Flaw detector for wire rope

A flaw detection device and steel cable technology, applied in the direction of material magnetic variables, etc., can solve problems such as large pushing force, influence of leakage magnetic flux detection value, and difficulty in setting, and achieve the effects of suppressing vibration, suppressing output changes, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the best mode of the flaw detection device for carrying out the steel cable of the present invention will be described with reference to the drawings.

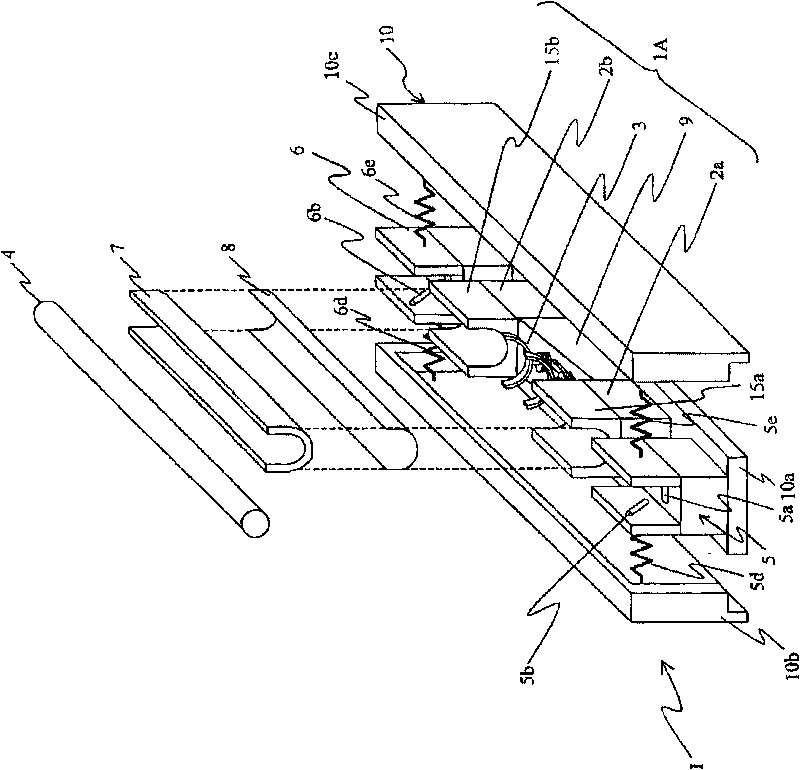

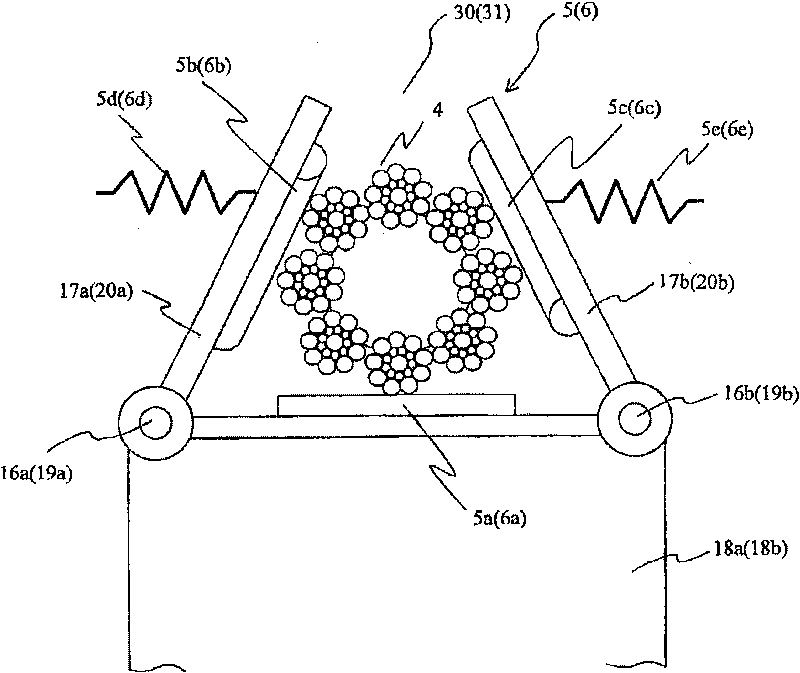

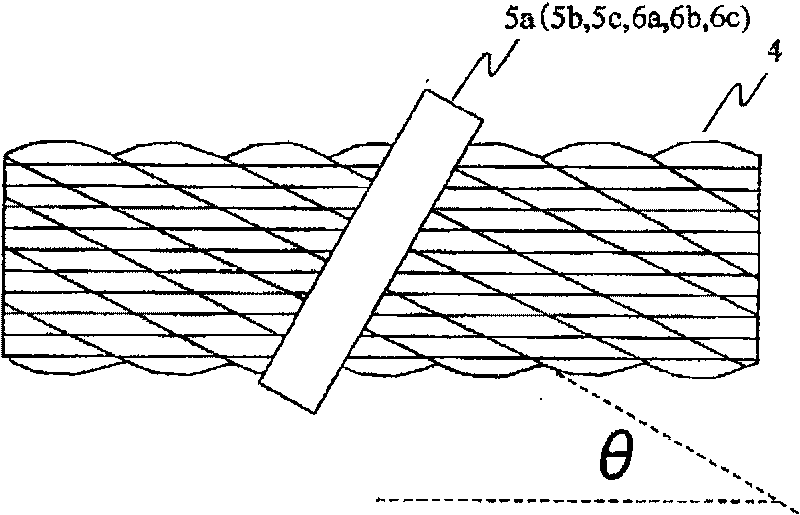

[0027] figure 1 It is an exploded perspective view showing the structure of the flaw detection device for a steel cable according to the first embodiment of the present invention, figure 2 It is a front view showing the positioning mechanism included in the first embodiment of the present invention, image 3 It is a figure which shows the positional relationship of a rotating body and a wire rope in the flaw detection inspection of a wire rope implemented by 1st Embodiment of this invention.

[0028] Such as figure 1 As shown, the steel cable flaw detection device 1 according to the first embodiment of the present invention has: a housing 10 formed by a bottom plate 10a and a pair of side plates 10b, 10c; and a magnetic flux detection member 1A arranged in the center of the housing 10 A pair of position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com