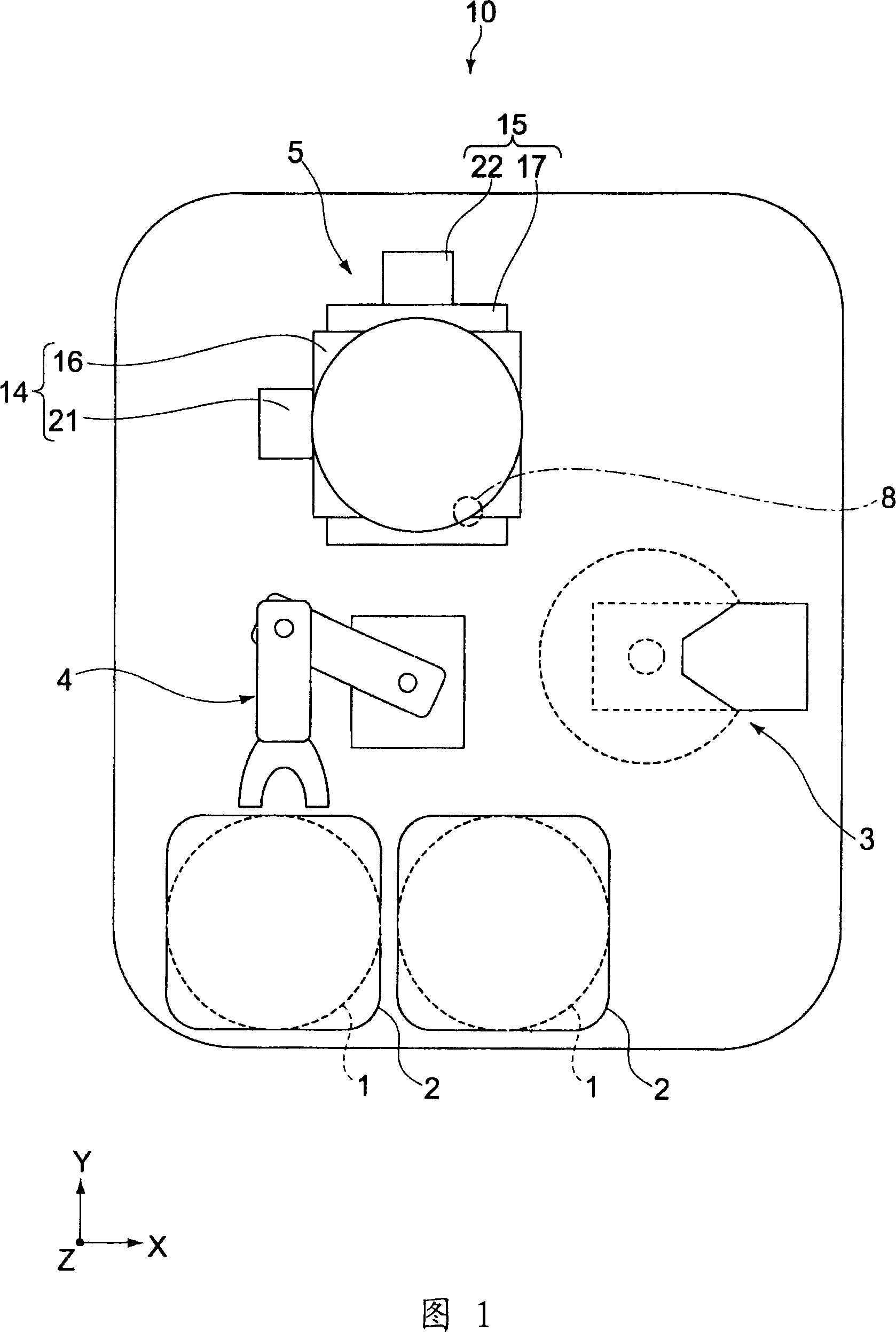

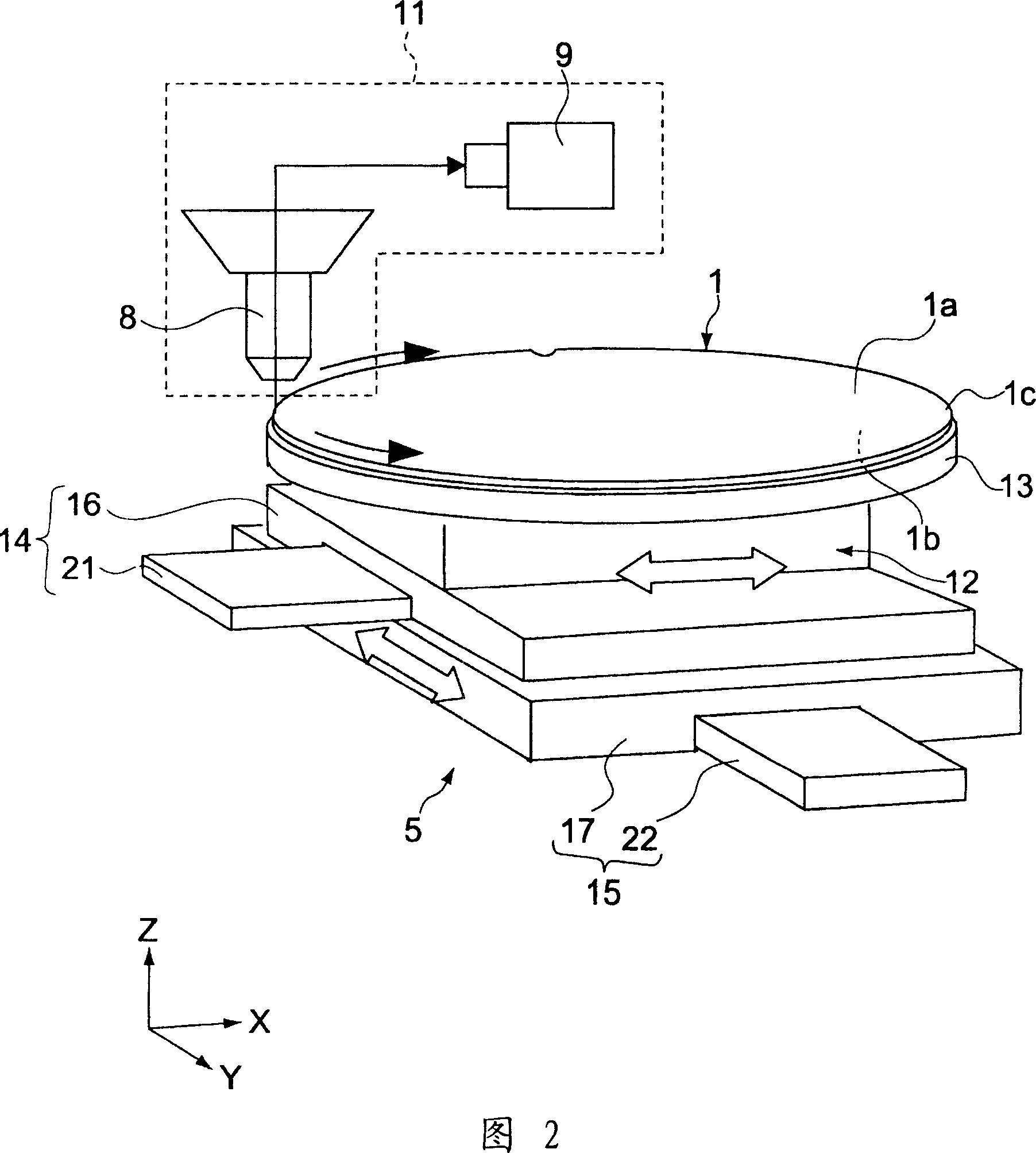

[0033] FIG. 1 is a schematic plan view showing a defect inspection device according to an embodiment of the present invention.

[0034] The defect inspection apparatus 10 includes: a cassette 2 for accommodating a semiconductor wafer substrate 1 (hereinafter simply referred to as a wafer); a pre-positioner 3; an XY moving mechanism 5; a transfer robot 4; and an imaging device 11 (see FIG. 2 ). The transfer robot 4 transfers the wafer 1 between the cassette 2 , the pre-positioner 3 and the XY moving mechanism 5 . The pre-positioner 3 roughly adjusts (pre-positions) the in-plane rotation angle of the wafer 1 transferred from the transfer robot 4 .

[0035] The defect inspection apparatus 10 handles wafers 1 of, for example, 8 inches and 12 inches, but wafers 1 of sizes other than the above-mentioned sizes can also be handled. The box 2 may be either an open type or a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com