Expansion device

A technology of expansion device and valve body, which is applied in the direction of fluid circulation arrangement, refrigeration components, refrigerators, etc., can solve the problems of insufficient cooling capacity, large overlap between valve hole and valve body, insufficient flow rate and set flow rate, etc. , to achieve the effect of ensuring cooling capacity, reducing abnormal noise, and reducing inhalation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

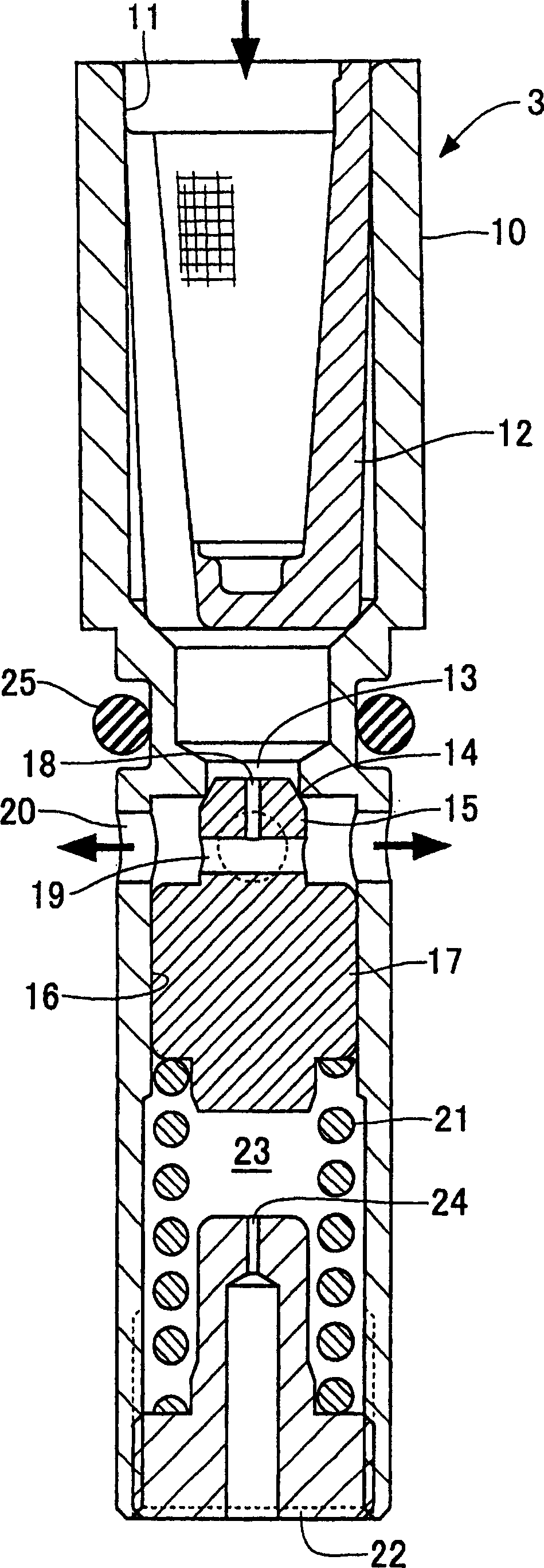

[0024] Below, referring to the accompanying drawings, to be applied to the use of CO 2 Embodiments of the present invention will be described in detail using the case of a refrigeration cycle of a vehicle air conditioner as a refrigerant as an example.

