Chenille sofa fabric with high wear resistance and preparation method thereof

A chenille and high wear-resistant technology, which is applied in the field of high wear-resistant chenille sofa fabrics and its preparation, can solve the problems of densification and hook shedding of chenille yarn wear-resistant fabrics, and meet the requirements of High requirements for aesthetics and functionality, not easy to get hooked off the line, and the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

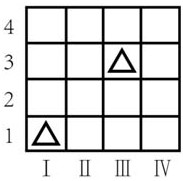

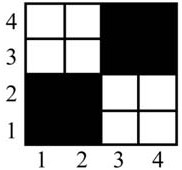

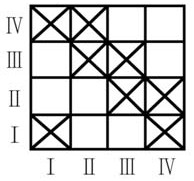

[0031] Example 1, a high wear-resistant chenille sofa fabric, is a double-layered weave structure formed by interweaving warp and weft yarns, the warp yarn is a polyester-cotton blended yarn with a fineness of 21.5 tex, and the weft yarn 2 is chenille Yarn, chenille yarn includes core yarn and pile decoration yarn, the core yarn is polyester with a fineness of 18.4tex, and the pile decoration yarn is polypropylene fiber with a fineness of 19.3 tex; Weave, the surface weave is "2 / 2 square weave", the inner weave is "2 / 2 twill weave", the binding method of the double-layer weave structure is "bottom to top", the warp and weft yarns of the surface weave and the inner weave The alignment ratio is "1:1".

Embodiment 2

[0032] Embodiment 2, a preparation method of a highly wear-resistant chenille sofa fabric, comprising the following steps: step (1) yarn design, step (2) yarn dyeing, step (3) fabric structure design, step (4) ) weaving, step (5) wear-resistant finishing.

[0033] In step (1), in the design of the yarn, the yarn is a warp yarn and a weft yarn; the warp yarn is a polyester-cotton blended yarn, which has greater yarn strength, reduces broken ends during weaving, and can improve weaving efficiency and fabric quality, the fineness of the warp yarn is 21.5tex; the weft yarn is chenille yarn, the core yarn of the chenille yarn is high-strength polyester, and the yarn fineness is 18.4tex, and the fluff decorative yarn is High wear-resistant polypropylene with a yarn fineness of 19.3 tex; the chenille yarn meets the style of sofa fabrics, with mixed ground patterns, and the pile decorative yarn wreath is of moderate size.

[0034] Step (2), in yarn dyeing, adopt one-bath two-step met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com