Variable-frequency motor with damping effect

A frequency conversion motor and shock-absorbing effect technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of lack of buffer mechanism and motor damage in frequency conversion motors, and achieve obvious buffering effects, vibration suppression, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

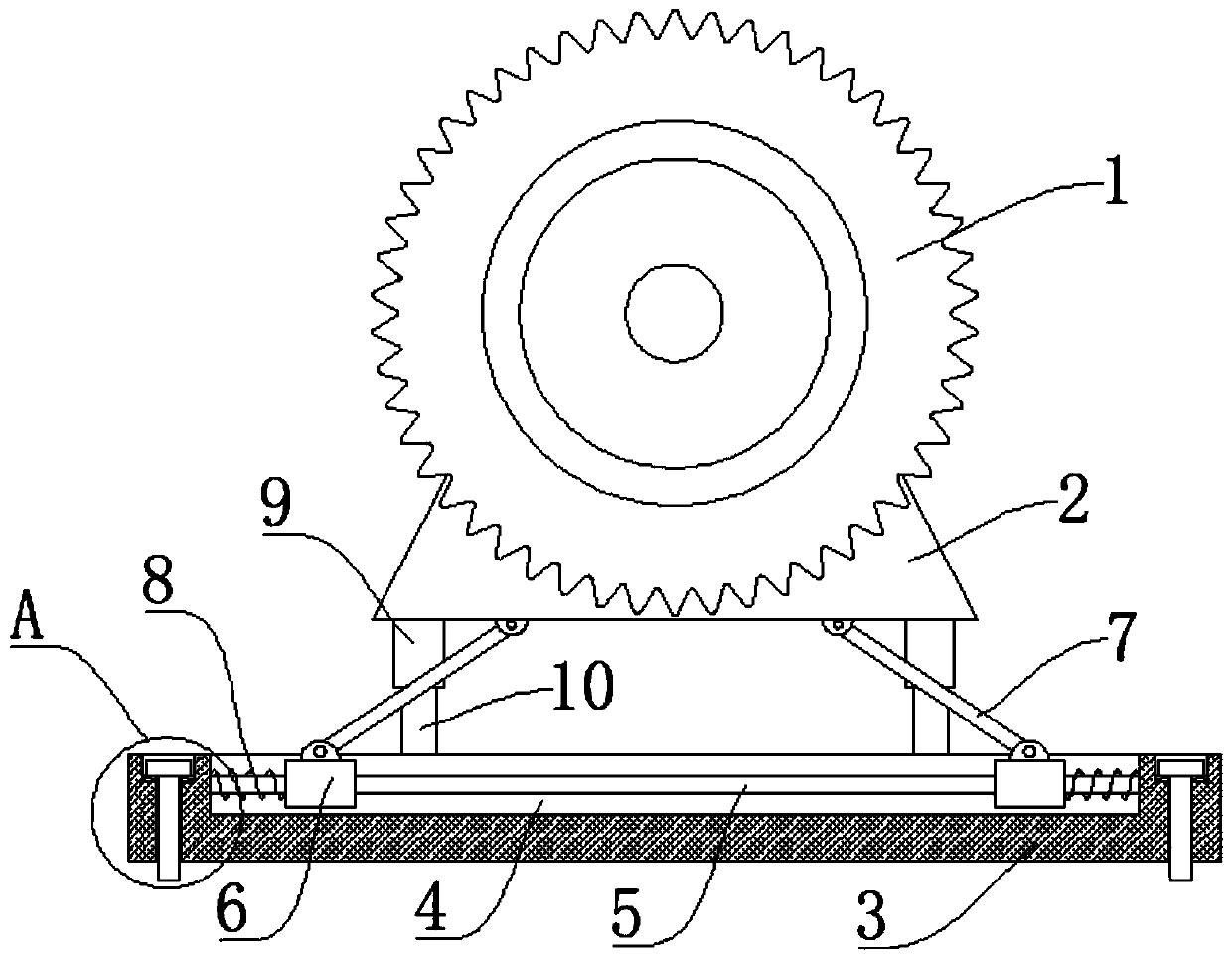

[0017] Reference Figure 1-3 , A variable frequency motor with damping effect, comprising a variable frequency motor body 1. The bottom end of the variable frequency motor body 1 is fixedly welded with a stabilizer 2. A support base 3 is arranged under the stabilizer 2, and the support base 3 and the stabilizer 2 A buffer mechanism is provided in the middle, and the buffer mechanism includes a square groove 4 opened on the top surface of the support base 3, a smooth round rod 5 is fixed in the square groove 4, a slider 6 is slid on the smooth round rod 5, and the slider 6 rotates. A support rod 7 is connected. One end of the support rod 7 away from the slider 6 is rotated and arranged under the stabilizer 2. The sliding rod 5 is sleeved with a spring 8, and the two ends of the spring 8 are perpendicular to the slider 6 and the square groove 4 respectively. Offset against the side wall, by setting the smooth round rod 5 and the slider 6, and the slider 6 is indirectly connected ...