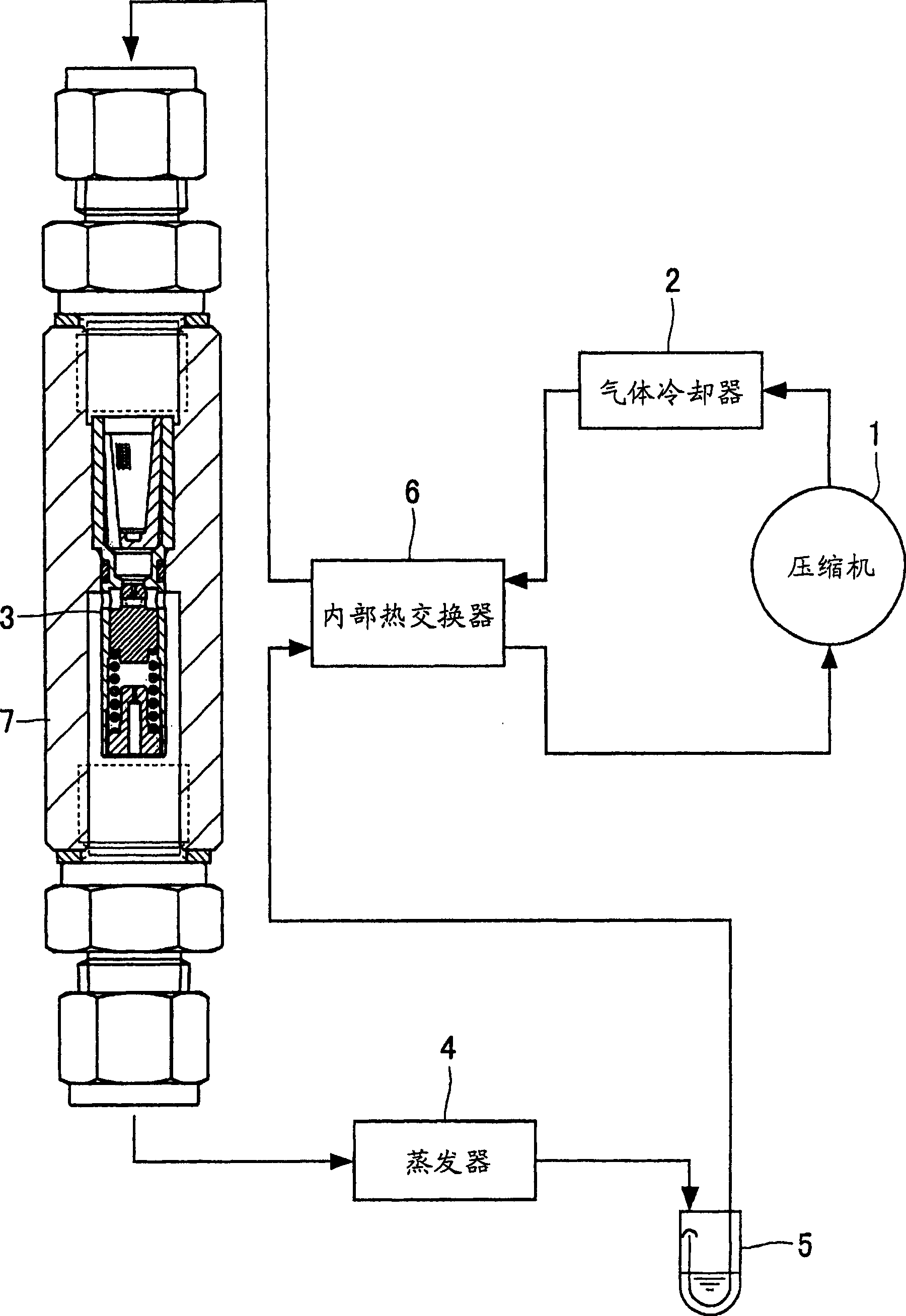

[0025] figure 1 is a schematic diagram of a refrigeration cycle using the expansion device of the present invention.

[0026] The refrigeration cycle includes: a compressor 1 for compressing refrigerant; a gas cooler 2 for cooling the compressed refrigerant; an expansion device 3 for adiabatically expanding the cooled refrigerant; The evaporator 4 where the expanded refrigerant evaporates; the liquid separation reservoir 5, which is provided on the downstream side of the evaporator 4, for storing the remaining refrigerant; the internal heat exchanger 6, which utilizes the The refrigerant sent to the compressor 1 cools the refrigerant cooled in the gas cooler 2 .

