Double-sided composite card paper and preparation method thereof

A composite card, double-sided technology, applied in the field of papermaking, can solve problems such as unfavorable factories to expand production, extremely high operating process requirements, and increase product failure rate, etc., to reduce the sizing process control requirements, improve flexibility, and achieve The effect of economic growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following embodiments are intended to further illustrate the present invention, rather than limit the present invention.

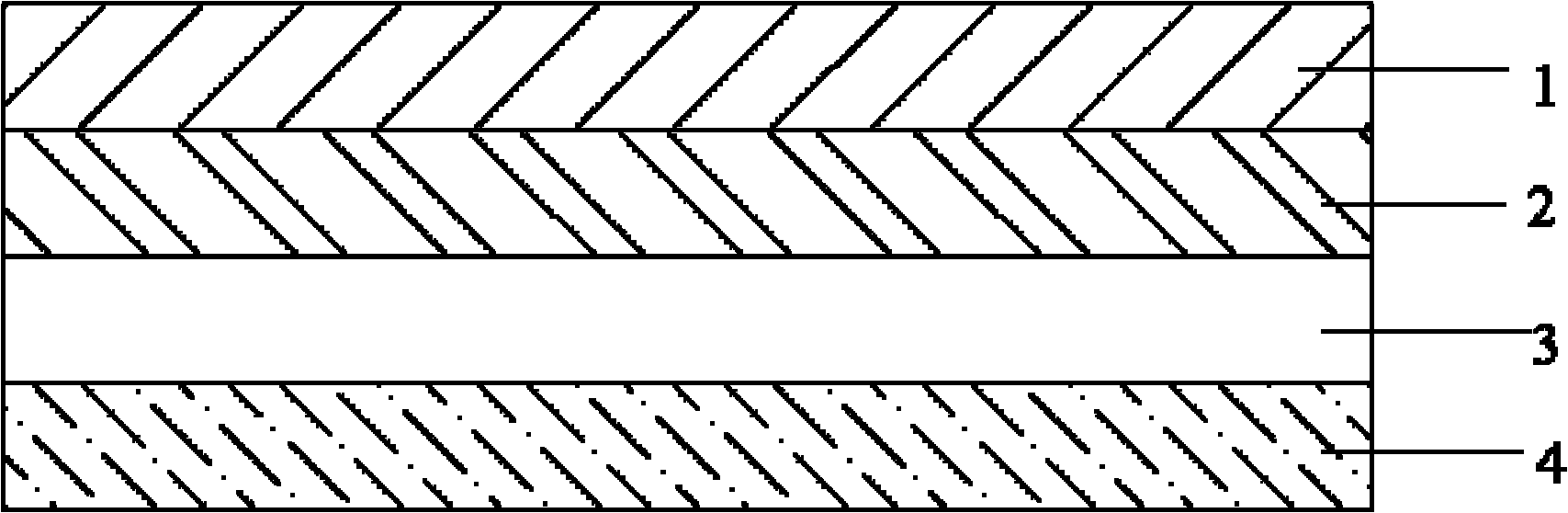

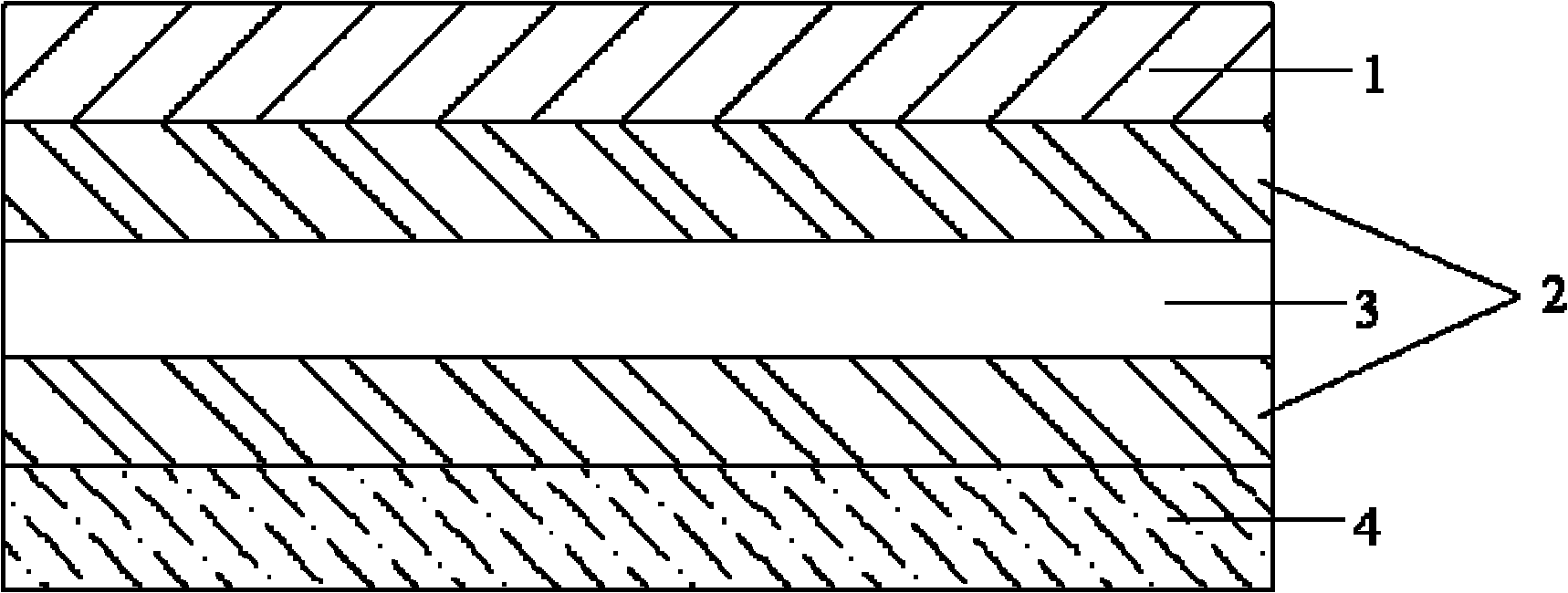