Embodiment 2

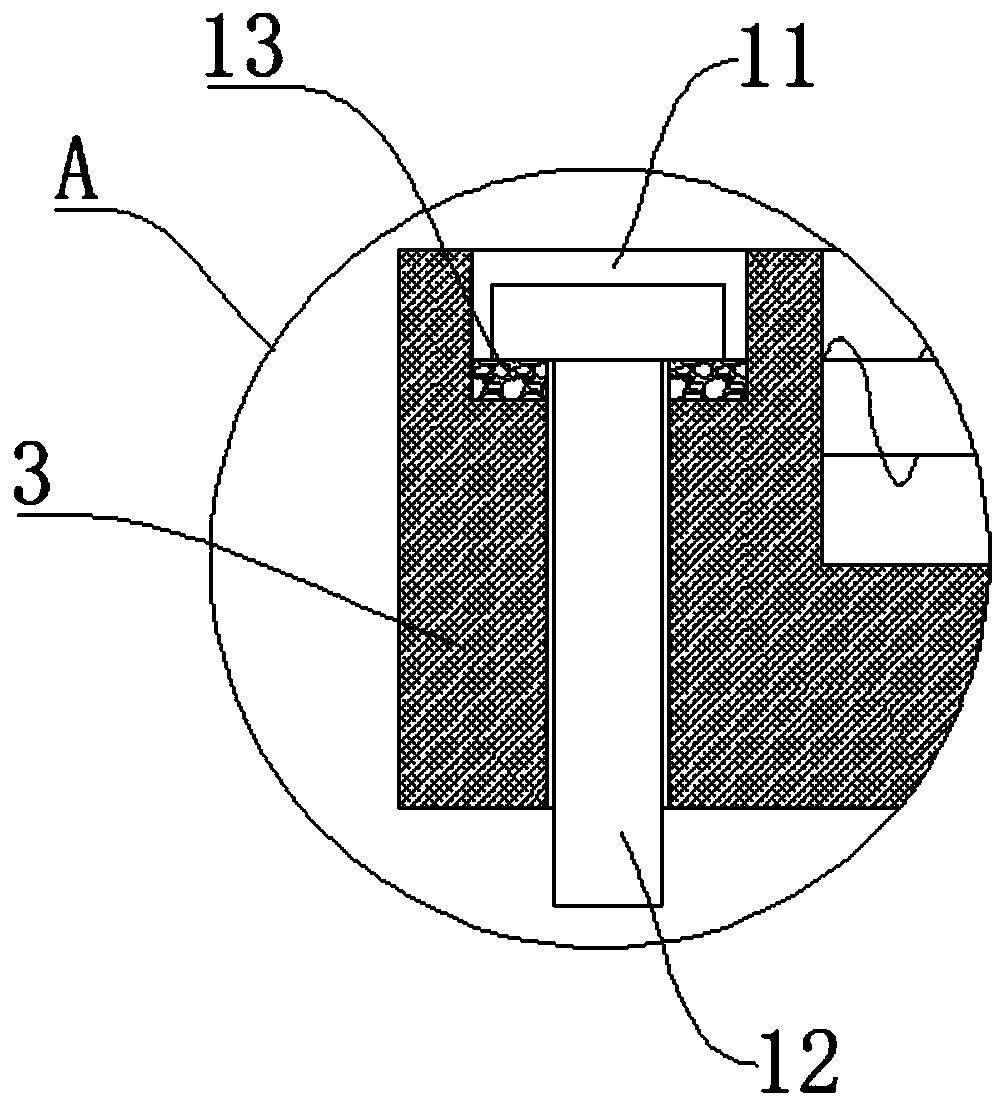

[0020] Reference image 3 As another preferred embodiment of the present invention, the difference from embodiment 1 is that a rubber gasket 13 is placed in the fixing groove 11, and the fixing bolt 12 is pressed on the rubber gasket 13. The rubber gasket 13 can be set A reverse force is exerted on the fixing bolt 12 to increase the thread friction between the fixing bolt 12 and the ground, and to prevent the fixing bolt 12 from loosening.

