High-efficiency filter sheets for air microfiltration membrane filters

A microfiltration membrane and filter technology, applied in the field of filters, can solve problems such as affecting the cleanliness of clean rooms, affecting human respiratory health, secondary pollution of indoor environment, etc., to improve the phenomenon of return air, improve acid and alkali resistance, Improve the effect of filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

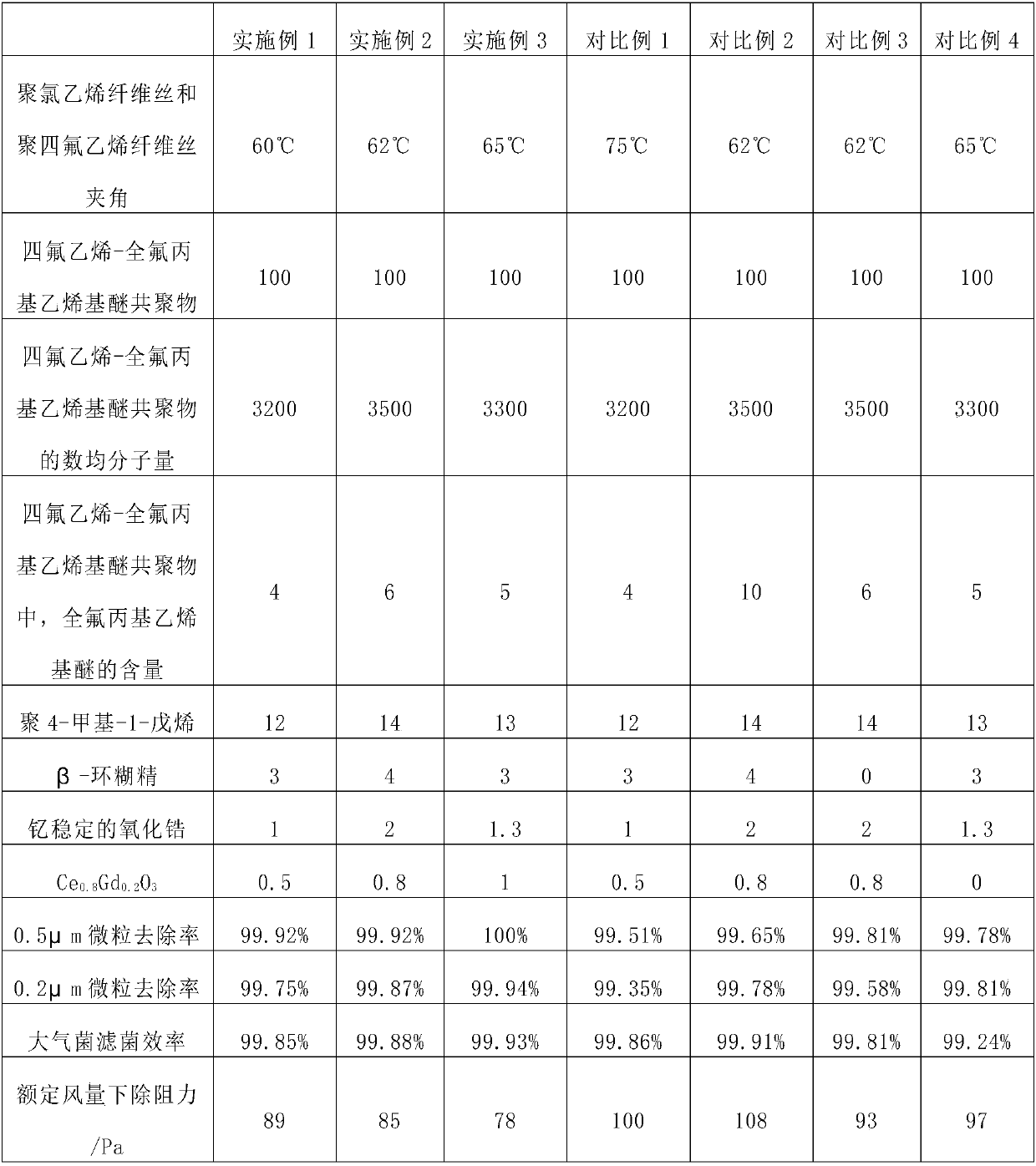

[0022] This case provides a high-efficiency filter sheet for an air microfiltration membrane filter, which includes a polyvinyl chloride fiber layer and a polytetrafluoroethylene fiber layer, wherein the fiber filaments in the polyvinyl chloride fiber layer and the polytetrafluoroethylene fiber layer are respectively It is arranged in one direction, and the fiber filaments in the polyvinyl chloride fiber layer and the fiber filaments in the polytetrafluoroethylene fiber layer are at an angle of 60-65°C; research has found that after the two layers of fiber filaments are at a certain angle, The size of this angle can affect the wind resistance and filtering effect of the filter. Although it is more common to use two layers of fiber filaments perpendicular to each other in the prior art, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com