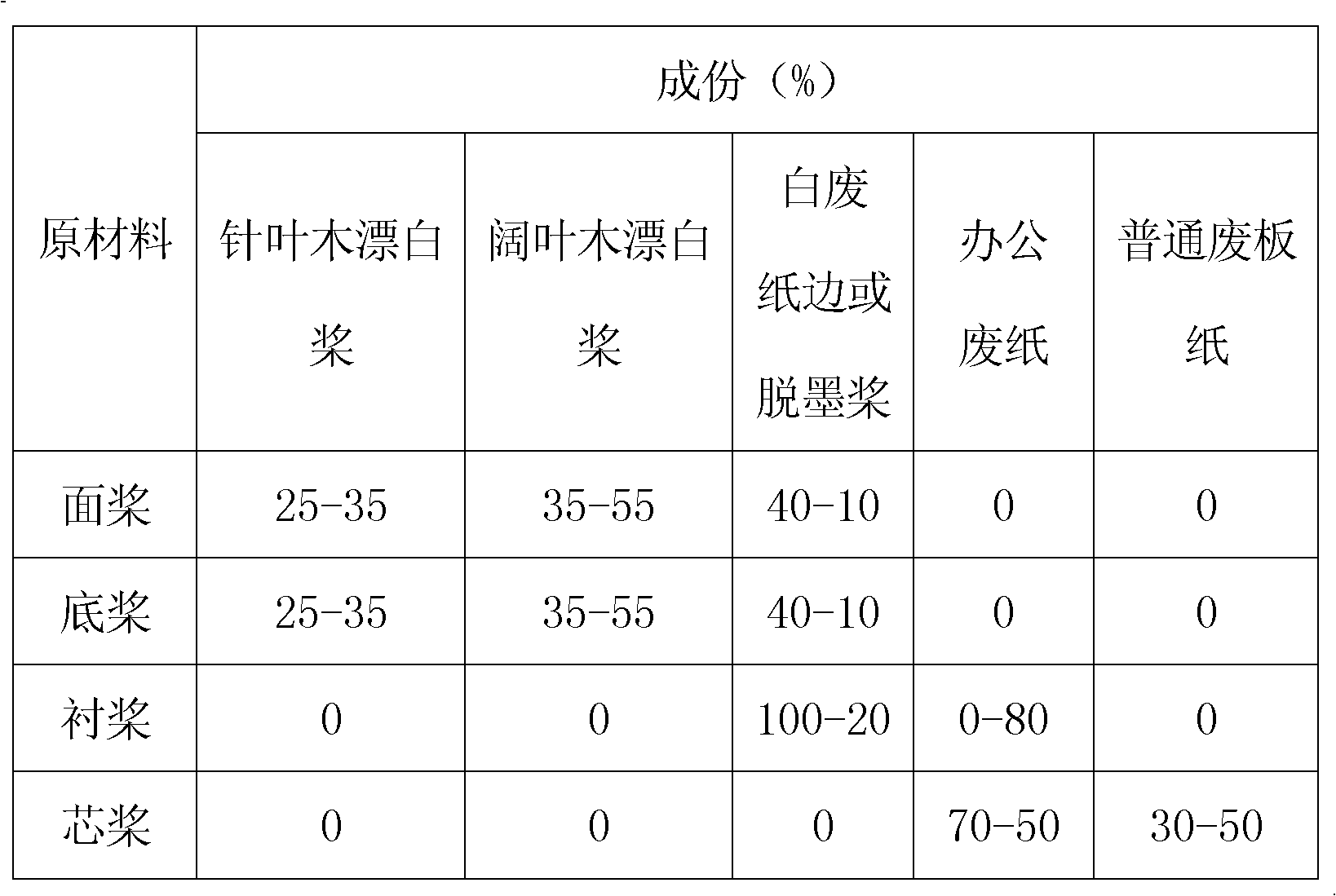

[0035] In the wet part of the paper machine, one side of the core paddle is covered with the liner paddle, the other side is covered with the bottom paddle, and finally the face paddle is covered on the liner paddle surface, or the liner paddle is covered on both sides of the core paddle, and then the face paddle is covered on one side of the liner paddle. The paddle on the other side covers the bottom paddle. According to Table 1 and Table 2 or Table 3, prepare the slurry and sizing.

[0036] Table 1

[0037]

[0038] Table 2

[0039]

[0040] table 3

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com