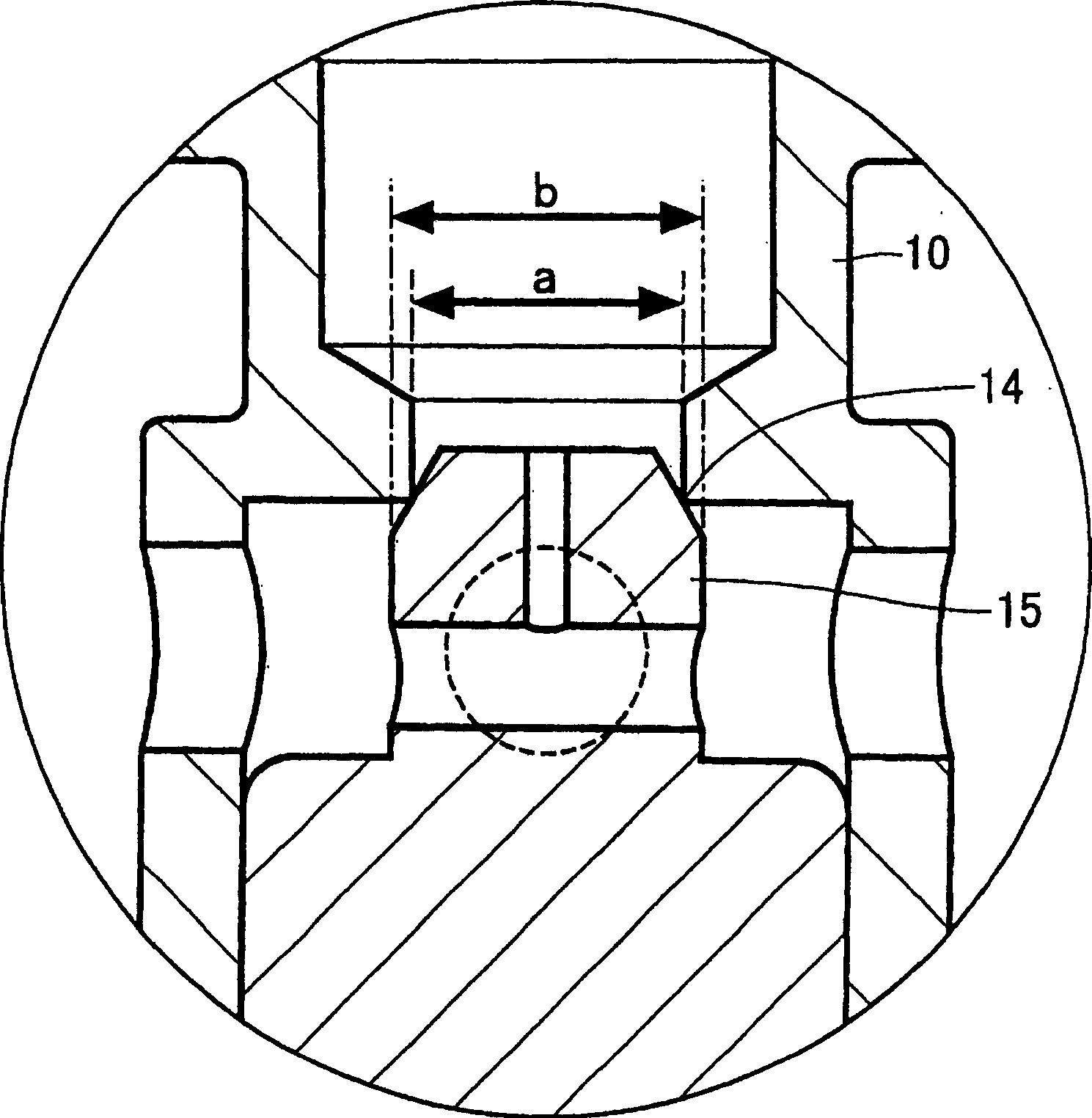

[0027] The expansion device 3 is provided inside the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com