Embodiment 3

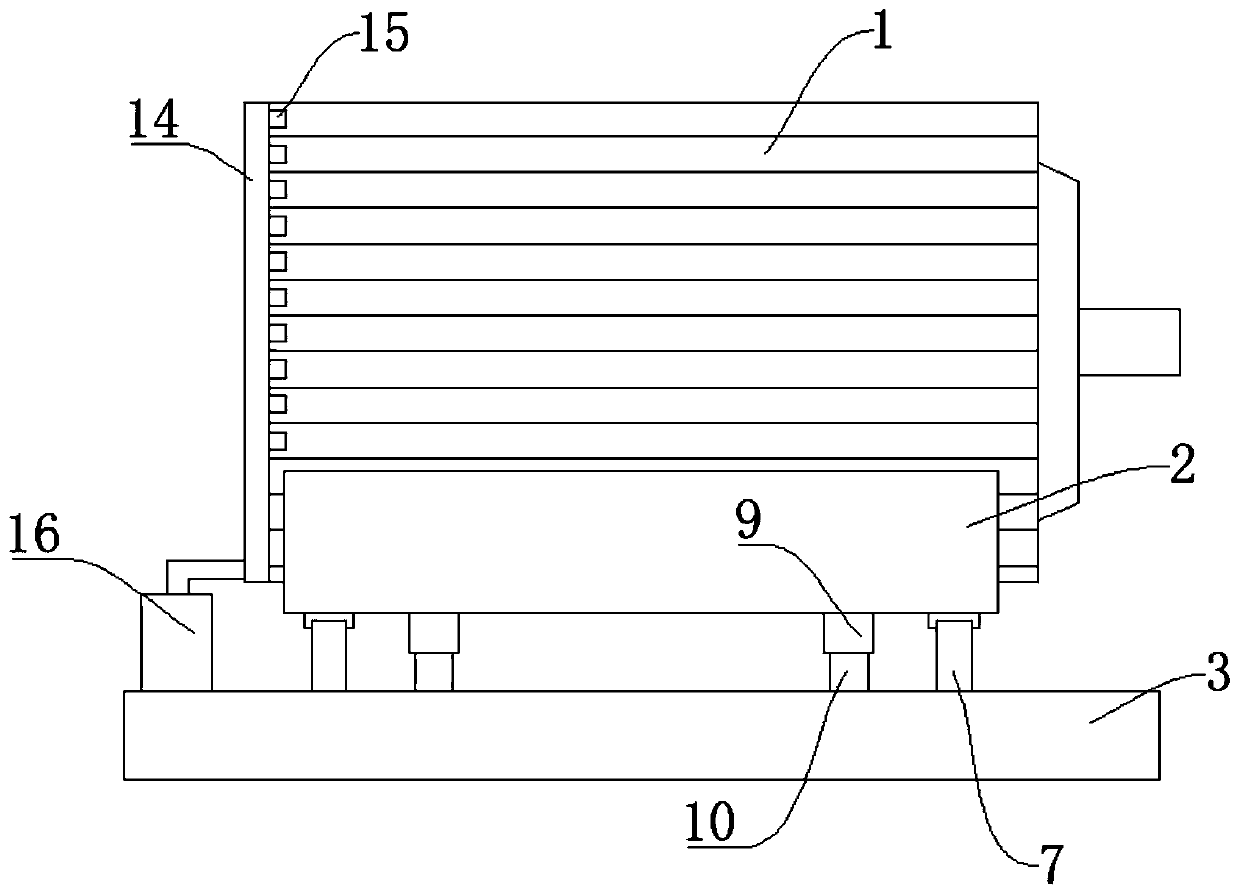

[0022] Reference figure 2 As another preferred embodiment of the present invention, the difference from embodiment 1 is that the outer side of the inverter motor body 1 is set in a wave shape, and the side of the inverter motor body 1 away from the output end is fixedly provided with a hollow ring 14, the hollow ring 14 is provided with an air outlet 15, which is located in the trough on the outside of the frequency conversion motor body 1, and an air pump 16 is fixedly installed on the supporting base plate 3. The air pump 16 and the hollow ring 14 are connected by a pipe, the air pump 16 is turned on, and the hollow ring 14 Inflate, the airflow will be discharged from the air outlet 15 at this time, and the airflow discharged from the air outlet 15 will quickly take away the heat outside the inverter motor body 1, and the outside of the inverter motor body 1 is set in a wave shape to heat the heat of the motor Ability, and the air outlet 15 is located at the trough, which rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com